Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (5): 1414-1419.doi: 10.13229/j.cnki.jdxbgxb20180145

Characteristics of aerodynamics for an automobile by fluid-structure coupled method

Xing-jun HU( ),Zheng HUI,Peng GUO,Yang-hui ZHANG,Jing-long ZHANG,Jing-yu WANG(

),Zheng HUI,Peng GUO,Yang-hui ZHANG,Jing-long ZHANG,Jing-yu WANG( ),Fei LIU

),Fei LIU

- State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

CLC Number:

- U461.1

| 1 | 胡兴军. 汽车空气动力学[M]. 北京: 人民交通出版社, 2014. |

| 2 | 朱文峰, 林佩剑, 周辉. 高速流固耦合效应下车窗密封机理建模与分析[J]. 汽车工程, 2015, 37(12): 1395-1399. |

| ZhuWen-feng, LinPei-jian, ZhouHui. Modeling and analysis of window sealing mechanism of high speed fluid-solid coupling effect[J]. Automotive Engineering, 2015, 37(12): 1395-1399. | |

| 3 | 李田. 高速列车流固耦合计算方法及动力学性能研究[D]. 成都: 西南交通大学牵引动力国家重点实验室, 2012. |

| LiTian. Study on fluid-structure coupling calculation method and dynamics performance of high speed train[D]. Chengdu: State Key Laboratory of Traction Power, Southwest Jiaotong University, 2012. | |

| 4 | CaiC S, ZhangW, LiuX Z, et al. Framework of wind-vehicle-bridge interaction analysis and its applications[J]. Journal of Earthquake and Tsunami, 2013, 7(3): 132-141. |

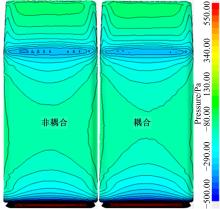

| 5 | 谢超, 谷正气, 宗轶琦, 等. 流固耦合作用对汽车侧窗气动噪声的影响[J]. 中国机械工程, 2014, 25(24): 3391-3396. |

| XieChao, GuZheng-qi, ZongYi-qi, et al. Influence of solid coupling on aerodynamic noise of automobile side window[J]. China Mechanical Engineering, 2014, 25(24): 3391-3396. | |

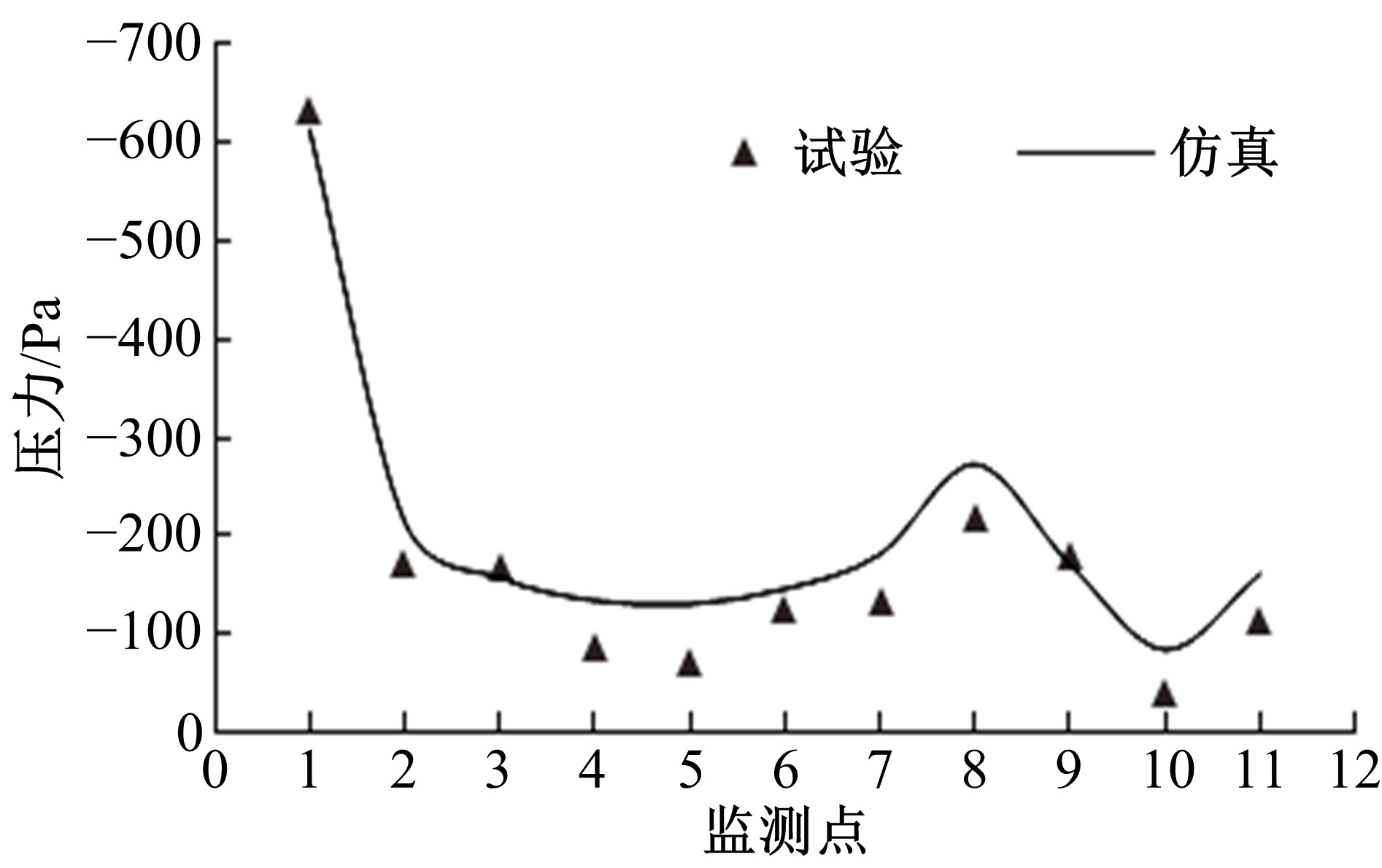

| 6 | 朱晖, 杨志刚. 类车体流固耦合现象实验及数值分析[J]. 同济大学学报: 自然科学版, 2014, 42(11): 1694-1699. |

| ZhuHui, YangZhi-gang. Experimental and numerical analysis for fluid structure interaction phenomenon of ahmed body[J]. Journal of Tongji University (Natural Science), 2014, 42(11): 1694-1699. | |

| 7 | 钱若军, 董石麟, 袁行飞. 流固耦合理论研究进展[J]. 空间结构, 2008, 14(1): 3-15. |

| QianRuo-jun, DongShi-lin, YuanXing-fei. Research progress in fluid-solid coupling theory[J]. Spatial structure, 2008, 14(1): 3-15. | |

| 8 | 苏波, 钱若军, 袁行飞. 流固耦合界面信息传递理论和方法研究进展[J]. 空间结构, 2010, 16(1): 3-10. |

| SuBo, QianRuo-jun, YuanXing-fei. Advabces in researchon theory and method of data exchange on coupling interface for FSI analysis[J]. Spatial structure, 2010, 16(1): 3-10. | |

| 9 | SAE J2071—1994. Aerodynamic testing of road vehicles-open throat wind tunnel adjustment[S]. |

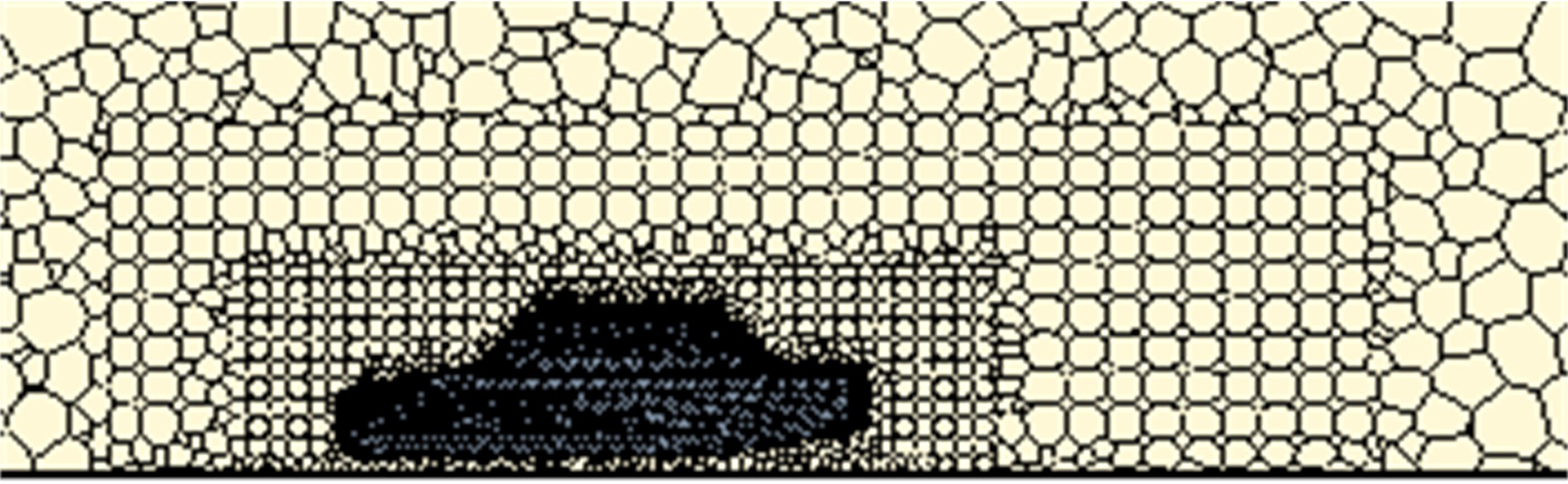

| 10 | 杨博, 傅立敏. 轿车外流场网格生成策略及数值模拟[J]. 农业机械学报, 2007, 38(4): 8-11. |

| YangBo, FuLi-min. Mesh generation strategies of the external flow field around a sedan and the numerical simulation research[J]. Journal of Agricultural Mechanization, 2007, 38(4): 8-11. | |

| 11 | SimoneS. Numerical flow simulations of a detailed car underbody[C]∥SAE Technical Paper, 2001-01-0703. |

| 12 | 康顺. 计算域选取对CFD模拟结果的影响[C]∥中国工程热物理学会2004年热机气动热力学学术会议论文集, 西安, 2004: 128-133. |

| 13 | SongK S, KangS O, JunS O, et al. Aerodynamic design optimization of rear body shapes of a sedan for drag reduction[J]. International Journal of Automotive Technology, 2012, 13(6): 905-914. |

| 14 | KangS O, JunS O, ParkH I, et al. Actively translating a rear diffuser device for the aerodynamic drag reduction of a passenger car[J]. International Journal of Automotive Technology, 2012, 13(4): 583-592. |

| 15 | SchroeckD, KrantzW, WiddeckeN, et al. Unsteady aerodynamic properties of a vehicle model and their effect on driver and vehicle under side wind conditions[J]. SAE International Journal of Passenger Cars-Mechanical Systems, 2011, 4(1): 108-119. |

| 16 | 张英朝, 张喆, 李杰. 汽车风洞支撑干扰扣除方法研究[J]. 实验流体力学, 2011, 25(3): 16-19. |

| ZhangYing-chao, ZhangZhe, LiJie. Method to eliminate the interference of model support in automotive wind tunnel[J]. Journal of Experiments in Fluid Mechanics, 2011, 25(3): 16-19. | |

| 17 | 张英朝. 基于仿真与实验的汽车风洞修正研究[D]. 长春: 吉林大学汽车工程学院, 2010. |

| ZhangYing-chao. Wind tunnel correction based on simulation and experiment[D]. Changchun: College of Automotive Engineering, Jilin University, 2010. |

| [1] | Fang-wu MA,Lu HAN,Yang ZHOU,Shi-ying WANG,Yong-feng PU. Multi material optimal design of vehicle product using polylactic acid composites [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1385-1391. |

| [2] | Zhen-hai GAO,Tian-jun SUN,Lei HE. Causal reasoning decision⁃making for vehicle longitudinal automatic driving [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1392-1404. |

| [3] | Bo ZHANG,Jian-wei ZHANG,Kong-hui GUO,Hai-tao DING,Hong-qing CHU. Current control of permanent magnet synchronous motor for road feeling simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1405-1413. |

| [4] | Jing LI,Qiu⁃jun SHI,Peng LIU,Ya⁃wei HU. Neural network sliding mode control of commercial vehicle ABS based on longitudinal vehicle speed estimation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1017-1025. |

| [5] | Shun YANG,Yuan⁃de JIANG,Jian WU,Hai⁃zhen LIU. Autonomous driving policy learning based on deep reinforcement learning and multi⁃type sensor data [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1026-1033. |

| [6] | Xin CHEN,Ming LI,Xin⁃jian RUAN,Ning WANG,Jia⁃ning WANG. Investigation of vortical structures in wake of Ahmed body by delayed detached⁃eddy simulation turbulence model using immersed boundary method [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1034-1042. |

| [7] | Hua ZHOU,Zhi⁃gang YANG,Hui ZHU. Aerodynamic calculation of MIRA model correlated with wind tunnel test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1043-1053. |

| [8] | Ji⁃qing CHEN,Meng⁃meng LIU,Feng⁃chong LAN. Experiment on overcharge safety of NCM battery and battery pack [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1072-1080. |

| [9] | Run⁃dong LIU,Jun MAO,Yan⁃hong XI,Hong⁃yu ZHANG,Fei PENG. Pressure pulse on windbreak impacting by cross⁃wind coupling with high⁃speed trains passing each other [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1054-1062. |

| [10] | Guo⁃feng QIN,Jing⁃xin NA,Wen⁃long MU,Wei TAN,Jian⁃ze LUAN,Hao SHEN. Degradation failure of adhesively bonded CFRP/aluminum alloy subjected to high temperature environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1063-1071. |

| [11] | Li⁃bin ZHANG,Dao WU,Hong⁃ying SHAN,Xiang⁃jing DENG. Design of axle load self⁃adjusting system for multi⁃axle vehicle based on brake tester [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1081-1091. |

| [12] | Shou⁃tao LI,Qiu⁃yuan LI,Hui LIU,Hui DING,Yan⁃tao TIAN,Ding⁃li YU. Sliding mode variable structure strategy for vehicle stability control [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1288-1292. |

| [13] | CHANG Cheng,SONG Chuan-xue,ZHANG Ya-ge,SHAO Yu-long,ZHOU Fang. Minimizing inverter capacity of doubly-fed machine driving electric vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1629-1635. |

| [14] | XI Li-he,ZHANG Xin,SUN Chuan-yang,WANG Ze-xing,JIANG Tao. Adaptive energy management strategy for extended range electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1636-1644. |

| [15] | HE Ren,YANG Liu,HU Dong-hai. Design and analysis of refrigeration system supplied by solar auxiliary power of refrigerator car [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1645-1652. |

|

||