吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (9): 2147-2155.doi: 10.13229/j.cnki.jdxbgxb20220296

• • 上一篇

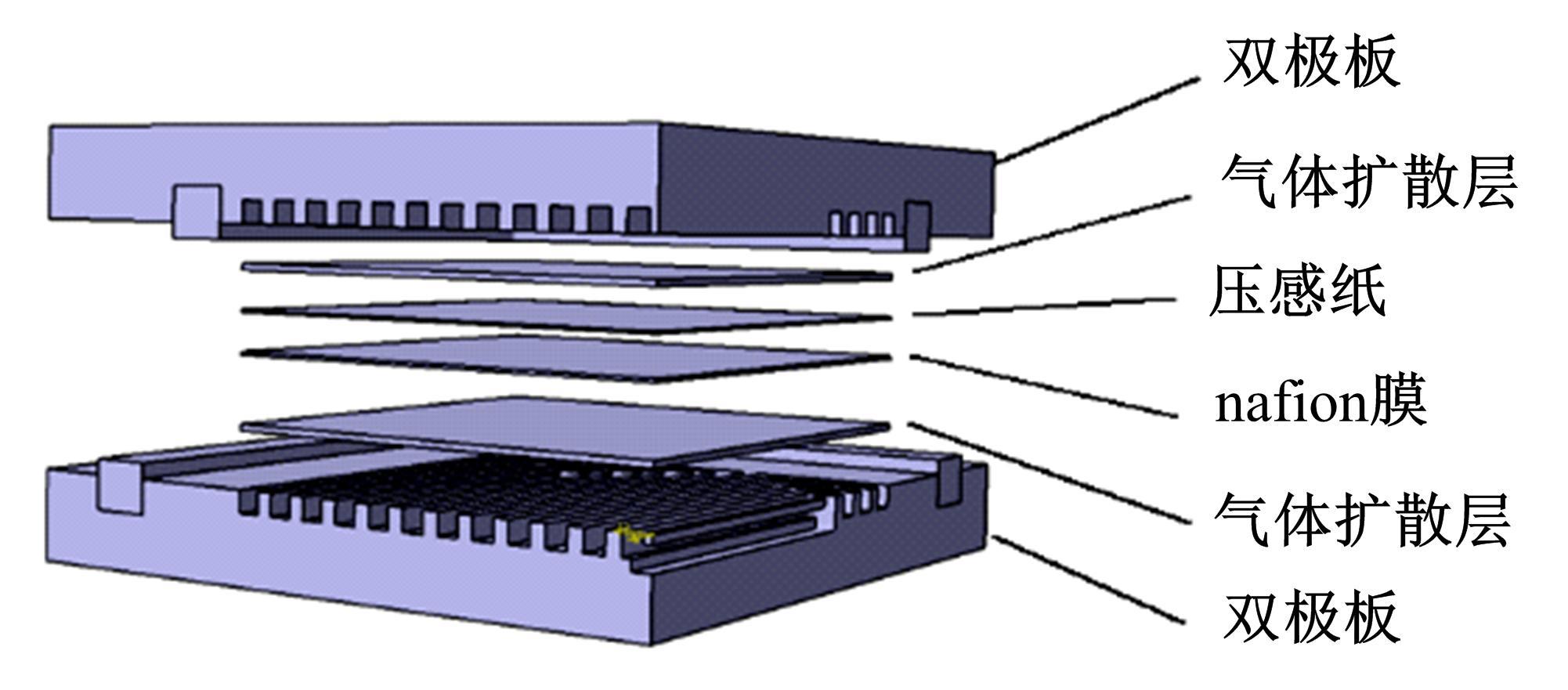

质子交换膜燃料电池气体扩散层的力学改进模型

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Improved mechanical model of gas diffusion layer in proton exchange membrane fuel cell

Yang XIAO( ),Jie WANG,Meng-jun LIU,Fa-qing YANG,Tian-yao ZHANG,Wei LAN(

),Jie WANG,Meng-jun LIU,Fa-qing YANG,Tian-yao ZHANG,Wei LAN( )

)

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

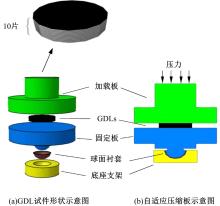

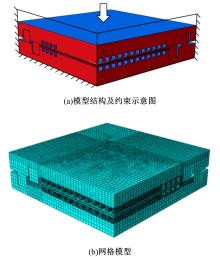

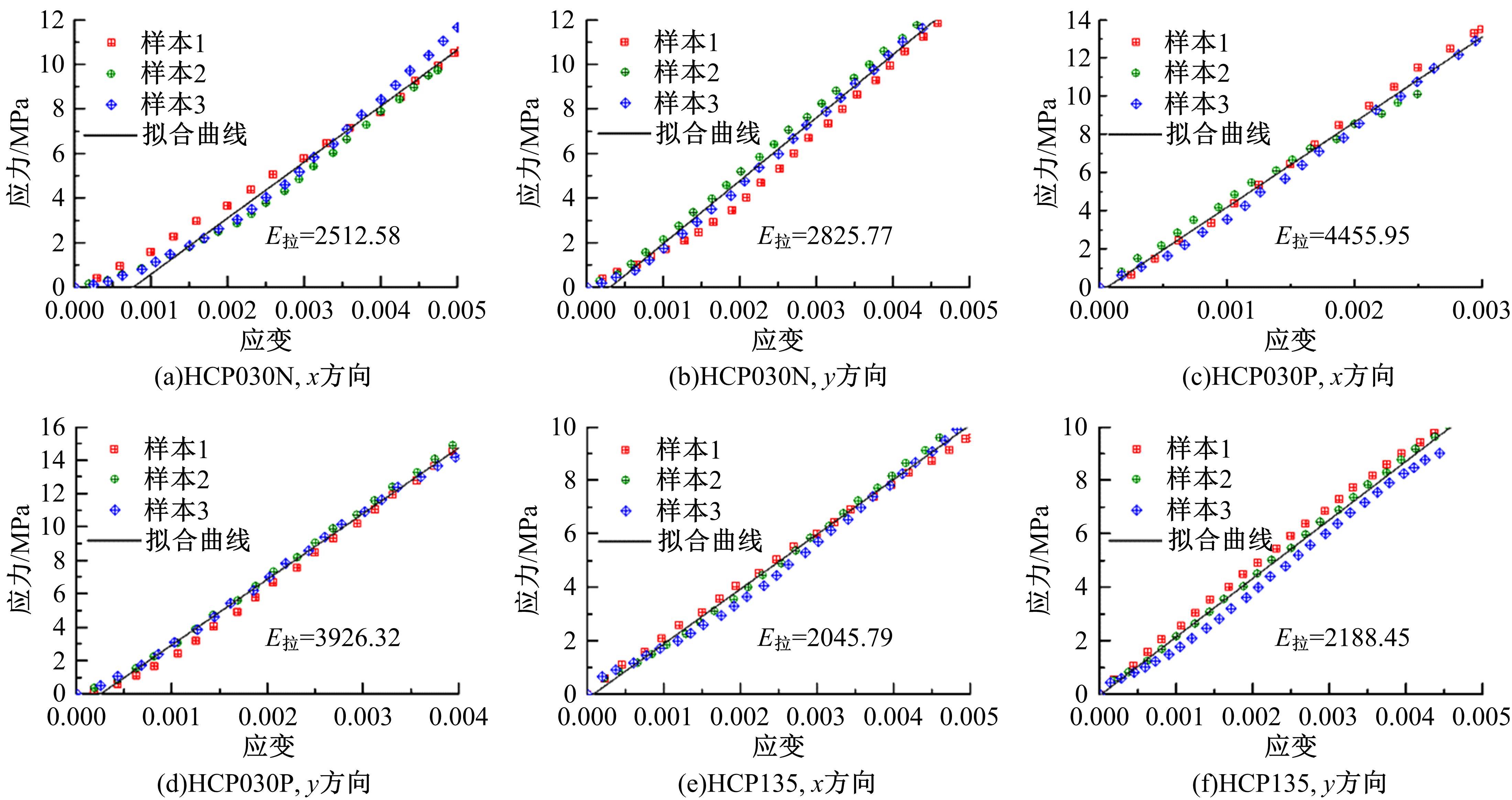

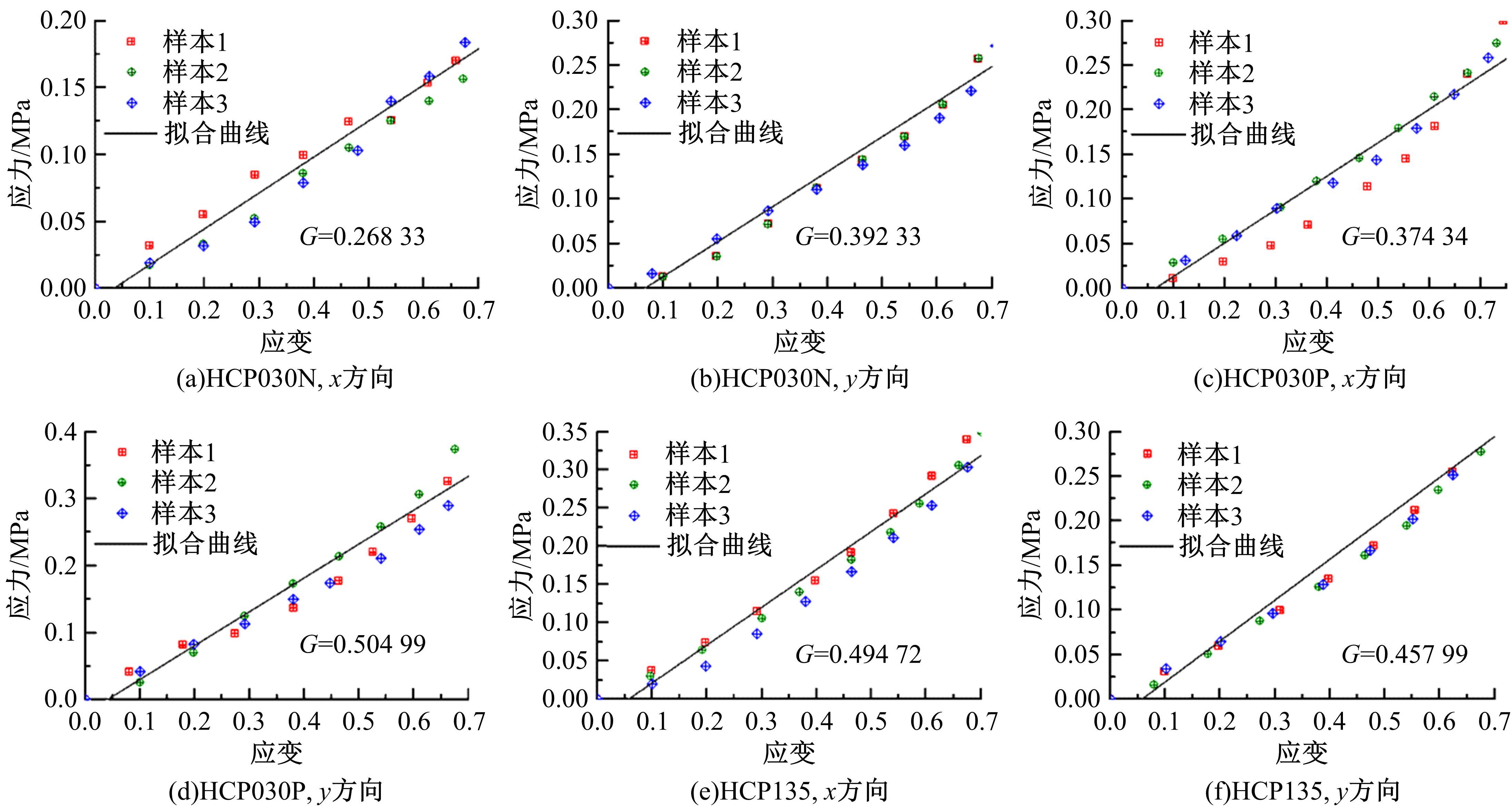

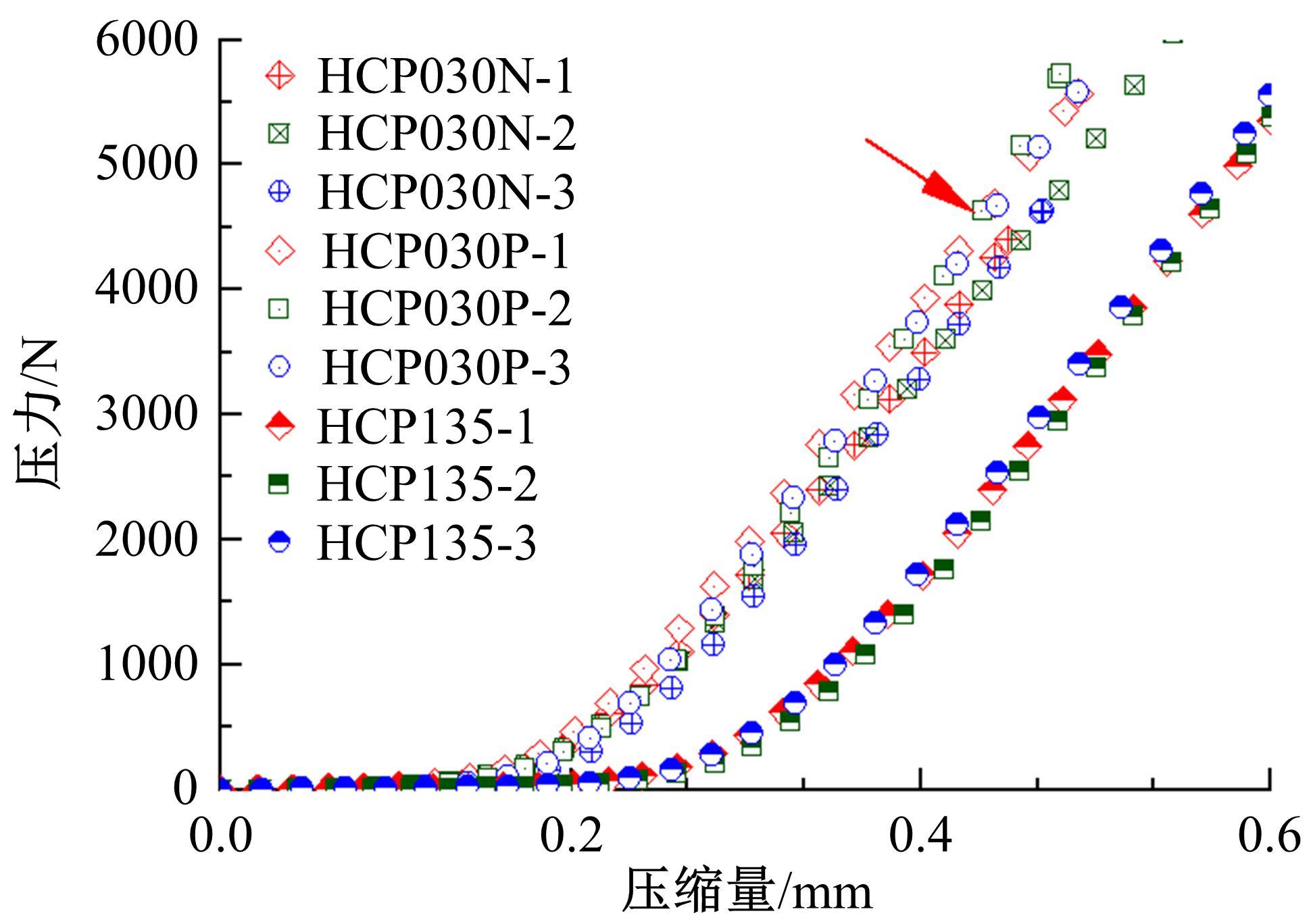

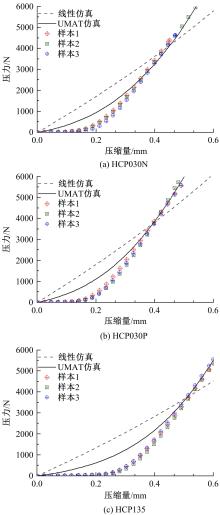

针对质子交换膜燃料电池膜电极结构力学特性复杂,导致工程中的仿真分析结果难以与真实情况吻合的问题,对膜电极结构中气体扩散层的复杂力学行为进行描述,进而改进燃料电池力学仿真的准确性。首先,提出了气体扩散层微观结构的改进模型,并通过实验的方法确定了模型参数。然后,利用UMAT用户子程序在Abaqus中进行有限元仿真验证。实验与仿真结果表明,本文力学改进模型能够较好地模拟气体扩散层的非线性力学行为,可以提高燃料电池工程仿真的准确度,可应用于燃料电池装配及机械寿命预测的工程分析中。

中图分类号:

- U41

| 1 | 叶跃坤, 池滨, 江世杰, 等. 质子交换膜燃料电池膜电极耐久性的提升[J]. 化学进展, 2019, 31(12): 1637-1652. |

| Ye Yue-kun, Chi Bin, Jiang Shi-jie, et al. Improvement of membrane electrode durability for proton exchange membrane fuel cells [J]. Progress in Chemistry, 2019, 31(12): 1637-1652. | |

| 2 | 汪圣龙, 唐浩林, 潘牧, 等. 膜电极结构对质子交换膜燃料电池性能的影响[J]. 材料导报, 2003, 17(10): 37-40. |

| Wang Sheng-long, Tang Hao-lin, Pan Mu, et al. Effect of membrane electrode structure on the performance of proton exchange membrane fuel cells[J]. Materials Review, 2003, 17(10): 37-40. | |

| 3 | Han K, Hong B K, Kim S H, et al. Influence of anisotropic bending stiffness of gas diffusion layers on the degradation behavior of polymer electrolyte membrane fuel cells under freezing conditions[J]. International Journal of Hydrogen Energy, 2010, 35(22): 12317-12328. |

| 4 | Cho J, Oh H, Park J, et al. Effect of the micro porous layer design on the dynamic performance of a proton exchange membrane fuel cell[J]. International Journal of Hydrogen Energy, 2014, 39(1): 459-468. |

| 5 | Norouzifard V, Bahrami M. Deformation of PEM fuel cell gas diffusion layers under compressive loading: an analytical approach[J]. J Power Sources, 2014, 264: 92-99. |

| 6 | Gigos P A, Faydi Y, Meyer Y. Mechanical characterization and analytical modeling of gas diffusion layers under cyclic compression[J]. International Journal of Hydrogen Energy, 2015, 40(17): 5958-5965. |

| 7 | Xiao Y, Gao Z H, Gao F, et al. Improved analytical modeling and mechanical characterization of gas diffusion layers under compression load[J]. Energy Science Engineering, 2020, 8(8): 2799-2807. |

| 8 | Yoon W, Huang X Y. A multiphysics model of PEM fuel cell incorporating the cell compression effects[J]. Journal of The Electrochemical Society, 2010, 157(5): B680-B690. |

| 9 | Bates A, Mukherjee S, Hwang S, et al. Simulation and experimental analysis of the clamping pressure distribution in a PEM fuel cell stack[J]. International Journal of Hydrogen Energy, 2013, 38(15): 6481-6493. |

| 10 | Silberstein M N, Boyce M C. Hygro-thermal mechanical behavior of Nafion during constrained swelling[J]. Journal of Power Sources, 2011, 196(7): 3452-3460. |

| 11 | Kusoglu A, Karlsson A M, Santare M H, et al. Mechanical response of fuel cell membranes subjected to a hygro-thermal cycle[J]. J Power Sources, 2006, 161(2): 987-996. |

| 12 | Lu Z, Kim C, Karlsson A M, et al. Effect of gas diffusion layer modulus and land-groove geometry on membrane stresses in proton exchange membrane fuel cells[J]. Journal of Power Sources, 2011, 196(10): 4646-4654. |

| 13 | Hottinen T, Himanen O, Karvonen S, et al. Inhomogeneous compression of PEMFC gas diffusion layer[J]. Journal of Power Sources, 2007, 171(1): 113-121. |

| 14 | Nitta I, Hottinen T, Himanen O, et al. Inhomogeneous compression of PEMFC gas diffusion layer[J]. Journal of Power Sources, 2007, 171(1): 26-36. |

| 15 | Herr N, Nicod J M, Varnier C. Decision process to manage useful life of multi-stacks fuel cell systems under service constraint[J]. Renewable Energy, 2017, 105:590-600. |

| 16 | Khajeh-Hosseini-Dalasm N, Sasabe T, Tokumasu T, et al. Effects of polytetrafluoroethylene treatment and compression on gas diffusion layer microstructure using high-resolution X-ray computed tomography[J]. Journal of Power Sources, 2014, 266: 213-221. |

| 17 | Shahraeeni M, Hoorfar M. Pore-network modeling of liquid water flow in gas diffusion layers of proton exchange membrane fuel cells[J]. International Journal of Hydrogen Energy, 2014, 39(20): 10697-10709. |

| 18 | Zenyuk I V, Parkinson D Y, Connolly L G, et al. Gas-diffusion-layer structural properties under compression via X-ray tomography[J]. Journal of Power Sources, 2016, 328: 364-376. |

| 19 | Straubhaar B, Pauchet J, Prat M. Water transport in gas diffusion layer of a polymer electrolyte fuel cell in the presence of a temperature gradient. Phase change effect[J]. International Journal of Hydrogen Energy, 2015, 40(35): 11668-11675. |

| 20 | Yin Y, Wu T T, He P, et al. Numerical simulation of two-phase cross flow in microstructure of gas diffusion layer with variable contact angle[J]. International Journal of Hydrogen Energy, 2014, 39(28): 15772-15785. |

| 21 | Vikram A, Chowdhury P R, Phillips R K, et al. Measurement of effective bulk and contact resistance of gas diffusion layer under inhomogeneous compression—Part I: Electrical conductivity[J]. Journal of Power Sources, 2016, 320: 274-285. |

| 22 | Roy Chowdhury P, Vikram A, Phillips R K, et al. Measurement of effective bulk and contact resistance of gas diffusion layer under inhomogeneous compression—Part II: Thermal conductivity[J]. Journal of Power Sources, 2016, 320: 222-230. |

| 23 | Garcia-Salaberri P A, Vera M, Zaera R. Nonlinear orthotropic model of the inhomogeneous assembly compression of PEM fuel cell gas diffusion layers[J]. International Journal of Hydrogen Energy, 2011, 36(18): 11856-11870. |

| 24 | .硫化橡胶或热塑性橡胶拉伸应力应变性能的测定 [S]. |

| [1] | 杨子荣,李岩,冀雪峰,刘芳,郝冬. 质子交换膜燃料电池运行工况参数敏感性分析[J]. 吉林大学学报(工学版), 2022, 52(9): 1971-1981. |

| [2] | 张佩,王志伟,杜常清,颜伏伍,卢炽华. 车用质子交换膜燃料电池空气系统过氧比控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 1996-2003. |

| [3] | 刘镇宁,江柯,赵韬韬,樊文选,卢国龙. 大功率质子交换膜燃料电池测试系统的开发及试验[J]. 吉林大学学报(工学版), 2022, 52(9): 2025-2033. |

| [4] | 陈凤祥,张俊宇,裴冯来,侯明涛,李其朋,李培庆,王洋洋,张卫东. 质子交换膜燃料电池氢气供应系统的建模及匹配设计[J]. 吉林大学学报(工学版), 2022, 52(9): 1982-1995. |

| [5] | 张恒,詹志刚,陈奔,隋邦杰,潘牧. 气体扩散层各向异性传输特性的孔尺度模拟[J]. 吉林大学学报(工学版), 2022, 52(9): 2055-2062. |

| [6] | 裴尧旺,陈凤祥,胡哲,翟双,裴冯来,张卫东,焦杰然. 基于自适应LQR控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2014-2024. |

| [7] | 池训逞,侯中军,魏伟,夏增刚,庄琳琳,郭荣. 基于模型的质子交换膜燃料电池系统阳极气体浓度估计技术综述[J]. 吉林大学学报(工学版), 2022, 52(9): 1957-1970. |

| [8] | 左建林,刘恩渤,贾政斌,徐圣昊,肖建林. 基于内侧半月板结构设计的仿生假体有限元分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2319-2324. |

| [9] | 王新彦,江泉,吕峰,易政洋. 基于参数化模型的零转弯半径割草机侧翻稳定性[J]. 吉林大学学报(工学版), 2021, 51(5): 1908-1918. |

| [10] | 李洪雪,李世武,孙文财,王琳虹,杨志发. 考虑垂向⁃侧向运动的半挂列车动力学建模及分析[J]. 吉林大学学报(工学版), 2021, 51(2): 549-556. |

| [11] | 宫亚峰,宋加祥,毕海鹏,谭国金,胡国海,林思远. 装配式箱涵结构缩尺模型静载试验及有限元分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1728-1738. |

| [12] | 李战东,陶建国,罗阳,孙浩,丁亮,邓宗全. 核电水池推力附着机器人系统设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1820-1826. |

| [13] | 古海东,罗春红. 疏排桩-土钉墙组合支护基坑土拱效应模型试验[J]. 吉林大学学报(工学版), 2018, 48(6): 1712-1724. |

| [14] | 刘祥勇, 李万莉. 包含蓄能器的电液比例控制模型[J]. 吉林大学学报(工学版), 2018, 48(4): 1072-1084. |

| [15] | 胡满江, 罗禹贡, 陈龙, 李克强. 基于纵向频响特性的整车质量估计[J]. 吉林大学学报(工学版), 2018, 48(4): 977-983. |

|

||