吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2733-2740.doi: 10.13229/j.cnki.jdxbgxb.20221407

• 农业工程·仿生工程 • 上一篇

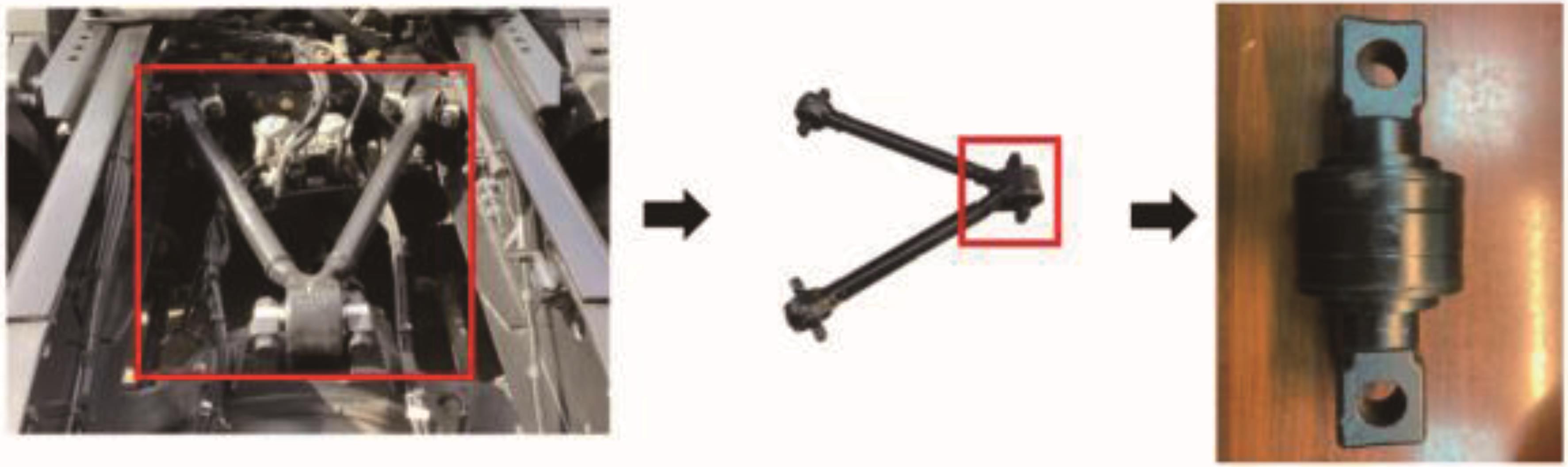

推力杆球铰仿生表面改进及有限元分析

- 吉林大学 材料科学与工程学院,长春 130022

Thrust rod ball hinge bionic surface improvement and finite element analysis

Hua-min LIU( ),Shu-han YANG,Yi LI,Ce LIANG,Qi-gang Han(

),Shu-han YANG,Yi LI,Ce LIANG,Qi-gang Han( )

)

- College of Materials Science and Engineering,Jilin University,Changchun 130022,China

摘要:

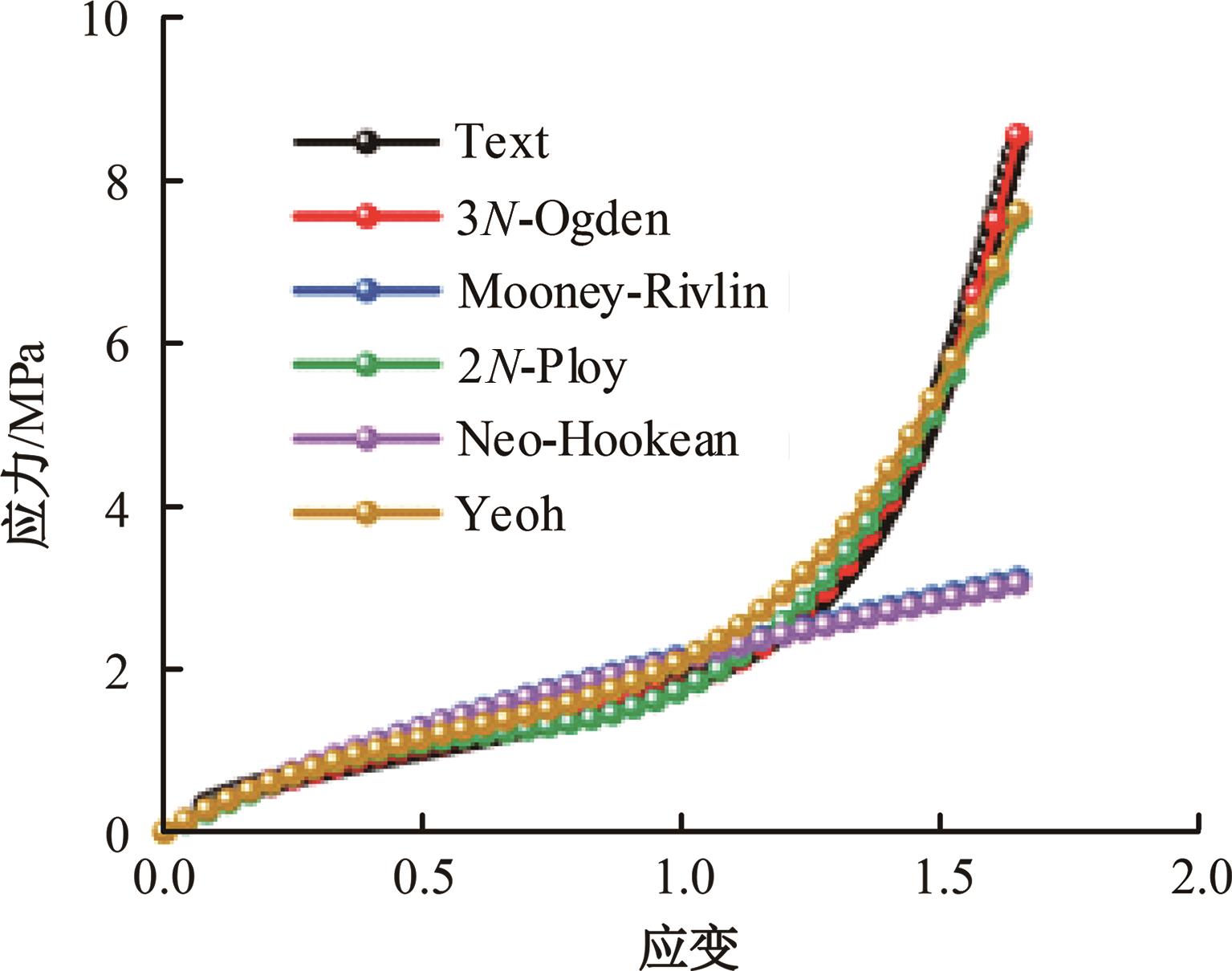

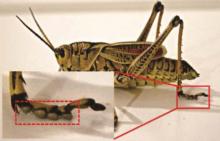

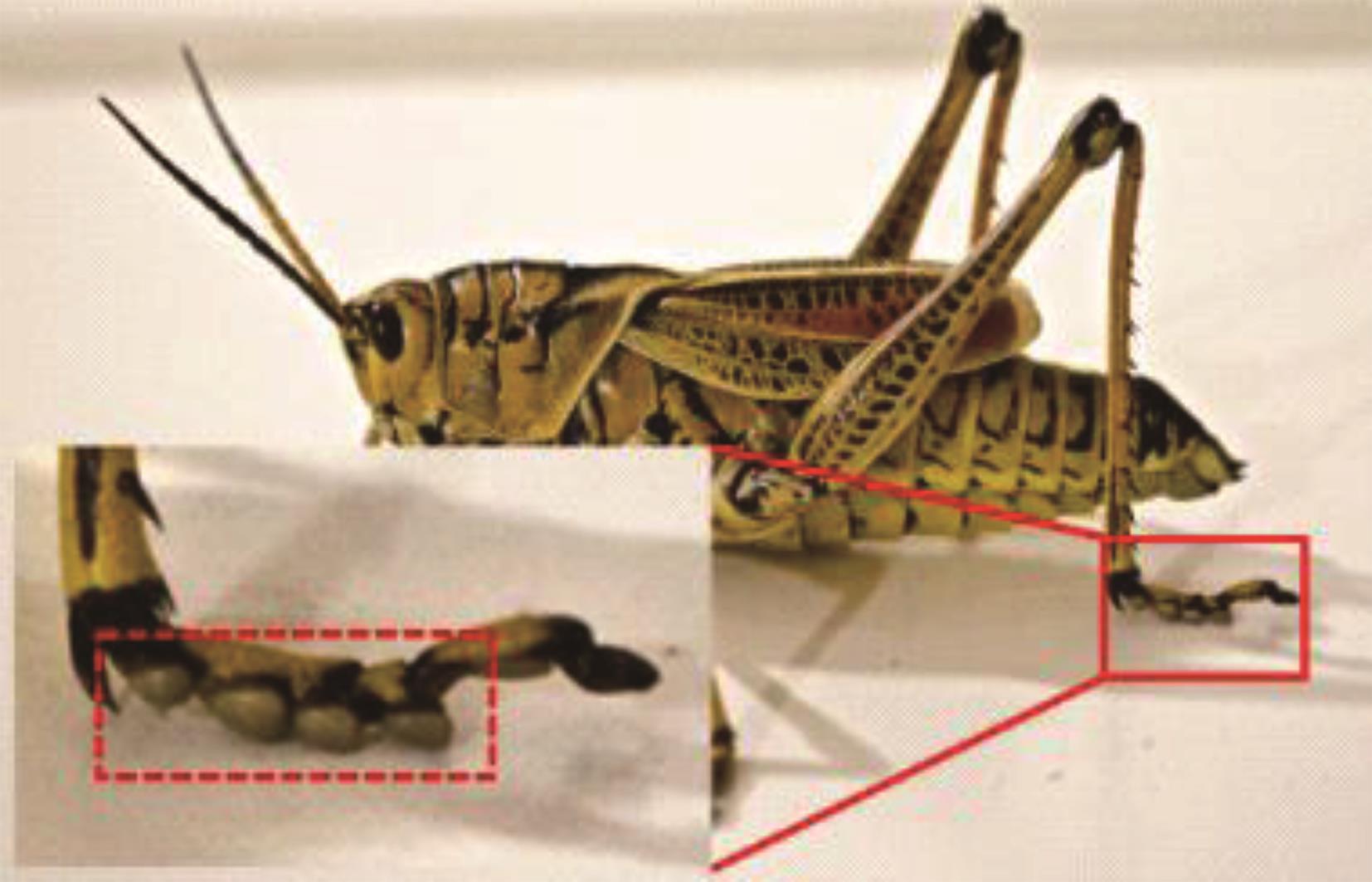

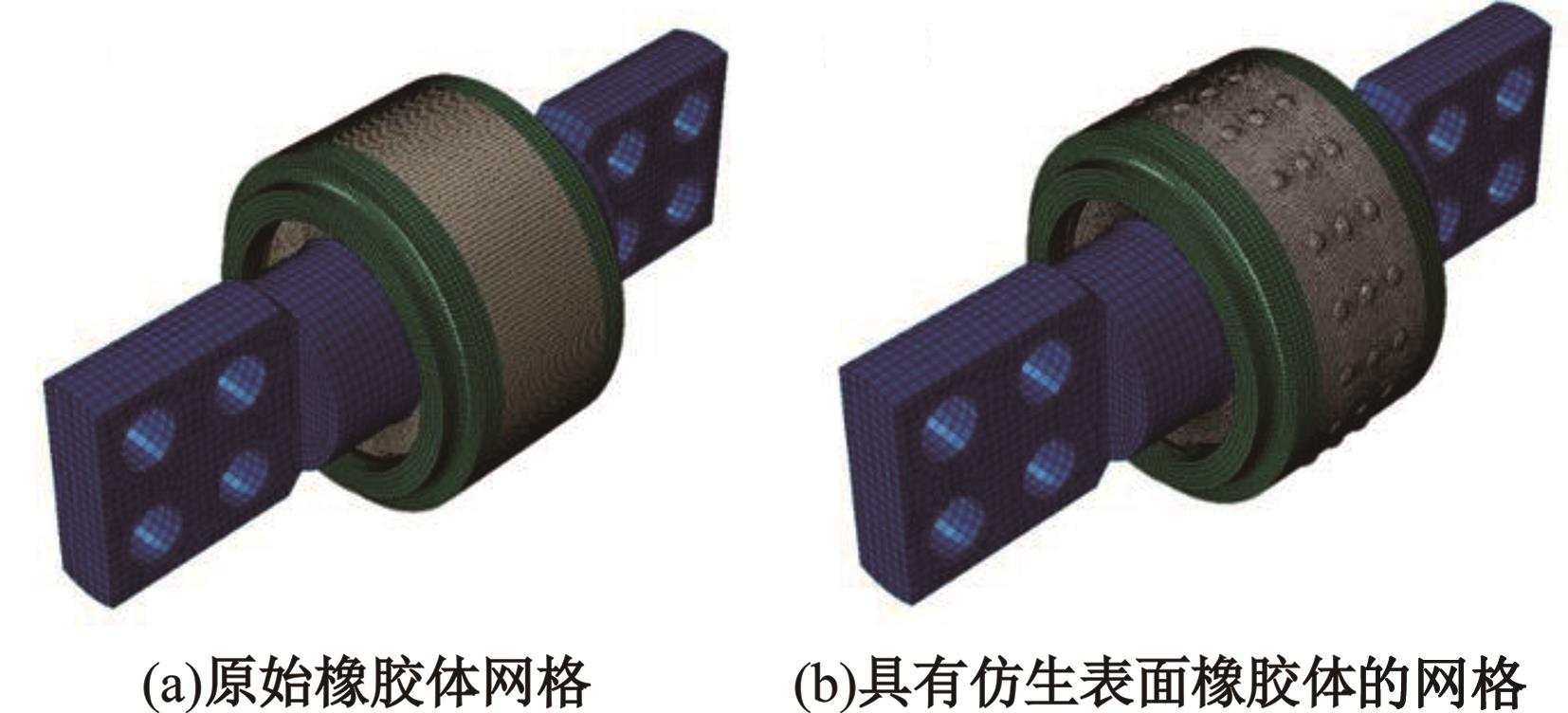

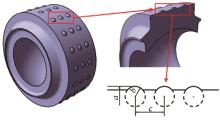

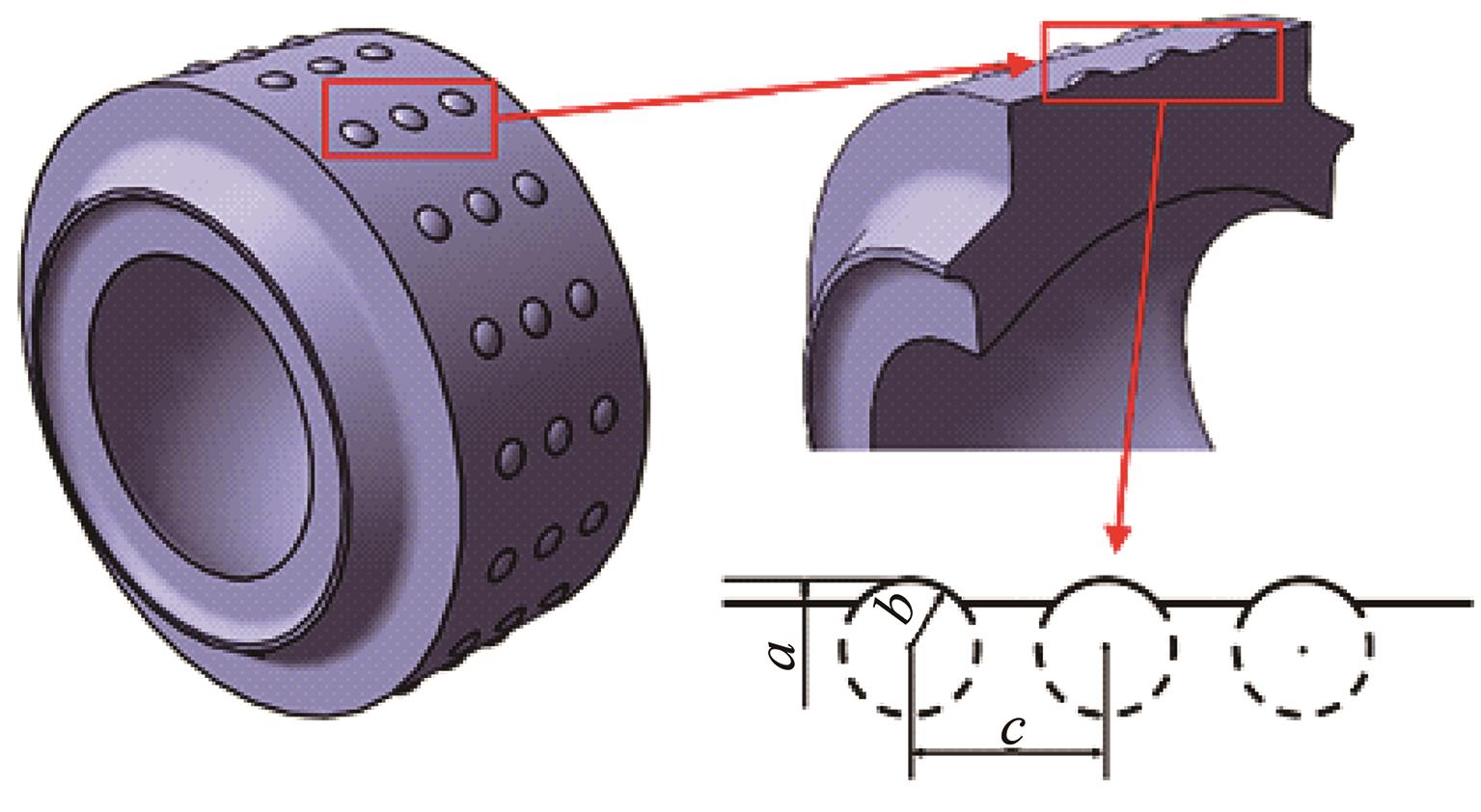

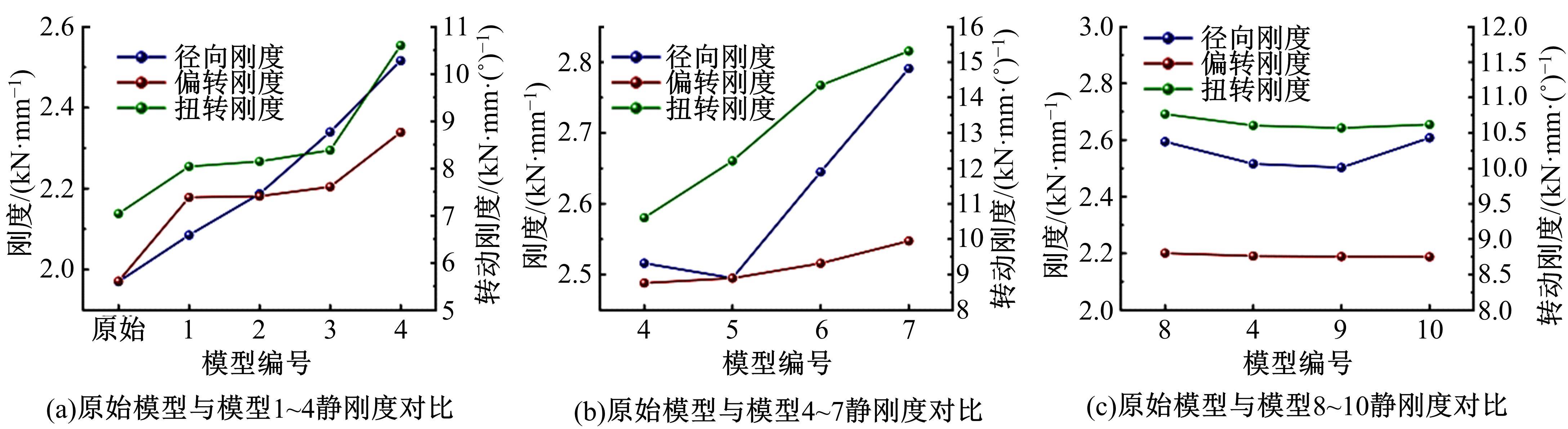

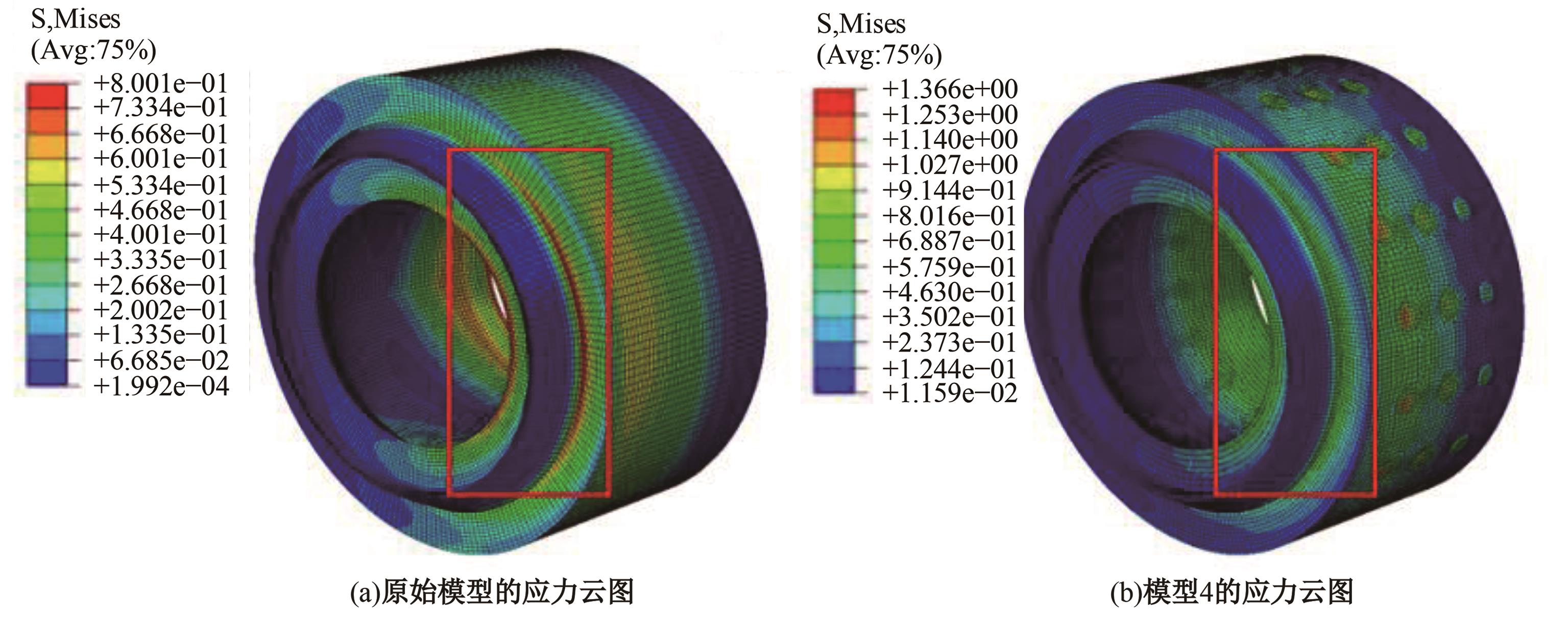

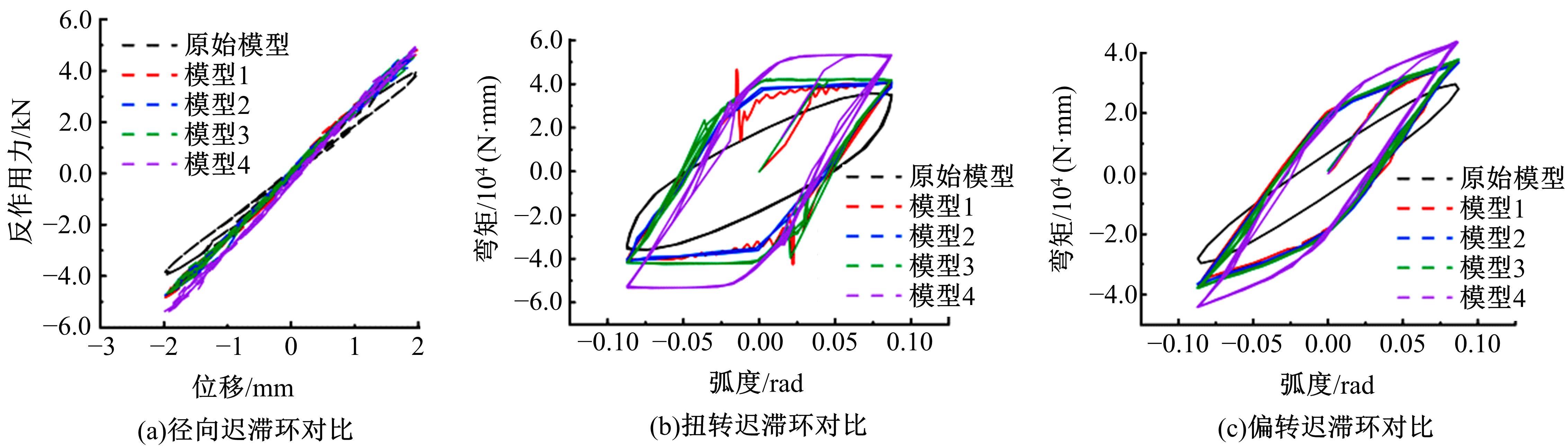

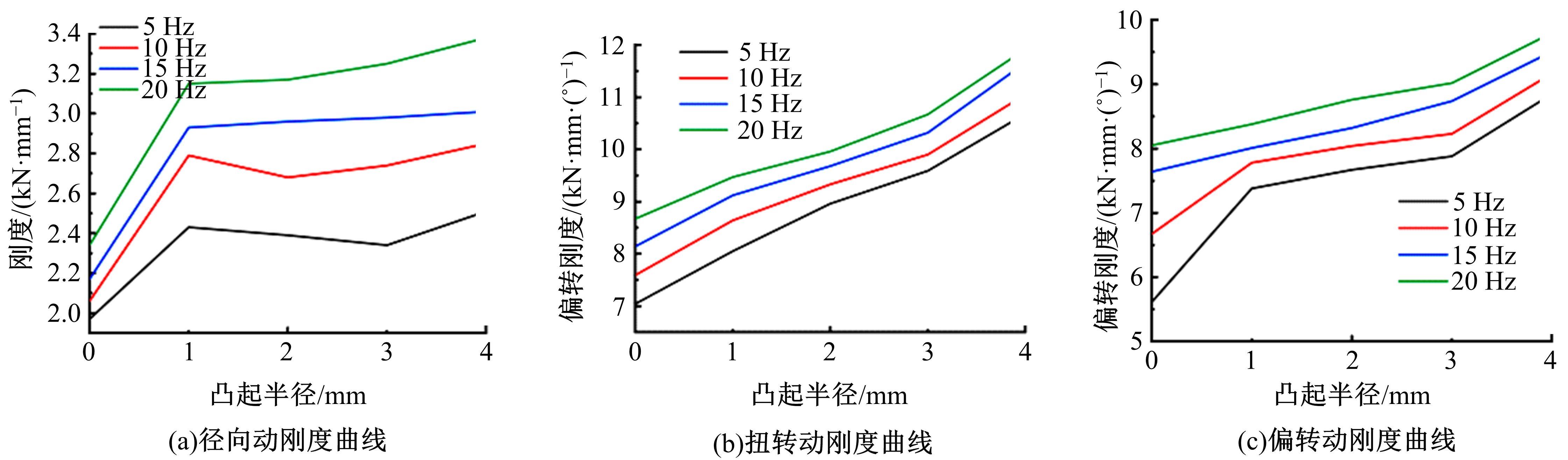

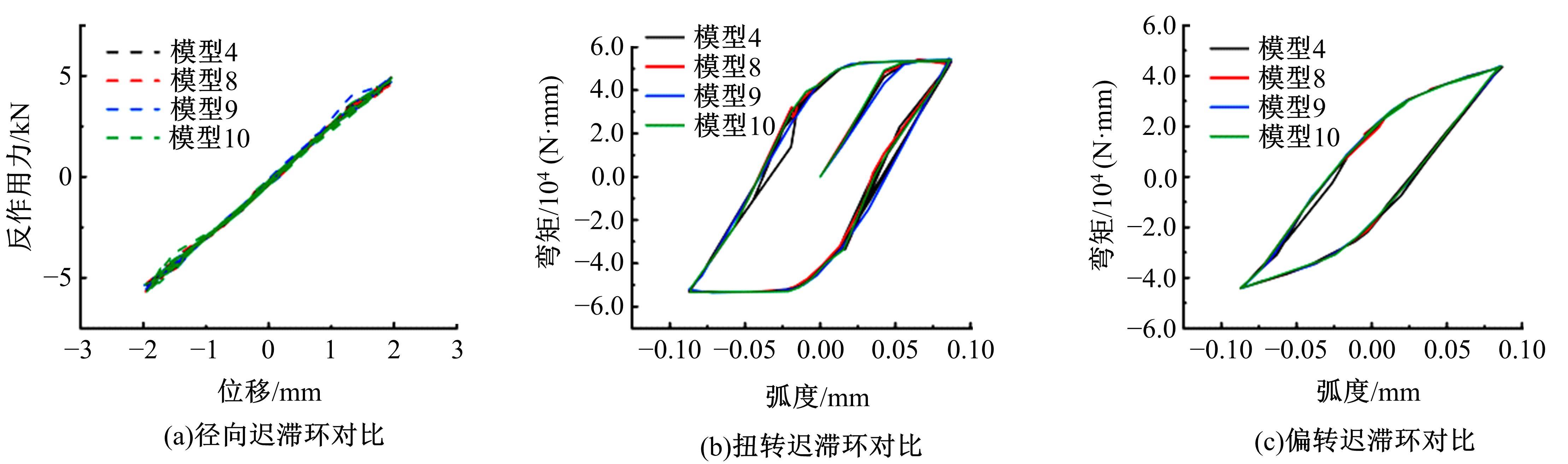

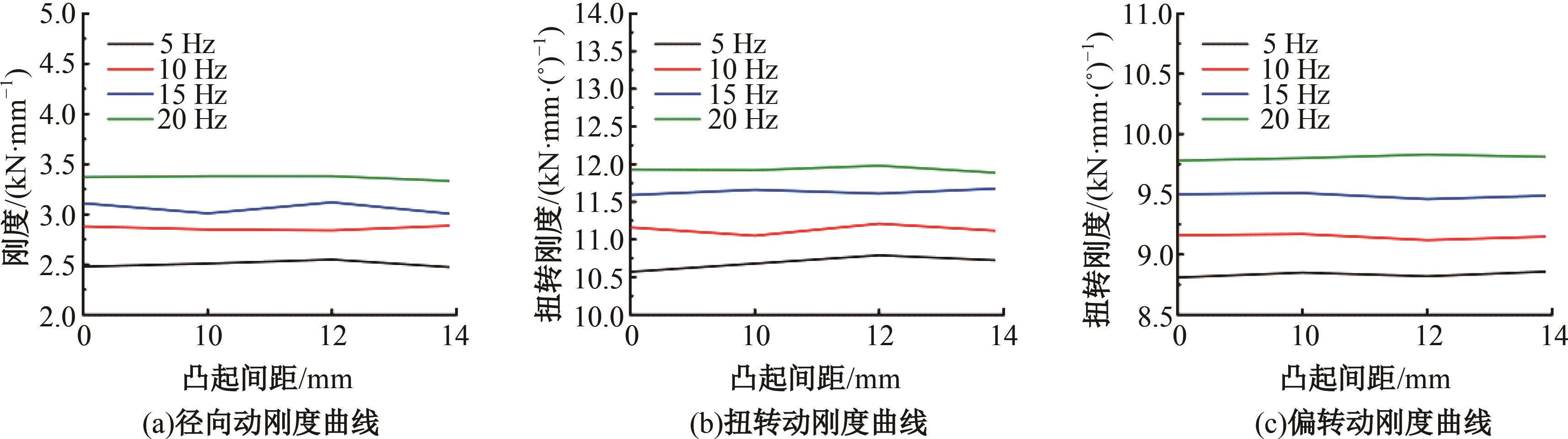

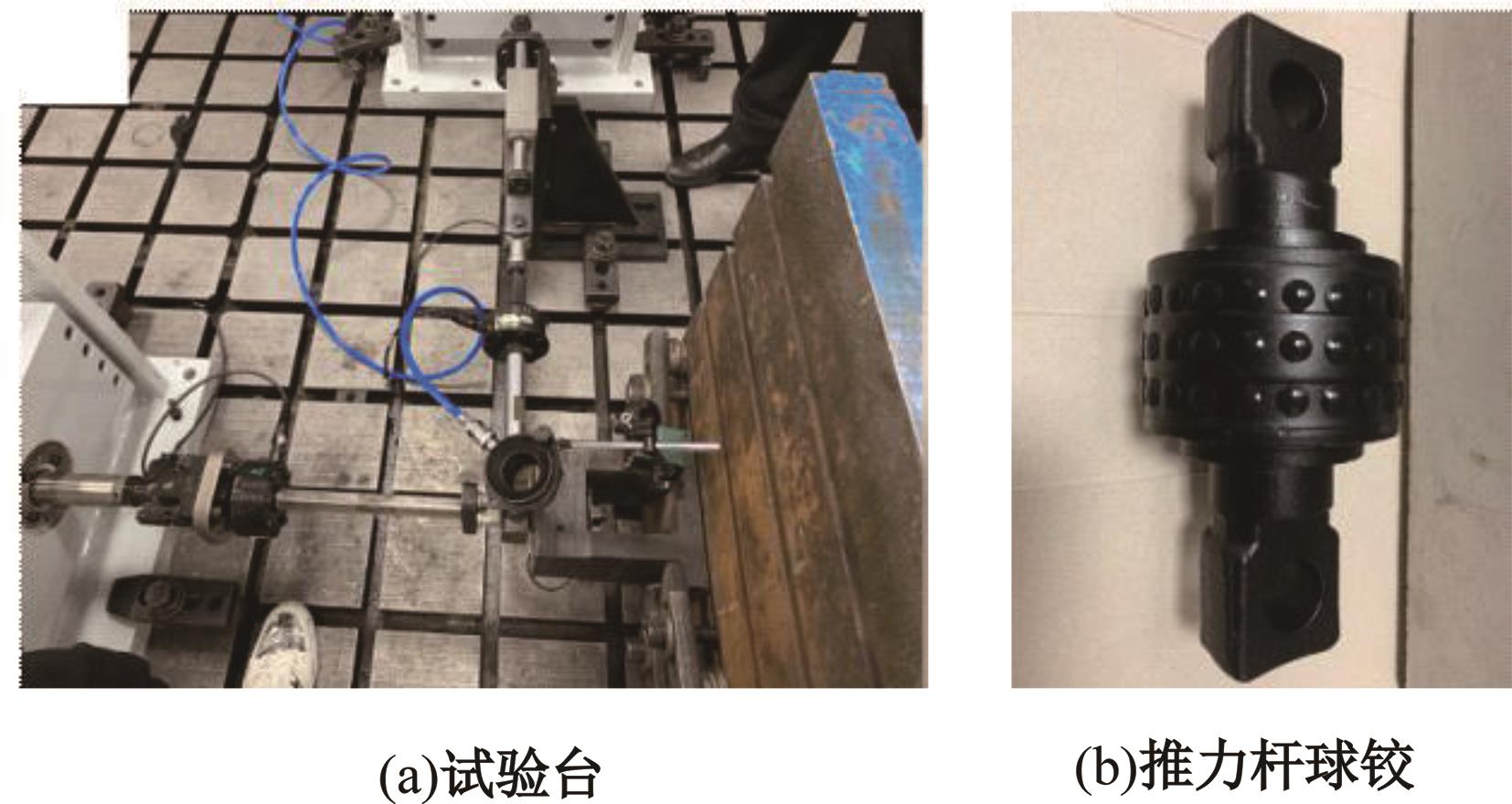

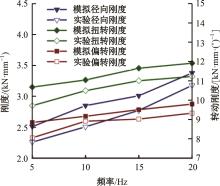

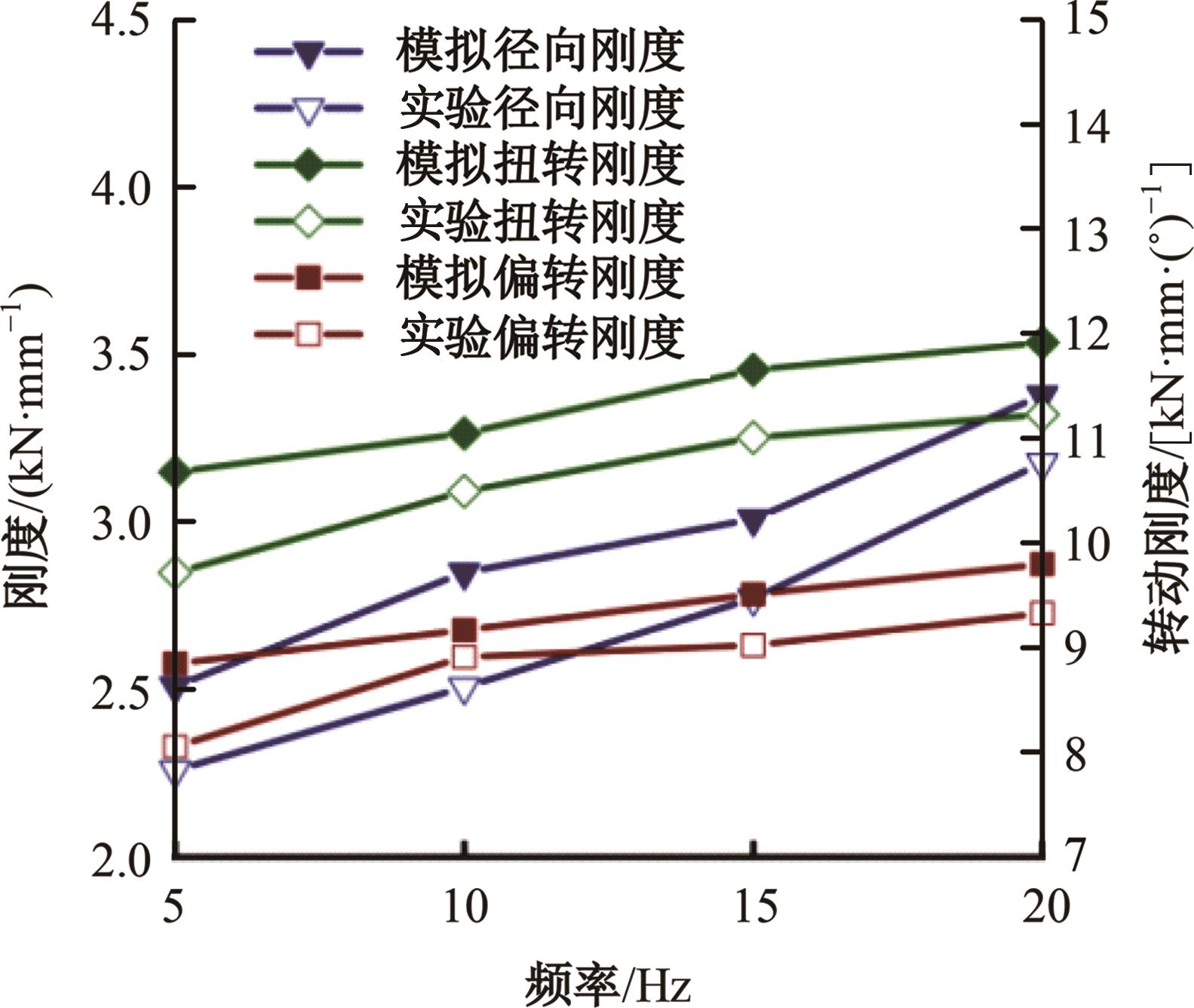

将蝗虫足垫的仿生学增摩原理应用于商用车的推力杆球铰橡胶表面,在橡胶球铰表面构建仿生球冠状柔性凸起,增加球铰的刚度。改变仿生柔性凸起的高度、半径、间距,利用Abaqus软件进行有限元分析,对推力杆球铰的径向刚度、偏转刚度和扭转刚度进行研究。结果表明:凸起高度为1 mm,半径为4 mm,间距为10 mm时效果最佳。最后,综合分析了最优方案,并通过模拟和实验验证了该方案的可行性。

中图分类号:

- TG356

| 1 | Feng G Y, Shi W K, Zhang H, et al. Research on the fatigue life prediction method of thrust rod[J]. Mathematical Problems in Engineering, 2016, 2016:No. 1254037. |

| 2 | Feng G Y, Shi W K, Wang Q, et al. Finite element analysis of static characteristic of rubber spherical joint for commercial vehicle thrust rod[J]. Advanced Materials Research, 2013, 710: 273-276. |

| 3 | 冯国雨. 商用车推力杆性能优化与疲劳寿命预测研究[D]. 长春:吉林大学汽车工程学院, 2016. |

| Feng Guo-yu. Performance optimization and fatigue life prediction of commercial vehicle thrust rod [D]. Changchun:College of Automotive Engineering, Jilin University, 2016. | |

| 4 | 王倩. 重型商用车推力杆结构优化与耐久性研究[D]. 长春:吉林大学汽车工程学院, 2013. |

| Wang Qian. Structure optimization and durability research of heavy commercial vehicle thrust rod[D]. Changchun:College of Automotive Engineering, Jilin University, 2013. | |

| 5 | Li Z, Shi W K, Wang Q, et al. Force and simulation analysis of thrust rod on heavy commercial vehicle balanced suspension[J]. Applied Mechanics and Materials, 2013, 387: 94-99. |

| 6 | 李赞. 商用车推力杆结构改进与性能研究[D]. 长春:吉林大学汽车工程学院, 2015. |

| Li Zan. Structure improvement and performance study of thrust rod on ccmmercial vehicle[D] Changchun:College of Automotive Engineering, Jilin University, 2015. | |

| 7 | 李磊. 重型商用车推力杆橡胶球铰的设计与寿命研究[D]. 长春:吉林大学汽车工程学院, 2017. |

| Li Lei. Structure design and fatigue life study of rubber bushing for commercial vehicle thrust rod [D]. Changchun:College of Automotive Engineering,Jilin University, 2017. | |

| 8 | 史文库,刘国政, 陈志勇. 橡胶的可压缩性在推力杆球铰有限元分析中的应用[J]. 西安交通大学学报, 2017, 51(9): 63-68, 76. |

| Shi Wen-ku, Liu Guo-zheng, Chen Zhi-yong. Application of rubber compressibility to finite element analysis for thrust rod[J]. Journal of Xi'an Jiaotong University, 2017, 51(9): 63-68, 76. | |

| 9 | 刘巧斌,史文库,高承明,等. 采用灰色Savitzky-Golay滤波的商用车推力杆橡胶球铰非对称迟滞建模[J]. 西安交通大学学报, 2019, 53(5): 82-91, 99. |

| Liu Qiao-bin, Shi Wen-ku, Gao Cheng-ming, et al. Asymmetrical hysteresis modelling basedd on Savitzky-Golay filter for rubber hinge on thrust rod of commercial vehicle[J]. Journal of Xi'an Jiaotong University, 2019, 53(5): 82-91, 99. | |

| 10 | 柯俊,祖洪飞, 史文库. 基于有限元法及遗传算法的推力杆球铰多目标优化方法[J]. 汽车工程, 2020, 42(2): 178-183. |

| Ke Jun, Zu Hong-fei, Shi Wen-ku. A multi-objective optimization method for the spherical hinge of a thrust rod based on the finite elemnet method and genetic algorithm [J]. Automotive Engineering, 2020, 42(2):178-183. | |

| 11 | 杨银辉, 晁鹏翔, 申国伟,等. 重卡推力杆载荷分析及结构优化[J]. 汽车实用技术,2018(19): 39-41. |

| Yang Yin-hui, Chao Peng-xiang, Shen Guo-wei,et al. Load analysis and structure optimization for truck thrust rod[J]. Automobile Applied Technology, 2018 (19):39-41. | |

| 12 | 翁明武, 刘飞, 李杨欢, 等. 自卸车推力杆的失效改进[J]. 汽车实用技术, 2018(18): 79-81. |

| Weng Ming-wu, Liu Fei, Li Yang-huan,et al. Dump truck thrust bar failure improvement [J]. Automobile Applied Technology, 2018 (18):79-81. | |

| 13 | 卜继玲, 周炜, 李建林, 等. 带橡胶球铰的车用推力杆稳定性分析[J]. 湘潭大学自然科学学报, 2016, 38(1): 39-41, 46. |

| Bu Ji-ling, Zhou Wei, Li Jian-lin, et al. Stability analysis of vehicle torque rod based on the rubber[J]. Natural Science Journal of Xiangtan University, 2016, 38(1): 39-41, 46. | |

| 14 | 曹洲, 王印, 梁津,等. 商用车V型推力杆失效分析[J]. 汽车实用技术. 2021, 46(14): 69-72. |

| Cao Zhou, Wang Yin, Liang Jin, et al. Failure analysis of V-type thrust bar of commercial vehicle[J]. Automobile Applied Techonlogy, 2021, 46(14):69-72. | |

| 15 | 潘博. 重卡用推力杆挡圈脱落机理分析及其结构优化设计[D]. 北京: 清华大学车辆与运载学院, 2017. |

| Pan Bo. Failure analysis of the thrust rod retaining ring for heavy duty truck and the structural optimization design [D]. Beijing:School of Vehicle and Mobility,Tsinghua University, 2017. | |

| 16 | 张俊荣, 张排排, 唐春红,等. 轻量化铝合金推力杆结构设计及其性能研究[J]. 汽车工艺与材料, 2021(8): 13-17. |

| Zhang Jun-rong, Zhang Pai-pai, Tang Chun-hong,et al. Structural design and performance research on lightweight aluminum alloy thrust rod[J]. Automobile Technology& Material, 2021(8):13-17. | |

| 17 | 张子尧. 基于Kriging模型的球铰芯轴预成形多目标优化[D]. 镇江:江苏大学材料科学与工程学院, 2016. |

| Zhang Zi-yao. Multi-target preform optimization for spherical hinge mandrel based on Kriging model methodology [D]. Zhenjiang:School of Materials Science & Engineering,Jiangsu University, 2016. | |

| 18 | 刘峰. 基于有限元分析的推力杆球铰硫化模具设计[D]. 长沙:湖南大学机械与运载工程学院, 2016. |

| Liu Feng. Design of vulcanization mould of torque rod bushing based on FEA[D]. Changsha:College of Mechanical and Vehicle Engineering, Hunan University, 2016. | |

| 19 | van Den Boogaart L M, Langowski J K A, Amador G J. Studying stickiness: methods, trade-offs, and perspectives in measuring reversible biological adhesion and friction [J]. Biomimetics, 2022, 7(3): 1-19. |

| 20 | Wang L X, Zhou Q, Xu S Y, et al. Investigation of the sliding friction behaviors of locust on slippery plates[J]. Chinese Science Bulletin, 2009, 54(24): 4549-4554. |

| 21 | Dai Z D, Stanislav G. Contact mechanics of pad of grasshopper (Insecta: Orthoptera) by finite element methods[J]. Chinese Science Bulletin, 2009, 54(4): 549-555. |

| 22 | Woodward M A, Sitti M. Morphological intelligence counters foot slipping in the desert locust and dynamic robots[J]. Proceedings of the National Academy of Sciences of the United States of America, 2018, 115(36): E8358-E8367. |

| [1] | 杨志军,张驰,黄观新. 基于浮动坐标法的刚柔耦合定位平台力学模型[J]. 吉林大学学报(工学版), 2024, 54(2): 385-393. |

| [2] | 肖阳,王洁,刘孟军,杨发庆,张天瑶,兰巍. 质子交换膜燃料电池气体扩散层的力学改进模型[J]. 吉林大学学报(工学版), 2022, 52(9): 2147-2155. |

| [3] | 左建林,刘恩渤,贾政斌,徐圣昊,肖建林. 基于内侧半月板结构设计的仿生假体有限元分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2319-2324. |

| [4] | 宫亚峰,宋加祥,毕海鹏,谭国金,胡国海,林思远. 装配式箱涵结构缩尺模型静载试验及有限元分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1728-1738. |

| [5] | 古海东,罗春红. 疏排桩-土钉墙组合支护基坑土拱效应模型试验[J]. 吉林大学学报(工学版), 2018, 48(6): 1712-1724. |

| [6] | 刘国政, 史文库, 陈志勇. 考虑安装误差的准双曲面齿轮传动误差有限元分析[J]. 吉林大学学报(工学版), 2018, 48(4): 984-989. |

| [7] | 孙荣军, 谷拴成, 居培, 高科. 基于有限元分析的煤矿井下新型弧角型聚晶金刚石复合片钻头优化设计[J]. 吉林大学学报(工学版), 2017, 47(6): 1991-1998. |

| [8] | 陈东辉, 刘伟, 吕建华, 常志勇, 吴婷, 慕海锋. 基于虾夷扇贝体表结构的玉米茬根捡拾器仿生设计[J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

| [9] | 吴越, 杨志刚, 陈龙, 康晓涛, 张东伟. 压电悬臂梁多模态发电装置的仿真与试验[J]. 吉林大学学报(工学版), 2015, 45(4): 1162-1167. |

| [10] | 张彦玲, 孙瞳, 侯忠明, 李运生. 隔板式钢-混凝土曲线组合梁弯扭性能[J]. 吉林大学学报(工学版), 2015, 45(4): 1107-1114. |

| [11] | 于振环,张娜,刘顺安. 基于流-固耦合的车辆减振器动态非线性仿真分析[J]. 吉林大学学报(工学版), 2015, 45(1): 16-21. |

| [12] | 李成, 朱红红, 铁瑛, 何龙. 单搭胶/螺栓混合连接结构的应力分布与载荷分配[J]. 吉林大学学报(工学版), 2013, 43(04): 933-938. |

| [13] | 马云海, 王悦明, 潘春祥, 张志君. 鲍鱼壳体纳米力学特性及有限元分析[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 437-439. |

| [14] | 郭孔辉,邱恩超. 基于环模型的轮胎滚动接触有限元分析[J]. 吉林大学学报(工学版), 2011, 41(03): 597-0601. |

| [15] | 张俊秋,韩志武,江佳廉,戈超,吕尤,王超飞. 柔性与形态耦合仿生抗冲蚀三维数值模拟[J]. 吉林大学学报(工学版), 2011, 41(01): 139-0143. |

|

||