Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (6): 2108-2120.doi: 10.13229/j.cnki.jdxbgxb20200301

Analysis of damage model of mortars strengthened with CFRP under ultimate freeze⁃thaw and load

Shuan-cheng GU1( ),Hong-bin NIE1,2(

),Hong-bin NIE1,2( )

)

- 1.School of Architecture and Civil Engineering,Xi′an University of Science and Technology,Xi′an 710054,China

2.College of Rail Engineering,Shaanxi Railway Institute,Wei Nan 714000,China

CLC Number:

- TU531

| 1 | 岳清瑞,陈小兵,牟宏远.碳纤维材料(CFRP)加固修补混凝土结构新技术[J].工业建筑,1998(11):1-5, 34. |

| Yue Qing-rui,Chen Xiao-bing,Mu Hong-yuan. New technology of carbon fibre reinforced plastics on strengthening & repairing concrete structures[J]. Industrial Construction, 1998(11):1-5, 34. | |

| 2 | 叶列平,赵树红,李全旺,等.碳纤维布加固混凝土柱的斜截面受剪承载力计算[J].建筑结构学报,2000(2):59-67. |

| Ye Lie-ping, Zhao Shu-hong, Li Quan-wang,et al. Caleulation of shear strength of concrete column strengthened with carbon fibre reinforced plastics[J].Journal of Building Structures,2000(2):59-67. | |

| 3 | 赵彤,张景明,谢剑,等.碳纤维布改善钢筋混凝土短柱延性的试验研究[J].世界地震工程,2001(1):82-86. |

| Zhao Tong, Zhang Jing-ming, Xie Jian, et al. Experimentls study on the application of continuous carbon fibre reinforced plastics sheet to improve the dyctility of reinforced concrete short columns[J].World Information of Earthquake Enginering,2001(1):82-86. | |

| 4 | 陈少雄. 碳纤维布和角钢复合加固钢筋混凝土柱抗震性能研究[D].武汉:武汉大学土木建筑工程学院,2004. |

| Chen Shao-xiong. Experimental research on seismis behavior of reinforced concrete columns combination rehabilitation with bonded steel angles and carbon fibre reinforced plastics sheet[D]. Wuhan:School of Civil Engineering,Wuhan University,2004. | |

| 5 | 卢亦焱,童光兵,赵国藩,等.外包角钢与碳纤维布复合加固钢筋混凝土偏压柱承载力计算分析[J].土木工程学报,2006(8):19-25. |

| Lu Yi-yan, Tong Guang-bing, Zhao Guo-fan,et al. Analysis of the bearing capacity of RC eccentr ic compression columns encased in angle steels and strengthened with CFRP[J].China Civil Engineering Journal,2006(8):19-25. | |

| 6 | 顾冬生,吴刚,吴智深,等.CFRP加固高轴压比钢筋混凝土短圆柱抗震性能试验研究[J].工程抗震与加固改造,2006(6):71-77. |

| Gu Dong-sheng, Wu Gang, Wu Zhi-shen,et al. Experimental study on seismic performance of RC short circular columns strengthened with CFRP composites under high-level compression[J].Earthquake Resistant Engineering and Retrofitting,2006(6):71-77. | |

| 7 | 苑寿刚. CFRP约束带载加固混凝土柱滞回性能试验研究[D].沈阳:东北大学资源与土木工程学院,2009. |

| Yuan Shou-gang. Experimental study on the hysteretic behavior of preloaded concrete columns with CFRP confinement[D]. Shenyang:College of Resources and Civil Engineering,Northeastern University,2009. | |

| 8 | 李趁趁,高丹盈,赵军.干湿环境下FRP全裹与条带间隔加固混凝土圆柱耐久性试验研究[J].土木工程学报,2009,42(11):8-14. |

| Li Chen-zhen, Gao Dan-ying, Zhao Jun. Experimental study on durability of FRP entirely-wrapped concrete cylinders and FRP strip-wrapped concrete cylinders under wet-dry cycles insaltsolution[J]. China Civil Engineering Journal, 2009,42(11):8-14. | |

| 9 | 聂红宾. CFRP布加固冻融损伤混凝土构件力学性能研究[D].沈阳:沈阳大学,2013. |

| Nie Hong-bin. Research on behavior of freeze-thaw damageable concrete members strengthened by CFRP sheets[D].Shenyang:Shenyang University,2013. | |

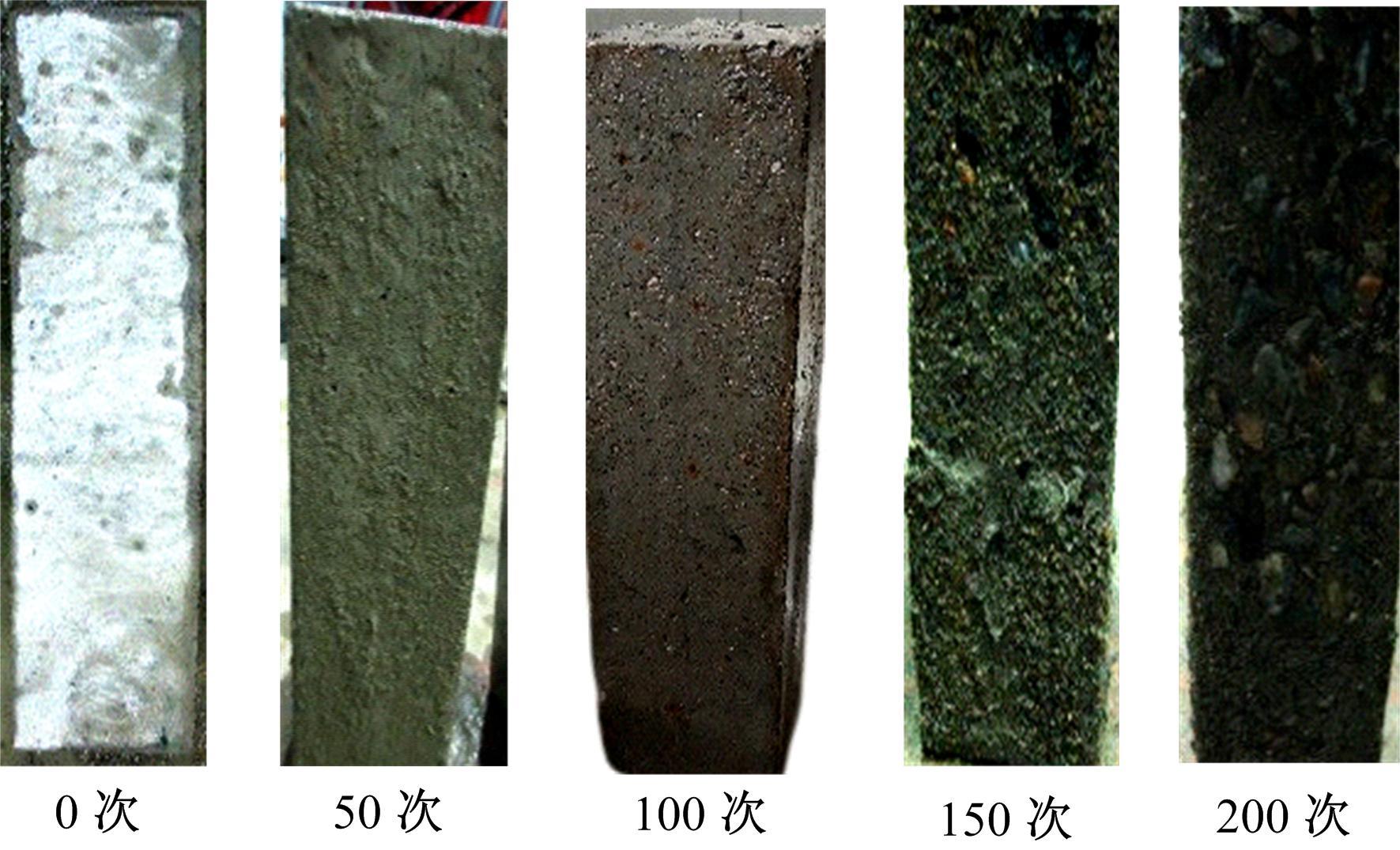

| 10 | 张凯,姜福香,殷彦波.冻融循环下CFRP加固混凝土结构耐久性试验研究[J].工程建设,2015,47(1):7-11, 19. |

| Zhang Kai, Jiang Fu-xiang, Yin Yan-bo. Experimental study on durability of concrete structure reinforced with CFRP in freeze-thaw cycle[J]. Engineering construction,2015,47(1):7-11, 19. | |

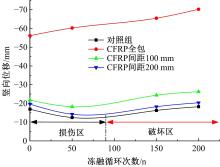

| 11 | 王苏岩,宋泽林,丁荔.冻融循环与持载对CFRP加固高强混凝土梁变形性能的影响[J].建筑科学与工程学报,2017,34(2):26-32. |

| Wang Su-yan,Song Ze-lin,Ding Li.Influence of freeze-thaw cycles and sustained loads on deformation performance of high strength concrete beam strengthened with CFRP[J]. Journal of Architecture and Civil engineer,2017,34(2):26-32. | |

| 12 | 洪雷,江海鑫,王苏岩.冻融循环下预应力CFRP加固高强混凝土耐久性[J].铁道科学与工程学报,2017,14(2):227-232. |

| Hong Lei, Jiang Hai-xin, Wang Su-yan. Durability of high strength concrete strengthened with prestressed CFRP under freeze-thaw cycles[J]. Journal of Railway Science and Engineering,2017,14(2):227-232. | |

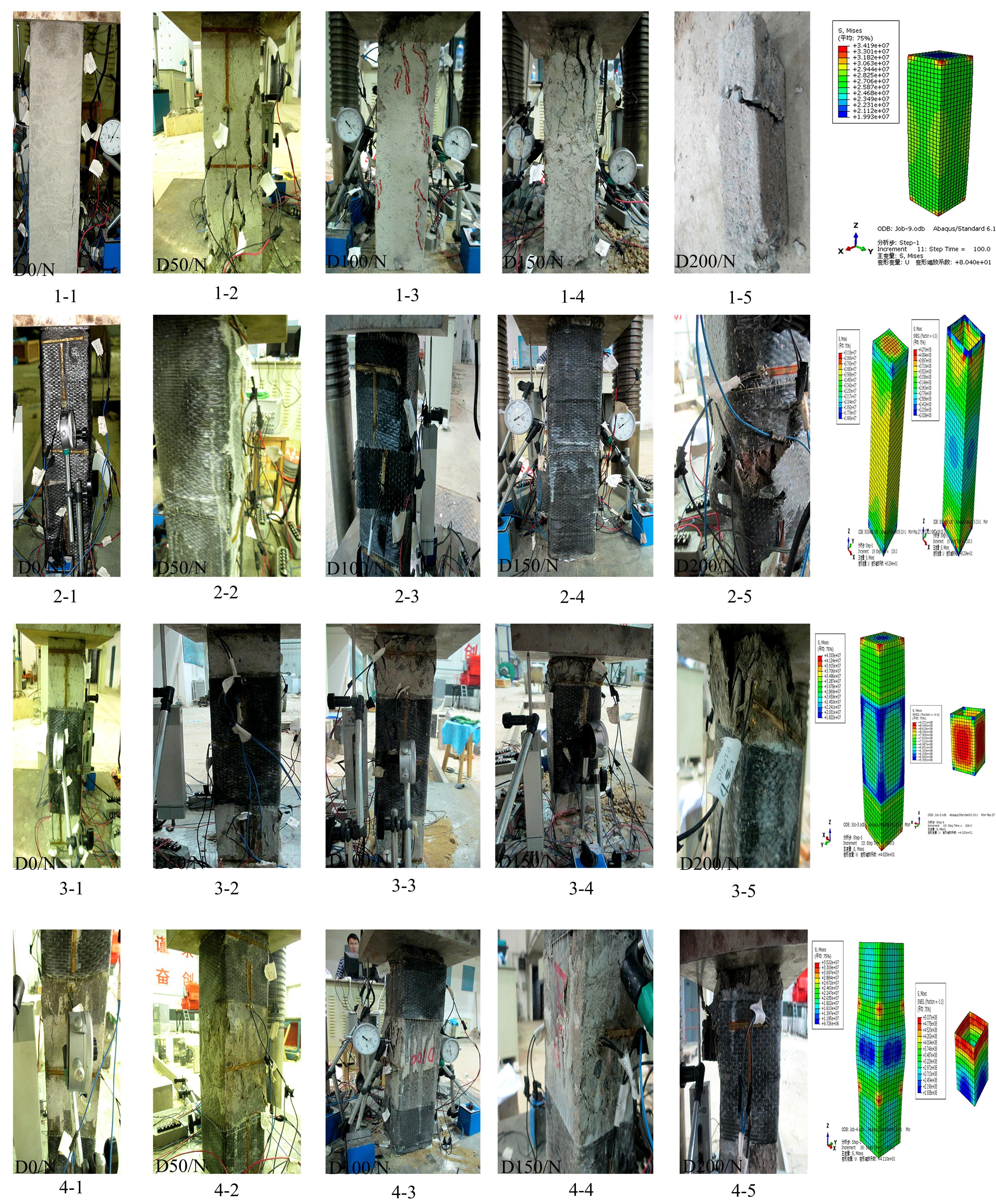

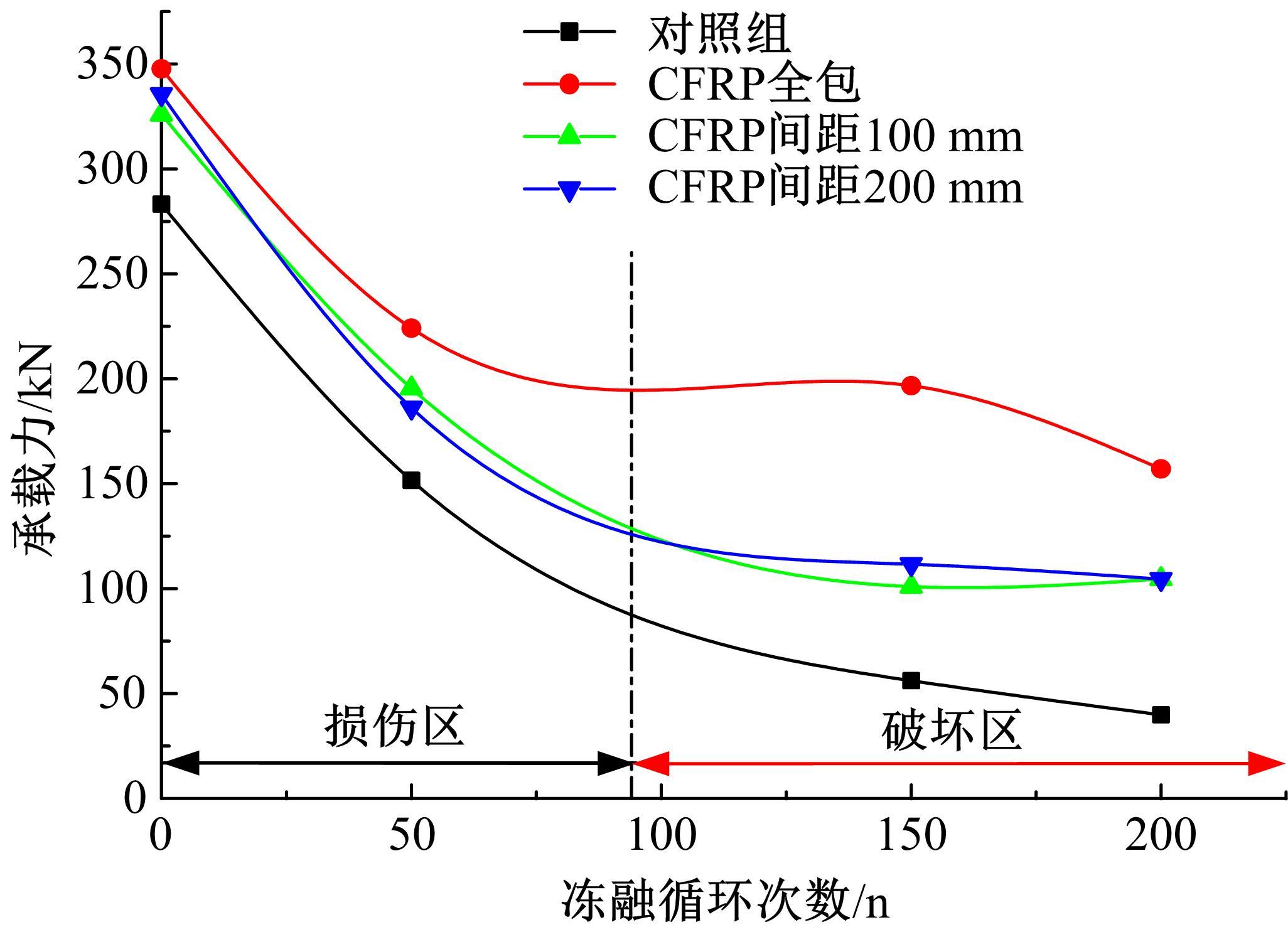

| 13 | 何媛媛,武丽,董江峰,等.CFRP加固对冻融再生混凝土短柱承载性能的影响[J].建筑材料学报, 2019, 22(3):451-458, 466. |

| He Yuan-yuan, Wu Li, Dong Jiang-feng,et al. The effects of CFRP reinforcement on the strength of recycled concrete column under cycled feeze-thaw environment[J]. Journal of Building Materials, 2019, 22(3):451-458, 466. | |

| 14 | 普通混凝土长期性能和耐久性能试验方法标准:[S]. 北京: 中国建筑工业出版社, 2009. |

| 15 | 段安. 受冻融混凝土本构关系研究和冻融过程数值模拟[D].北京:清华大学土木工程系,2009. |

| Duan An. Research on constitutive relationship of frozen-thawed concrete and mathematical modeling of freeze-thaw process[D]. Beijing:Department of Civil Engineering,Tsinghua University, 2009. | |

| 16 | 杨苗苗,封建湖,程晓晗,等. 求解复杂交通流模型的低耗散中心迎风格式[J]. 计算机工程, 2019, 45(6): 37-44. |

| Yang Miao-miao,Feng Jian-hu,Cheng Xiao-han,et al. Low dissipation central-upwind scheme for solving complex traffic flow model[J]. Computer Engineering, 2019, 45(6): 37-44. | |

| 17 | 李趁趁. FRP加固混凝土结构耐久性试验研究[D].大连:大连理工大学建设工程学部,2006. |

| Li Chen-chen. Experimental study on durability of FRP reinforced concrete structures [D].Dalian: Faculty of Infrastructure Engineering,Dalian University of Technology,2006. |

| [1] | Jing ZHOU,Ya-jun LI,Wei-feng ZHAO,Zong-jian LUO,Guo-bin BU. Eccentric compression behavior of bamboo⁃plywood and steel⁃tube dual⁃confined dust⁃powder concrete columns [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2096-2107. |

| [2] | Guang-tai ZHANG,Lu-yang ZHANG,Guo-hua XING,Yin-long CAO,Bao YI. Seismic performance of steel⁃polypropylene hybrid fiber reinforced concrete shear wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 946-955. |

| [3] | Liu LIU,Wei-xing FENG. Field measurement and calculation analysis of tunnel shield tunnel construction based on NNBR model [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 245-251. |

| [4] | Wei-xiao XU,Yang CHENG,Wei-song YANG,Jia-chang JU,De-hu YU. Quasi-static test of RC frame-seismic wall dual structural system [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 268-277. |

| [5] | De-shan SHAN,Xiao ZHANG,Xiao-yu GU,Qiao LI. Analytical method for elongation of stayed-cable with catenary configuration [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 217-224. |

| [6] | Su-duo XUE,Jian LU,Xiong-yan LI,Ren-jie LIU. Influence of grid⁃jumping arrangement on static and dynamic performance of annular crossed cable⁃truss structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1687-1697. |

| [7] | Bo WANG,Yuan-zheng DONG,Li-xin DONG. Calculation of basic wind pressure based on short⁃term wind speed data [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1739-1746. |

| [8] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Experimental of loading-bearing capacity of one-way laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 654-667. |

| [9] | Peng-hui WANG,Hong-xia QIAO,Qiong FENG,Hui CAO,Shao-yong WEN. Durability model of magnesium oxychloride-coated reinforced concrete under the two coupling factors [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 191-201. |

| [10] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Mechanical properties of laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1509-1520. |

| [11] | Jun ZHANG,Cheng QIAN,Chun⁃yan GUO,Yu⁃jun QIAN. Dynamic design of building livability based on multi⁃source spatiotemporal data [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1169-1173. |

| [12] | Ning⁃hui LIANG,Qing⁃xu MIAO,Xin⁃rong LIU,Ji⁃fei DAI,Zu⁃liang ZHONG. Determination of fracture toughness and softening traction⁃separation law of polypropylene fiber reinforced concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1144-1152. |

| [13] | Lei ZHANG,Bao⁃guo LIU,Zhao⁃fei CHU. Model test of the influence on shield shaft owing to water loss settlement of deep sandstone aquifer layer [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 788-797. |

| [14] | ZHENG Yi-feng, ZHAO Qun, BAO Wei, LI Zhuang, YU Xiao-fei. Wind resistance performance of long-span continuous rigid-frame bridge in cantilever construction stage [J]. 吉林大学学报(工学版), 2018, 48(2): 466-472. |

| [15] | NI Ying-sheng, SUN Qi-xin, MA Ye, XU Dong. Calculation of capacity reinforcement about composite box girder with corrugated steel webs based on tensile stress region theory [J]. 吉林大学学报(工学版), 2018, 48(1): 148-158. |

|

||