| [1] |

蒋志军, 张志刚, 吕崇建,等. 汽车内饰包覆零件设计与工艺研究[J]. 汽车实用技术, 2018(7):131-134.

|

|

Jiang Zhi-jun, Zhang Zhi-gang, Lv Chong-jian, et al. Research on the design and process of automotive interior cladding parts[J]. Automotive Practical Technology, 2018(7): 131-134.

|

| [2] |

沃西源, 涂彬, 夏英伟,等. 复合材料胶接工艺和胶接接头内应力分析[J]. 航天返回与遥感, 2008, 29(1): 63-68.

|

|

Xi-yuan Wo, Tu Bin, Xia Ying-wei, et al. Analysis of the gluing process and internal stresses in bonding joints of composite materials[J]. Space Return and Remote Sensing, 2008, 29(1):63-68.

|

| [3] |

兰凤崇, 李忠超, 周云郊,等. 铝镁合金单搭接胶接接头应力分布及强度预测[J]. 吉林大学学报:工学版, 2015, 45(3): 726-732.

|

|

Lan Feng-chong, Li Zhong-chao, Zhou Yun-jiao, et al. Stress distribution and strength prediction of aluminium-magnesium alloy single lap bonded joints[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(3):726-732.

|

| [4] |

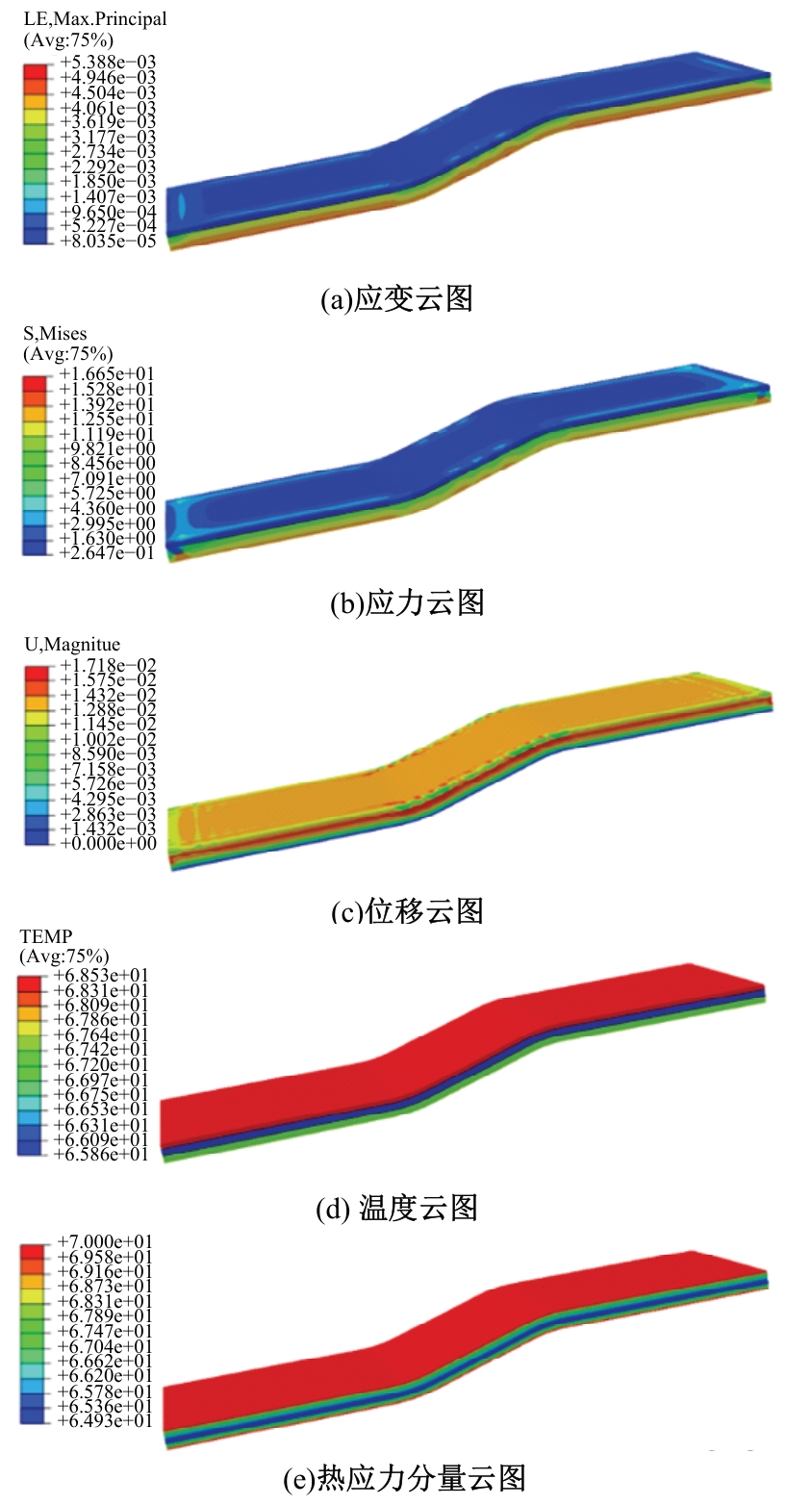

曹蕾蕾, 赵宁, 郭辉, 等. 单搭接接头温度场与热应力分布的研究[J]. 计算机仿真, 2009,26(5):307-310.

|

|

Cao Lei-lei, Zhao Ning, Guo Hui, et al. Study on temperature field and thermal stress distribution of single lap joint[J]. Computer Simulation, 2009,26(5):307-310.

|

| [5] |

Ji G, Ouyang Z, Li G, et al. Effects of adhesive thickness on global and local mixed mode I/II interfacial fracture of bonded steel joints[C]∥ASME 2011 Pressure Vessels and Piping Conference, Baltimore, Maryland, USA, 2011: 21-29.

|

| [6] |

Wang X Y, Zheng S. Analytical model of thermal stress distribution of bonded structure under temperature field[J]. International Journal of Adhesion and Adhesives, 2011, 31(6): 398-401.

|

| [7] |

Ichikawa K, Shin Y, Sawa T. A three-dimensional finite-element stress analysis and strength evaluation of stepped-lap adhesive joints subjected to static tensile loadings[J]. International Journal of Adhesion and Adhesives, 2008, 28(8):464-470.

|

| [8] |

Grant L D R, Adams R D, da Silva L F M. Effect of the temperature on the strength of adhesively bonded single lap and T joints for the automotive industry[J]. International Journal of Adhesion and Adhesives, 2009, 29( 5):535-542.

|

| [9] |

Mi Y, Crisfield M A, Davies G A O, et al. Progressive delamination using interface elements[J]. Journal of Composite Matrerials, 1998, 32(14):1246-1272.

|

| [10] |

Benzeggagh M L, Kenane M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus[J]. Composites Science and Technology, 1996, 56(4): 439-449.

|

| [11] |

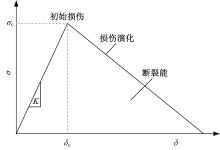

寇剑锋, 徐绯, 郭家平, 等. 黏聚力模型破坏准则及其参数选取[J]. 机械强度, 2011, 33(5): 714-718.

|

|

Kou Jian-feng, Xu Fei, Guo Jia-ping, et al. Damage criterion of cohesion model and its parameter selection[J]. Mechanical Strength, 2011, 33(5):714-718.

|

| [12] |

Davies P, Pomies F, Carlsson L A. Influence of water absorption on transverse tensile properties and shear fracture toughness of glass/polypropylene[J]. Journal of Composite Materials, 1996, 30(9):1004-1019.

|

| [13] |

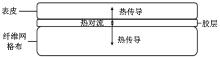

刘子文, 朴春德, 谢亮,等. 一维热传导条件下测点温度与加热时间的相关性研究[J]. 地球科学前沿, 2016, 6(2): 72-78.

|

|

Liu Zi-wen, Chun-de Piao, Xie Liang, et al. Correlation study of measurement point temperature and heating time under one-dimensional heat conduction conditions[J]. Frontiers of Earth Science, 2016, 6(2):72-78.

|

| [14] |

弗兰克P. 英克鲁佩勒, 大卫P.德维特, 狄奥多尔L.伯格曼, 等. 传热和传质基本原理[M]. 6版. 北京:化学工业出版社, 2007.

|

| [15] |

欧阳林辉. 温度环境对复合材料力学性能影响研究[D]. 西安:西北工业大学力学与土木建筑学院, 2015.

|

|

Ouyang Lin-hui. Research on the effect of temperature environment on mechanical properties of composite materials[D]. Xi'an: School of Mechanics and Civil Engineering, Northwestern Polytechnical University, 2015.

|

| [16] |

田宇. SiCp/AlSi3复合材料热残余应力有限元分析[D]. 长春:吉林大学材料科学与工程学院, 2009.

|

|

Tian Yu. Finite element analysis of thermal residual stresses in SiCp/AlSi3 composites[D]. Changchun:Colloge of Materials Science and Engineering,Jilin University, 2009.

|