吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (5): 1600-1607.doi: 10.13229/j.cnki.jdxbgxb20180340

• • 上一篇

焊接能量对Cu/Al超声波焊接接头组织与性能的影响

- 1. 吉林大学 材料科学与工程学院,长春130022

2. 河北艺博文化发展有限公司,石家庄050062

Effect of welding energy on microstructure and mechanical properties of Cu/Al joints welded by ultrasonic welding

Xiao-yan GU1( ),Dong-feng LIU1,Jing LIU1,Da-qian SUN1,Hui-feng MA2

),Dong-feng LIU1,Jing LIU1,Da-qian SUN1,Hui-feng MA2

- 1. College of Materials Science and Engineering, Jilin University, Changchun 130022, China

2. Hebei YiBo Culture Development Co. , Ltd. , Shijiazhuang 050062, China

摘要:

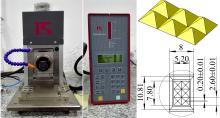

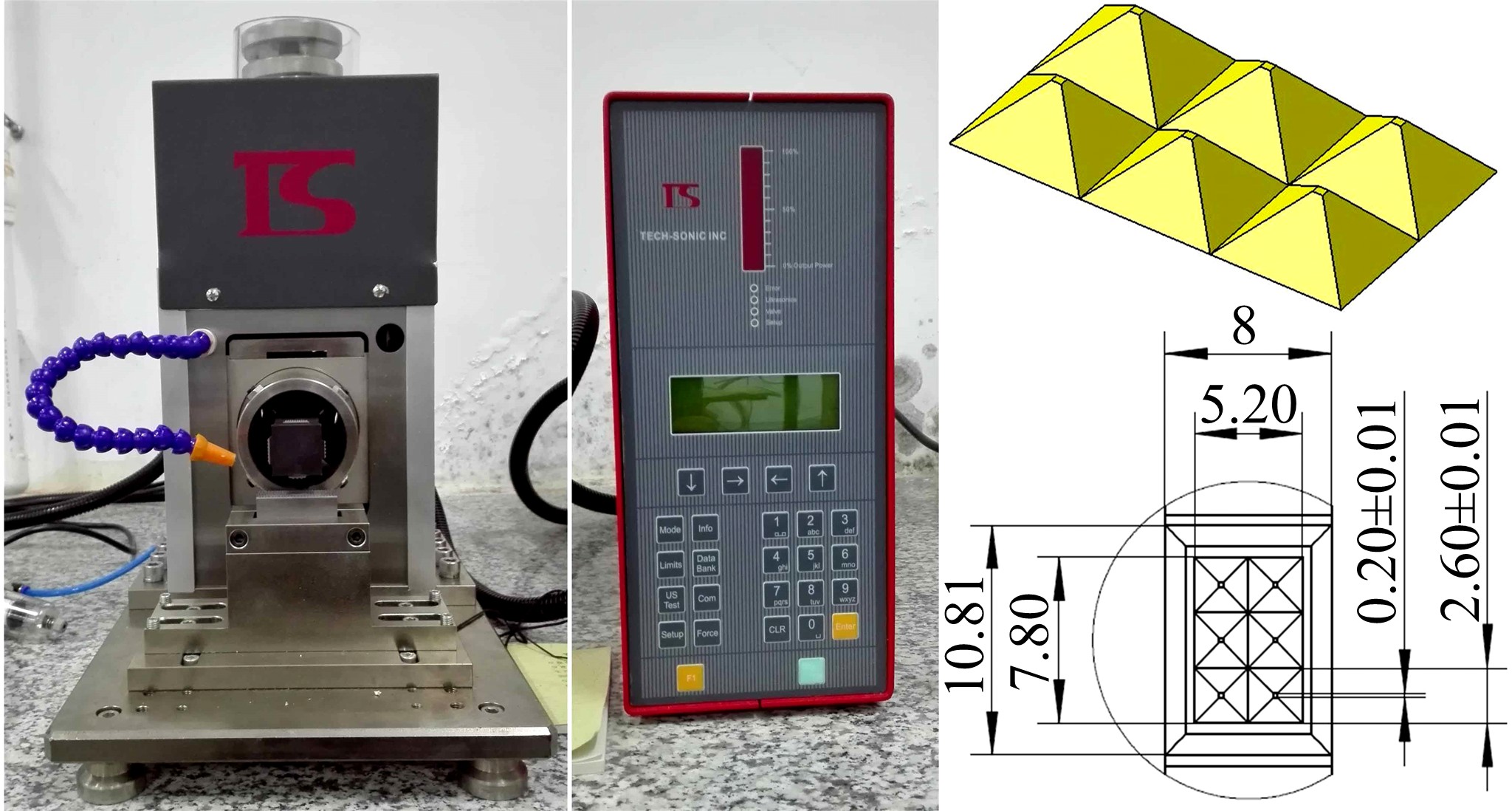

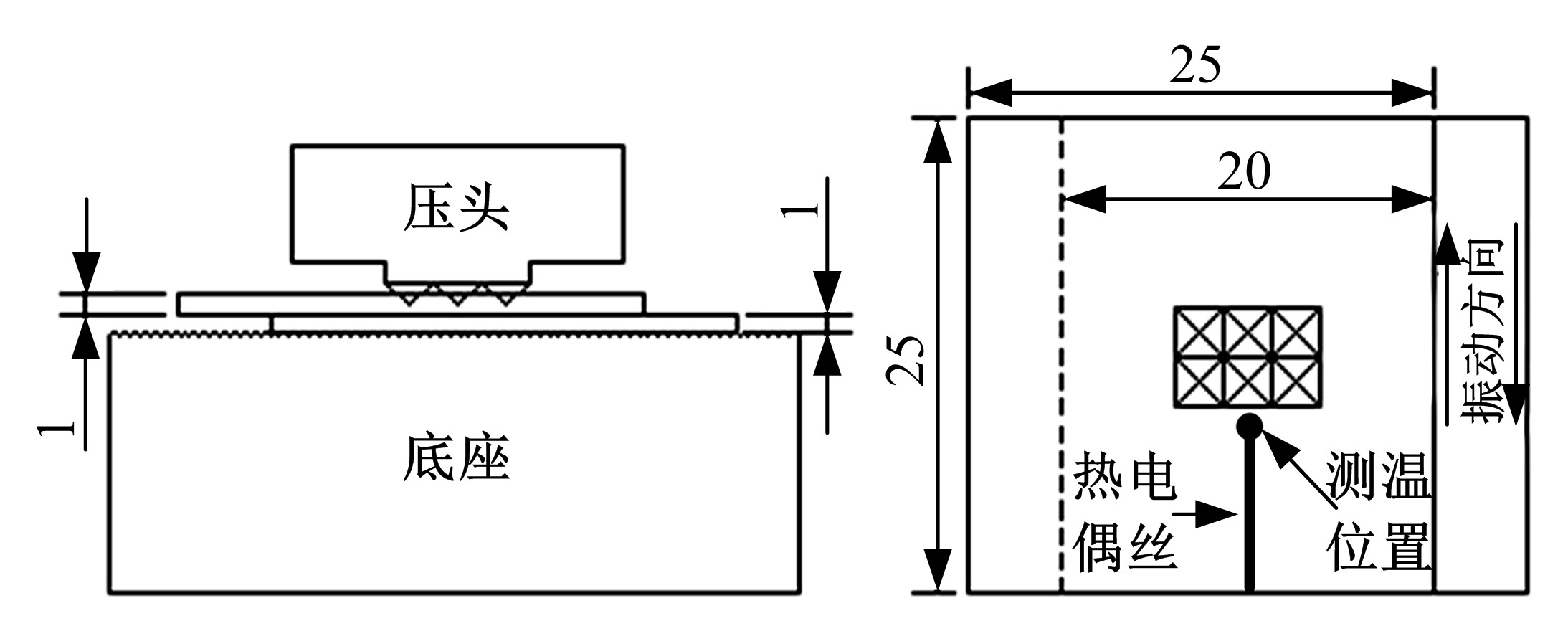

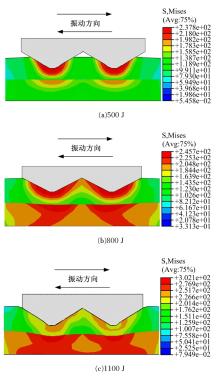

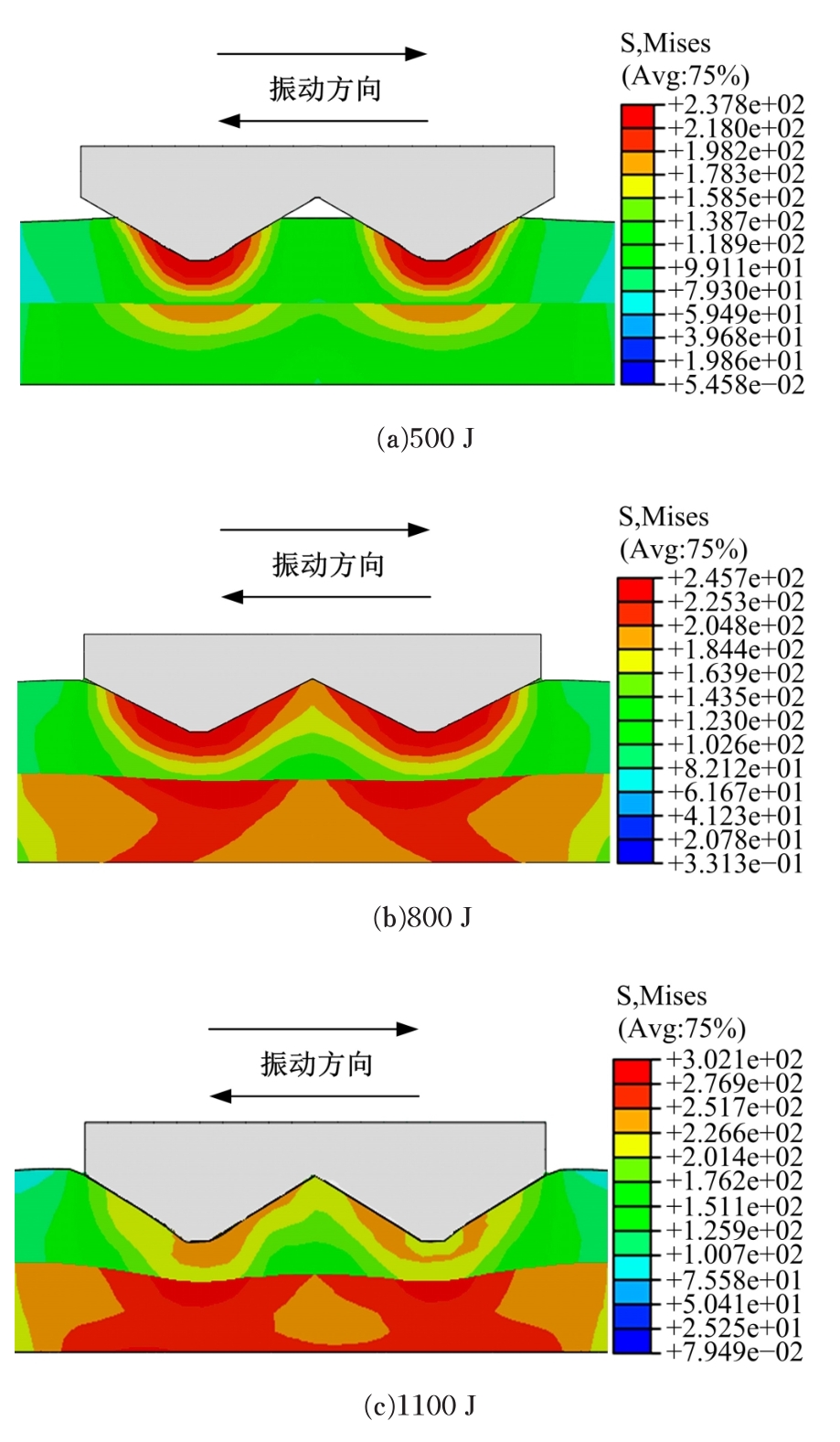

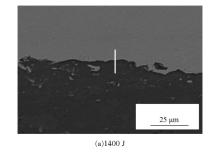

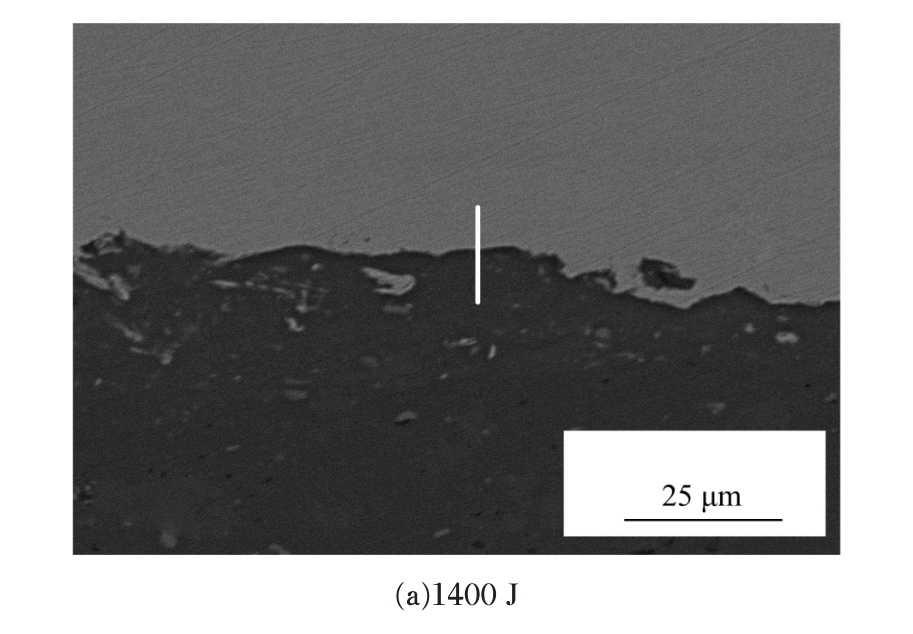

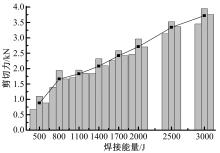

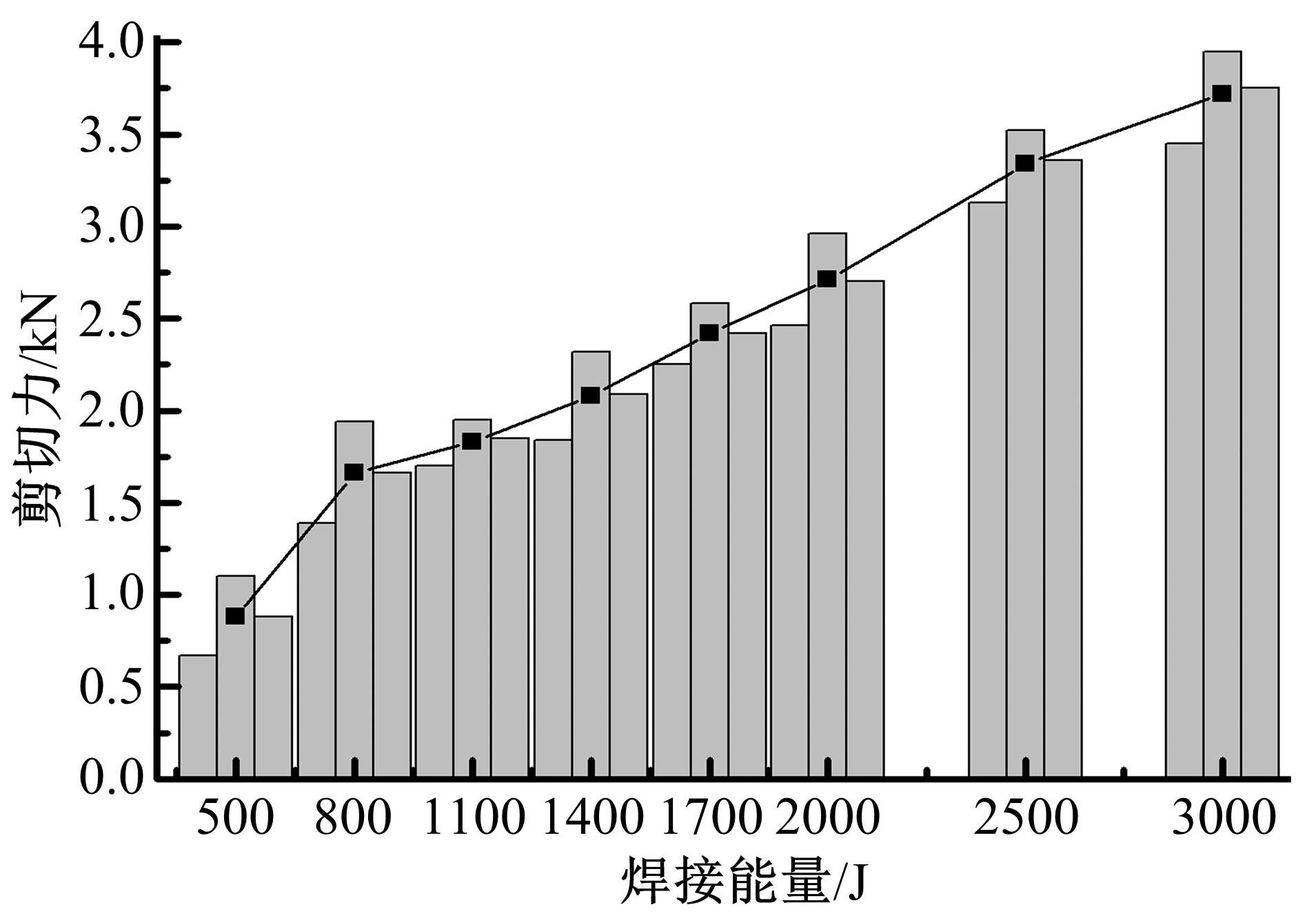

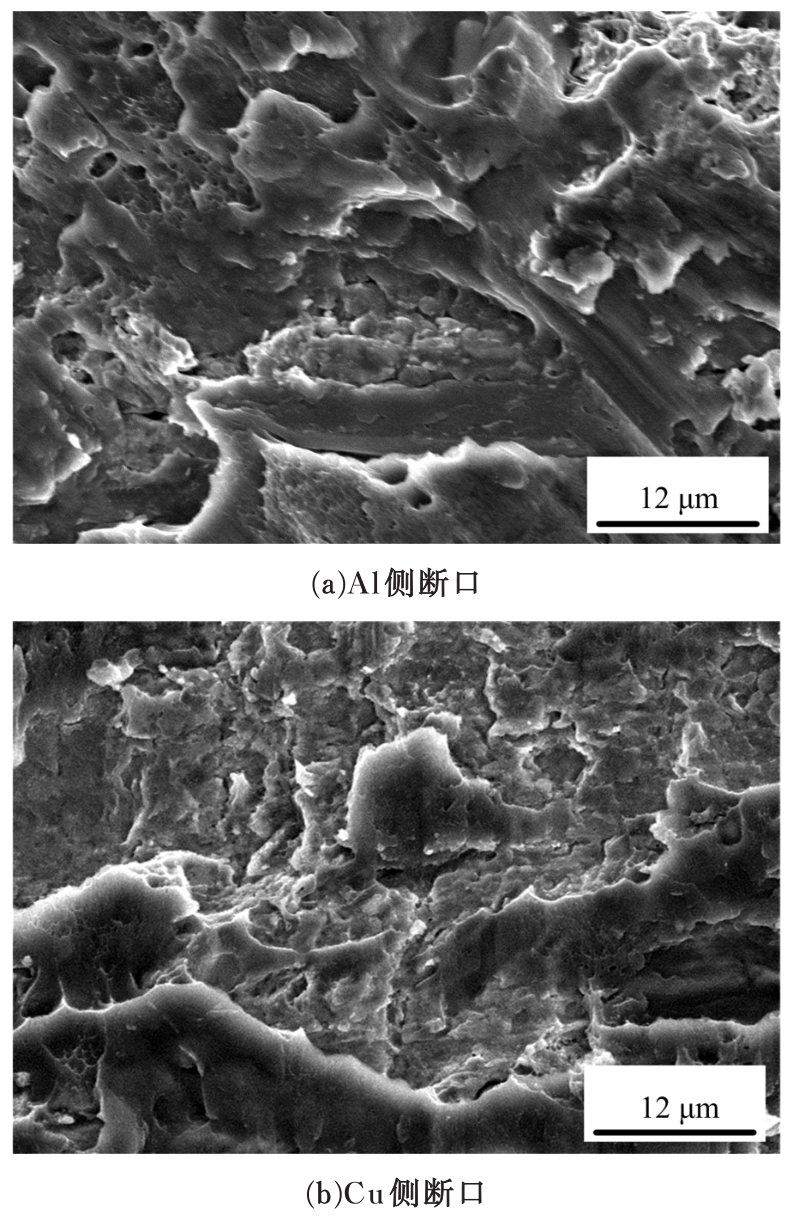

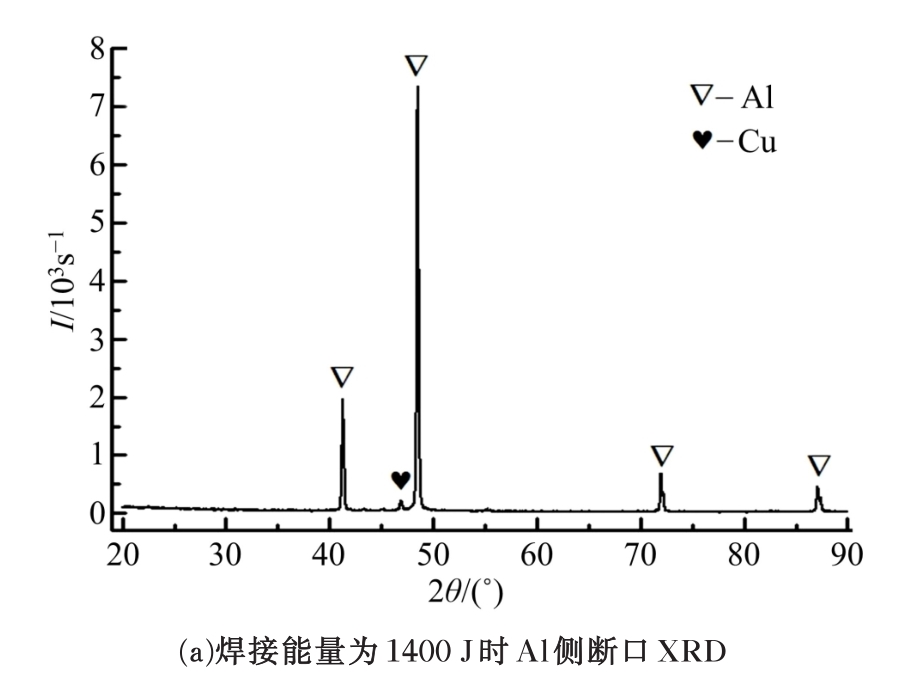

采用超声波焊接技术制备了Cu/Al异种金属搭接接头,运用UT-325型热电偶测温仪、光学显微镜(OM)、扫描电镜(SEM)、能谱仪(EDS)以及万能试验机对Cu/Al搭接接头进行了系统的研究。结果表明:随焊接能量增加Cu/Al界面处应力增大,导致界面摩擦力增大,产热量增加,原子活度和金属塑性流动能力相应增大,界面成形逐渐得到改善。此外,由于界面处应力分布不均,致使界面处金属发生塑性流动,形成漩涡状塑性变形。随焊接能量增大界面应力不均性更加显著,漩涡状塑性变形的程度增大。这种塑性变形会造成金属互锁,增大接头剪切力,接头最大剪切力达到3.72 kN。当焊接能量达到或高于1700 J时,Cu/Al界面处出现金属间化合物层,其主要组织为Al2Cu,接头断裂形式为韧-脆混合断裂。

中图分类号:

- TG453.9

| 1 | 田尤, 杨为民, 申俊峰, 等. 中国铜资源产业形势分析及发展对策建议[J]. 资源与产业, 2015, 17(4): 100-105. |

| TianYou, YangWei-min, ShenJun-feng, et al. Analysis and recommendations of Chinese copper resources industry situation[J]. Resour & Industries, 2015, 17(4): 100-105. | |

| 2 | FeiXin-jiang, YeYing, JinLiang-liang, et al. Special welding parameters study on Cu/Al joint in laser-heated friction stir welding[J]. Journal of Materials Processing Technology, 2018, 256: 160-171. |

| 3 | HailatM M, MianA, ChaudhuryZ A, et al. Laser micro-welding of aluminum and copper with and without tin foil alloy[J]. Microsystem Technologies, 2012, 18(1): 103-112. |

| 4 | MatsuokaS, ImaiH. Direct welding of different metals used ultrasonic vibration[J]. Journal of Materials Processing Technology, 2009, 209(2): 954-960. |

| 5 | 夏春智, 李亚江, 王娟. Cu/Al异种金属连接的研究现状[J]. 焊接, 2008(1): 17-20. |

| XiaChun-zhi, LiYa-jiang, WangJuan. Research status of joining of Cu/Al dissimilar metals[J]. Welding & Joining, 2008(1): 17-20. | |

| 6 | KoyamaK, ShinozakiK, IkedaK, et al. Evaluation of brazing properties using Al-Si-Mg-Bi brazing alloy—Development of brazing technique for Al-Cu dissimilar joint (Part 1)[J]. Journal of Light Metal Welding & Construction, 2002, 40(9): 13-20. |

| 7 | MysI, SchmidtM. Laser micro welding of copper and aluminum[J]. Proceedings of SPIE—The International Society for Optical Engineering, 2006, 6107: 28-33. |

| 8 | LiH, CaoB, YangJ W, et al. Modeling of resistance heat assisted ultrasonic welding of Cu-Al joint[J]. Journal of Materials Processing Technology, 2018, 256: 121-130. |

| 9 | 左迪. 铜-铝异种金属激光焊接研究[D]. 天津: 天津大学材料科学与工程学院, 2014. |

| ZuoDi. Research on dissimilar material laser welding between Cu and Al[D]. Tianjing: School of Materials Science and Engineering, Tianjin University, 2014. | |

| 10 | ChenQ, LinS, YangC, et al. Grain fragmentation in ultrasonic-assisted TIG weld of pure aluminum[J]. Ultrasonics Sonochemistry, 2017, 39: 403-413. |

| 11 | SatoY S, UrataM, KokawaH. Parameters controlling microstructure and hardness during friction-stir welding of precipitation-hardenable aluminum alloy 6063[J]. Metallurgical & Materials Transactions A, 2002, 33(3): 625-635. |

| 12 | UeokaT, TsujinoJ. Welding characteristics of aluminum and copper plate specimens welded by a 19 kHz complex vibration ultrasonic seam welding system[J]. Japanese Journal of Applied Physics, 2002, 41(1): 32-37. |

| 13 | MatsuokaS, ImaiH. Direct welding of different metals used ultrasonic vibration[J]. Journal of Materials Processing Technology, 2009, 209(2): 954-960. |

| 14 | FloodG. Ultrasonic energy welds copper to aluminum[J]. Welding Journal, 1997, 76(1): 43-45. |

| 15 | PretoriusR, VredenbergA M, SarisF W, et al. Prediction of phase formation sequence and phase stability in binary metal-aluminium thin-film systems using the effective heat of formation[J]. Journal of Applied Physics, 1991, 70(7): 3636-3646. |

| 16 | BraunovicM, AleksandrovN. Effect of electrical current on the morphology and kinetics of formation of intermetallic phases in bimetallic aluminum-copper joints[C]∥IEEE Holm Conference on Electrical Contacts, Pittsburgh, PA, 1993: 261-268. |

| [1] | 依卓,付文智,李明哲. 双层剖分式超高压模具数值模拟及实验[J]. 吉林大学学报(工学版), 2019, 49(5): 1593-1599. |

| [2] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [3] | 刘文权,盈亮,荣海,胡平. 基于损伤修正M⁃K模型的高强度钢成形极限预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1266-1271. |

| [4] | 张学广,贾明萌,刘纯国,何广忠. 基于增量控制的型材拉弯轨迹设计及有限元仿真[J]. 吉林大学学报(工学版), 2019, 49(4): 1272-1279. |

| [5] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [6] | 戴岩, 聂少锋, 周天华. 带环梁的方钢管约束钢骨混凝土柱-钢梁节点滞回性能有限元分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1426-1435. |

| [7] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [8] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [9] | 陈俊甫, 管志平, 杨昌海, 牛晓玲, 姜振涛, 宋玉泉. 金属棒试样拉伸和扭转试验应变范围和力学特性对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

| [10] | 梁晓波, 蔡中义, 高鹏飞. 夹芯复合板柱面成形的数值模拟及试验[J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [11] | 刘子武, 李剑峰. 叶片材料FV520B再制造熔覆层冲蚀损伤行为及评价[J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [12] | 刘纯国, 刘伟东, 邓玉山. 多点冲头主动加载路径对薄板拉形的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [13] | 吕萌萌, 谷诤巍, 徐虹, 李欣. 超高强度防撞梁热冲压成形工艺优化[J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [14] | 王辉, 周杰, 熊煜, 陶亚平, 向荣. 基于逆向工程的复杂曲面冲压件回弹补偿[J]. 吉林大学学报(工学版), 2017, 47(6): 1842-1847. |

| [15] | 张志强, 刘从豪, 何东野, 李湘吉, 李纪萱. 基于性能梯度分布的硼钢热冲压工艺对形状精度的影响[J]. 吉林大学学报(工学版), 2017, 47(6): 1829-1833. |

|

||