Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (1): 220-225.doi: 10.13229/j.cnki.jdxbgxb20210541

Mixing power test and viscosity model of asphalt mixture

Nie-yang-zi LIU1( ),Xin RONG2,Hong-hai LIU2(

),Xin RONG2,Hong-hai LIU2( ),Qing-hua BIAN3,Hai LAN2

),Qing-hua BIAN3,Hai LAN2

- 1.School of Transportation Engineering,Chang'an University,Xi'an 710064,China

2.Key Laboratory of Road Construction Technology and Equipment,Ministry of Education,Chang'an University,Xi'an 710064,China

3.Research and Development Center of Highway Construction and Maintenance Technology,Materials and Equipment,Transportation Industry,Gansu Road and Bridge Construction Group Co. ,Ltd. ,Lanzhou 730030,China

CLC Number:

- U414

| 1 | 李志伟,贺海,董彪,等. 温拌沥青混合料施工工艺研究[J]. 筑路机械与施工机械化, 2013,30(6):52-56. |

| Li Zhi-wei, He Hai, Dong Biao, et al. Research on construction technology of warm mixing asphalt mixture[J]. Road Machinery & Construction Mechanization, 2013, 30(6): 52-56. | |

| 2 | .民用机场沥青道面施工技术规范 [S]. |

| 3 | 张宜洛,董飞龙,赵少宗. TPS高粘沥青施工温度的确定[J]. 筑路机械与施工机械化,2019, 36(5): 35-40. |

| Zhang Yi-luo, Dong Fei-long, Zhao Shao-zong. Determination of construction temperature of TPS high-viscosity asphalt[J]. Road Machinery & Construction Mechanization, 2019, 36(5): 35-40. | |

| 4 | 陈华鑫. 改性沥青的黏度特性和施工温度控制[J]. 石油沥青, 2003, 17(4): 43-46. |

| Chen Hua-xin. Modified asphalt viscosity characteristics and construction temperature control[J]. Petroleum Pitch, 2003, 17(4): 43-46. | |

| 5 | 郑传峰,冯玉鹏,郭学东,等. 粉胶比对沥青胶浆低温黏结强度的影响[J]. 吉林大学学报:工学版, 2016, 46(2): 426-431. |

| Zheng Chuan-feng, Feng Yu-peng, Guo Xue-dong, et al. Effect of filler-to-bitumen ratio on low-temperature cohesive strength of asphalt mortar[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(2): 426-431. | |

| 6 | Xiang L, Bo L C, Meng J, et al. Influence of short-term aging on anti-cracking performance of warm modified asphalt at intermediate temperature[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 582:No.123877. |

| 7 | 孙培,韩森,高榕,等. 基于评价SBS改性沥青高温性能的修正软化点方法[J]. 铁道科学与工程学报, 2017, 14(2): 250-256. |

| Sun Pei, Han Sen, Gao Rong, et al. A revised softening point method based on evaluation the high temperature property of SBS modified asphalt[J]. Journal of Railway Science and Engineering, 2017, 14(2): 250-256. | |

| 8 | Gudimettla J M, Cooley L A, Brown E R. Workability of hot-mix asphalt[J]. Transportation Research Record, 2004, 1891: 229-237. |

| 9 | 张琛,汪海年,尤占平,等. 橡胶沥青混合料和易性与压实特性的相关性[J]. 东南大学学报:自然科学版, 2016, 46(1): 202-208. |

| Zhang Chen, Wang Hai-nian, You Zhan-ping, et al. Correlation between workability and compaction property of rubber asphalt mixture[J]. Journal of Southeast University (Natural Science Edition), 2016, 46(1): 202-208. | |

| 10 | 侯曙光. 热拌与温拌沥青混合料和易性试验[J].南京工业大学学报, 2011, 33(5): 36-39. |

| Hou Shu-guang. Hot mix and warm mix asphalt mixture workability test[J]. Journal Nanjing Tech University, 2011, 33(5): 36-39. | |

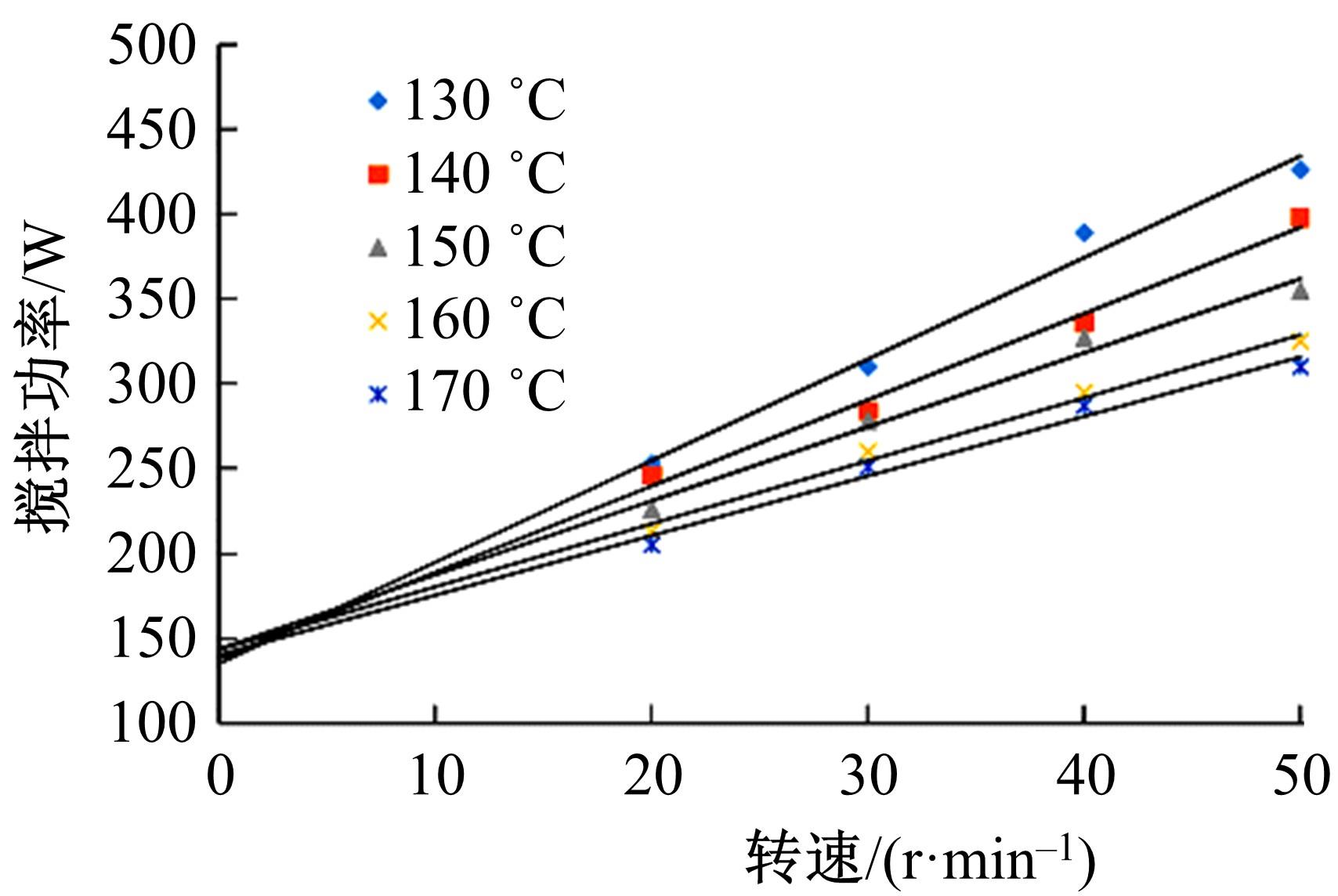

| 11 | 延西利,田辉黎,延喜乐,等. 沥青混合料的变速拌和功率测试与拌和流变模型[J]. 交通运输工程学报, 2016, 16(5): 1-7. |

| Yan Xi-li, Tian Hui-li, Yan Xi-le, et al. Asphalt mixture variable speed mixing power test and mixing rheological model[J]. Journal of Traffic and Transportation Engineering, 2016, 16(5): 1-7. | |

| 12 | 延西利,景宏君,游庆龙,等. 沥青混合料的拌和流动特性及和易性指数[J]. 土木工程学报, 2019, 52(10): 120-128. |

| Yan Xi-li, Jing Hong-jun, You Qing-long, et al. Mixing flow characteristic and workability index of asphalt mixtures[J]. China Civil Engineering Journal, 2019, 52(10): 120-128. | |

| 13 | 李昂.不同性质沥青混合料的变速拌和及和易性指数研究[D]. 西安:长安大学公路学院, 2017. |

| Li Ang. Experiment at different mixing velocities and workability index of asphalt mixture with different bitumen[D]. Xi'an: School of Highway, Chang'an University, 2017. | |

| 14 | 李梦怡. 高黏改性剂对沥青流变性能的影响[J]. 公路交通科技,2018, 35(4): 14-20. |

| Li Meng-yi. Effect of high viscosity modifier on rheological property of asphalt[J]. Journal of Highway and Transportation Research and Development, 2018, 35(4): 14-20. | |

| 15 | 延西利,梁春雨,艾涛. 基于沥青与石料界面剪切的黏塑性流变模型研究[J].土木工程学报, 2014, 47(2): 136-144. |

| Yan Xi-li, Liang Chun-yu, Ai Tao. Research on viscoelastic rheological model based on the interfacial shear of asphalt and stone[J]. China Civil Engineering Journal, 2014, 47(2): 136-144. | |

| 16 | 黄刚,何兆益,黄涛. 沥青混合料动态蠕变黏弹性特性分析[J]. 东南大学学报:自然科学版, 2012, 42(6): 1211-1216. |

| Huang Gang, He Zhao-yi, Huang Tao. Analysis of dynamic creep viscoelastic properties of asphalt mixture[J]. Journal of Southeast University (Natural Science Edition), 2012, 42(6): 1211-1216. | |

| 17 | Behl A, Chandra S, Aggarwal V K, et al. Zero shear viscosity of bitumen-filler mastics of warm-mix binders[J]. Journal of Materials in Civil Engineering, 2014, 27(1): 46-51. |

| 18 | Wang H P, Liu X Y, Apostolidis P, et al. Rheological behavior and its chemical interpretation of crumb rubber modified asphalt containing warm-mix additives[J]. Transportation Research Record, 2018, 2672(28): 337-348. |

| 19 | Zhang Feng, Hu Chang-bin, Zhuang Wei-long. The research for low-temperature rheological properties and structural characteristics of high-viscosity modified asphalt[J]. Journal of Thermal Analysis & Calorimetry, 2018, 131(2): 1025-1034. |

| [1] | Liu YANG,Chuang-ye WANG,Meng-yan WANG,Yang CHENG. Traffic flow characteristics of six⁃lane freeways with a dedicated lane for automatic cars [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2043-2052. |

| [2] | Zheng-feng ZHOU,Xiao-tao YU,Ya-le TAO,Mao ZHENG,Chuan-qi YAN. High-temperature performance evaluation of resin and elastomer high viscosity asphalt based on grey correlation analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2078-2088. |

| [3] | Tao MA,Yuan MA,Xiao-ming HUANG. Optimal combination of key parameters of intelligent compaction based on multiple nonlinear regression [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2067-2077. |

| [4] | Hai-bin WEI,Shuan-ye HAN,Hai-peng BI,Qiong-hui LIU,Zi-peng MA. Intelligent sensing road active ice and snow removal system and experimental technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1411-1417. |

| [5] | Sui-ning ZHENG,Rui HE,Tian-yu LU,Zi-yi XU,Hua-xin CHEN. Preparation and evaluation of RET/rubber composite modified asphalt and asphalt mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1381-1389. |

| [6] | Bo-wen GUAN,Wen-jin DI,Fa-ping WANG,Jia-yu WU,Shuo-wen ZHANG,Zhi-xun JIA. Damage of concrete subjected to sulfate corrosion under dry⁃wet cycles and alternating loads [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1112-1121. |

| [7] | Fan YANG,Chen-chen LI,Sheng LI,Hai-lun LIU. Numerical simulation of continuously reinforced concrete pavement with double⁃layer reinforcement under effect of temperature shrinkage [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1122-1132. |

| [8] | Hai-bin WEI,Zi-peng MA,Hai-peng BI,Han-tao LIU,Shuan-ye HAN. Conductive rubber composite pavement paving technology based on mechanical response analysis method [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 531-537. |

| [9] | Zhuang-zhuang LIU,You-wei ZHANG,Peng-yu JI,Abshir Ismail Yusuf,Lin LI,Ya-zhen HAO. Study on heat transfer characteristics of electric heating snow melting asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 523-530. |

| [10] | Shuang SHI,Lan-qin LIN,Tao MA,Lin-hao GU,Yan-ning ZHANG. Molecular dynamics‒based stability of biomass prime coat oil [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 197-209. |

| [11] | Xu CHEN,Chao-fei CAO,Jing SHANG,Ming-xing HUANG,Chang-fa AI,Dong-ya Ren. Evaluation of influence of gradation segregation on pavement moisture damage under action of dynamic and static water environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 210-219. |

| [12] | Yong PENG,Xiu-fang ZHANG,Ze-yu GUO,Xue-yuan LU,Yan-wei LI. Influence of aggregate contact characteristics on shear fatigue life of asphalt mixtures using discrete element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 178-187. |

| [13] | Ya-zhen SUN,Zhi ZHENG,Wei-ming HUANG,Jin-chang WANG. Structural analysis of cement pavement with cracks based on state⁃space method [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 188-196. |

| [14] | Cheng-lin SHI,Yong WANG,Chun-li WU,Wen-zhu SONG. Modification of calculation method for active earth pressure on embankment retaining wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1394-1403. |

| [15] | Qing-lin GUO,Qiang LIU,Chun-li WU,Li-li LI,Yi-ming LI,Fu-chun LIU. Local temperature field and healing level of crack in conductive asphalt and mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1386-1393. |

|

||