Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (1): 170-177.doi: 10.13229/j.cnki.jdxbgxb20210559

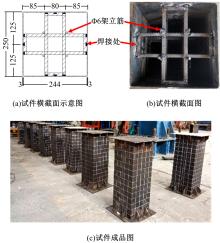

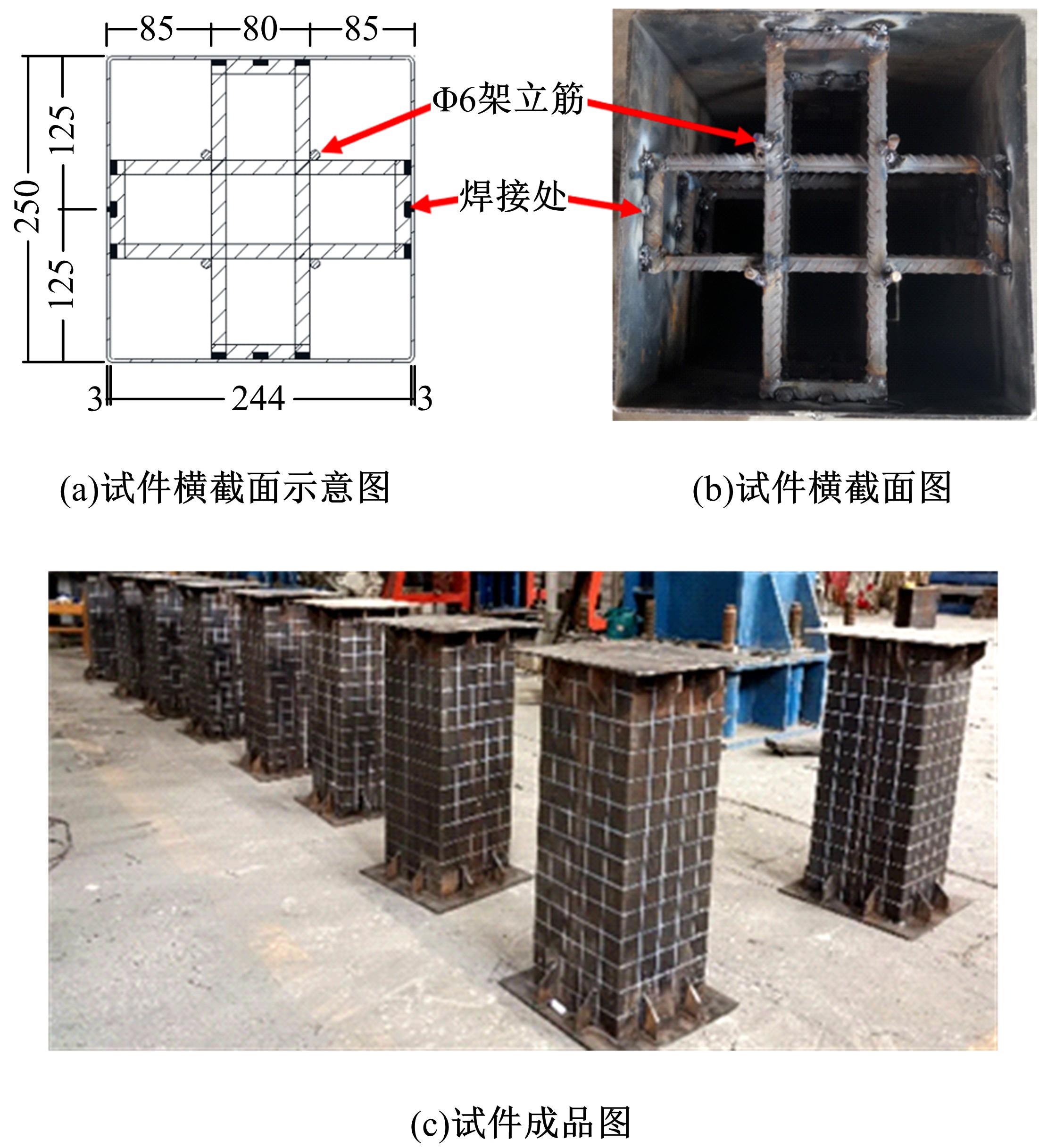

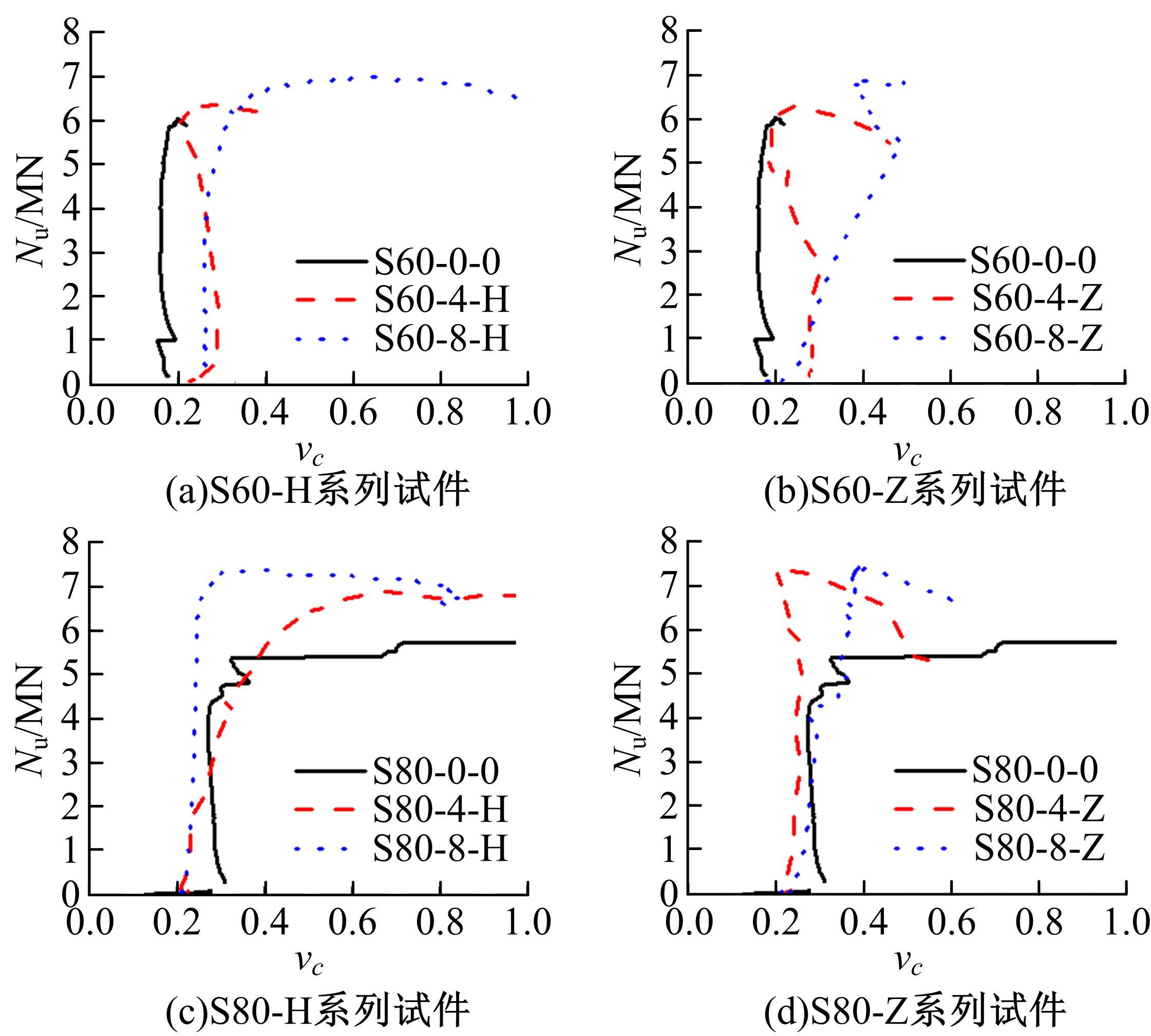

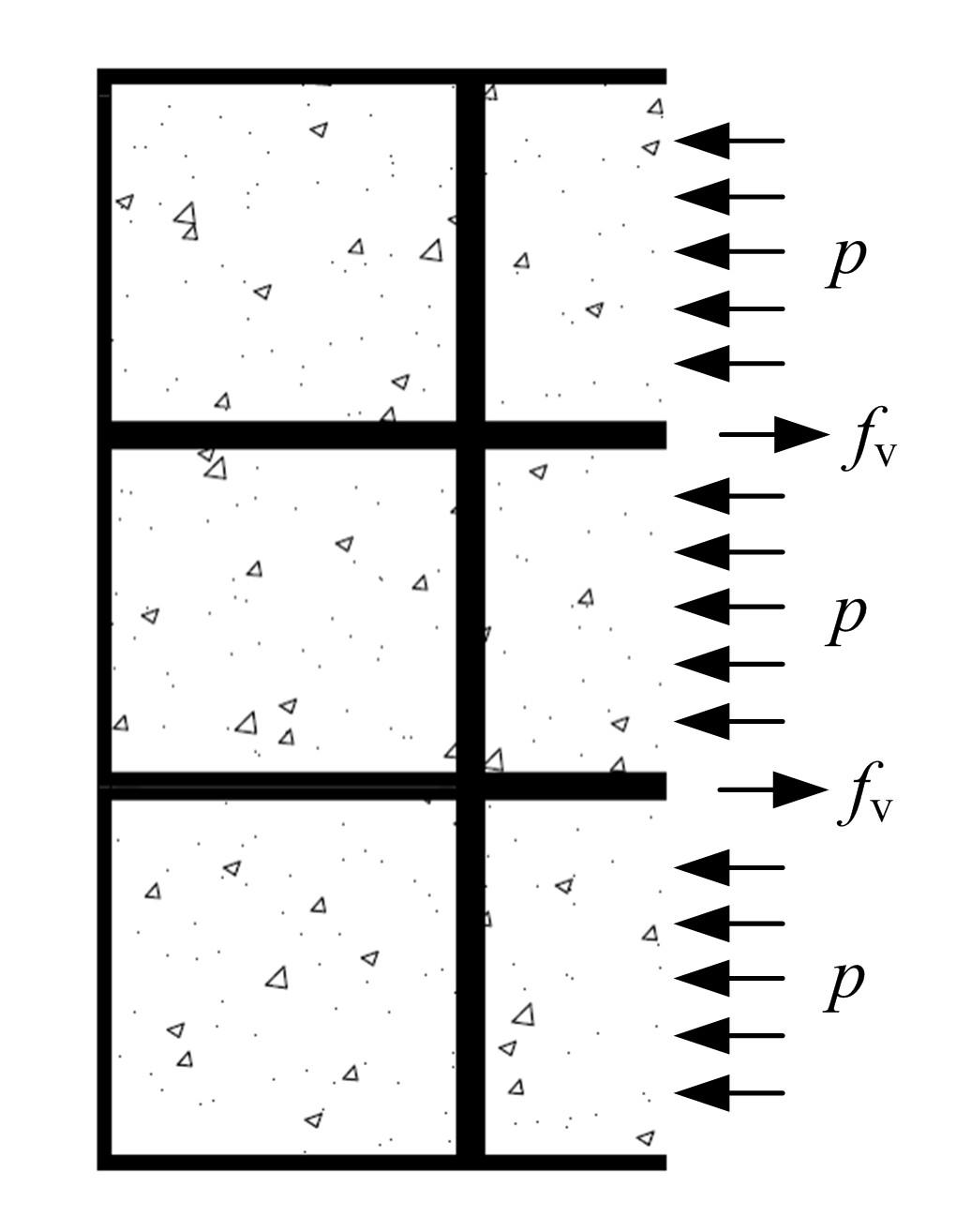

Axial compression performance of thin⁃walled concrete⁃filled square steel tube short columns confined by stirrup

Jun CHEN( ),Jia-gui NI,Zhe LIU,Wen-bo MA,Xu-hua DENG(

),Jia-gui NI,Zhe LIU,Wen-bo MA,Xu-hua DENG( )

)

- College of Civil Engineering and Mechanics,Xiangtan University,Xiangtan 411105,China

CLC Number:

- TU398

| 1 | 李斌,郭世壮,高春彦.带肋薄壁方钢管混凝土短柱轴压力学性能试验研究[J].混凝土,2018(3):53-55, 59. |

| Li Bin, Guo Shi-zhuang, Gao Chun-yan. Experimental research on mechanics behavior of stub-column concrete-filled thin-walled stiffened square steel tube under axial load[J]. Concrete, 2018(3): 53-55, 59. | |

| 2 | 张信龙,陈勇,刘庆东,等.配筋方钢管混凝土短柱受压试验和承载力计算[J].混凝土,2020(12):11-14, 20. |

| Zhang Xin-long, Chen Yong, Liu Qing-dong, et al. Axial compression test and calculation of bar-reinforced concrete filled square steel tubular stub column[J]. Concrete, 2020(12):11-14, 20. | |

| 3 | 万城勇,查晓雄.配筋钢管混凝土轴压短柱受力性能试验研究[J].建筑结构学报,2013,34():259-266. |

| Wan Cheng-yong, Zha Xiao-xiong. Experiment study of reinforced concrete filled steel tubular columns subjected to axial compression[J]. Journal of Building Structures, 2013,34(Sup.1):259-266. | |

| 4 | Wang Qing-xiang, Zhao Da-zhou, Guan Ping. Experimental study on the strength and ductility of steel tubular columns filled with steel-reinforced concrete[J]. Engineering Structures,2004,26(7):907-915. |

| 5 | Ding Fa-xing, Zhu Jiang, Cheng Shan-shan, et al. Comparative study of stirrup-confined circular concrete-filled steel tubular stub columns under axial loading[J]. Thin-walled Structures,2018,123:294-304. |

| 6 | Ding Fa-xing, Lu De-ren, Bai Yu, et al. Comparative study of square stirrup-confined concrete-filled steel tubular stub columns under axial loading[J]. Thin-walled Structures,2016,98:443-453. |

| 7 | 朱江,丁发兴,王莉萍.带拉筋圆钢管混凝土轴压短柱受力性能研究[J].建筑结构学报,2017,38():285-290. |

| Zhu Jiang, Ding Fa-xing, Wang Li-ping. Mechanical behavior of stirrup-confined circular concrete-filled steel tubular stub columns under axial loading[J]. Journal of Building Structures, 2017,38(Sup.1):285-290. | |

| 8 | 饶玉龙,张继承,李勇,等.高强冷弯矩形钢管混凝土短柱轴压承载力试验[J].华侨大学学报:自然科学版,2019,40(3):338-343. |

| Rao Yu-long, Zhang Ji-cheng, Li Yong, et al. Experiment on mechanical behavior of concrete-filled high-strength cold-formed steel tube short column under axial load[J]. Journal of Huaqiao University (Natural Science),2019,40(3):338-343. | |

| 9 | 丁发兴,刘怡岑,吕飞,等.拉筋接触方式对高轴压比大尺寸钢管混凝土柱滞回性能影响试验研究[J]. 建筑结构学报,2021,42(9):62-72. |

| Ding Fa-xing, Liu Yi-cen, Lv Fei, et al. Pseudo-static tests of stirrup-confined concrete-filled steel tube columns under high axial pressure: the influence of contact mode between stirrup and steel tube[J]. Journal of Building Structures,2021,42(9):62-72. | |

| 10 | 丁发兴,付磊,龚永智,等.方钢管混凝土轴压短柱的力学性能研究[J].深圳大学学报:理工版,2014,31(6):583-592. |

| Ding Fa-xing, Fu Lei, Gong Yong-zhi, et al. Behavior of concrete-filled square steel tubular stub columns under axially compressive loading[J]. Journal of Shenzhen University Science and Engineering, 2014,31(6):583-592. | |

| 11 | 蔡绍怀.现代钢管混凝土结构[M].北京:人民交通出版社,2007. |

| 12 | 韩林海,杨有福.矩形钢管混凝土轴心受压构件强度承载力的试验研究[J].土木工程学报,2001,34(4):22-31. |

| Han Lin-hai, Yang You-fu. Study on axial bearing capacity of concrete filled steel tube columns with rectangular section[J]. China Civil Engineering Journal, 2001,34(4): 22-31. | |

| 13 | ACI 318―14. Building code requirements for structural concrete and commentary [S]. |

| 14 | 熊公玉,熊明祥.高强钢丝网片增强矩形钢管混凝土短柱轴压力学性能研究[J]. 广东建材,2019,35(2):56-60, 19. |

| Xiong Gong-yu, Xiong Ming-xiang. Study on axial pressure performance of rectangular steel tube concrete short column reinforced by high-strength steel mesh sheet[J]. Guangdong Building Materials, 2019,35(2): 56-60, 19. | |

| 15 | Lu De-ren, Wang Wen-jun, Ding Fa-xing, et al. The impact of stirrups on the composite action of concrete-filled steel tubular stub columns under axial loading[J]. Structures, 2021(30):756-802. |

| 16 | Ding Fa-xing, Lu De-ren, Bai Yu, et al. Comparative study of square stirrup-confined concrete-filled steel tubular stub columns under axial loading[J]. Thin-walled Structures, 2016(98):443-453. |

| [1] | Di WU,Wen-hua GENG,Hong-mei LI,Da-qian SUN. Electron backscattered diffraction analysis on interface of aluminum/steel joints produced by plasma arc welding⁃brazing [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1331-1337. |

| [2] | Yi-hong WANG,Qiao-luo TIAN,Guan-qi LAN,Sheng-fa YAO,Jian-xiong ZHANG,Xi LIU. Experimental research on the mechanical properties of concrete column reinforced with 630 MPa high⁃strength steel under large eccentric loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2626-2635. |

| [3] | Jing ZHOU,Ya-jun LI,Wei-feng ZHAO,Zong-jian LUO,Guo-bin BU. Eccentric compression behavior of bamboo⁃plywood and steel⁃tube dual⁃confined dust⁃powder concrete columns [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2096-2107. |

| [4] | De-lei YANG,Le-wei TONG. Calculation formula of SCF for CHS⁃CFSHS welded T⁃joints with brace under axial tension [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1891-1899. |

| [5] | ZHUNG Wei-min, ZHAO Wen-zeng, XIE Dong-xuan, LI Bing. Joint performance analysis on connection of ultrahigh-strength steel and aluminum alloy with hot riveting [J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [6] | ZHUANG Wei-min, XIE Dong-xuan, YU Tian-ming, YU Wan-dong. Numerical simulation of hot forming of high-strength steel based on damage-phase transformation constitutive model [J]. 吉林大学学报(工学版), 2015, 45(4): 1206-1212. |

| [7] | MIAO Hong, ZUO Dun-wen, WANG Min, ZHANG Rui-hong, WANG Hong-feng. Effect of technological parameters on quality of Q460 high-strength-steel internal thread formed by cold extrusion [J]. 吉林大学学报(工学版), 2012, 42(01): 68-73. |

|

||