吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1555-1562.doi: 10.13229/j.cnki.jdxbgxb.20221103

• 材料科学与工程 • 上一篇

焊剂对焊接熔池液态金属表面张力的影响

- 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050

Effect of flux on surface tension of liquid metal in welding pool

Chun-kai LI( ),Yue DAI,Jia-xin WANG,Yu-fen GU,Yu SHI,Bao-long XI

),Yue DAI,Jia-xin WANG,Yu-fen GU,Yu SHI,Bao-long XI

- State Key Laboratory of Advanced Processing and Reuse of Nonferrous Metals,Lanzhou University of Technology,Lanzhou 730050,China

摘要:

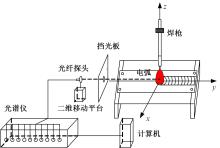

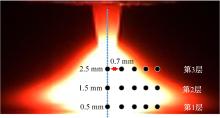

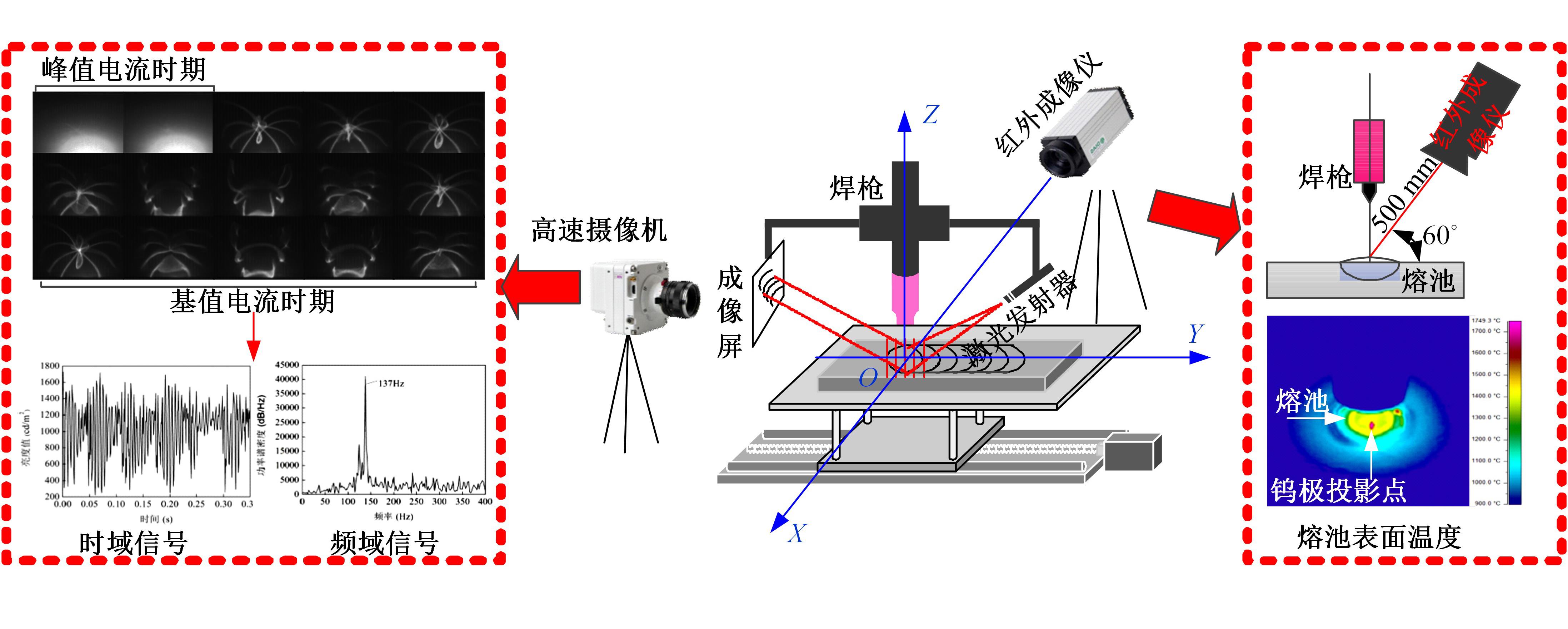

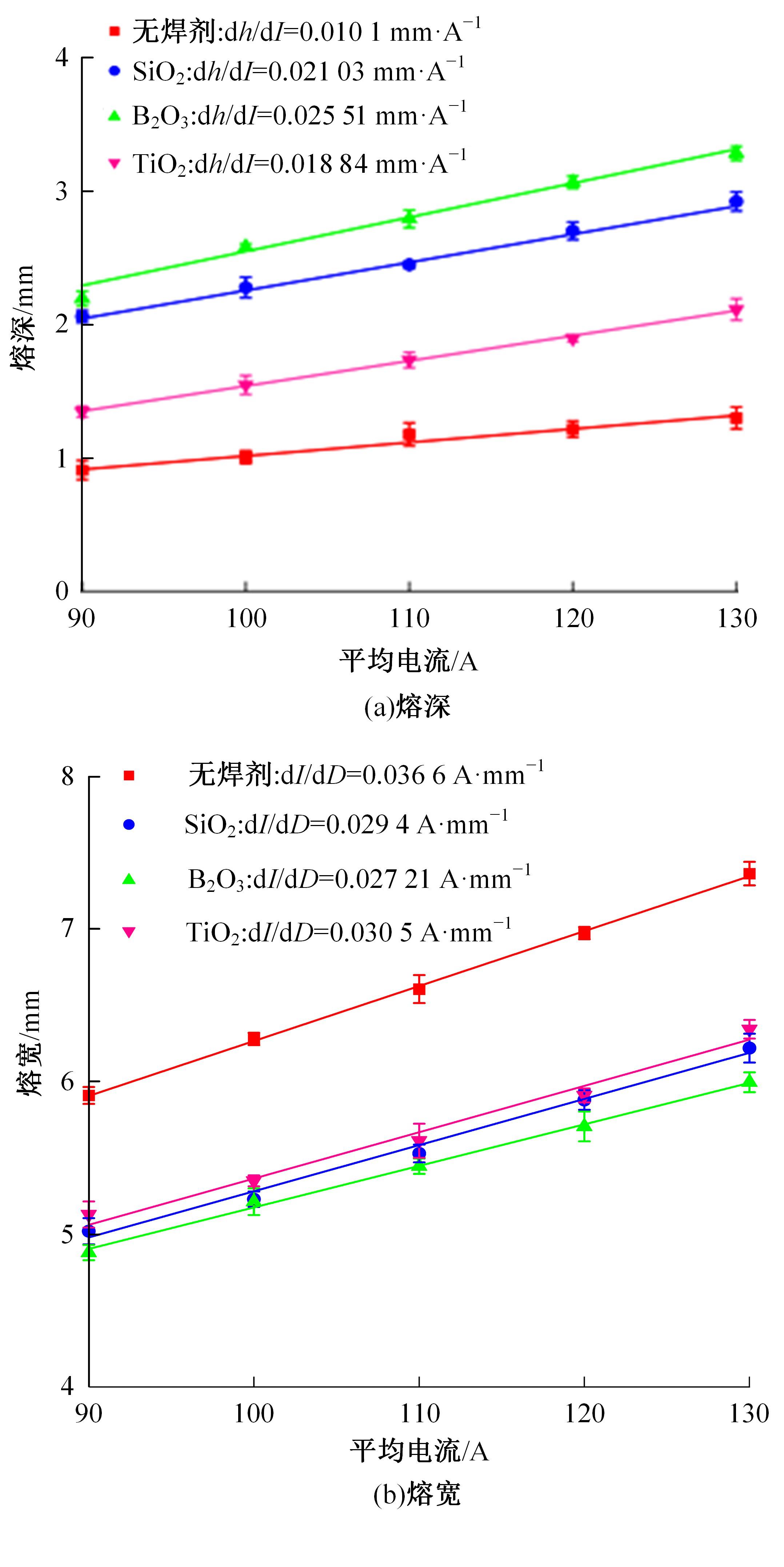

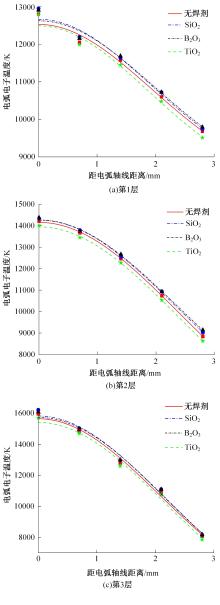

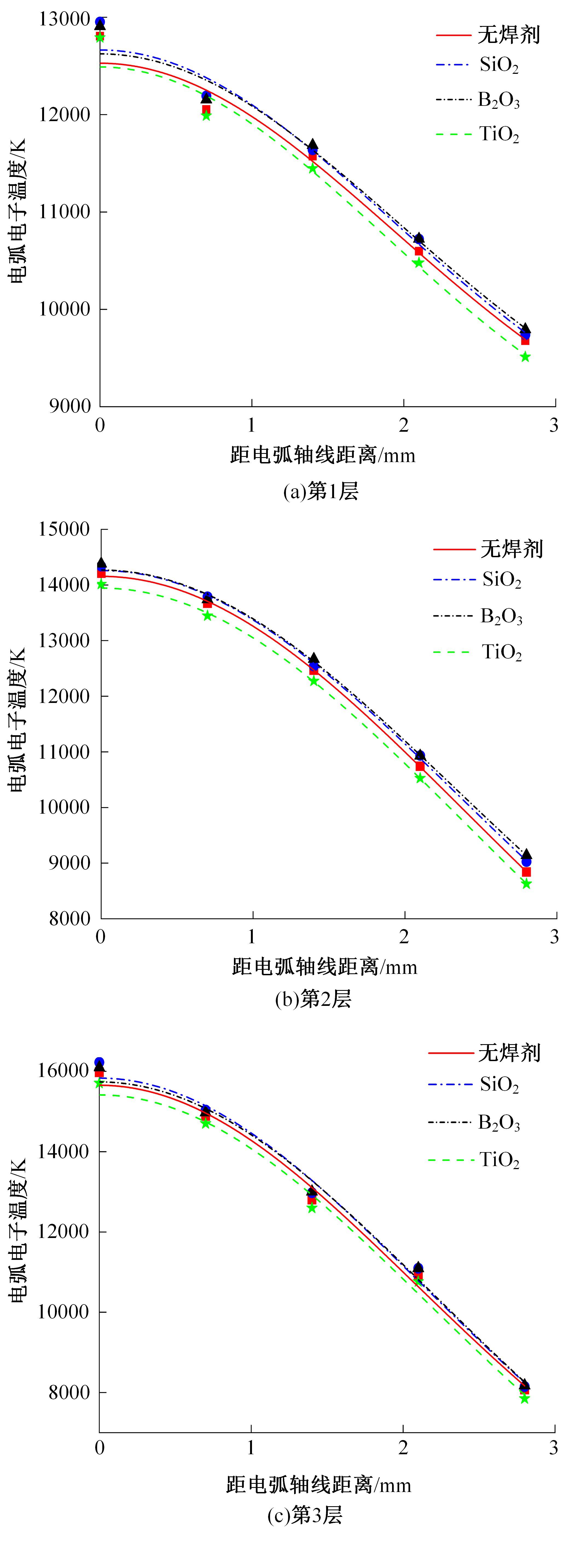

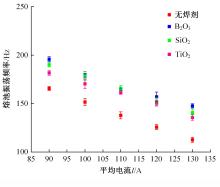

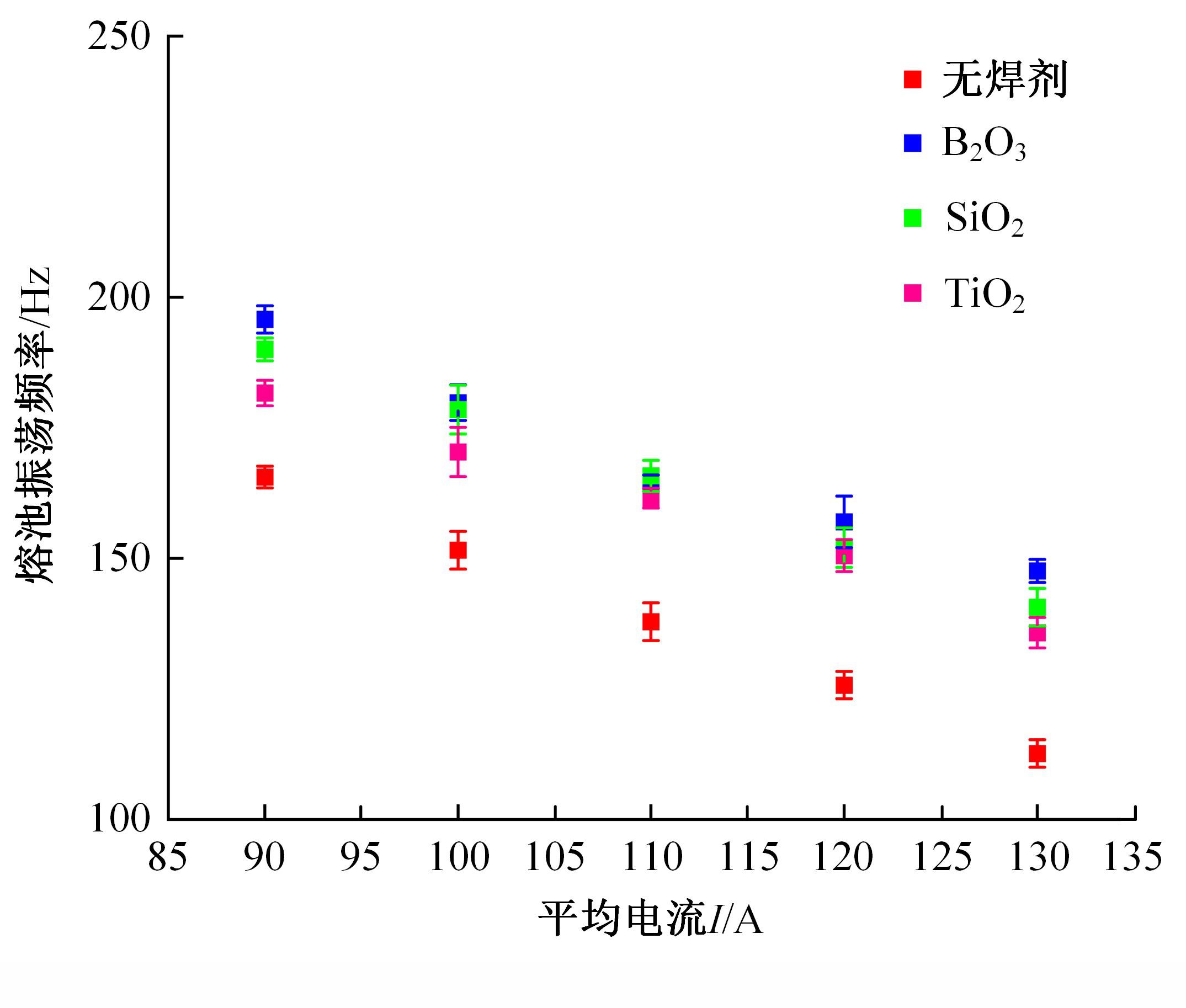

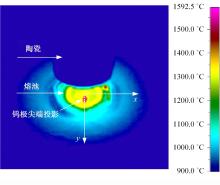

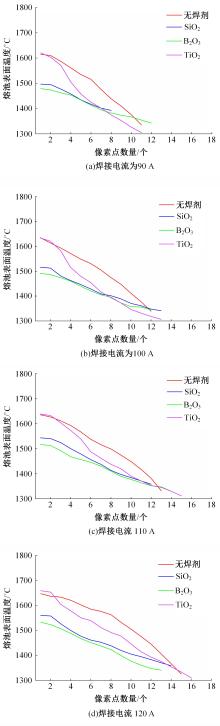

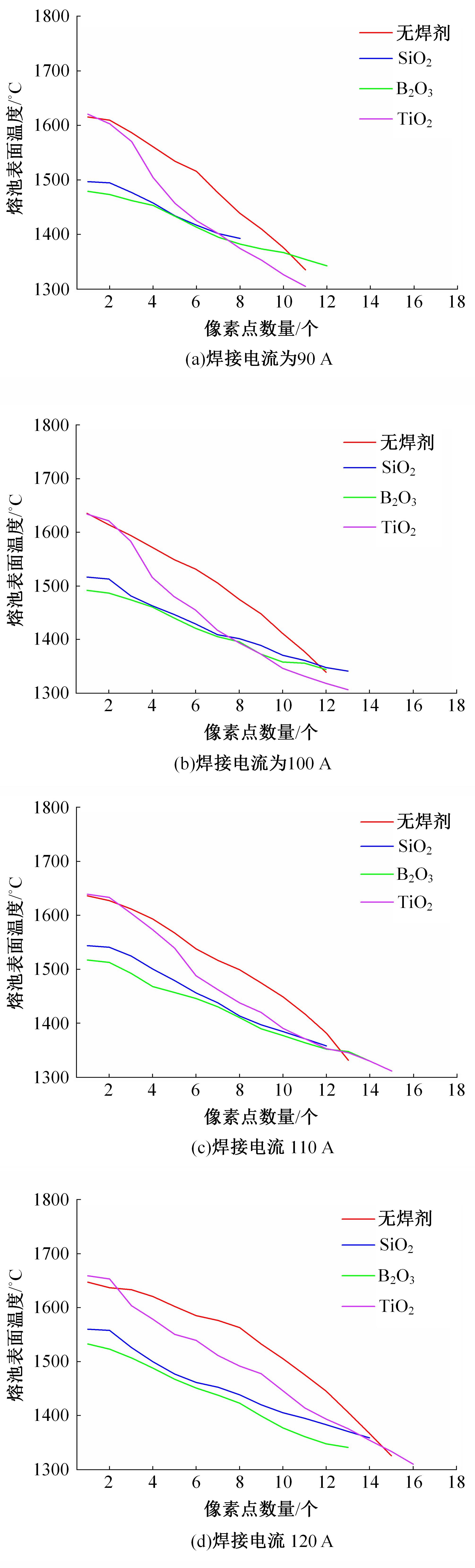

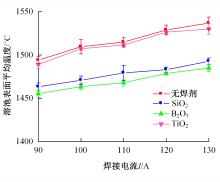

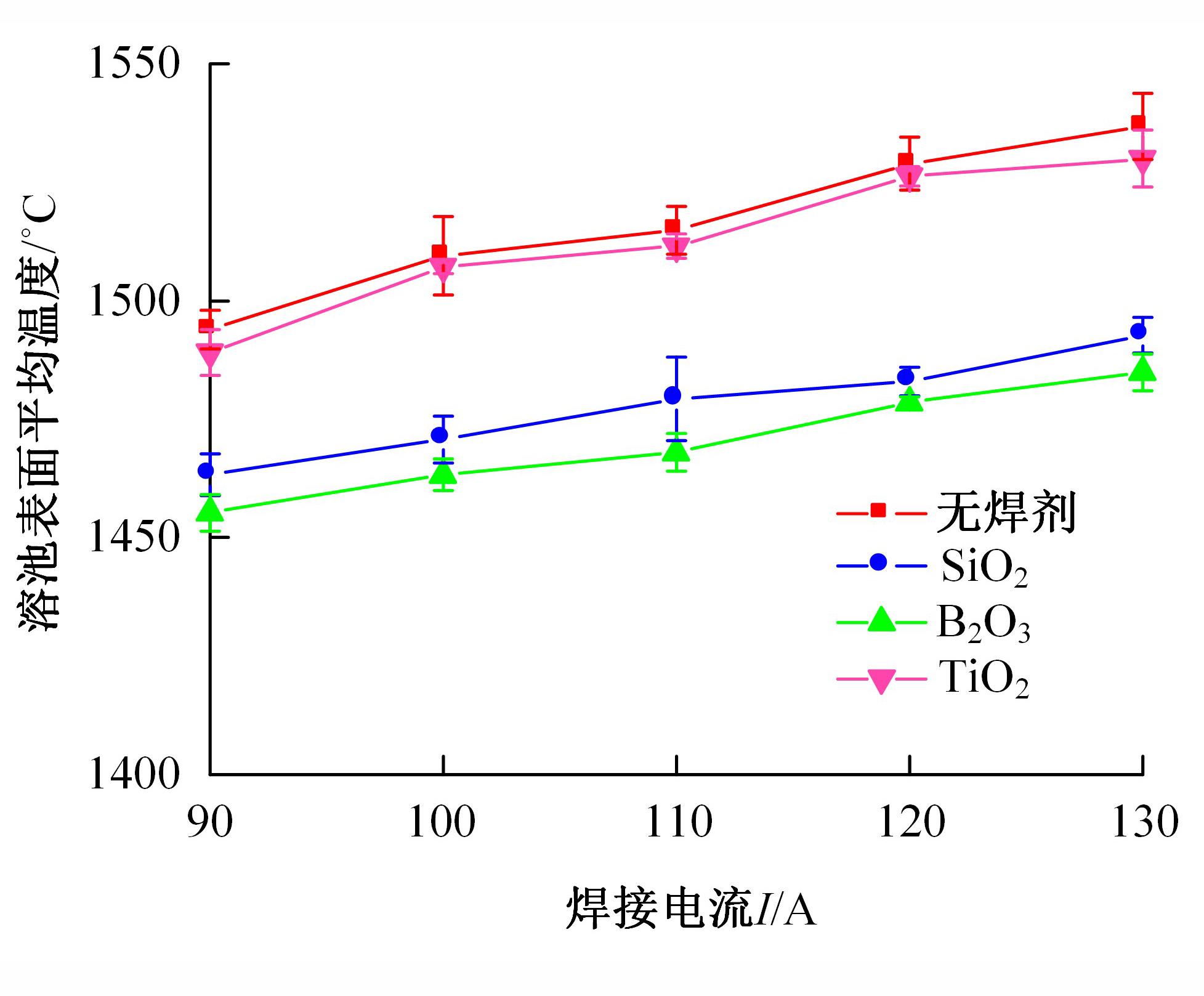

基于电弧光谱诊断和熔池振荡原理分别建立了电弧电子温度和熔池液态金属表面张力动态测量系统,研究了3种典型氧化物焊剂对TIG电弧热源作用下熔池表面张力的影响。结果表明:氧化物的引入不会对电弧整体温度产生明显影响,但能够使熔池液态金属平均表面张力温度梯度由负变正,且熔池表面张力温度梯度与氧化物的熔点有关,氧化物熔点越低,熔池的表面张力温度梯度越大。

中图分类号:

- TG444

| 1 | Wakimoto T, Katoh K, Ueda Y, et al. Measurement of dynamic surface tension for liquid metal by capillary jet method[J]. International Journal of Heat and Fluid Flow, 2017, 66: 243-248. |

| 2 | Farzadi A, Esfahani M M, Zaree A S R. Theoretical and experimental investigation of gas metal arc weld pool in commercially pure aluminum: effect of welding current on geometry[J]. Journal of Central South University, 2017, 24(11): 2556-2564. |

| 3 | Yu F, Wei Y. Effect of surface tension anisotropy and welding parameters on initial instability dynamics during solidification: a phase-field study[J]. Metallurgical and Materials Transactions a-Physical Metallurgy and Materials Science, 2018, 49A (8): 3293-3305. |

| 4 | Yang M, Liu H, Qi B. The surface depression and temperatures in molten pool with pulsed arc welding [J]. Journal of Manufacturing Processes, 2019, 37: 130-138. |

| 5 | Kim C K, Kim J H, Hong H U, et al. Behavior of weld pool convection and columnar-to-equiaxed grain transition in gas tungsten arc welds of ferritic stainless steels with different aluminum contents[J]. Journal of Materials Processing Technology, 2021, 289:No.116496. |

| 6 | Kurtulmus M. Effects of welding parameters on penetration depth in mild steel A-TIG welding[J]. Scientia Iranica, 2019, 26(3): 1400-1404. |

| 7 | Pandya D, Badgujar A, Ghetiya N. A novel perception toward welding of stainless steel by activated TIG welding: a review[J]. Materials and Manufacturing Processes, 2021, 36 (8): 877-903. |

| 8 | Chu Q, Zhang M, Li J, et al. Intermetallics in CP-Ti/X65 bimetallic sheets filled with Cu-based flux-cored wires[J]. Materials & Design, 2016, 90: 299-306. |

| 9 | 商延赓,孙大千,郎波,等.金属间化合物对Sn-Ag-Cu无铅钎料钎焊接头性能的影响[J].吉林大学学报:工学版, 2006, 36(6): 846-850. |

| Shang Yan-geng, Sun Da-qian, Lang Bo, et al. Effects of intermetallic compounds on the properties of Sn-Ag-Cu lead-free solder joints[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(6): 846-850. | |

| 10 | Wang X X, Huang J K, Huang Y, et al. Investigation of heat transfer and fluid flow in activating TIG welding by numerical modeling[J]. Applied Thermal Engineering, 2017, 113: 27-35. |

| 11 | Zhao C X, Steijn V V, Richardson I M, et al. Unsteady interfacial phenomena during inward weld pool flow with an active surface oxide[J]. Science and Technology of Welding and Joining, 2009, 14(2): 132-140. |

| 12 | Huang Y M, Zhang F, Yuan J, et al. Investigation on surface morphology and microstructure of double-wire+arc additive manufactured aluminum alloys based on spectral analysis[J]. Journal of Manufacturing Processes, 2022, 84: 639-651. |

| 13 | Li C K, Shi Y, Gu Y F, et al. Monitoring weld pool oscillation using reflected laser pattern in gas tungsten arc welding[J]. Journal of Materials Processing Technology, 2018, 255: 876-885. |

| 14 | Shi Y, Li C K, Du L M, et al. Frequency characteristics of weld pool oscillation in pulsed gas tungsten arc welding[J]. Journal of Manufacturing Processes, 2016, 24: 145-151. |

| 15 | Liu G H, Liu M H, Yi Y Y, et al. Activated flux tungsten inert gas welding of 8 mm-thick AISI 304 austenitic stainless steel[J]. Journal of Central South University, 2015, 22(3): 800805. |

| 16 | 刘凤尧, 杨春利, 林三宝,等. 活性化TIG焊熔深增加机理的研究[J]. 金属学报, 2003(6): 661-665. |

| Liu Feng-yao, Yang Chun-li, Lin San-bao, et al. Mechanism of incerasing A-TIG welding penetration [J]. Acta Metallurgica Sinica, 2003(6): 661-665. | |

| 17 | 赵玉珍, 雷永平, 史耀武. A-TIG焊中氧含量对熔池流动方式影响的数值模拟[J]. 金属学报, 2004, 40(10): 1085-1092. |

| Zhao Yu-zhen, Lei Yong-ping, Shi Yao-wu. Modeling of the effects of oxygen content on flow patterns in A-TIG welding[J]. Acta Metallurgica Sinica, 2004, 40(10): 1085-1092. |

| [1] | 回丽,金磊,宋万万,周松,安金岚. 转向架用SMA490BW钢不同焊接区域裂纹扩展速率[J]. 吉林大学学报(工学版), 2024, 54(3): 650-656. |

| [2] | 何银水,肖贺,罗沧海,张宇,余卓骅,袁海涛. 基于层次分析过程的厚板T形接头弧焊焊接位置自主决策[J]. 吉林大学学报(工学版), 2024, 54(3): 657-662. |

| [3] | 周晓,梁燚杰,奚中轩,王宇涛. 白车身B柱焊接变形模拟及预变形控制方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2212-2218. |

| [4] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [5] | 谷晓燕,隋成龙,狄星,孟政宇,朱开轩,楚长春. 焊接能量对铜/钛超声波焊接接头性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1669-1676. |

| [6] | 谷晓燕,刘东锋,刘婧,孙大千,马会峰. 焊接能量对Cu/Al超声波焊接接头组织与性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1600-1607. |

| [7] | 王春生, 邹丽, 杨鑫华. 基于邻域粗糙集的铝合金焊接接头疲劳寿命影响因素分析[J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

| [8] | 徐涛, 刘光洁, 葛海潮, 张炜, 于征磊. 焊接热源局部坐标移动曲线路径建模方法[J]. 吉林大学学报(工学版), 2014, 44(6): 1704-1709. |

| [9] | 黄健康1, 何翠翠1, 2, 石玗1, 樊丁1. 铝/钢异种金属焊接接头界面Al-Fe金属间化合物生成及其热力学分析[J]. 吉林大学学报(工学版), 2014, 44(4): 1037-1041. |

| [10] | 李欣,王刚,陆冠含,谷诤巍,徐虹. 22MnB5热成形钢板钨极氩弧焊接性能[J]. 吉林大学学报(工学版), 2014, 44(3): 708-711. |

| [11] | 谭越, 马文星, 卢秀泉. 基于流固耦合的冲焊型液力变矩器焊接强度分析[J]. 吉林大学学报(工学版), 2013, 43(04): 928-932. |

| [12] | 王文权, 商延赓, 李秀娟, 王春生, 张桂兰. 激光焊接650 MPa相变诱发塑性钢的组织与性能[J]. , 2012, 42(05): 1203-1207. |

| [13] | 谷诤巍, 于思彬, 韩立军, 孟佳, 沈永波, 徐虹. 激光焊接速度对超高强度钢焊缝微观组织和显微硬度的影响 [J]. , 2012, (03): 656-659. |

| [14] | 谷诤巍, 于思彬, 韩立军, 孟佳, 徐虹. 超高强度钢与低合金钢的激光搭接焊性能[J]. 吉林大学学报(工学版), 2012, 42(02): 349-353. |

| [15] | 白志范, 李桂中, 王超. S355J2W+N钢焊接接头显微组织与力学性能[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 202-204. |

|

||