Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (6): 1915-1922.doi: 10.13229/j.cnki.jdxbgxb.20230938

Previous Articles Next Articles

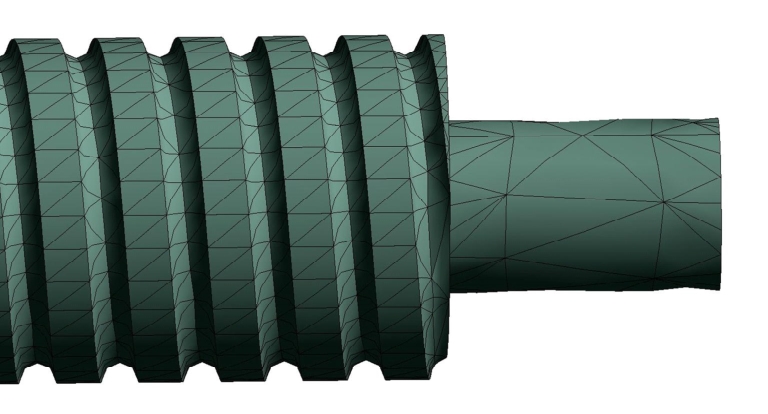

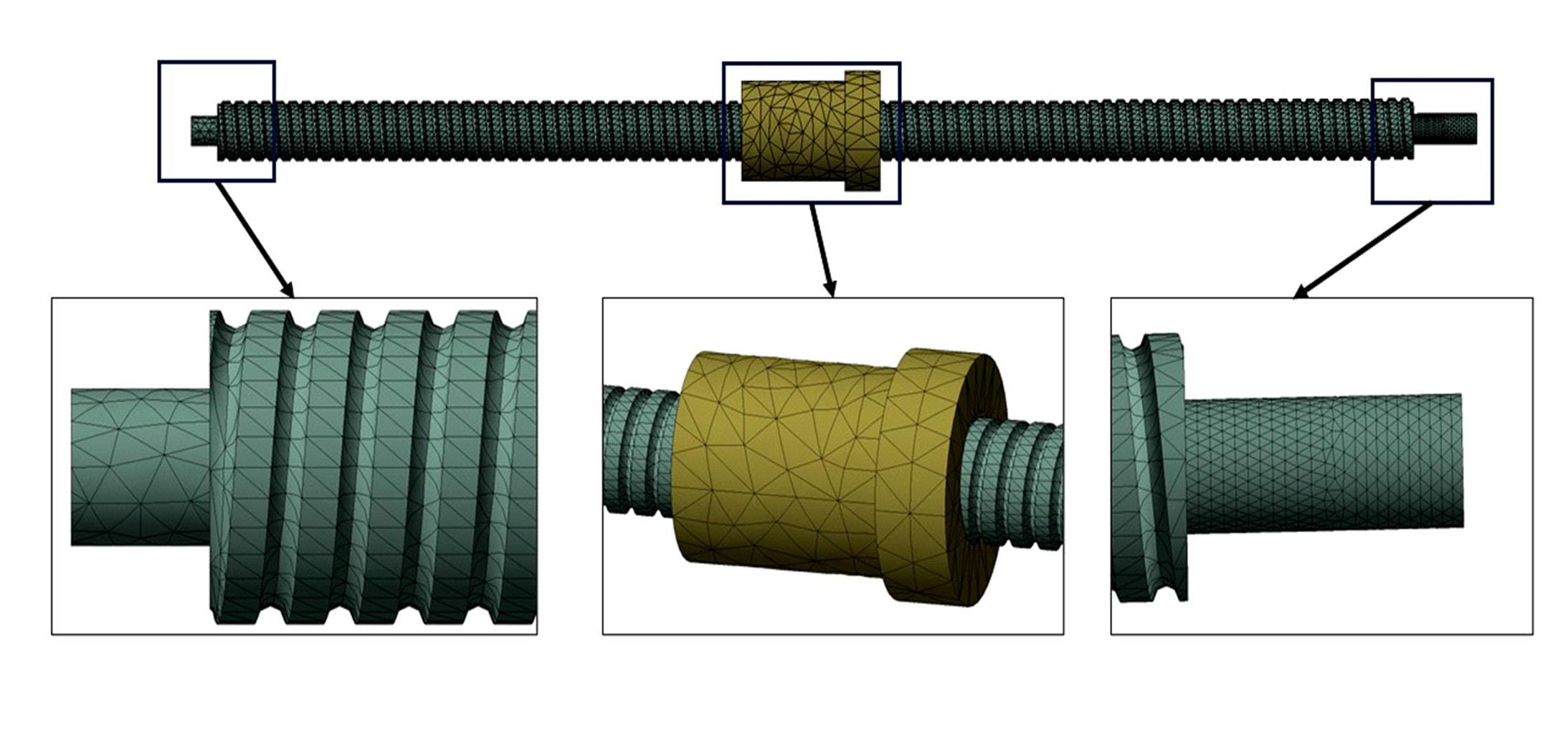

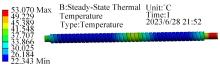

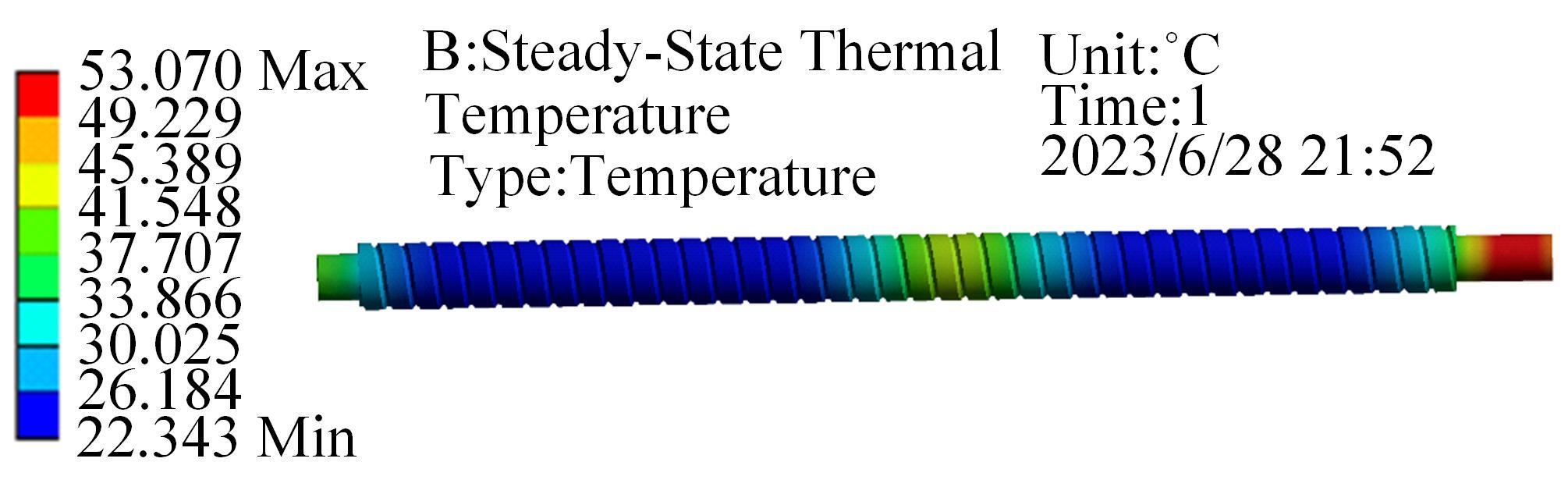

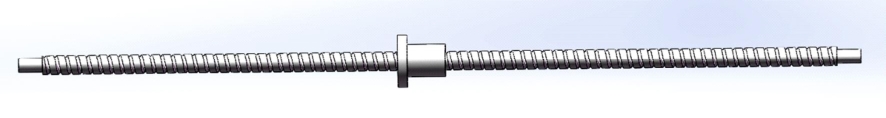

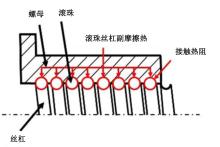

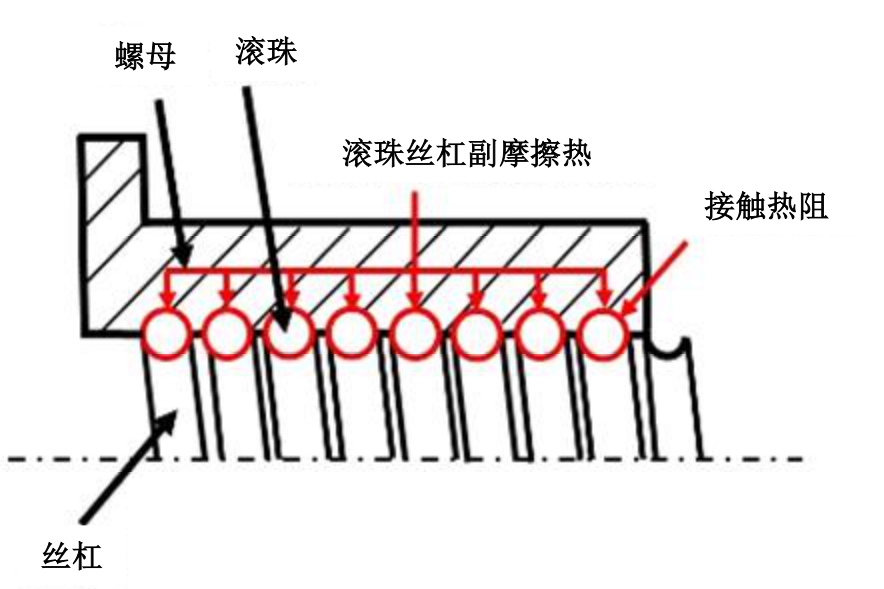

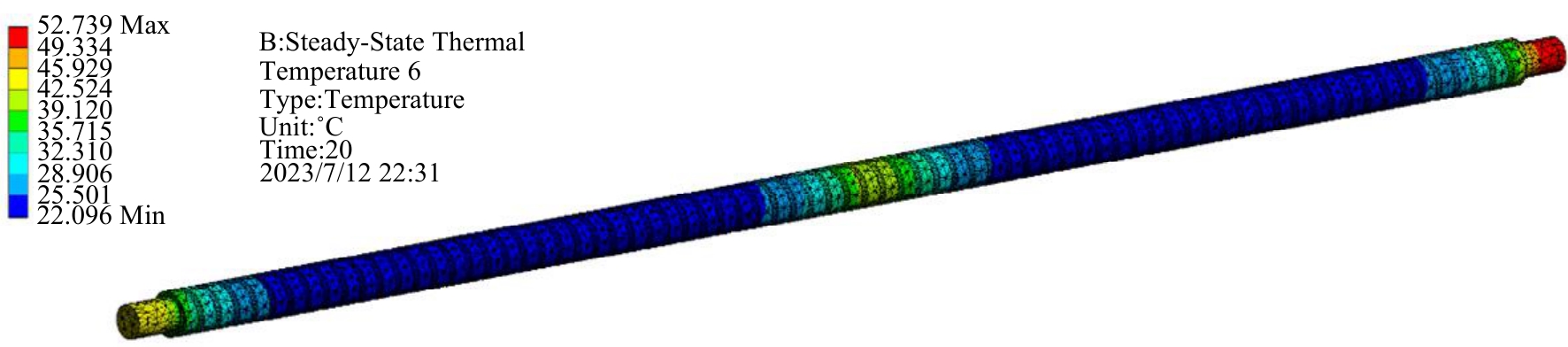

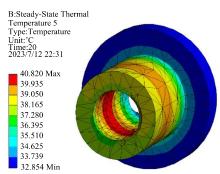

Influence of contact thermal resistance on temperature rise characteristics of high⁃speed ball screw

Ge-dong JIANG1,2( ),Hao WANG1,Ya-bin JING1

),Hao WANG1,Ya-bin JING1

- 1.School of Mechanical Engineering,Xi'an Jiaotong University,Xi'an 710049,China

2.Shaanxi Provincial Key Laboratory of Intelligent Robots,Xi'an 710049,China

CLC Number:

- TH132

| [1] | 刘璐, 周华西, 陈传海, 等. 基于竞争失效模型的滚珠丝杠副可靠性设计建模[J]. 吉林大学学报: 工学版, 2022, 52(2): 458-465. |

| Liu Lu, Zhou Hua-xi, Chen Chuan-hai, et al. Reliability design model of ball screws based on competition failure[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(2): 458-465. | |

| [2] | 程强, 王畅, 齐宝宝, 等. 虑及结构参数误差的滚珠丝杠接触载荷建模与分析[J]. 吉林大学学报: 工学版, 2022, 52(2): 353-360. |

| Cheng Qiang, Wang Chang, Qi Bao-bao, et al. Modeling and analysis of contact load of ball screw with error of structural parameters[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(2): 353-360. | |

| [3] | 夏军勇, 吴波, 胡友民, 等. 多变化热源下的滚珠丝杠热动态特性[J]. 中国机械工程, 2008(8): 955-958. |

| Xia Jun-Yong, Wu Bo, Hu You-min, et al. The thermal dynamic characteristic of ball-screw under the variational muti-thermal source[J]. China Mechanical Engineering, 2008(8): 955-958. | |

| [4] | Su D X, Li Y, Zhao W H, et al. Transient thermal error modeling of a ball screw feed system[J]. International Journal of Advanced Manufacturing Technology, 2023, 124(7/8): 2095-2107. |

| [5] | Wang H T, Li F H, Cai Y L, et al. Experimental and theoretical analysis of ball screw under thermal effect[J]. Tribology International, 2020, 152: No.106503. |

| [6] | 张义民, 王孟卓, 李铁军. 不同温升下受轴向载荷的球轴承内部接触热阻计算方法[J]. 机械设计与制造, 2021(5): 128-132. |

| Zhang Yi-min, Wang Meng-zhuo, Li Tie-jun. Internal contact thermal resistance calculation method of ball bearings subjected to axial load at different temperatures rise[J]. Machinery Design & Manufacture, 2021(5): 128-132. | |

| [7] | Gao X S, Ma J Q, Li Q, et al. Modeling of thermal contact resistance of ball screws considering the load distribution of balls[J]. Journal of Thermal Science and Engineering Applications, 2021, 13(4): 1-13. |

| [8] | Gao X S, Wang M, Liu X B. Modeling and application of thermal contact resistance of ball screws[J]. Journal of Central South University, 2019, 26(1): 168-183. |

| [9] | Yang J, Zhang D S, Mei X S, et al. Thermal error simulation and compensation in a jig-boring machine equipped with a dual-drive servo feed system[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2014, 229(1): 43-63. |

| [10] | Min X, Jiang S. A thermal model of a ball screw feed drive system for a machine tool[J]. Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science, 2011, 225: 186-193. |

| [11] | Bossmanns B, Tu J F. A thermal model for high speed motorized spindles[J]. International Journal of Machine Tools and Manufacture, 1999, 39(9): 1345-1366. |

| [12] | 葛世荣, 朱华. 摩擦学的分形[M]. 北京: 机械工业出版社, 2005. |

| [13] | 王润琼, 朱立达, 朱春霞. 基于域扩展因子和微凸体相互作用的结合面接触刚度模型研究[J]. 机械工程学报, 2018, 54(19): 88-95. |

| Wang Run-qiong, Zhu Li-da, Zhu Chun-xia. Investigation of contact stiffness model for joint surfaces based on domain expansion factor and asperity interaction[J]. Journal of Mechanical Engineering, 2018, 54(19): 88-95. | |

| [14] | Liu J L, Ma C, Wang S L, et al. Thermal boundary condition optimization of ball screw feed drive system based on response surface analysis[J]. Mechanical Systems and Signal Processing, 2019, 121: 471-495. |

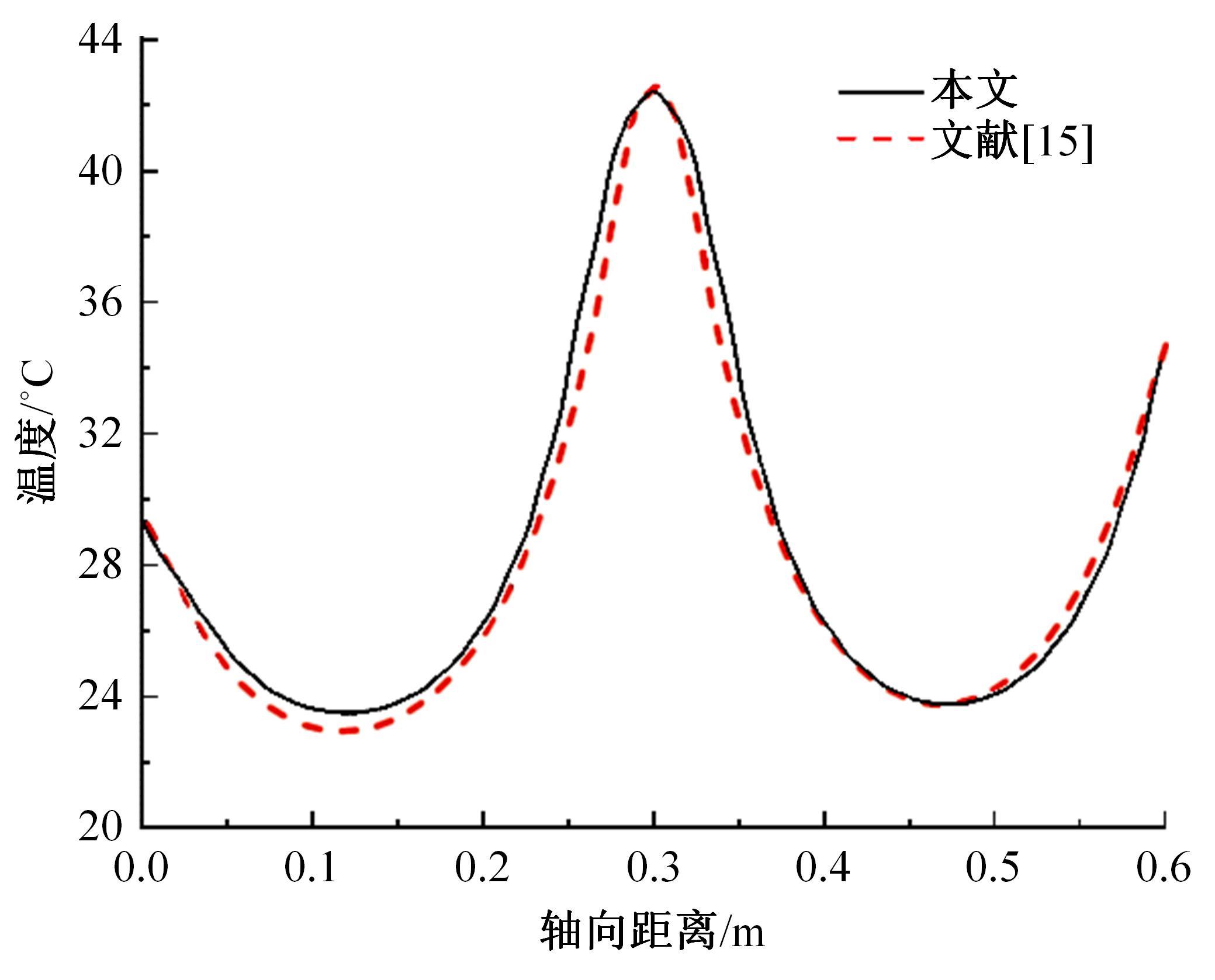

| [15] | 胡冕, 丁晓红. 热管滚珠丝杠热性能仿真和实验[J]. 中国机械工程, 2020, 31(20): 2445-2453. |

| Hu Mian, Ding Xiao-hong. Numerical and experiental investigations of thermal performance for heat pipe ball screws[J]. China Mechanical Engineering, 2020, 31(20): 2445-2453. |

| [1] | Yong-gang WANG,He-jian LIU,Chuan-yang WANG,Lei WANG,Run-dong QIAN,Dong-ya LI,Yi-jun DONG. Hot corrosion behaviors of CrCoNi medium entropy alloy by laser melting deposition [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1544-1551. |

| [2] | Chang-long ZHAO,Chen MA,Jun-bao YANG,Qin-xiang ZHAO,Xiao-yu JIA,Hong-nan MA. Influence of pre⁃set surface texture on laser cladding of 316L coatings [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 899-911. |

| [3] | Lei SHANG,Ping YANG,Xiang-guo YANG,Jian-xin PAN,Jun YANG,Meng-ru ZHANG. Temperature control of proton exchange membrane fuel cell thermal management system based on APSO-BP-PID control strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2401-2413. |

| [4] | Hua-min LIU,Shu-han YANG,Yi LI,Ce LIANG,Qi-gang Han. Thrust rod ball hinge bionic surface improvement and finite element analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2733-2740. |

| [5] | Lin JIANG,Guo-long LI,Shi-long WANG,Kai XU,Zhe-yu LI. Thermal expansion error modeling of feed axis based on principal component regression [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2149-2155. |

| [6] | Ze-qiang ZHANG,Can WANG,Jun-qi LIU,Dan JI,Si-lu LIU. Parallel row ordering problem based on improved sparrow search algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1851-1861. |

| [7] | Cai-xia SHU,Jia YANG,Qing-xi LIAO,Xing-yu WAN,Jia-cheng YUAN. Design and experiment of diversion type double-cylinder cyclone separation system for rapeseed combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1807-1820. |

| [8] | Li HUI,Lei JIN,Wan-wan SONG,Song ZHOU,Jin-lan AN. Crack growth rate of SMA490BW steel in different welding areas for bogie [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 650-656. |

| [9] | Zhi-jun YANG,Chi ZHANG,Guan-xin HUANG. Mechanical model of rigid⁃flexible coupling positioning stage based on floating coordinate method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 385-393. |

| [10] | Yun-tong LI,Xing-yu WAN,Qing-xi LIAO,Yin-lei LIU,Qing-song ZHANG,Yi-tao LIAO. Design and experiment of wide folding rape windrower based on crawler type power chassis [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3740-3754. |

| [11] | Wei-jun WU,Jiang-bo WU,Jia-le ZHANG,Qiang ZHOU,Qiao-hong YANG,Xun-peng QIN. Stability analysis and scale synthesis of new multifunctional aerial work platform [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3450-3459. |

| [12] | Lei WANG,Xiao-peng LIU,Song ZHOU,Jin-lan AN,Hong-jie ZHANG,Jia-hui CONG. Effect of ultrasonic rolling on fatigue crack propagation behavior of 2024 aluminum alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3486-3495. |

| [13] | Huan-lin ZHOU,Xin GUO,Xuan WANG,Li-xue FANG,Kai LONG. Topology optimization design of multiphase porous structures considering geometric nonlinearity [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 2754-2763. |

| [14] | Lin-rong SHI,Wu-yun ZHAO. Design and test of rolling spoon type flaxes precision hole sower for caraway in northwest cold and arid agricultural region [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2706-2717. |

| [15] | Bo-sen CHAI,Guang-yi WANG,Dong YAN,Guo-ren ZHU,Jin ZHANG,Heng-sheng LYU. Numerical simulation of cavitation in torque converter and analysis of its influence on performance [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2236-2244. |

|