Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (2): 296-309.doi: 10.13229/j.cnki.jdxbgxb20211031

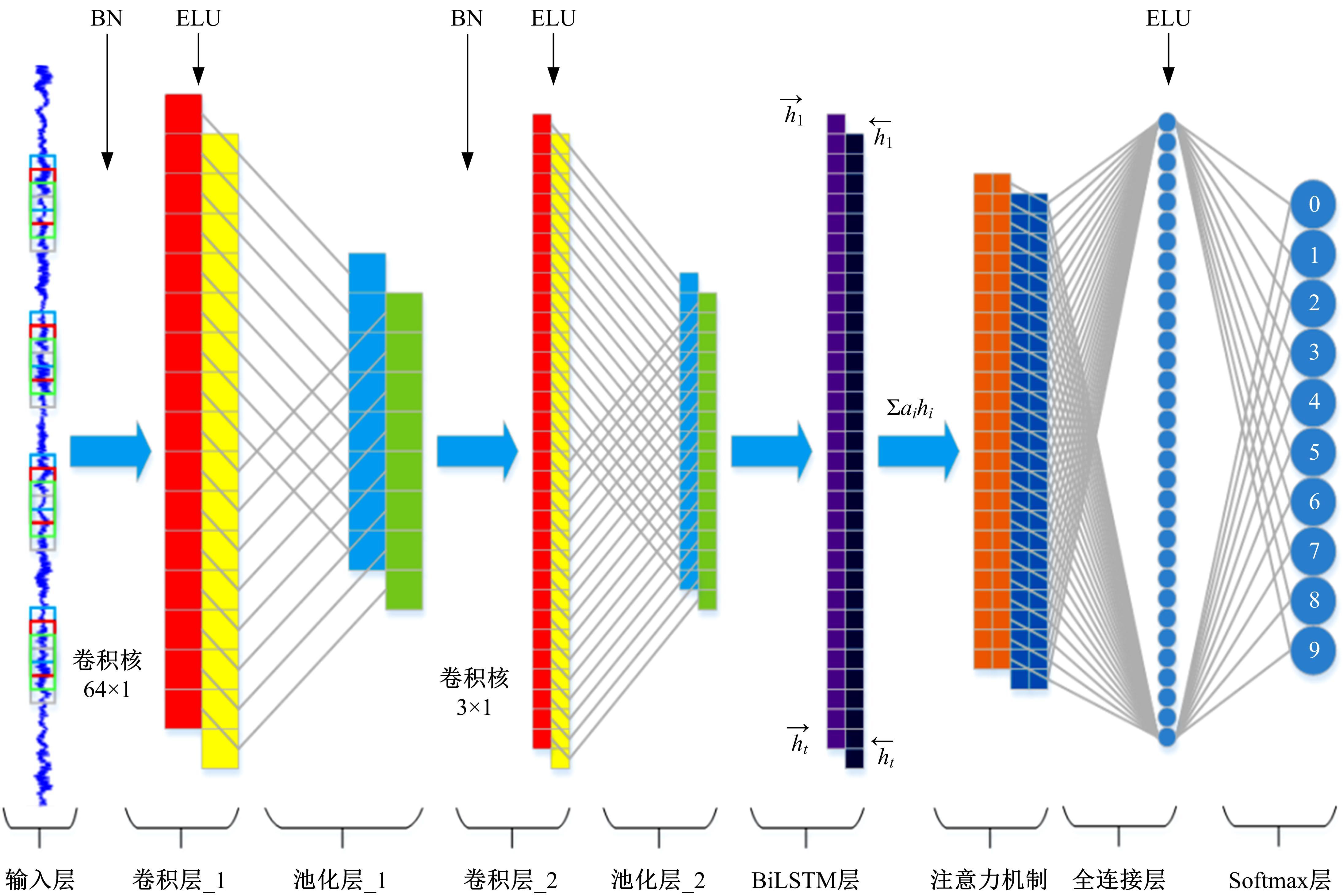

Stable anti⁃noise fault diagnosis of rolling bearing based on CNN⁃BiLSTM

Xiao⁃lei CHEN1,2,3( ),Yong⁃feng SUN1,Ce LI1,2,3,Dong⁃mei LIN1,2,3

),Yong⁃feng SUN1,Ce LI1,2,3,Dong⁃mei LIN1,2,3

- 1.College of Electrical and Information Engineering,Lanzhou University of Technology,Lanzhou 730050,China

2.Key Laboratory of Gansu Advanced Control for Industrial Processes,Lanzhou University of Technology,Lanzhou ;730050

3.National Demonstration Center for Experimental Electrical and Control Engineering Education,Lanzhou University of Technology,Lanzhou 730050,China

CLC Number:

- TP277

| 1 | Liu R, Yang B, Zio E, et al. Artificial intelligence for fault diagnosis of rotating machinery: a review[J]. Mechanical Systems & Signal Processing, 2018, 108:33⁃47. |

| 2 | Wang B, Lei Y, Li N, et al. A hybrid prognostics approach for estimating remaining useful life of rolling element bearings[J]. IEEE Transactions on Reliability, 2020,69(1):401⁃412. |

| 3 | Ahmad W, Khan S A, Kim J M. A hybrid prognostics technique for rolling element bearings using adaptive predictive models[J]. IEEE Transactions on Industrial Electronics, 2018,65(2):1577⁃1584. |

| 4 | Wen L, Li X, Gao L, et al. A new convolutional neural network based data⁃driven fault diagnosis method[J]. IEEE Transactions on Industrial Electronics, 2018,65(7):5990⁃5998. |

| 5 | Li Y, Ding K, He G, et al. Non⁃stationary vibration feature extraction method based on sparse decomposition and order tracking for gearbox fault diagnosis[J]. Measurement, 2018, 124:453⁃469. |

| 6 | Wu C, Jiang P, Ding C, et al. Intelligent fault diagnosis of rotating machinery based on one⁃dimensional convolutional neural network[J]. Computers in Industry, 2019, 108:53⁃61. |

| 7 | 解晓婷,李少波,杨观赐,等.基于FFT与CS⁃SVM的滚动轴承故障诊断[J].组合机床与自动化加工技术,2019,542(4):90⁃94. |

| Xie Xiao⁃ting, Li Shao⁃bo, Yang Guan⁃ci, et al. Fault diagnosis of rolling bearing based on FFT and CS⁃SVM [J]. Modular Machine Tool and Automatic Processing Technology, 2019, 542(4):90⁃94. | |

| 8 | 陈彦龙,张培林,李兵,徐超,王国德.基于DCT和GA-SVM的轴承故障诊断[J].计算机工程,2012,38(19):247-249, 253. |

| Chen Yan-long, Zhang Pei-lin, Li Bing, Xu Chao, Wang Guo-de.Bearing fault diagnosis based on DCT and GA-SVM[J].Computer Engineering,2012,38(19):247-249, 253. | |

| 9 | Lee C Y, Cheng Y H. Motor fault detection using wavelet transform and improved PSO⁃BP neural network[J]. Processes, 2020, 8(10):1322. |

| 10 | Zhu H, Wang X, Yang Z, et al. Sparse representation based on adaptive multiscale features for robust machinery fault diagnosis[J]. Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science, 2015, 229(12):2303⁃2313. |

| 11 | Zhao H, Guo S, Gao D. Fault feature extraction of bearing faults based on singular value decomposition and variational modal decomposition[J]. Journal of Vibration and Shock, 2016,35(22):183⁃188. |

| 12 |

王进花,胡佳伟,曹洁,黄涛.基于自适应VMD和IELM的滚动轴承多故障诊断[J/OL].吉林大学学报:工学版:1-10.[2022-01-21].DOI:10.13229/j.cnki.jdxbgxb20200856.

doi: 10.13229/j.cnki.jdxbgxb20200856 |

|

Wang Jin-hua, Hu Jia-wei, Cao Jie, Huang Tao.Multiple fault diagnosis of rolling bearing based on adaptive VMD and IELM[J/OL].Journal of Jilin University(Engineering Edition):1-10.[2022-01-21].DOI:10.13229/j.cnki.jdxbgxb20200856.

doi: 10.13229/j.cnki.jdxbgxb20200856 |

|

| 13 | 王普,李天垚,高学金,等. 分层自适应小波阈值轴承故障信号降噪方法[J]. 振动工程学报, 2019, 32(3): 548⁃556. |

| Wang Pu, Li Tian⁃yao, Gao Xue⁃jin, et al. Hierarchical adaptive wavelet threshold denoising method for bearing fault signals[J]. Chinese Journal of Vibration Engineering, 2019, 32(03): 548⁃556. | |

| 14 | 朱军,闵祥敏,孔凡让,等. 基于分量筛选奇异值分解的滚动轴承故障诊断方法研究[J].振动与冲击, 2015, 34(20): 61⁃65. |

| Zhu Jun, Min Xiang⁃min, Kong Fan⁃rang, et al. Research on fault diagnosis method of rolling bearing based on component screening singular value decomposition[J]. Vibration and Shock, 2015, 34(20): 61⁃65. | |

| 15 | Bakir T, Boussaid B, Hamdaoui R, et al. Fault detection in wind turbine system using wavelet transform: multi⁃resolution analysis[C]//International Multi conference on Systems, IEEE, 2015: 1⁃6. |

| 16 | Wang H, Xu J, Yan R, et al. Intelligent bearing fault diagnosis using multi⁃head attention⁃based CNN[J]. Procedia Manufacturing, 2020, 49: 112⁃118. |

| 17 | 曲建岭,余路,袁涛,等. 基于卷积神经网络的层级化智能故障诊断算法[J]. 控制与决策, 2019, 34(12): 2619⁃2626. |

| Qu Jian⁃ling, Yu Lu, Yuan Tao, et al. A hierarchical intelligent fault diagnosis algorithm based on convolutional neural network[J]. Control and Decision, 2019, 34(12): 2619⁃2626. | |

| 18 | Chen X, Zhang B, Gao D. Bearing fault diagnosis base on multi⁃scale CNN and LSTM model[J]. Journal of Intelligent Manufacturing, 2021, 32: 971⁃987. |

| 19 | 张根保,李浩,冉琰,等. 一种用于轴承故障诊断的迁移学习模型[J].吉林大学学报:工学版, 2020, 50(5): 1617⁃1626. |

| Zhang Gen⁃bao, Li Hao, Ran Yan, et al. A transfer learning model for bearing fault diagnosis[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(5): 1617⁃1626. | |

| 20 | Wei Z, Peng G, Li C, et al. A new deep learning model for fault diagnosis with good anti⁃noise and domain adaptation ability on raw vibration signals[J]. Sensors, 2017, 17(2): 425. |

| 21 | Zhang W, Li C, Peng G, et al. A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load[J]. Mechanical Systems and Signal Processing, 2018, 100: 439⁃453. |

| 22 | Li X, Zhang W, Din Q. A robust intelligent fault diagnosis method for rolling element bearings based on deep distance metric learning[J]. Neurocomputing, 2018, 310(8): 77⁃95. |

| 23 | Jin G, Zhu T, Akram M W, et al. An adaptive anti⁃noise neural network for bearing fault diagnosis under noise and varying load conditions[J]. IEEE Access, 2020, 8: 74793⁃74807. |

| 24 | Hamada M S, Ryan K J. Combined analysis of overlapping stratified random sample and simple random sample data[J]. Quality and Reliability Engineering International, 2016, 32(1): 309⁃314. |

| 25 | Smith W A, Randall R B. Rolling element bearing diagnostics using the case Western Reserve University data: a benchmark study[J]. Mechanical Systems and Signal Processing, 2015, 64⁃65: 100⁃131. |

| 26 | 黄南天,杨学航,蔡国伟,等. 采用非平衡小样本数据的风机主轴承故障深度对抗诊断[J]. 中国电机工程学报, 2020, 40(2): 215⁃226. |

| Huang Nan⁃tian, Yang Xue⁃hang, Cai Guo⁃wei, et al. Depth counter⁃diagnosis of fan main bearing faults using unbalanced small sample data[J]. Proceedings of the Chinese Society of Electrical Engineering, 2020, 40(2): 215⁃226. | |

| 27 | Ioffe S, Szegedy C. Batch normalization: accelerating deep network training by reducing internal covariate shift[J]. JMLR org, 2015, arXiv:. |

| 28 | Li Y, Fan C, Li Y, et al. Improving deep neural network with multiple parametric exponential linear units[J]. Neurocomputing, 2016, 301(2): 11⁃24. |

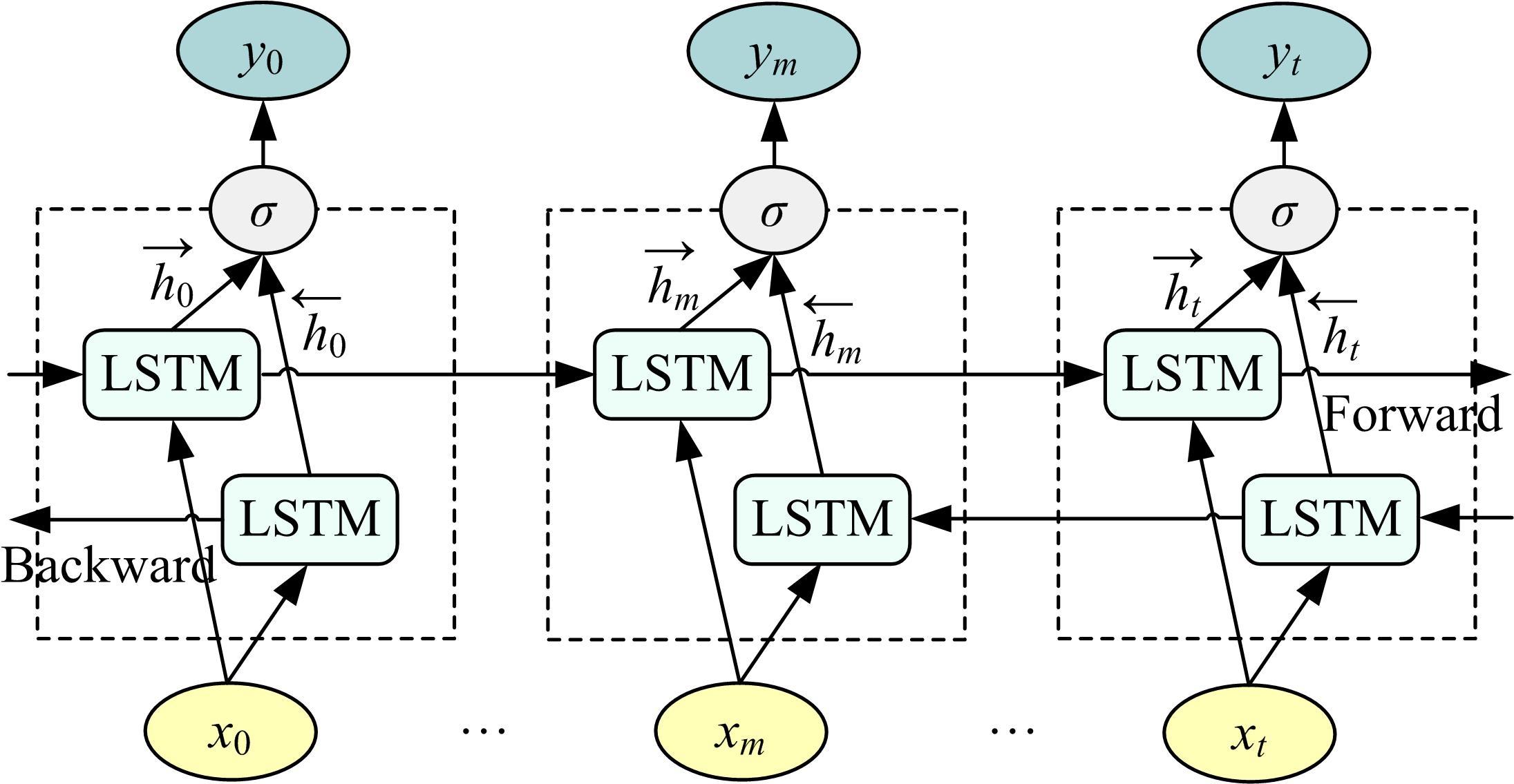

| 29 | Hochreiter S, Schmidhuber J. Long short⁃term memory[J]. Neural Computation, 1997, 9(8): 1735⁃1780. |

| 30 | Brocki L, Marasek K. Deep belief neural networks and bidirectional long⁃short term memory hybrid for speech recognition[J]. Archives of Acoustics, 2015, 40(2): 191⁃195. |

| 31 | Kingma D P, Ba J. Adam: A method for stochastic optimization[J]. arXiv preprint arXiv:, 2014. |

| 32 | Rusiecki A. Trimmed categorical cross‐entropy for deep learning with label noise[J]. Electronics Letters, 2019, 55(6): 319-320. |

| [1] | Guo-fa LI,Yan-bo WANG,Jia-long HE,Ji-li WANG. Research progress and development trend of health assessment of electromechanical equipment [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 267-279. |

| [2] | Shao-jiang DONG,Peng ZHU,Xue-wu PEI,Yang LI,Xiao-lin HU. Fault diagnosis of rolling bearing under variable operating conditions based on subdomain adaptation [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 288-295. |

| [3] | Liang DUAN,Chun-yuan SONG,Chao LIU,Wei WEI,Cheng-ji LYU. State recognition in bearing temperature of high-speed train based on machine learning algorithms [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 53-62. |

| [4] | Hong-kui XU,Tong-tong JIANG,Xin LI,Bin-xiang JIANG,Yong-lei WANG. LTE uplink interference analysis combined with denoising autoencoder and extreme learning machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 195-203. |

| [5] | Gui-xia LIU,Zhi-yao PEI,Jia-zhi SONG. Prediction of protein-ATP binding site based on deep learning [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 187-194. |

| [6] | Xian-yan KUANG,Hui-chao LUO,Rui ZHONG,Peng OUYANG. Bus arrival time prediction based on wavelet neural network optimized by Beetle Antennae Search [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 110-117. |

| [7] | Hong-zhi WANG,Ting-ting WANG,Huang-shui HU,Xiao-fan LU. PID control based on BP neural network optimized by Q⁃learning for speed control of BLDCM [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2280-2286. |

| [8] | Yuan-hong LIU,Pan-pan GUO,Yan-sheng ZHANG,Xin LI. Feature extraction of sparse graph preserving projection based on Riemannian manifold [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2268-2279. |

| [9] | Shi-jun YANG,Yu-long PEI,Heng-yan PAN,Guo-zhu CHENG,Wen-hui ZHANG. Characteristics analysising and prediction of dwelling time of urban bus [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2031-2039. |

| [10] | Dan-tong OUYANG,Bi-ge ZHANG,Nai-yu TIAN,Li-ming ZHANG. Fail data reduction algorithm combining configuration checking with local search [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2144-2153. |

| [11] | Hui ZHONG,Heng KANG,Ying-da LYU,Zhen-jian LI,Hong LI,Ruo-chuan OUYANG. Image manipulation localization algorithm based on channel attention convolutional neural networks [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1838-1844. |

| [12] | Wen-long TENG,Bing-hu CONG,Yun-kun SHANG,Yu-chen ZHANG,Tian BAI. Modeling of building energy consumption prediction based on MEA⁃BP neural network [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1857-1865. |

| [13] | Tao CHEN,Jing QIN,Hua ZHAO,Qing-peng SU,Yong LYU,Kai ZHONG,Ying-bo WANG,Yi-qiang PEI. Prediction of gasoline engine steady state exhaust based on model group prediction method [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1565-1574. |

| [14] | Lao-hu YUAN,Dong-shan LIAN,Liang ZHANG,Yi LIU. Fault diagnosis of key mechanical components of aircraft based on densenet and support vector machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1635-1641. |

| [15] | Xiao-long ZHU,Zhong XIE. Automatic construction of knowledge graph based on massive text data [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1358-1363. |

|

||