吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (2): 375-384.doi: 10.13229/j.cnki.jdxbgxb.20220350

• 车辆工程·机械工程 • 上一篇

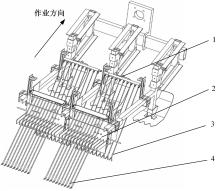

自适应振动式稻田株间柔性机械除草性能试验

- 华南农业大学 工程学院,广州 510642

Adaptive vibration type flexible mechanical weeding test between rice plants

Xue-shen CHEN( ),Yue-song XIONG,Nan CHENG,Xu MA(

),Yue-song XIONG,Nan CHENG,Xu MA( ),Long QI

),Long QI

- College of Engineering,South China Agricultural University,Guangzhou 510642,China

摘要:

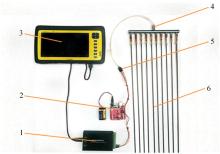

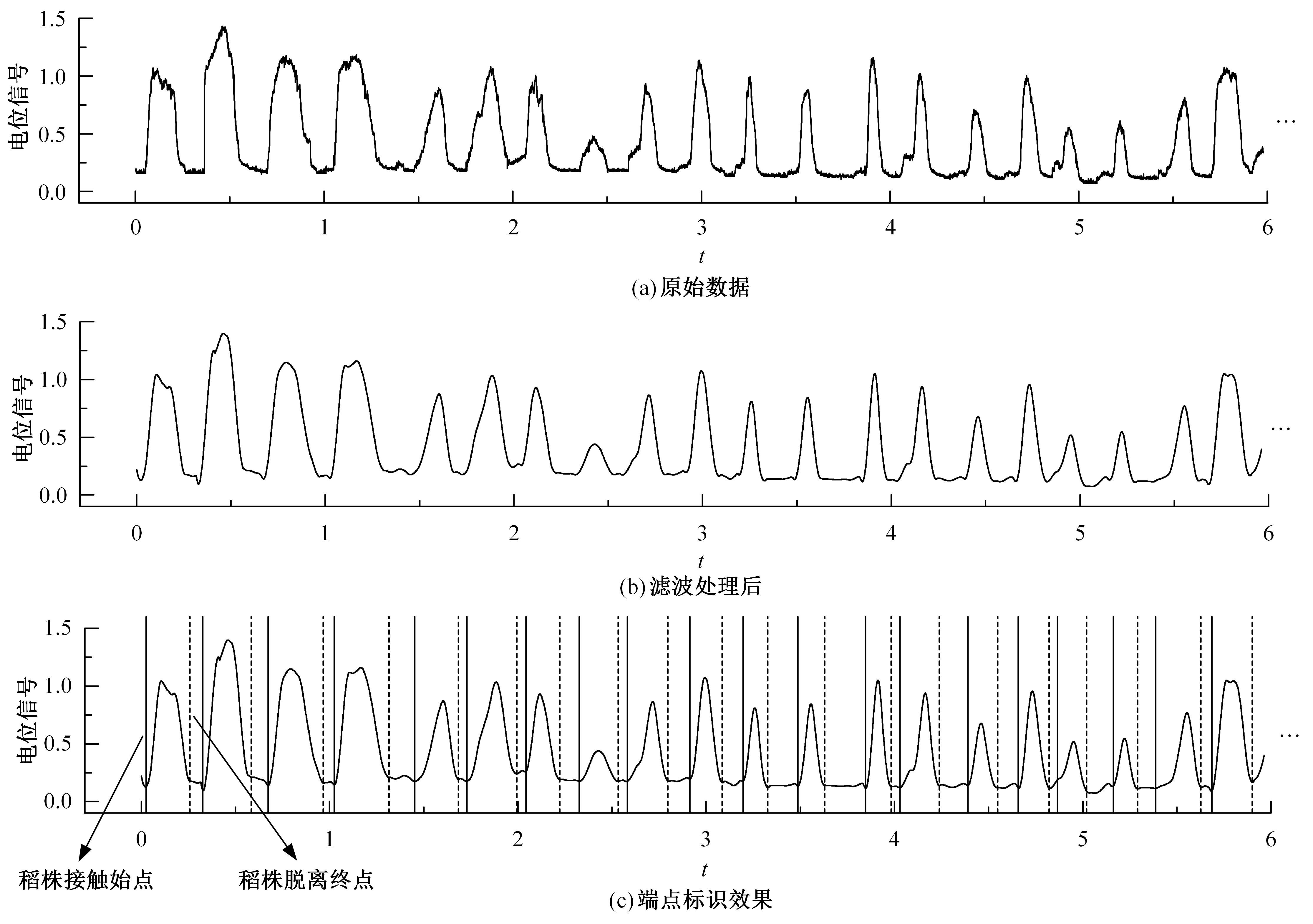

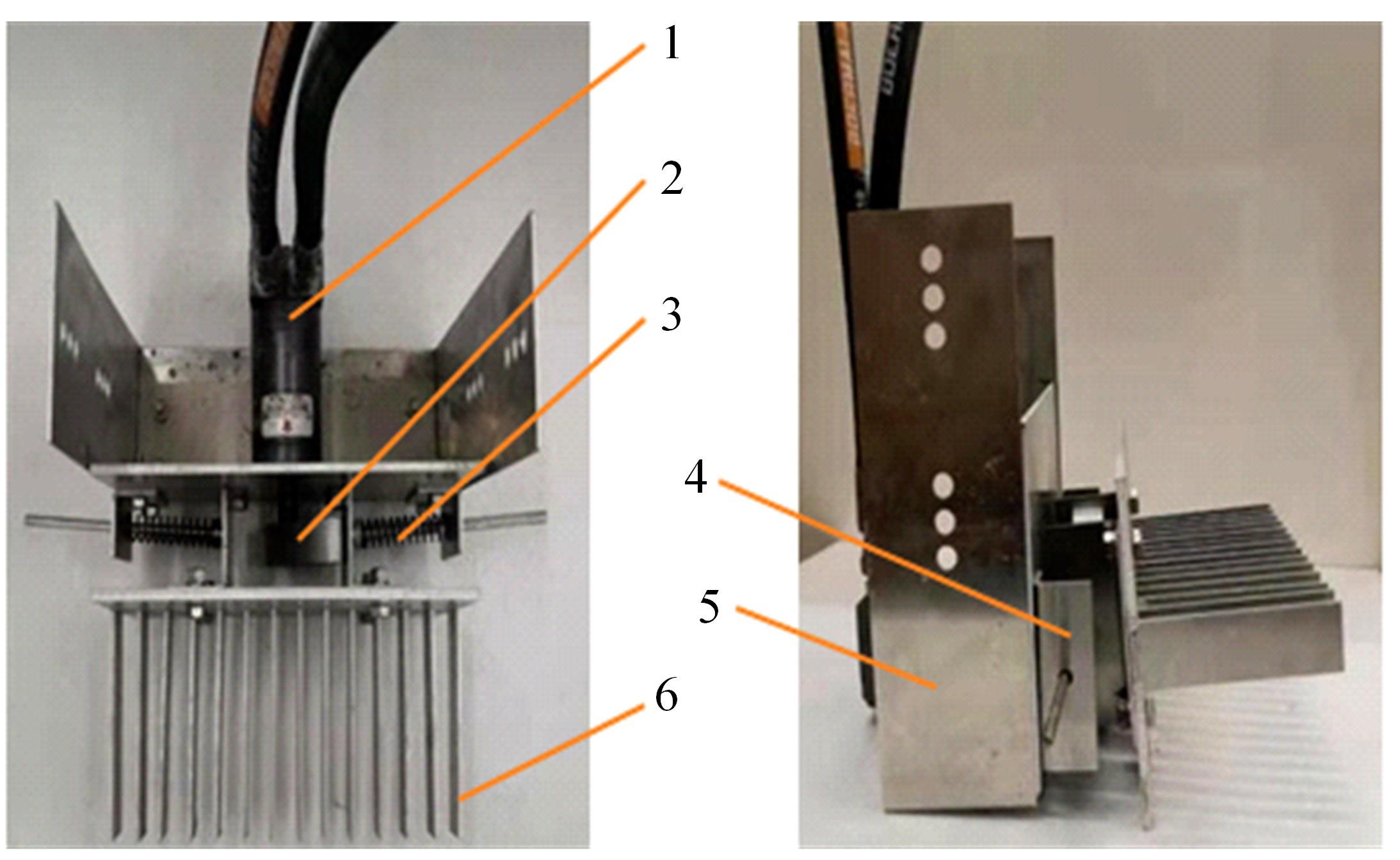

为解决现有稻田株间机械除草作业性能严重依赖机具对行质量的问题,设计了一种无需避苗作业的株间除草机。该机采用双排柔性刷指作为除草部件,前排除草部件纵向梳刷拉拔杂草,同时对梳刷后稻株倒伏状态进行自动识别。后排除草部件横向振动拨耙杂草,同时根据前排识别结果实时控制振动作业的启停,用以兼顾除草率与伤苗率。基于触觉感知方法建立了稻株倒伏识别系统,通过气压传感器的电位变化获取稻株根系与前排刷指相互作用的力学反馈数据,以电位峰度及均值为辨识特征,基于支持向量机构建稻株倒伏与未倒伏辨识模型,实现稻株倒伏自动识别。应用液压马达构建了后排除草部件的横向振动系统,对前排除草部件作用下已倒伏稻株停止振动作业,实现振动作业的自适应控制。稻株倒伏识别田间试验表明:稻株倒伏识别精度为83.11%。除草模式对比试验结果表明:无感知振动模式的除草率为58.11%,伤苗率为21.39%;无感知无振动模式的除草率为27.89%,伤苗率为4%;有感知振动模式的除草率为56.17%,伤苗率为5.83%。综合试验结果可知,有感知振动除草模式更适宜稻田株间杂草机械防控的生产要求。

中图分类号:

- S237

| 1 | 张帅. 我国主要农作物田杂草防控技术[J]. 杂草学报, 2020,38(2): 50-55. |

| Zhang Shuai. Weed control techniques in farmland of China[J]. Journal of Weeds, 2020, 38(2): 50-55. | |

| 2 | 金远明,王传惠,吴富梅,等. 化学除草组合用药对直播水稻田杂草的药效实验[J]. 湖北植保,2019(5): 14-15. |

| Jin Yuan-ming, Wang Chuan-hui, Wu Fu-mei, et al. Chemical herbicide combination drug effectiveness experiment on live rice field weeds[J]. Hubei Plant Protection, 2019(5): 14-15. | |

| 3 | 李杨,马智宏,李冰茹,等. 我国主要作物中除草剂登记情况及存在问题[J]. 食品安全质量检测学报,2018,9(17): 4483-4488. |

| Li Yang, Ma Zhi-hong, Li Bing-ru, et al. Registration status and existing problems of herbicides in the major crops in China[J]. Journal of Food Safety and Quality, 2018, 9(17): 4483-4488. | |

| 4 | 董立尧,高原,房加鹏,等. 我国水稻田杂草抗药性研究进展[J]. 植物保护,2018,44(5): 69-76. |

| Dong Li-yao, Gao Yuan, Fang Jia-peng, et al. Research progress on the herbicide-resistance of weeds in rice fields in China[J]. Journal of Plant protection, 2018, 44(5): 69-76. | |

| 5 | 齐月,李俊生,闫冰,等. 化学除草剂对农田生态系统野生植物多样性的影响[J]. 生物多样性,2016,24(2): 228-236. |

| Qi Yue, Li Jun-sheng, Yan Bing, et al. Impact of herbicides on wild plant diversity in agro-ecosystems[J]. Biodiversity Science, 2016, 24(2): 228-236. | |

| 6 | 崔思远,曹光乔,张文毅,等. 适宜机插株行距促进水稻生长提高产量[J]. 农业工程学报,2014,30(22): 37-43. |

| Cui Si-yuan, Cao Guang-qiao, Zhang Wen-yi, et al. Suitable mechanical transplanting spacing promoting rice growth and increasing rice yield[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(22): 37-43. | |

| 7 | 胡雅杰,邢志鹏,龚金龙,等. 适宜机插株行距提高不同穗型粳稻产量[J]. 农业工程学报,2013,29(14): 33-44. |

| Hu Ya-jie, Xing Zhi-peng, Gong Jin-long, et al. Suitable spacing in and between rows of plants by machinery improves yield of different panicle type japonica rices[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(14): 33-44. | |

| 8 | 齐龙,梁仲维,蒋郁,等. 轻型水田除草机的设计及试验[J]. 吉林大学学报: 工学版,2016,46(3): 1004-1012. |

| Qi Long, Liang Zhong-wei, Jiang Yu, et al. Design and field test of lightweight paddy weeder[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(3): 1004-1012. | |

| 9 | 齐龙,刘闯,蒋郁. 水稻机械除草技术装备研究现状及智能化发展趋势[J]. 华南农业大学学报,2020,41(6): 29-36. |

| Qi Long, Liu Chuang, Jiang Yu. Present status and intelligent development prospects of mechanical weeding technology and equipment for rice[J]. Journal of South China Agricultural University, 2020, 41(6): 29-36. | |

| 10 | 王金武,李超,李鑫,等. 铺膜插秧后水田3SCJ-1型除草机设计与试验[J]. 农业机械学报,2018,49(4): 102-109. |

| Wang Jin-wu, Li Chao, Li Xin, et al. Design and experiment of 3SCJ-1 type weeding machine for paddy field applied to film mulching and transplanting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(4): 102-109. | |

| 11 | 马旭,齐龙,梁柏,等. 水稻田间机械除草装备与技术研究现状及发展趋势[J]. 农业工程学报,2011,27(6): 162-168. |

| Ma Xu, Qi Long, Liang Bo, et al. Present status and prospects of mechanical weeding equipment and technology in paddy field[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(6): 162-168. | |

| 12 | Ishii H, Satho M. Three performance of paddy weeding machine and improvements in the performance[J]. The Crop Science Society of Japan, 2006, 21: 22-23. |

| 13 | 牛春亮,王金武,唐继武,等. 稻田株间除草弹齿齿形及安装方式分析与试验[J]. 农机化研究,2017,39(12): 176-179. |

| Niu Chun-liang, Wang Jin-wu, Tang Ji-wu, et al. Analysis and test on weed-tooth type and installation mode of inter-plant weeds in rice field[J]. Journal of Agricultural Mechanization Research, 2017, 39(12): 176-179. | |

| 14 | 牛春亮,王金武,马莉莎,等. 双弧形水稻株间除草部件设计及切土轨迹研究[J]. 农机化研究,2016,38(12): 122-126. |

| Niu Chun-liang, Wang Jin-wu, Ma Li-sha, et al. Double curved rice strains between analysis and design of key components weeding setsudo track[J]. Journal of Agricultural Mechanization Research, 2016, 38(12): 122-126. | |

| 15 | 三菱農機株式会社,株式会社キュウホー.除草機[P].2007105006,[2007-04-26]. |

| 16 | 周福君,王文明,李小利, 等. 凸轮摇杆式摆动型玉米株间除草装置设计与试验[J]. 农业机械学报,2018,49(1): 77-85. |

| Zhou Fu-jun, Wang Wen-ming, Li Xiao-li, et al. Design and experiment of cam rocker swing intra-row weeding device for Maize[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(1): 77-85. | |

| 17 | 吴崇友,张敏,金诚谦,等. 2BYS-6型水田中耕除草机设计与试验[J]. 农业机械学报,2009,40(7): 51-54. |

| Wu Chong-you, Zhang Min, Jin Cheng-qian, et al. Design and experiment of 2BYS6 type paddy weeding-cultivating machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(7): 51-54. | |

| 18 | 王金峰,高观保,闫东伟,等. 水田电动双行深施肥除草机设计与试验[J]. 农业机械学报,2018,49(7): 46-57. |

| Wang Jin-feng, Gao Guan-bao, Yan Dong-wei, et al. Design and experiment of electric control double row deep fertilizing weeder in paddy field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 46-57. | |

| 19 | 王金武,李超,李鑫,等. 铺膜插秧后水田3SCJ-1型除草机设计与试验[J]. 农业机械学报,2018,49(4): 102-109. |

| Wang Jin-wu, Li Chao, Li Xin, et al. Design and experiment of 3SCJ-1 type weeding machine for paddy field applied to film mulching and transplanting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(4): 102-109. | |

| 20 | 王金峰,王金武,闫东伟,等. 3SCJ-2型水田行间除草机设计与试验[J]. 农业机械学报,2017,48(6): 71-78. |

| Wang Jin-feng, Wang Jin-wu, Yan Dong-wei, et al. Design and experiment of 3SCJ-2 type row weeding machine for paddy field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 71-78. | |

| 21 | 董春华,曾希柏,刘强,等. 有机无机肥配施对晚稻产量和杂草群落的影响[J]. 核农学报, 2016, 30(9): 1815-1823. |

| Dong Chun-hua, Zeng Xi-bai, Liu Qiang, et al. Effects of combined application of organic and inorganic fertilizer on weed community and late rice yield[J]. Journal of Nuclear Agriculture, 2016, 30(9): 1815-1823. | |

| 22 | 郭保卫,许轲,张洪程,等. 有序摆抛栽超高产栽培对水稻根系形态生理特征的影响[J]. 中国水稻科学,2016,30(6): 611-625. |

| Guo Bao-wei, Xu Ke, Zhang Hong-cheng, et al. Effect of ordered transplanting and optimized broadcasting on rice root system morphological and physiological characteristics under super high-yielding cultivation[J]. Journal of China Rice Science, 2016, 30(6): 611-625. | |

| 23 | 邱佩,崔远来,韩焕豪,等. 淹灌和间歇灌溉对晚稻田杂草群落多样性的影响[J]. 农业工程学报,2015,31(22): 115-121. |

| Qiu Pei, Cui Yuan-lai, Han Huan-hao, et al. Effect of flooding irrigation and intermittent irrigation patterns on weed community diversity in late rice fields[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(22): 115-121. | |

| 24 | 董春华,刘强,高菊生,等. 不同施肥模式下水稻生育期间杂草群落特征[J]. 草业学报,2013,22(3): 218-226. |

| Dong Chun-hua, Liu Qiang, Gao Ju-sheng, et al. Effects of different fertilization models on the characteristics of weed communities during the rice growing seasons[J]. Acta Prataculturae Sinica, 2013, 22(3): 218-226. | |

| 25 | 郑文汉,齐龙,曹聪,等. 分蘖期深施液体氮肥对水稻分蘖及产量影响[J]. 农机化研究,2020,42(7): 160-165. |

| Zheng Wen-han, Qi Long, Cao Cong, et al. Effects of deep placement liquid fertilizer in tillering stage on tillering dynamics and yield components[J]. Journal of Agricultural Mechanization Research, 2020, 42(7): 160-165. | |

| 26 | 齐龙,赵柳霖,马旭,等. 3GY-1920型宽幅水田中耕除草机的设计与试验[J]. 农业工程学报,2017,33(8): 47-55. |

| Qi Long, Zhao Liu-lin, Ma Xu, et al. Design and test of 3GY-1920 wide-swath type weeding-cultivating machine for paddy[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(8): 47-55. | |

| 27 | 郭洁,陈祥献,黄海,等. 基于峰度的电力变压器铁芯松动故障在线监测方法[J]. 仪器仪表学报,2010,31(11): 2401-2407. |

| Guo Jie, Chen Xiang-xian, Huang Hai, et al. Application of kurtosisin online detection of transformer iron coreloosenes[J]. Chinese Journal of Scientific Instrument, 2010, 31(11): 2401-2407. | |

| 28 | 杨兆升,王媛,管青. 基于支持向量机方法的短时交通流量预测方法[J]. 吉林大学学报: 工学版, 2006, 36(6): 881-884. |

| Yang Zhao-sheng, Wang Yuan, Guan Qing. Short-time traffic prediction method based on SVM[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(6): 881-884. |

| [1] | 杨福增,孙景彬,李亚男,张亚洲,刘志杰. 郁闭果园图传遥控式割草机的设计与性能试验[J]. 吉林大学学报(工学版), 2024, 54(1): 281-293. |

| [2] | 王永烁,康建明,彭强吉,陈英凯,方会敏,牛萌萌,王少伟. 果树株间避障除草机设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2410-2420. |

| [3] | 刘鹏举. 基于深度神经网络的物联网安全态势自动辨识算法设计[J]. 吉林大学学报(工学版), 2023, 53(7): 2121-2126. |

| [4] | 王果,郭文凯,王长春. 配电网拓扑辨识研究综述及展望[J]. 吉林大学学报(工学版), 2023, 53(2): 312-327. |

| [5] | 史文库,张曙光,张友坤,陈志勇,江逸飞,林彬斌. 基于改进海鸥算法的磁流变减振器模型辨识[J]. 吉林大学学报(工学版), 2022, 52(4): 764-772. |

| [6] | 李伟,宋海生,陆浩宇,史文库,王强,王晓俊. 复合材料板簧迟滞特性线性辨识方法[J]. 吉林大学学报(工学版), 2022, 52(4): 829-836. |

| [7] | 胡云峰,丁一桐,赵志欣,蒋冰晶,高金武. 柴油发动机燃烧过程数据驱动建模与滚动优化控制[J]. 吉林大学学报(工学版), 2021, 51(1): 49-62. |

| [8] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [9] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

| [10] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [11] | 刘兆惠, 王超, 吕文红, 管欣. 基于非线性动力学分析的车辆运行状态参数数据特征辨识[J]. 吉林大学学报(工学版), 2018, 48(5): 1405-1410. |

| [12] | 袁朝春, 张龙飞, 陈龙, 何友国, 范兴根. 基于路面辨识的主动避撞系统制动性能[J]. 吉林大学学报(工学版), 2018, 48(2): 407-414. |

| [13] | 孙博华, 邓伟文, 朱冰, 吴坚, 王姗姗. 基于反应式行为的车辆运动意图辨识[J]. 吉林大学学报(工学版), 2018, 48(1): 36-43. |

| [14] | 晋超琼, 张葆, 李贤涛, 申帅, 朱枫. 基于扰动观测器的光电稳定平台摩擦补偿策略[J]. 吉林大学学报(工学版), 2017, 47(6): 1876-1885. |

| [15] | 温博轩, 王伟达, 项昌乐, 杨磊, 凌川. 机电复合传动系统发动机模型集辨识[J]. 吉林大学学报(工学版), 2017, 47(5): 1358-1366. |

|

||