Journal of Jilin University(Engineering and Technology Edition) ›› 2026, Vol. 56 ›› Issue (1): 265-274.doi: 10.13229/j.cnki.jdxbgxb.20240548

Previous Articles Next Articles

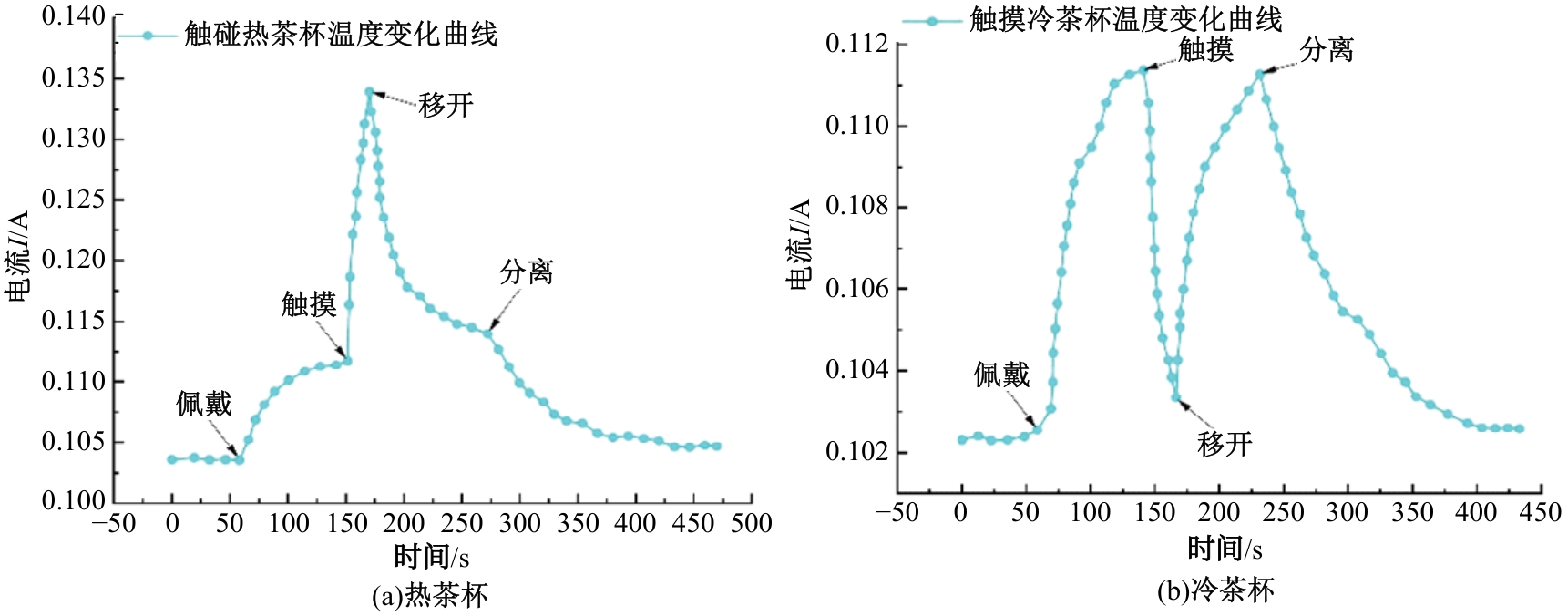

Wearable temperature sensor based on conductive nano-modified textile fiber materials

Zhi-gang LI1,2( ),Rui-xin WANG1,2,Zhang WEN3,Zi-long YANG1,2

),Rui-xin WANG1,2,Zhang WEN3,Zi-long YANG1,2

- 1.College of Information Science and Engineering,Northeastern University,Shenyang 110819,China

2.Hebei Key Laboratory of Micro-Nano Precision Optical Sensing and Measurement Technology,Qinhuangdao 066004,China

3.Daqing Oilfield Co. ,Ltd. ,Petro China,Daqing 163453,China

CLC Number:

- TP273

| [1] | Liu W, Tian X, Yang D, et al. Evaluation of individual thermal sensation at raised indoor temperatures based on skin temperature build[J]. Building and Environment, 2021, 188(15): No.107486. |

| [2] | El-Radhi A S. Fever in Common Infectious Diseases[M]. Clinical Manual of Fever in Children, 2009: 81-135.. |

| [3] | Korman P, Straburzyńska-Lupa A, Romanowski W, et al. Temperature changes in rheumatoid hand treated with nitrogen vapors and cold air[J]. Rheumatology International, 2012, 32: 2987-2992. |

| [4] | Huang Y, Zhou M, Yuan F. Clinical features and risk factors of fever in acute gouty arthritis[J]. BioMed Research International, 2022: No.8798838. |

| [5] | Knapp J P, Kakish J E, Bridle B W, et al. Tumor temperature: friend or foe of virus-based cancer immunotherapy[J]. Biomedicines, 2022, 10(8): No.2024. |

| [6] | Wu Y, Zhang Z, Liu H, et al. Age differences in thermal comfort and physiological responses in thermal environments with temperature ramp build[J]. Building and Environment,2023, 228(15):No.109887. |

| [7] | Chugh V, Basu A, Kaushik A, et al. E-skin–based advanced wearable technology for health management[J]. Current Research in Biotechnology,2023,5:No.100129. |

| [8] | Yang Y, Cui T, Li D, et al. Breathable electronic skins for daily physiological signal monitoring[J].Nano-micro Lett, 2022, 14(1): No.161. |

| [9] | Deng Z, Guo L, Chen X, et al. Smart wearable systems for health monitoring[J]. Sensors, 2023, 23: No. 2479. |

| [10] | Tarar A A, Mohammad U, Srivastava S K. Wearable skin sensors and their challenges: a review of transdermal, optical, and mechanical sensors[J]. Biosensors, 2020,10(6): No.56. |

| [11] | Lin M, Zheng Z, Yang L, et al. A high-performance, sensitive, wearable multifunctional sensor based on rubber/CNT for human motion and skin temperature detection[J]. Advanced Material,2022, 34:No. 2107309. |

| [12] | Hu X, Xia X X, Huang S C, et al. Development of adhesive and conductive resilin-based hydrogels for wearable sensors[J]. Biomacromolecules, 2019, 20(9): 3283-3293. |

| [13] | Lin X Z, Xue H, Li F, et al.All-nanofibrous ionic capacitive pressure sensor for wearable applications[J].ACS Applied Materials & Interfaces, 2022,14 (38): 43844-43852. |

| [14] | Zhang L, Kumar K S, He H, et al. Fully organic compliant dry electrodes self-adhesive to skin for long-term motion-robust epidermal biopotential monitoring[J]. Nature Communications, 2020, 11: No. 4683. |

| [15] | Mahsa-Hamedi S, Samaneh-Kordrostami Z. Fabrication of a high-sensitive wearable temperature sensor with an improved response time based on PEDOT: PSS/rGO on a flexible kapton substrate[J]. Journal of Materials Science: Materials in Electronics, 2022, 33(9): 6954-6968. |

| [16] | Li X, Chen S, Peng Y, et al. Materials, preparation strategies, and wearable sensor applications of conductive fibers: a review[J]. Sensors,2022,22(8):No.3028. |

| [17] | Chen Y, Hart J, Suh M, et al. Electromechanical characterization of commercial conductive yarns for E-Textiles[J]. Textiles, 2023, 3: 294-306. |

| [18] | 余龙. 碳纳米管纱线的制备与表面功能化及在智能纺织品领域的应用[D]. 无锡: 江南大学纺织科学与工程学院, 2023. |

| Yu Long. Preparation and surface functionalization of carbon nanotube yarn and its application in intelligent textile field[D]. Wuxi: College of Textile Science and Engineering, Jiangnan University, 2023. | |

| [19] | Zhu Q, Wang Z, Zeng H, et al. Effects of graphene on various properties and applications of silicone rubber and silicone resin[J]. Composites Part A: Applied Science and Manufacturing, 2021, 142: No.106240. |

| [20] | Liu J, Wang Y, Li X, et al. Graphene-based wearable temperature sensors: a review[J]. Nanomaterials,2023, 13(16): No.2339. |

| [21] | Tiwari S K, Sahoo S, Wang N, et al.Graphene research and their outputs: status and prospect[J]. Journal of Science: Advanced Materials and Devices,2020, 5(1): 10-29. |

| [22] | Sharma P, Karol V, Kaur S, et al. Fabrication and Interfacial Bonding of CNT-reinforced Metal Matrix Composites[M]. Metal Matrix Composites: A Modern Approach to Manufacturing. Bentham Science Publishers, 2024: 116-146. |

| [23] | Yin Q, Hu Y Y, Qin Y T, et al. Construction of polyimide films with excellent dimensional stability and toughness via incorporating point-to-face multi-coordination structure[J]. Composites Part B: Engineering, 2021, 208: No.108566. |

| [24] | 张春艳. 多层纤维增强环氧复合材料层状结构设计与电磁屏蔽效能简化预测[D]. 太原: 中北大学材料科学与工程学院, 2024. |

| Zhang Chun-yan. Layered structure design and simplified prediction of electromagnetic shielding effectiveness of multilayer fiber reinforced epoxy composites[D]. Taiyuan:College of Materials Science and Engineering,North University of China, 2024. | |

| [25] | Li Y, Zhou Z, He Y. Solid lubrication system and its plasma surface engineering: a review[J]. Lubricants,2023, 11: No.473. |

| [26] | Liu J, Bao S, Wang X. Applications of graphene-based materials in sensors: a review[J]. Micromachines, 2022, 13(2): No.184. |

| [27] | Hou N, Zhao Y, Jiang R, et al. Flexible piezoresistive sensor based on surface modified dishcloth fibers for wearable electronics device[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022,650: No.129638. |

| [28] | 石洪富, 邓自刚, 柯志昊, 等. 平板式永磁电动悬浮系统设计与实验研究[J]. 电工技术学报, 2024, 39(5): 1270-1283. |

| Shi Hong-fu, Deng Zi-gang, Ke Zhi-hao, et al. Design and experimental study of flat permanent magnet electric suspension system[J]. Journal of Electrical Technology, 2024, 39(5): 1270-1283. | |

| [29] | Wang Y, Luke J, Privitera A, et al. The critical role of the donor polymer in the stability of high-performance non-fullerene acceptor organic solar cells[J]. Joule, 2023, 7(4): 810-829. |

| [30] | Cui B, Pan F, Ding B, et al. Fiber aggregation in nanocomposites: aggregation degree and its linear relation with the percolation threshold[J]. Materials, 2023, 16(1): No.15. |

| [31] | Jeong S Y, Lee J U, Hong S M, et al. Highly skin-conformal laser-induced graphene-based human motion monitoring sensor[J]. Nanomaterials, 2021, 11:No.951. |

| [32] | Boey J Y, Lee C K, Tay G S. Factors affecting mechanical properties of reinforced bioplastics: a review[J]. Polymers, 2022, 14(18): No.3737. |

| [33] | Tang N, Zheng Y, Jiang X, et al. Wearable sensors and systems for wound healing-related ph and temperature detection[J]. Micromachines,2021,12(4):No.430. |

| [34] | Zhang T, Zhang M, Shen Y, et al. Mitigating the damage of ultra-high performance concrete at elevated temperatures using synergistic flame-retardant polymer fibres[J]. Cement and Concrete Research, 2022,158: No.10683 |

| [35] | Gangwar R K, Kumari S, Pathak A K, et al. Optical fiber based temperature sensors: a review[J]. Optics,2023, 4(1): 171-197. |

| [36] | Shuvo I I, Shah A, Dagdeviren C. Electronic textile sensors for decoding vital body signals: state-of-the-art review on characterizations and recommendations[J]. Advanced Intelligent Systems, 2022, 4(4): No. 2100223. |

| [37] | Wei L, Wang S, Shan M, et al. Conductive fibers for biomedical applications[J]. Bioactive Materials, 2023, 22: 343-364. |

| [38] | Mohamed A, Tonkonogovas A, Stankevičius A, et al. Fabrication of high-strength graphene oxide/carbon fiber nanocomposite membranes for hydrogen separation applications[J]. Process Safety and Environmental Protection, 2023, 172: 941-949. |

| [39] | Wu S. An overview of hierarchical design of textile-based sensor in wearable electronics[J]. Crystals,2022, 12: No.555. |

| [40] | Li X, Cui T, Li X, et al. Wearable temperature sensors based on reduced graphene oxide films[J]. Materials, 2023, 16(17): No.5952. |

| [1] | Wen-bo LI,Hua-cheng XIE,Shu-you YU,Bao-jun LIN,Hong CHEN. Obstacle avoidance control for truck platoon using distributed model predictive control [J]. Journal of Jilin University(Engineering and Technology Edition), 2026, 56(1): 247-256. |

| [2] | Fei WANG,Heng-hui LU,Dang LU. Vehicle stability control based on UniTire model [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(9): 2864-2873. |

| [3] | Shu-you YU,Ze-peng LIU,Bao-jun LIN,Hong CHEN. Data⁃driven distributed predictive control of vehicle platoons [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(9): 3056-3068. |

| [4] | Peng-yuan SUN,Guo-dong CHEN,Hui-feng ZHANG,Wei-xuan CHEN,Shuai LIU. Adaptive observer⁃based estimation of exhaust gas flow in hydrogen internal combustion engines [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(9): 2837-2846. |

| [5] | Shou-tao LI,Xiang-yi JIA,Jun ZHU,Hong-yan GUO,Ding-li YU. Uncontrolled intersections decision⁃making method for intelligent driving vehicles based on Level⁃K [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(9): 3069-3078. |

| [6] | Jin-wu GAO,Shao-long SUN,Shun-yao WANG,Bing-zhao GAO. Speed fluctuation suppression strategy of range extender based on motor torque compensation [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(8): 2475-2486. |

| [7] | Xin-chun LI,He-yuan SUN,Chi XU. Network resource allocation method of aerospace edge computing based on deep Q network algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(7): 2418-2424. |

| [8] | Shu-you YU,Hua-cheng XIE,Wen-bo LI,Yong-fu LI,Hong CHEN,Bao-jun LIN. Digital twin driven longitudinal and lateral control of truck platoon [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1994-2002. |

| [9] | Jing-hua ZHAO,Da LIU,Yu-qi ZHOU,Long WEN,Qian-yu LIU,Jie LIU,Fang-xi XIE. Air⁃fuel ratio control of engines based on Gaussian process regression intake prediction [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1854-1861. |

| [10] | Nan-nan ZHAO,Feng JIN,Hong-yu DING. Nonlinear active noise control algorithm based on weighted optimization AF [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1722-1727. |

| [11] | Xun GONG,Hang REN,Hua-lin ZHANG,Jie-yu WANG,Yun-feng HU,Yao SUN. Eco⁃heating control method for connected electric automotive heat pump system in winter conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 820-828. |

| [12] | Peng SHEN,Xiao-hua LI,Hui LIU. Prescribed finite-time tracking control with input buffer for a manipulator system [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 63-73. |

| [13] | Guo LIU,Jian XIONG,Xiu-jian YANG,Yang-fan HE. Intelligent vehicle trajectory tracking control based on curvature augmentation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3717-3728. |

| [14] | Hao-zhe CAO,Jin-ben ZHOU,Li-hua LI. Repetitive gradient learning parameter estimation of quantized Wiener system [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3673-3680. |

| [15] | Xiu-lan SONG,Wei-hao CHAI,De-feng HE,Song-xiang YING. Security-oriented cooperative adaptive predictive cruise control for connected and automated vehicular platoons under DoS attacks [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(11): 3406-3416. |

|

||