Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (6): 2002-2009.doi: 10.13229/j.cnki.jdxbgxb20180429

Previous Articles Next Articles

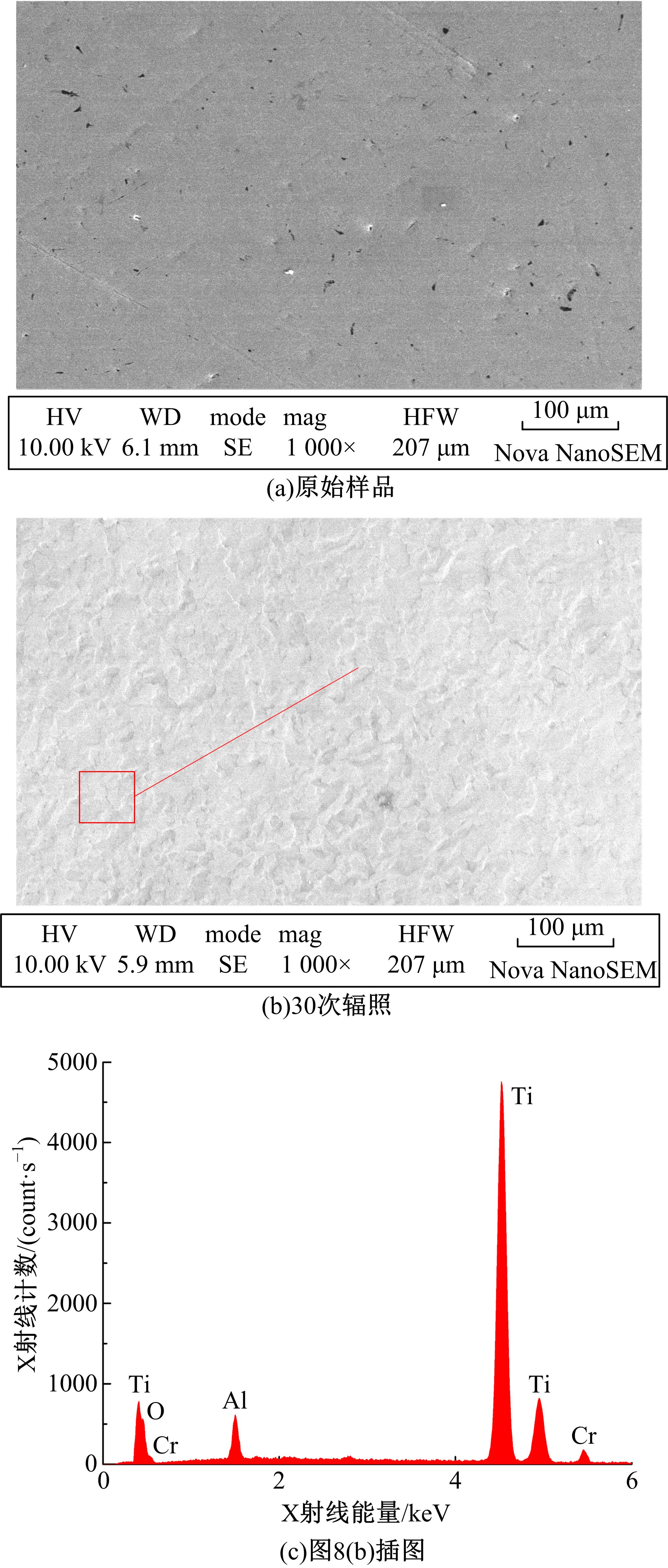

Preparation and property of Cr alloying layer on TC4 after surface alloying induced by high current pulsed electron beam

Qing-feng GUAN1( ),Xin-wen YAO1,Yang YANG1,Ling-yan ZHANG2,Di LIU1,Chen LI1,Peng LYU1(

),Xin-wen YAO1,Yang YANG1,Ling-yan ZHANG2,Di LIU1,Chen LI1,Peng LYU1( )

)

- 1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China

2. School of Science, Nanjing University of Science and Technology, Nanjing 210094, China

CLC Number:

- TG174.445

|

| [1] | Zhou SHI,Shu-qing KOU. Performance analysis and lightweight design of 36MnVS4 fracture⁃splitting connecting rod [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1992-2001. |

| [2] | Xin LI,Yan-peng SUN,Dan WANG,Jun-xu CHEN,Zheng-wei GU,Hong XU. Finite element numerical simulation for automobile front floor forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1608-1614. |

| [3] | Xin LI,Dan WANG,Jun⁃xu CHEN,Yan⁃peng SUN,Zheng⁃wei GU,Hong XU. Numerical simulation for handbrake fixed plate forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1258-1265. |

| [4] | Wen⁃quan LIU,Liang YING,Hai RONG,Ping HU. Forming limit prediction of high strength steel based on damage modified M⁃K model [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1266-1271. |

| [5] | Jin⁃zhong LU,Wan⁃ting ZHOU,Sheng⁃yang ZHANG,Yi⁃kai SHAO,Chang⁃yu WANG,Kai⁃yu LUO. Effect of coverage layer on corrosion resistance of 6061⁃T6 aluminum alloy subjected to laser shock peening [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 842-849. |

| [6] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [7] | HU Zhi-qing, YAN Ting-xu, LI Hong-jie, LYU Zhen-hua, LIAO Wei, LIU Geng. Effect of cryogenic treatment on punch-shearing performance of aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1524-1530. |

| [8] | QIU Xiao-ming, WANG Yin-xue, YAO Han-wei, FANG Xue-qing, XING Fei. Multi-objective optimization of resistance spot welding parameters for DP1180/DP590 using grey relational analysis based Taguchi [J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [9] | GUAN Qing-feng, DONG Shu-heng, ZHENG Huan-huan, LI Chen, ZHANG Cong-lin, LV-Peng. Cr surface alloying of 45# steel by high-current pulsed electron beam treatment [J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [10] | CHEN Jun-fu, GUAN Zhi-ping, YANG Chang-hai, NIU Xiao-ling, JIANG Zhen-tao, Song Yu-quan. Comparison of strain ranges and mechanical properties of metal rods under tension and torsion tests [J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

| [11] | LIANG Xiao-bo, CAI Zhong-yi, GAO Peng-fei. Numerical simulation and experiment of cylindrical forming of sandwich composite panel [J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [12] | LIU Zi-wu, LI Jian-feng. Erosion damage and evaluation of remanufacturing cladding layer for impeller metals FV520B [J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [13] | LIU Chun-guo, LIU Wei-dong, DENG Yu-shan. Effect of multi-point punch active loading path on the stretch-forming of sheet [J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [14] | LYU Meng-meng, GU Zheng-wei, XU Hong, LI Xin. Process optimization of hot stamping for anti-collision beam with ultra high strength [J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [15] | XING Hai-yan, GE Hua, LI Si-qi, YANG Wen-guang, SUN Xiao-jun. Hidden defect metal magnetic memory identification for welded joints based on fuzzy membership and maximum likelihood estimation [J]. 吉林大学学报(工学版), 2017, 47(6): 1854-1860. |

|