Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (5): 1552-1558.doi: 10.13229/j.cnki.jdxbgxb.20230865

Previous Articles Next Articles

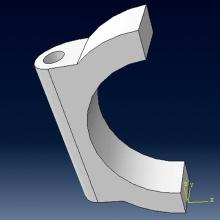

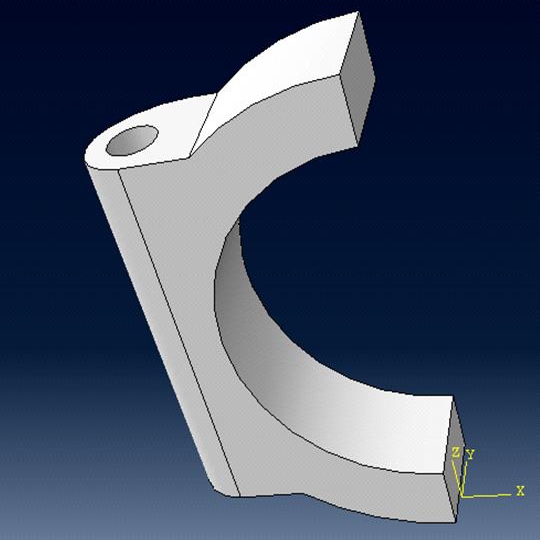

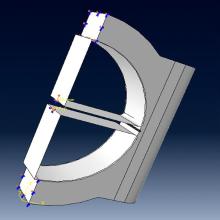

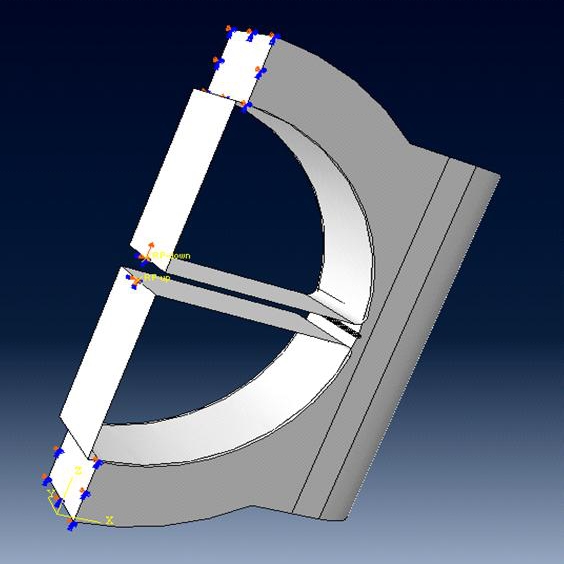

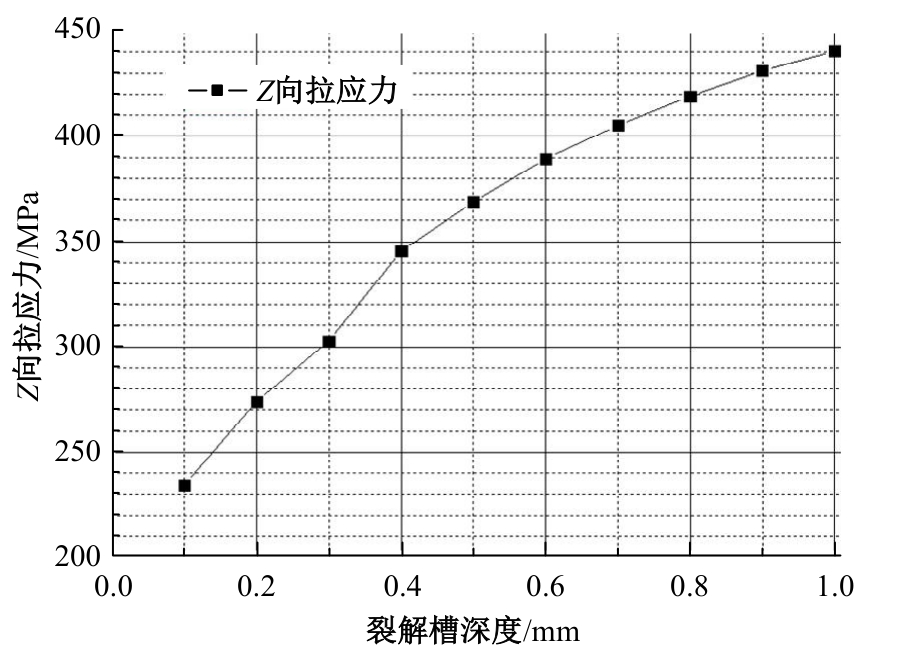

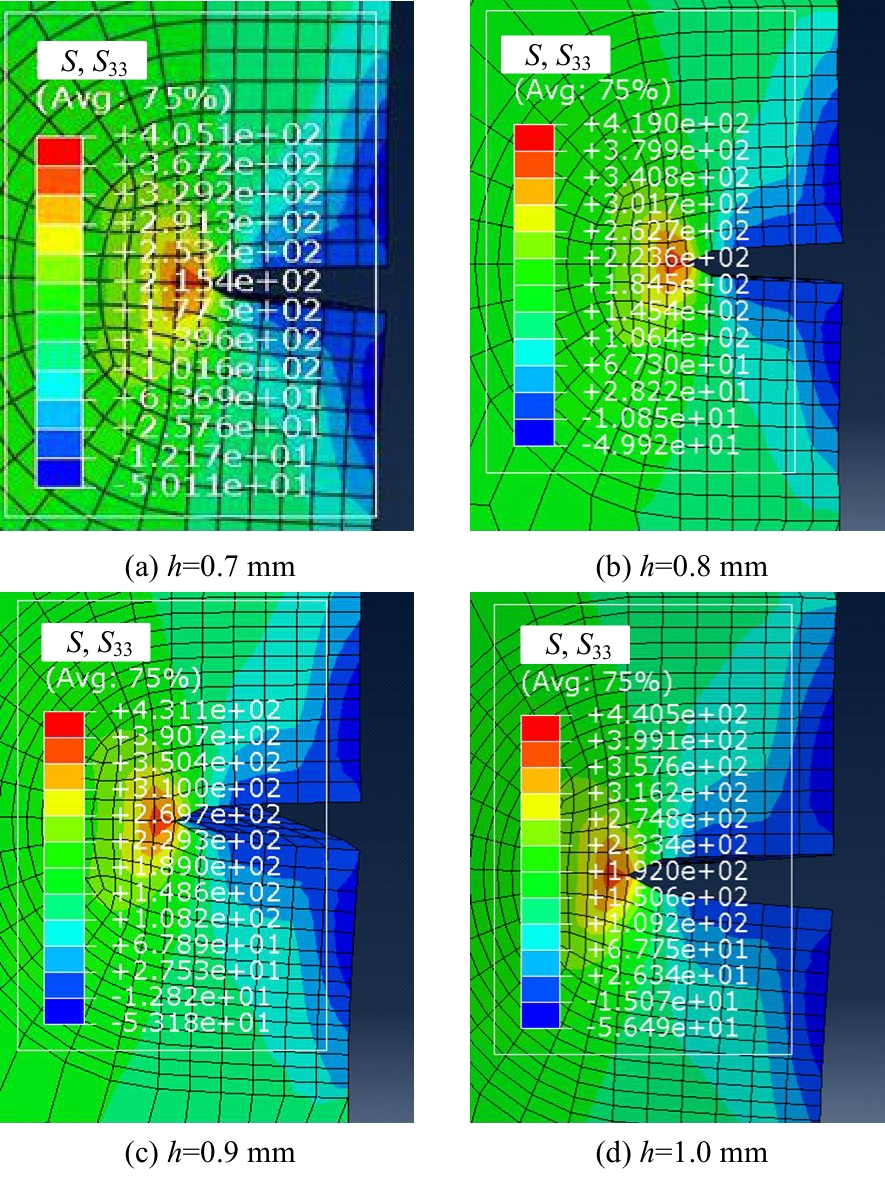

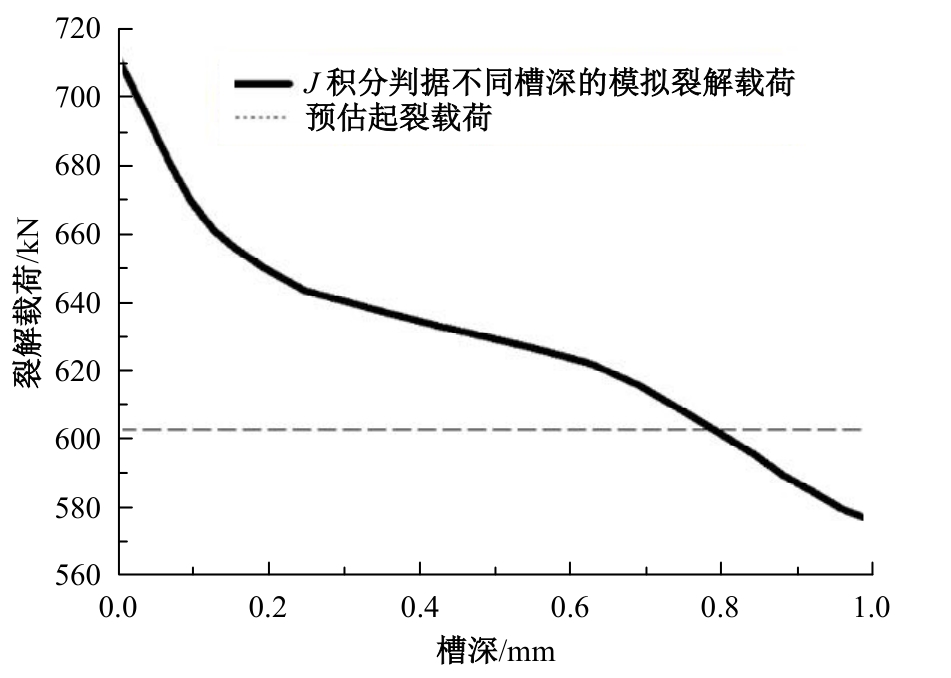

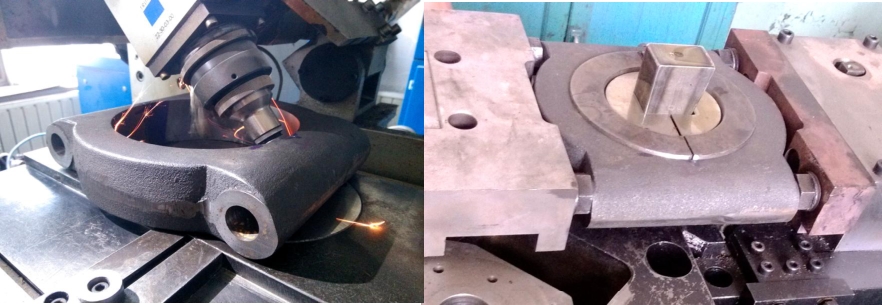

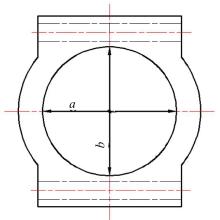

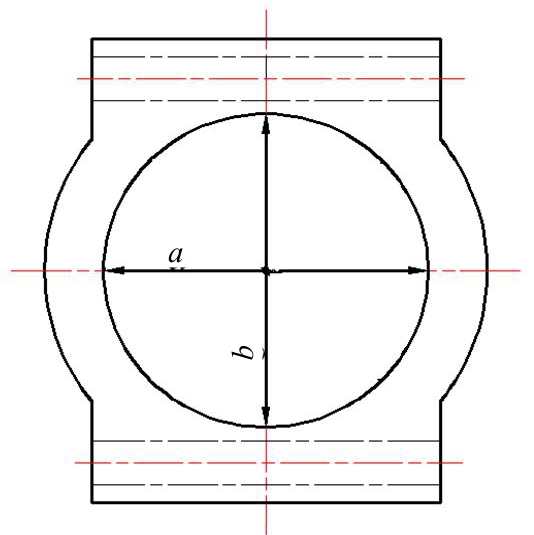

Influence of cracking groove depth on cracking performance of bearing seat of reducer housing

Yong ZHAO( ),Wen-ming JIN,Qi-feng ZHENG(

),Wen-ming JIN,Qi-feng ZHENG( ),Shu-qing KOU

),Shu-qing KOU

- School of Materials Science and Engineering,Jilin University,Changchun 130022,China

CLC Number:

- TK406

| [1] | 陆刚. 重型车驱动桥及其主要部件结构[J]. 商用车与发动机, 2009(47): 74-76. |

| Lu Gang. Driving axle & main parts of heavy commercial vehicle[J]. CVE, 2009(47): 74-76. | |

| [2] | 姚为民. 汽车构造下[M]. 北京:机械工业出版社,2022. |

| [3] | 瑞佩尔. 图解汽车变速器原理与构造[M]. 北京:化学工业出版社,2022. |

| [4] | 江业君, 张家政. 后桥主减速器壳体加工工艺探索[J]. 客车技术, 2005(1): 37-38. |

| Jiang Ye-jun, Zhang Jia-zheng. Exploration on processing technology of rear axle main reducer housing[J]. Bus Technology, 2005(1): 37-38. | |

| [5] | 刘景涛. 汽车驱动桥主减速器总成预加载荷研究及系统实现[D]. 杭州: 浙江大学机械与能源工程学院, 2009. |

| Liu Jing-tao.The research of pre-load for main reducer of automobile´s driving axle and the system development[D]. Hangzhou: School of Mechanical and Energy Engineering, Zhejiang University, 2009. | |

| [6] | Zhou S, Kou S Q. Study on fracture-split performance of 36MnVS4 and analysis of fracture-split easily-induced defects[J].Metals,2018,8(9):0809696. |

| [7] | Yang H Q, Kou S Q, Li Z Y,et al. 3D interconnected nitrogen-self-doped carbon aerogels as efficient oxygen reduction electrocatalysts derived from biomass gelatin[J]. RSC Advances, 2019, 69(9): 40301-40308. |

| [8] | Kou S Q, Shi Z, Song W F. Fracture-splitting processing performance study and comparison of the C70S6 and 36MnVS4 connecting rods[J]. SAE International Journal of Engines, 2018, 11(4): 463-474. |

| [9] | 杨慎华, 寇淑清, 何东野,等. 发动机缸体主轴承座裂解槽激光加工设备[P]. 中国: CN200710055511.3. |

| [10] | 王科. 减速器壳体的铸造工艺设计[J]. 汽车知识, 2023, 23(4): 96-98. |

| Wang Ke. Casting process design of reducer shell[J]. Automotive Knowledge,2023,23(4): 96-98. | |

| [11] | 李新宁, 李才儿, 黄桂英, 等. 减速器壳体高速加工技术研究及其应用[J]. 制造技术与机床, 2014(1): 35-38. |

| Li Xin-ning, Li Cai-er, Huang Gui-ying,et al. Research and application of speed- reducer shell's high speed processing technology[J]. Manufacturing Technology & Machine Tool, 2014(1) : 35-38. | |

| [12] | 李金华, 王海涛, 郑敬超. 高端乘用车减速器壳体加工方案[J]. 汽车工艺师, 2015(3): 24-25. |

| Li Jin-hua, Wang Hai-tao, Zheng Jing-chao. Machining scheme of reducer shell for high-end passenger cars[J]. Automotive Engineer, 2015(3): 24-25. | |

| [13] | 孟令健, 张孟枭, 李玉娟,等. 蠕墨铸铁RuT400与RuT450的拉伸与疲劳性能[J]. 上海金属, 2020, 42(4): 18-25. |

| Meng Ling-jian, Zhang Meng-xiao, Li Yu-juan,et al. Tensile and fatigue properties of vermicular graphite cast Irons RuT400 and RuT450[J]. Shanghai Metals,2020, 42(4): 18-25. | |

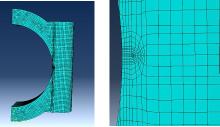

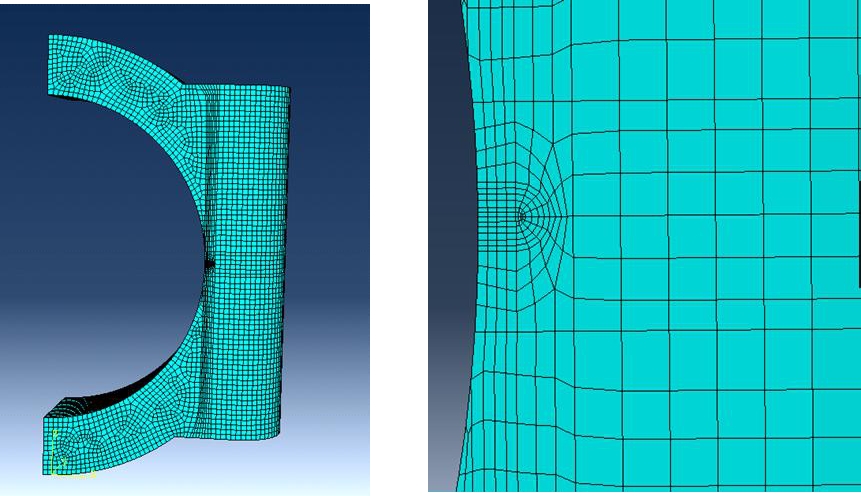

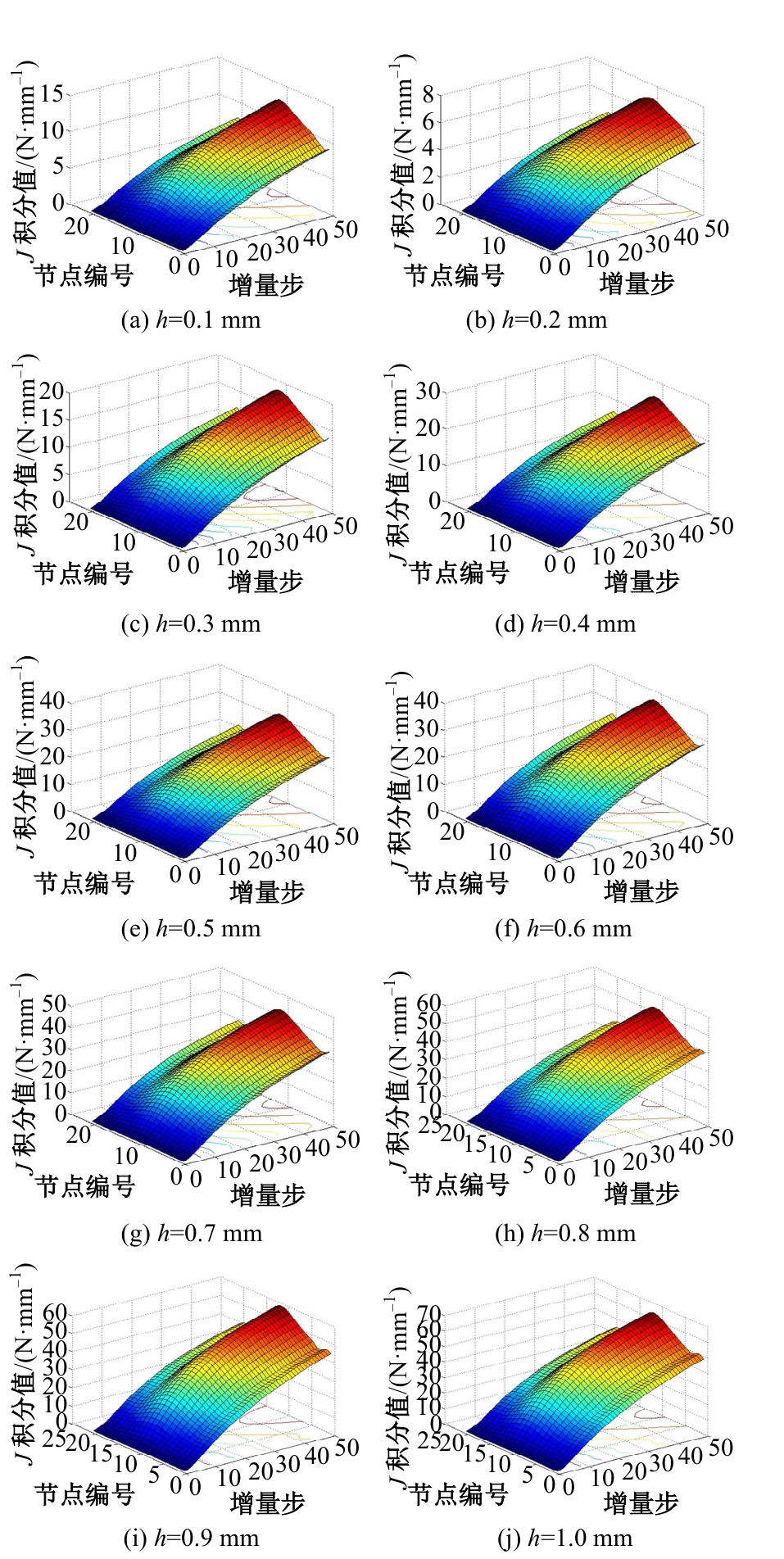

| [14] | 修亭亭. 后桥减速器壳体轴承座材料裂解性能数值模拟及实验研究[D]. 长春: 吉林大学材料科学与工程学院, 2020. |

| Xiu Ting-ting. Numerical simulation and experimental study on materialfracture splitting performance of rear axles'reducershell bearing seat[D]. Changchun: College of Materials Science and Engineering, Jilin University,2020. | |

| [15] | 寇淑清, 修亭亭, 金文明,等. 后桥主减速器壳体轴承座材料裂解性能数值分析[J]. 华南理工大学学报: 自然科学版, 2019, 47(7): 121-127. |

| Kou Shu-qing, Xiu Ting-ting, Jin Wen-ming, et al. Numerical analysis of cracking performance of rear axle main reducer housing bearing housing material[J]. Journal of South China University of Technology(Natural Science Edition), 2019, 47(7): 121-127. | |

| [16] | 赵勇. 基于小范围屈服断裂的连杆胀断参数研究及应用[D]. 长春: 吉林大学材料科学与工程学院, 2011. |

| Zhao Yong. Study on parameters of connecting rod fracture splitting based on fracture after small scale yielding and its application[D]. Changchun: College of Materials Science and Engineering, Jilin University, 2011. |

| [1] | Chang-shuai WANG,Cheng-cheng XU,Wei-lin REN,Chang PENG,Hao TONG. Impacts of driving ability recovery state on characteristics of traffic oscillation in automated driving takeover process [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 150-161. |

| [2] | Jin-xing WU,Yu-xiang MA,Jia-bang XIAO,Yao XU,Song-ge LI. Numerical simulation of erosion characteristics of H-type finned elliptical tubes [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2495-2501. |

| [3] | Hua-fei HE,Zhao-ping LI,Rui-an FU,Shao-lin MA,Ming-li HUANG. Experiment on seismic performance of prefabricated sidewall joints considering strata restraint effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1601-1611. |

| [4] | Shu-mei LOU,Yi-ming LI,Xin LI,Peng CHEN,Xue-feng BAI,Bao-jia CHENG. Thermal deformation behavior of graphene nanosheets reinforced 7075Al based on BP neural network and Arrhenius constitutive equation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1237-1245. |

| [5] | Qiu ZHAO,Peng CHEN,Yu-wei ZHAO,Ao YU. Overall mechanical performance of jointless bridges with arch structure behind abutment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1016-1027. |

| [6] | Yi-gang WANG,Yu-peng WANG,Hao ZHANG,Si-an ZHAO. Identification and analysis of aerodynamic noise sources in the bogie area of high⁃speed trains [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 346-355. |

| [7] | Wei-hua ZHANG,Jia-ming LIU,Li-peng XIE,Heng DING. Lane⁃changing model of autonomous vehicle in weaving area of expressway in intelligent and connected mixed environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 469-477. |

| [8] | Hui SONG,Da-yi QU,Shao-jie WANG,Tao WANG,Zi-yi YANG. Connected mixed traffic flow car-following model and stability analysis considering multiple vehicles response [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(11): 3220-3230. |

| [9] | Ren-jun LI,Yi-bing ZHAO,Li-dong GU,Hong-qiang TAN,Lin-sen SONG,Yan TIAN. Improved tilting method for vehicle mass center measurement [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(11): 3175-3183. |

| [10] | Zheng-lei YU,Qing CAO,Jun-dong ZAHNG,Peng-wei SHA,Jing-fu JIN,Wan-zhen WEI,Ping LIANG,Zhi-hui ZHANG. Mechanical properties of a bionic buffer structure of a lander based on additive manufacturing [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 3077-3084. |

| [11] | Xing WEI,Ya-jie GAO,Zhi-rui KANG,Yu-chen LIU,Jun-ming ZHAO,Lin XIAO. Numerical simulation of residual stress field of stud girth weld in low temperature environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 198-208. |

| [12] | Zhi ZHENG,Pei YUAN,Xuan-hui JIN,Si-si WEI,Bo GENG. Experimental on composite flexible anti⁃collision fender of bridge pier [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2581-2590. |

| [13] | Feng WANG,Shuang-rui LIU,Jia-ying WANG,Jia-ling SONG,Jun WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Size and shape effects of wind drag coefficients for porous structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1677-1685. |

| [14] | Chun-li WU,Shi-ming HUANG,Kui LI,Zheng-wei GU,Xiao-ming HUANG,Bing-tao ZHANG,Run-chao YANG. Analysis of pier action effect under flood based on numerical simulation and statistical analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1612-1620. |

| [15] | Zheng-wei GU,Pan ZHANG,Dong-ye LYU,Chun-li WU,Zhong YANG,Guo-jin TAN,Xiao-ming HUANG. Earthquake⁃induced residual displacement analysis of simply supported beam bridge based on numerical simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1711-1718. |

|