吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (8): 2181-2186.doi: 10.13229/j.cnki.jdxbgxb.20221360

轿车前轴摇臂衬套仿生柔性接触表面摩擦特性数值模拟

- 1.吉林大学 材料科学与工程学院,长春 130022

2.吉林大学 重庆研究院,重庆 401123

Numerical simulation on friction characteristics of rubber bushing with bionic flexible surfaces

Ce LIANG1( ),Min LI1,Yi LI1,2,Ji-cai LIANG1,2,Qi-gang HAN1(

),Min LI1,Yi LI1,2,Ji-cai LIANG1,2,Qi-gang HAN1( )

)

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Chongqing Research Institute,Jilin University,Chongqing 401123,China

摘要:

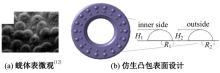

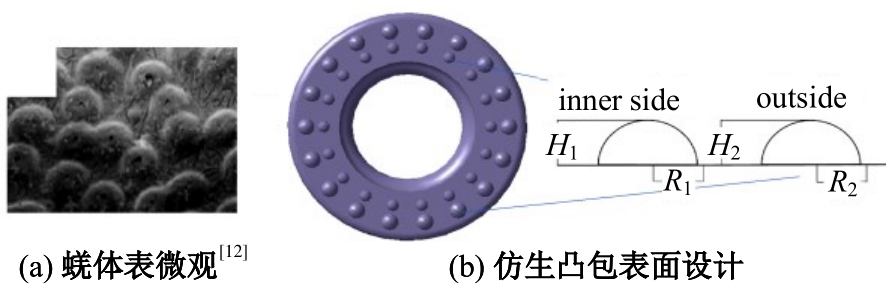

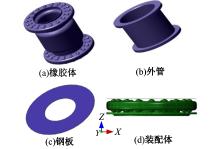

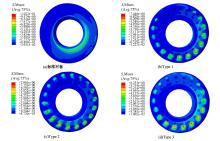

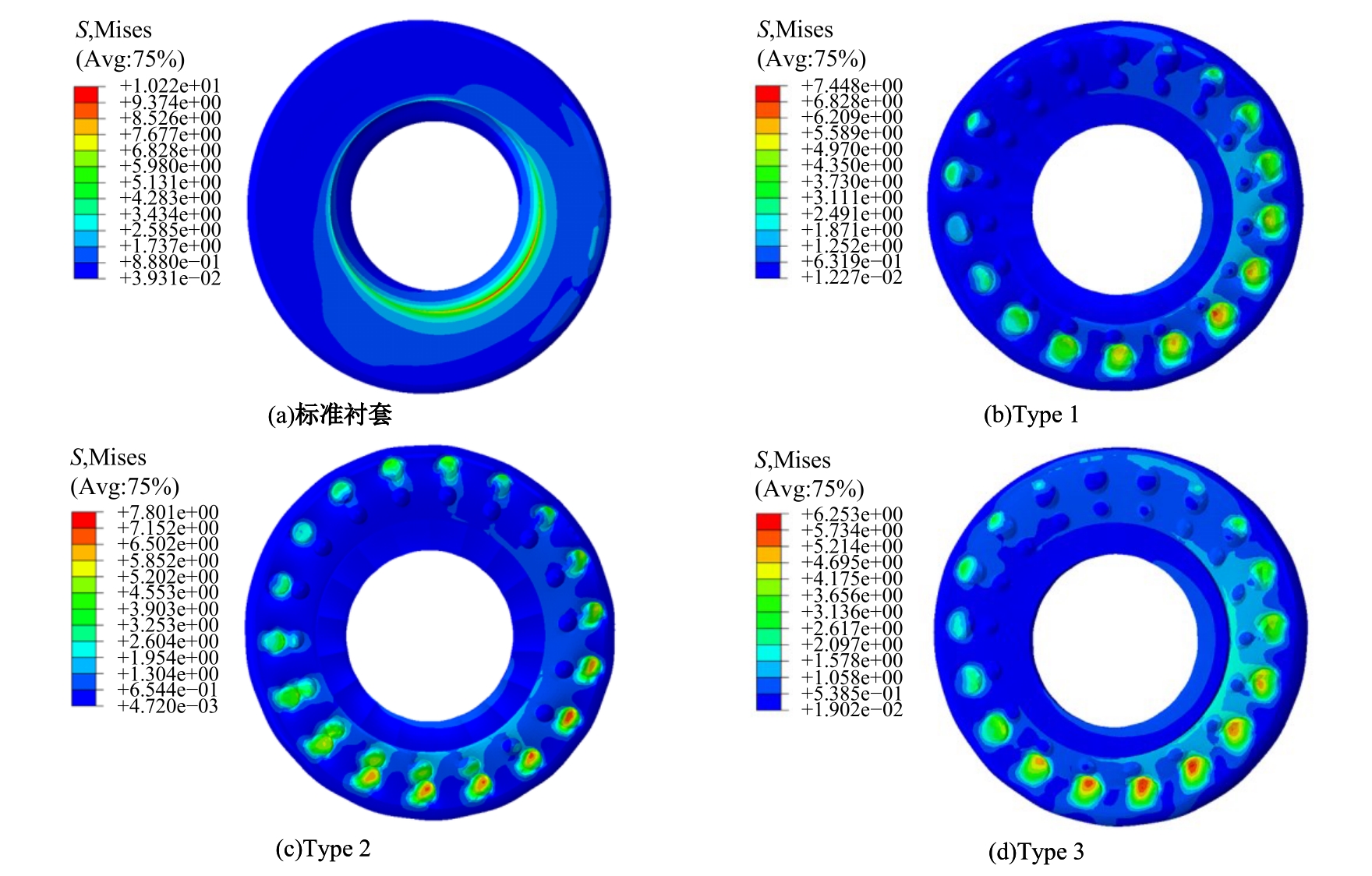

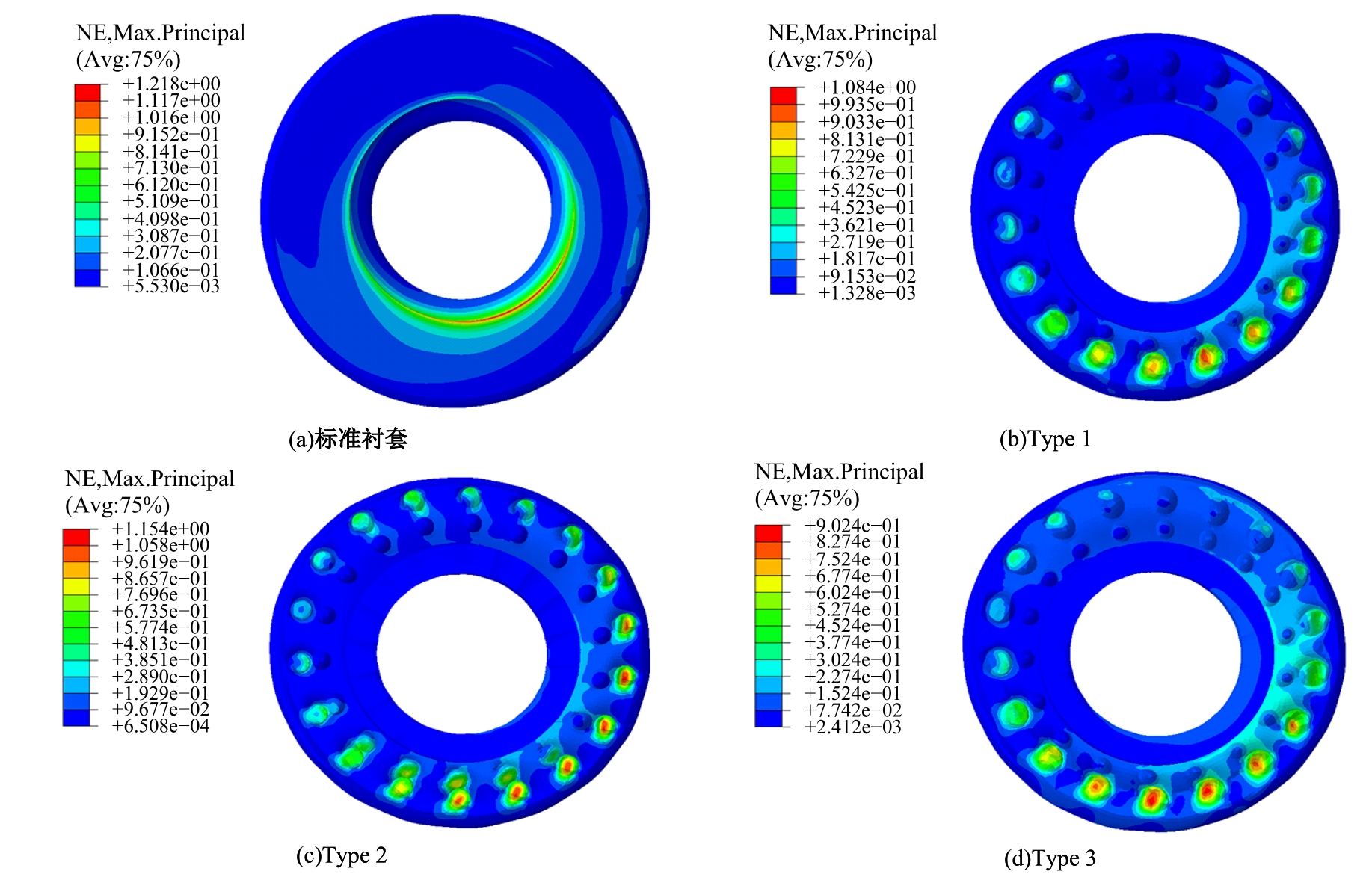

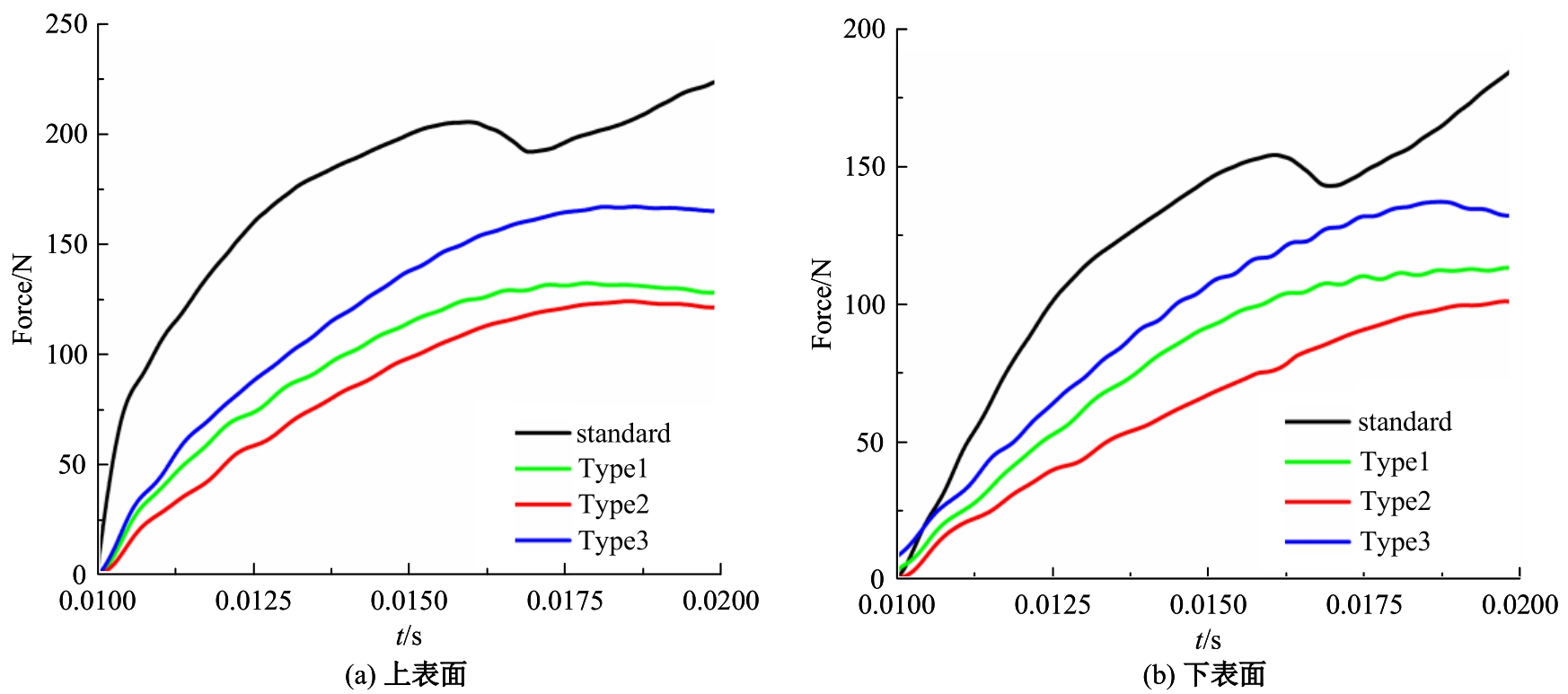

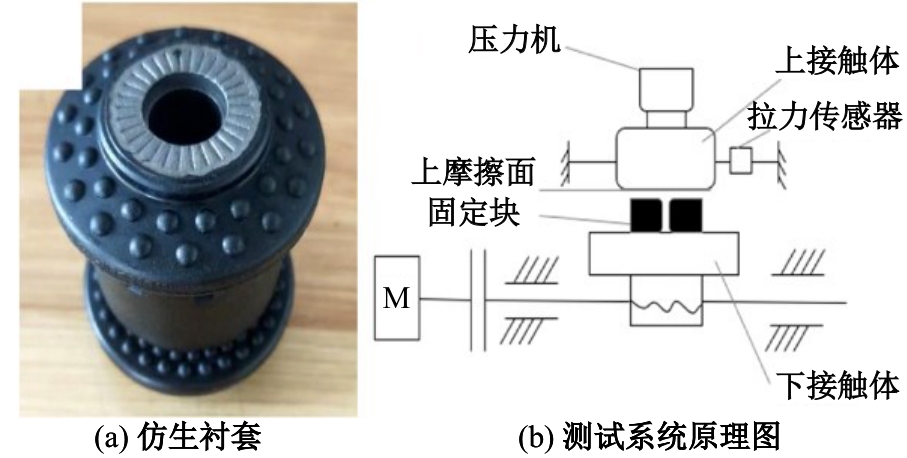

基于有限元软件ABAQUS,建立了表面具有类蜣螂头部凸包结构的轿车前轴摇臂衬套的柔性摩擦副摩擦过程的有限元模型,并对其摩擦特性进行验证。通过筛选合适的超弹性本构模型和改变衬套表面凸包结构的尺寸,模拟分析柔性摩擦副径向和扭转方向的力学特性变化规律。结果表明:仿生凸包设计改变了衬套受力时的最大应力和应变位置,降低了橡胶衬套开裂的可能性;仿生衬套表面的接触摩擦力和摩擦系数明显减小,其中Type2模型表面的减阻耐磨效果最好。

中图分类号:

- TG356

| 1 | Kentaro H, Shinichi S. Rubber suspension bushing model identified by general design parameters for initial design phase[J]. SAE International Journal of Vehicle Dynamics, Stability, and NVH, 2018, 2(4): 325-335. |

| 2 | Rivas T, Jonathan T M, Juan C, et al. Analytical design and optimization of an automotive rubber bushing[J]. Shock & Vibration, 2019, 2019: 1-13. |

| 3 | Kemna J, Edelmann J, Ploechl M. Influences on long-term behaviour of elastomer chassis bushings considering their geometric design and rubber compounds[J]. Polymer Testing, 2018, 65: 69-77. |

| 4 | 邓雄志,刘涛,苏泽博. 轿车底盘橡胶衬套半经验设计方法研究[J]. 汽车技术, 2018, 7: 54-58. |

| Deng Xiong-zhi, Liu Tao, Su Ze-bo. Research on half-empirical methodology of car chassis rubber bush[J]. Automobile Technology, 2018, 7: 54-58. | |

| 5 | 张海莉. 控制臂舒适性液压衬套的优化设计[J]. 汽车与新动力, 2022, 5(4): 66-70. |

| Zhang Hai-li. Optimal design of comfortable hydraulic bushing for control arm[J]. Automobile and New Powertrain, 2022, 5(4): 66-70. | |

| 6 | 童华,陈国银,祝效华. 谐壁厚螺杆钻具橡胶衬套线型设计与仿真分析[J]. 系统仿真学报, 2018, 2: 647-653. |

| Tong Hua, Chen Guo-yin, Zhu Xiao-hua. Linear design and simulation analysis for harmonic-distance rubber bushing of PDM[J]. Journal of System Simulation, 2018, 2: 647-653. | |

| 7 | Jia H L, Wang W J, Wang W P, et al. Application of anti-adhesion structure based on earthworm motion characteristics[J]. Soil and Tillage Research, 2018, 178(1): 159-166. |

| 8 | Gu Y Q, Zhao G, Liu H, et al. Characteristics of seal shell body's rubber ring with bionic dimpled surfaces of aerodynamic extinguishing cannon[J]. Journal of Central South University, 2013, 20(11): 3065-3076. |

| 9 | Peifer R, Lungarella M, Iida F. Self-organization, embodiment, and biologically inspired robotics[J]. Science, 2007, 318: 1088-1093. |

| 10 | Wang Z Z, Zhang Z H, Sun Y H, et al. Wear behavior of bionic impregnated diamond bits[J]. Tribology International, 2016, 94: 217-222. |

| 11 | 任露泉,丛茜,陈秉聪, 等. 几何非光滑典型生物体表防粘特性的研究[J]. 农业机械学报, 1992, 2: 29-35. |

| Ren Lu-quan, Cong Qian, Chen Bing-cong, et al. A study on the adhesion reducing character of geometric nonsmooth surface of typical animaL[J]. Transactions of the Chinese Society of Agricultural Machinery, 1992, 2: 29-35. | |

| 12 | 贾贤,任露泉,佟金, 等. 土壤动物体表非光滑对体表润湿性的影响[J]. 农业工程学报, 1995, 11: 1-4. |

| Jia Xian, Ren Lu-quan, Tong Jin, et al. Affectionsofsoilanimal´sunsmoothcuticlesonthewettabilityofthecuticles[J]. Transactions of The Chinese Society of Agricultural Engineering, 1995, 11: 1-4. | |

| 13 | 高晋,宋传学. 橡胶衬套刚度对悬架特性的影响[J]. 吉林大学学报: 工学版, 2010, 40(2): 324-329. |

| Gao Jin, Song Chuan-xue. Influence of rubber bushing stiffness on suspension performance[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(2): 324-329. | |

| 14 | 梁继才,孙磊明,刘天宝,等. 多巴胺改性硅炭黑增强橡胶复合材料性能[J]. 吉林大学学报: 工学版, 2022, 52(5): 1030-1036. |

| Liang Ji-cai, Sun Lei-ming, Liu Tian-bao, et al. Performance of dopamine modified silicon carbon black reinforced rubber composite[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(5): 1030-1036. |

| [1] | 韩笑,凌贤长,田爽,丛晟亦. 高铁有砟轨道路基注浆过程冒浆分析和控制[J]. 吉林大学学报(工学版), 2024, 54(2): 506-515. |

| [2] | 张永忠,马云海. 具有高效吸能特性的新型仿蜂窝多级薄壁结构[J]. 吉林大学学报(工学版), 2024, 54(1): 259-267. |

| [3] | 梁策,黄富雷,梁继才,李义. 日字形防护梁绕弯成形形变数值模拟[J]. 吉林大学学报(工学版), 2023, 53(12): 3397-3403. |

| [4] | 邹猛,郭子琦,陈朕,曹洪涛,朱建中,徐丽涵. 模拟月尘与典型金属材料摩擦磨损特性试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2307-2315. |

| [5] | 翁小辉,孙友宏,张书军,谢军,常志勇. 基于仿生鼻腔优化的油气检测方法与实验新技术[J]. 吉林大学学报(工学版), 2020, 50(1): 382-388. |

| [6] | 陈东良,臧睿,段鹏,赵伟鹏,翁旭涛,孙杨,唐艺鹏. 基于新月鱼尾推进理论的多连杆鱼骨仿生设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1246-1257. |

| [7] | 钱志辉, 周亮, 任雷, 任露泉. 具有仿生距下关节和跖趾关节的完全被动步行机[J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [8] | 陈东辉, 刘伟, 吕建华, 常志勇, 吴婷, 慕海锋. 基于虾夷扇贝体表结构的玉米茬根捡拾器仿生设计[J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

| [9] | 周杰, 罗艳, 王珣, 王辉, 李洋, 陶亚平. 基于响应面的封头冲压成形工艺多目标优化[J]. 吉林大学学报(工学版), 2016, 46(1): 205-212. |

| [10] | 高晋, 宋传学. 橡胶衬套刚度对悬架特性的影响[J]. 吉林大学学报(工学版), 2010, 40(02): 324-0329. |

| [11] | 郭孔辉;王爽;丁海涛;张建伟 . 后悬架非对称式橡胶衬套弹性耦合特性[J]. 吉林大学学报(工学版), 2007, 37(06): 1225-1228. |

| [12] | 杨树凯,宋传学,安晓娟,蔡章林 . 用虚拟样机方法分析悬架衬套弹性对 整车转向特性的影响[J]. 吉林大学学报(工学版), 2007, 37(05): 994-0999. |

|