Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (2): 505-514.doi: 10.13229/j.cnki.jdxbgxb20210658

Previous Articles Next Articles

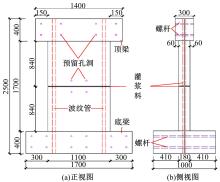

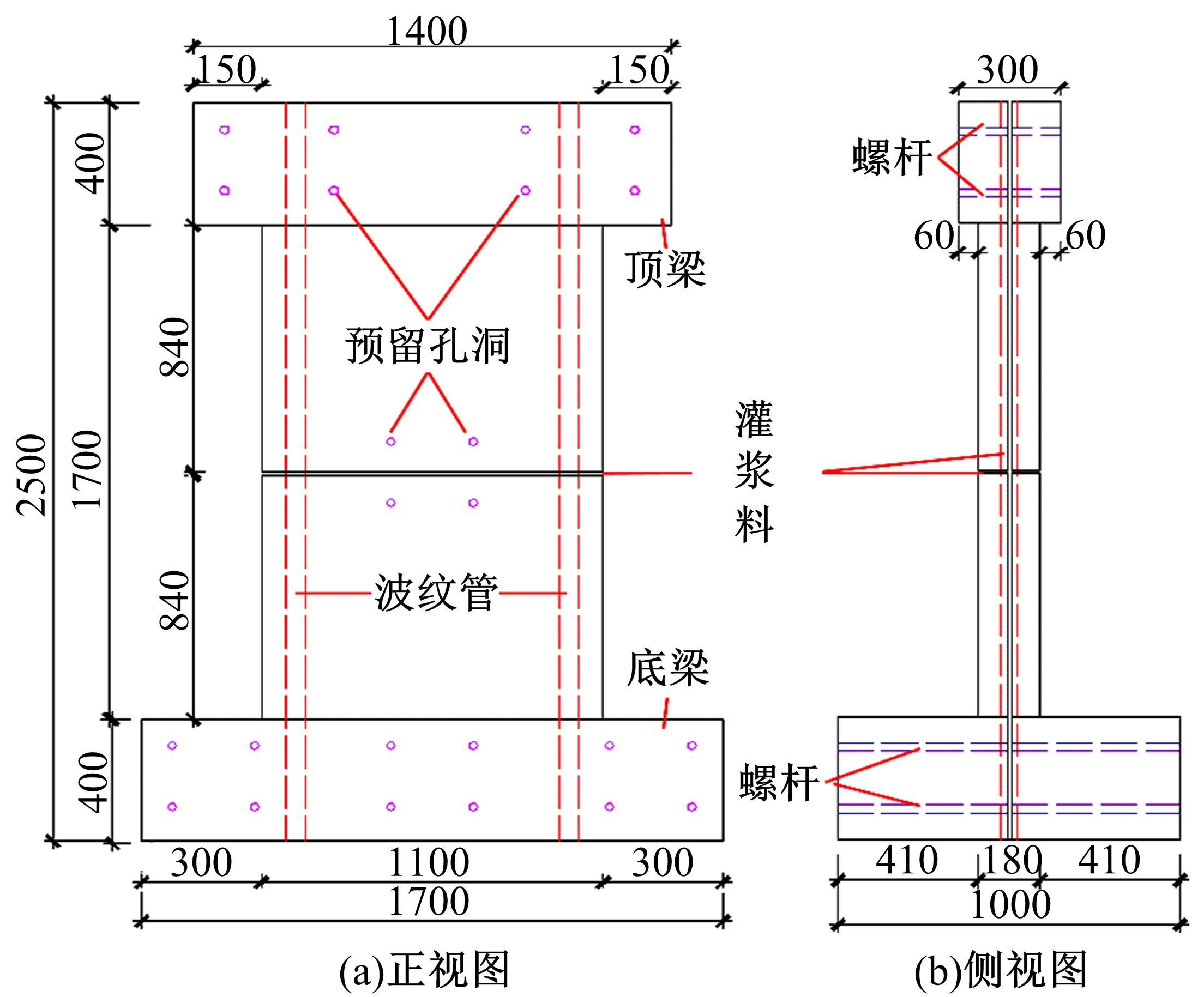

Seismic performance of connection joints between prefabricated prefinished volumetric construction

Qing-feng YAN1( ),Ji-gang ZHANG1,2(

),Ji-gang ZHANG1,2( ),Tao WANG1,De-gang CHEN3,You-sheng YU1,Ying-chun YANG4

),Tao WANG1,De-gang CHEN3,You-sheng YU1,Ying-chun YANG4

- 1.School of Civil Engineering,Qingdao University of Technology,Qingdao 266033,China

2.Collaborative Innovation Center for Engineering Construction and Safety of Shandong University Blue Economic Zone,Qingdao 266033,China

3.Qingjian Group Co. ,Ltd. ,Qingdao 266071,China

4.Ronghua (Qingdao) Construction Technology Co. ,Ltd. ,Qingdao 266500,China

CLC Number:

- TU398

| 1 | Hwang B G, Shan M, Looi K Y. Knowledge-based decision support system for prefabricated prefinished volumetric construction[J]. Au tomation in Construction, 2018, 94: 168-178. |

| 2 | Hwang B G, Shan M, Looi K Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction[J]. Journal of Cleaner Production, 2018, 183: 183-193. |

| 3 | Matthew G, Yang M G. Lean production theory-based simulation of modular construction processes[J]. Automation in Construction, 2019, 101(1): 227-244. |

| 4 | Chua Y S, Richard L J Y, Pang S D. Modelling of connections and lateral behavior of high-rise modular steel buildings[J]. Journal of Constructional Steel Research, 2020, 166: 105901. |

| 5 | Lv Y F, Li G Q, Cao K, et al. Behavior of splice connection during transfer of vertical load in full-scale corner-supported modular building[J]. Engineering Structures, 2021, 230: 111698. |

| 6 | Chen Z H, Niu X Y, Liu J D, et al. Seismic study on an innovative fully-bolted beam-column joint in prefabricated modular steel buildings[J]. Engineering Structures, 2021, 234: 111875. |

| 7 | Sukhi V S, David P T, Perera N, et al. Seismic mitigation of steel modular building structures through innovative inter-modular connections[J]. Heliyon, 2019, 5(11): 02751. |

| 8 | 向沛国. 装配式模块化建筑节点试验研究[D]. 哈尔滨: 哈尔滨工业大学土木工程学院, 2017. |

| Xiang Pei-guo. Experimental research on joint of fabricated modular buildings[D]. Harbin: School of Civil Engineering, Harbin Institute of Technology, 2017. | |

| 9 | 刘学春, 任旭, 詹欣欣, 等. 一种盒子式模块化装配式钢结构房屋梁柱节点受力性能分析[J]. 工业建筑,2018, 48(5): 62-69. |

| Liu Xue-chun, Ren Xu, Zhan Xin-xin, et al. Mechanical property analysis of beam-to-column connection in a box-type modular prefabricated steel structure building[J]. Industrial Construction, 2018, 48(5): 62-69. | |

| 10 | 刘学春,浦双辉,徐阿新,等.模块化装配式多高层钢结构全螺栓连接节点静力及抗震性能试验研究[J]. 建筑结构学报, 2015, 36(12): 43-51. |

| Liu Xue-chun, Pu Shuang-hui, Xu A-xin, et al. Experimental study on static and seismic performance of bolted joint in modularized multi-layer and high-rise prefabricated steel structures[J]. Journal of Building Structures, 2015, 36(12): 43-51. | |

| 11 | 刘学春,徐阿新,倪真,等.模块化装配式钢结构梁柱节点极限承载力分析与抗震性能研究[J].工业建筑, 2014, 44(8): 23-26, 60. |

| Liu Xue-chun, Xu A-xin, Ni Zhen, et al. Analysis of the limit bearing capacity and seismic performance of typical joint of truss-beam and column in fabricated high-rise steel structure[J]. Industrial Construction, 2014, 44(8): 23-26, 60. | |

| 12 | 熊枫,黄炎生,周靖,等.装配式内置双钢套管混凝土组合剪力墙的抗震性能试验研究[J]. 土木工程学报, 2021, 54(4): 8-17, 94. |

| Xiong Feng, Huang Yan-sheng, Zhou Jing,et al.Experimental study on seismic performance of precast concrete composite shear walls embedded with high-strength concrete-filled double steel tube[J]. China Civil Engineering Journal, 2021, 54(4): 8-17, 94. | |

| 13 | 龚永智,况锦华,柯福隆,等.UHPC连接的装配式剪力墙节点抗震性能试验[J].吉林大学学报:工学版, 2022, 52(10): 2367-2375. |

| Gong Yong-zhi, Kuang Jin-hua, Ke Fu-long, et al. Experiment on seismic behavior of assembled shear wall joints connected by ultra high performance concrete[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2367-2375. | |

| 14 | 陈俊,王韶纤,胥卉,等.负弯矩作用下可拆卸预制装配式组合梁力学性能试验[J].吉林大学学报:工学版, 2022, 52(3): 604-614. |

| Chen Jun, Wang Shao-xian, Xu Hui, et al. Experiment on mechanical properties of detachable prefabricated composite beams subjected to negative bending moment[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 604-614. | |

| 15 | 范亮,徐英铭,谭阳. 集束群钉式装配组合梁界面滑移计算理论研究[J/OL]. [2022-02-07]. |

| 16 | . 建筑抗震试验规程 [S]. |

| 17 | . 混凝土物理力学性能试验方法标准 [S]. |

| 18 | . 金属材料 拉伸试验 第1部分:室温试验方法 [S]. |

| 19 | Lu X Z, Xie L L, Guan H, et al. A shear wall element for nonlinear seismic analysis of super-tall buildings using OpenSees[J]. Finite Elements in Analysis & Design, 2015, 98: 14-25. |

| 20 | 曹徐阳,冯德成,王谆,等.基于OpenSEES的装配式混凝土框架节点数值模拟方法研究[J].土木工程学报, 2019, 52(4): 13-27. |

| Cao Xu-yang, Feng De-cheng, Wang Zhun, et al. Investigation on modelling approaches for prefabricated concrete beam-to-column connections using openSEES[J].China Civil Engineering Journal, 2019, 52(4): 13-27. |

| [1] | Wei-hong CHEN,Yan CHEN,Qiu-rong HONG,Shuang-shuang CUI,Xue-yuan YAN. Seismic performance of earthquake⁃damaged precast concrete frame structures strengthened with BRBs [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1817-1825. |

| [2] | Zhao-yi HE,Jin-feng LI,Wen ZHOU,Zhi-tao GUAN. Dynamic modulus of porous asphalt concrete and its prediction model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1375-1385. |

| [3] | Yong-zhi GONG,Jin-hua KUANG,Fu-long KE,Quan ZHOU,Xiao-yong LUO. Experiment on seismic behavior of assembled shear wall joints connected by ultra high performance concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2367-2375. |

| [4] | Shuan-cheng GU,Hong-bin NIE. Analysis of damage model of mortars strengthened with CFRP under ultimate freeze⁃thaw and load [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2108-2120. |

| [5] | Jing ZHOU,Ya-jun LI,Wei-feng ZHAO,Zong-jian LUO,Guo-bin BU. Eccentric compression behavior of bamboo⁃plywood and steel⁃tube dual⁃confined dust⁃powder concrete columns [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2096-2107. |

| [6] | Guang-tai ZHANG,Lu-yang ZHANG,Guo-hua XING,Yin-long CAO,Bao YI. Seismic performance of steel⁃polypropylene hybrid fiber reinforced concrete shear wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 946-955. |

| [7] | Wei-xiao XU,Yang CHENG,Wei-song YANG,Jia-chang JU,De-hu YU. Quasi-static test of RC frame-seismic wall dual structural system [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 268-277. |

| [8] | De-shan SHAN,Xiao ZHANG,Xiao-yu GU,Qiao LI. Analytical method for elongation of stayed-cable with catenary configuration [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 217-224. |

| [9] | Liu LIU,Wei-xing FENG. Field measurement and calculation analysis of tunnel shield tunnel construction based on NNBR model [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 245-251. |

| [10] | Su-duo XUE,Jian LU,Xiong-yan LI,Ren-jie LIU. Influence of grid⁃jumping arrangement on static and dynamic performance of annular crossed cable⁃truss structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1687-1697. |

| [11] | Bo WANG,Yuan-zheng DONG,Li-xin DONG. Calculation of basic wind pressure based on short⁃term wind speed data [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1739-1746. |

| [12] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Experimental of loading-bearing capacity of one-way laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 654-667. |

| [13] | Peng-hui WANG,Hong-xia QIAO,Qiong FENG,Hui CAO,Shao-yong WEN. Durability model of magnesium oxychloride-coated reinforced concrete under the two coupling factors [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 191-201. |

| [14] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Mechanical properties of laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1509-1520. |

| [15] | Jun ZHANG,Cheng QIAN,Chun⁃yan GUO,Yu⁃jun QIAN. Dynamic design of building livability based on multi⁃source spatiotemporal data [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1169-1173. |

|