吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (5): 1604-1616.doi: 10.13229/j.cnki.jdxbgxb.20230873

长沙压实黏土剪切特性及应力-应变关系表征

- 1.长沙理工大学 公路工程教育部重点实验室,长沙 410114

2.湘江实验室,长沙 410205

3.中交第二公路勘察设计研究院有限公司,武汉 430056

Shear properties and stress-strain relationships characterization of Changsha compacted clay

An-shun ZHANG1,2( ),Wei FU3,Jun-hui ZHANG1,2(

),Wei FU3,Jun-hui ZHANG1,2( ),Feng GAO1,2

),Feng GAO1,2

- 1.Key Laboratory for Highway Engineering of Ministry of Education,Changsha University of Science & Technology,Changsha 410114,China

2.Xiangjiang Laboratory,Changsha 410205,China

3.CCCC Second Highway Consultants Co. ,Ltd. ,Wuhan 430056,China

摘要:

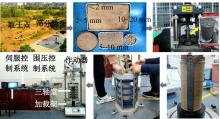

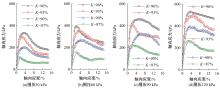

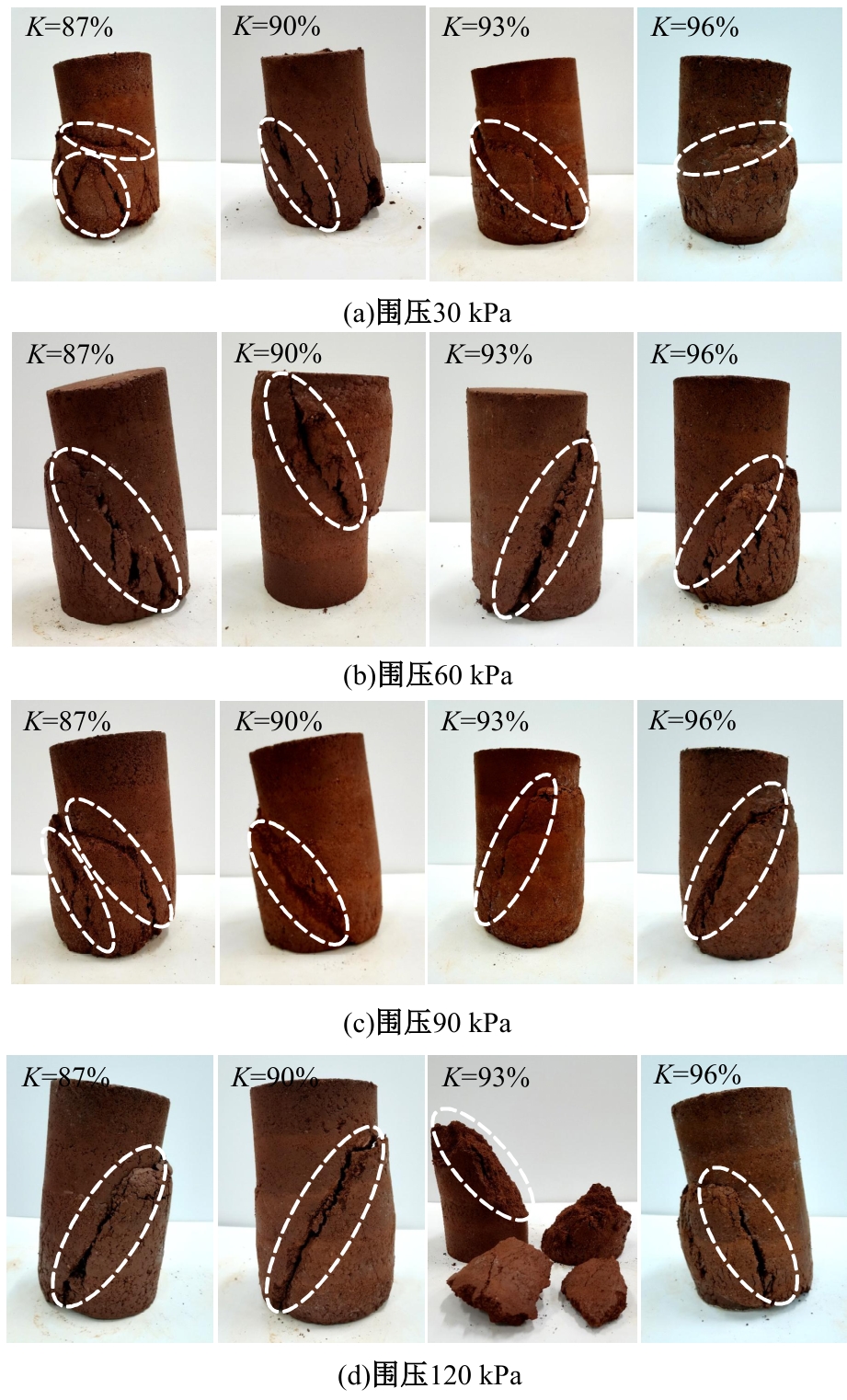

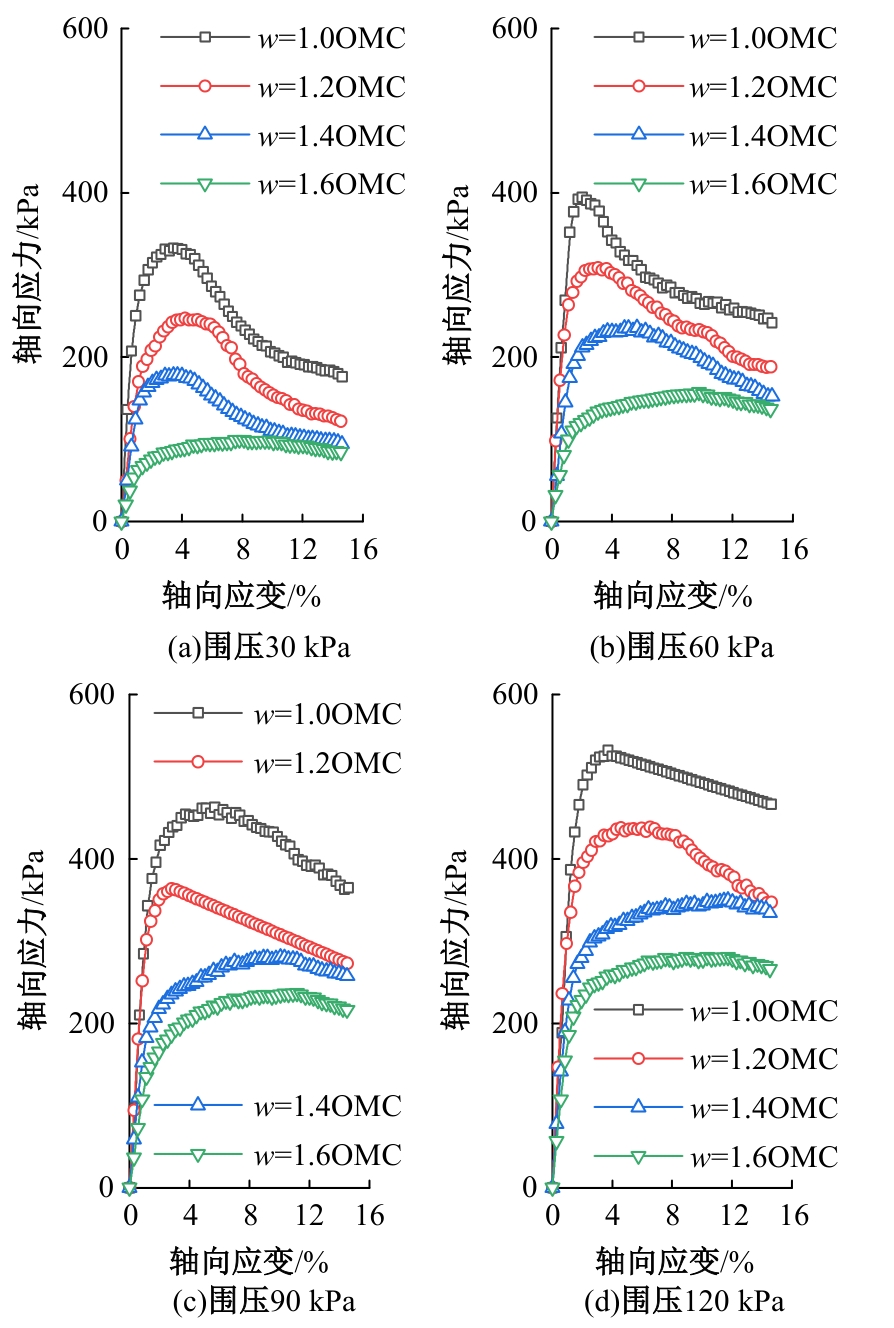

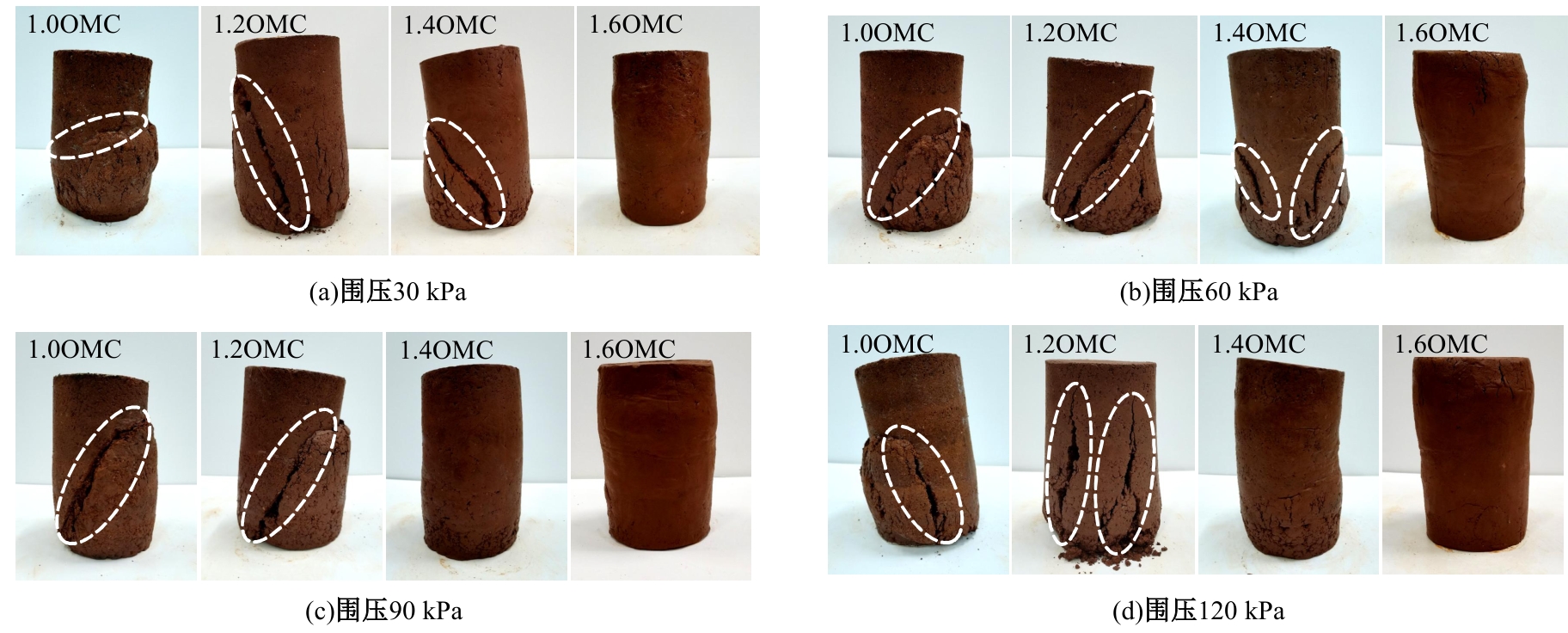

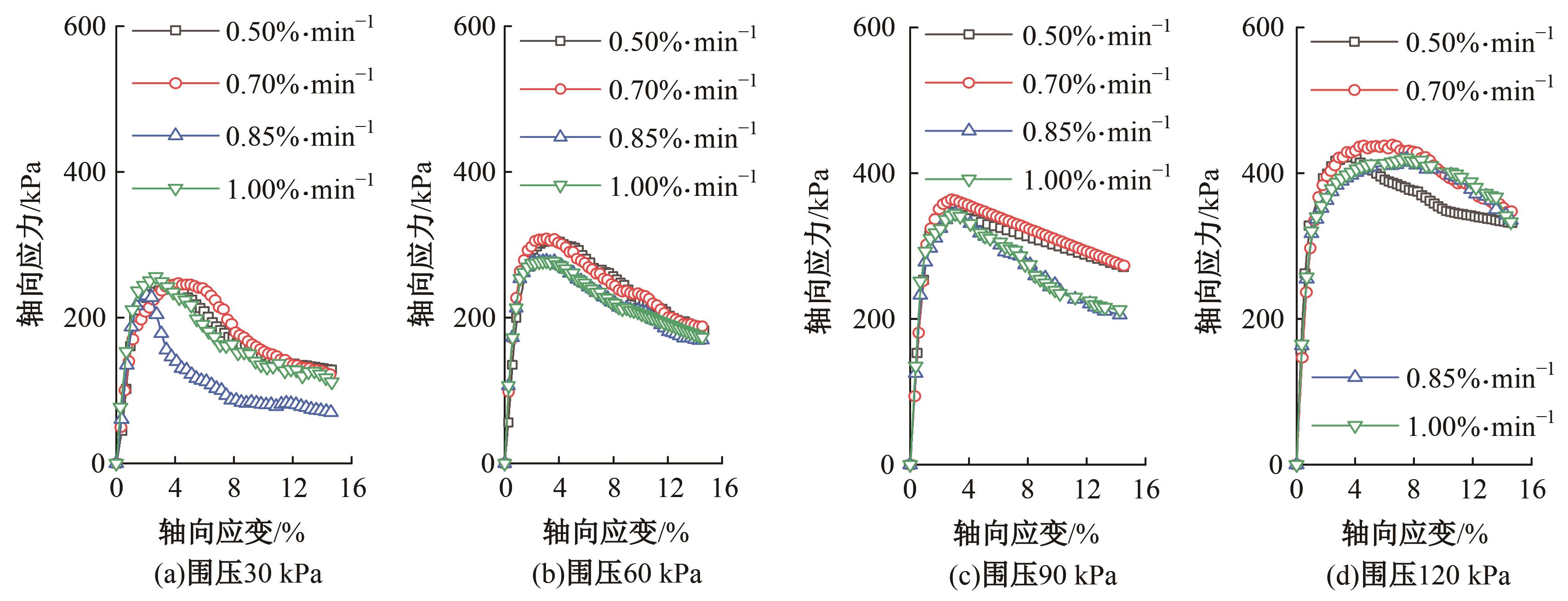

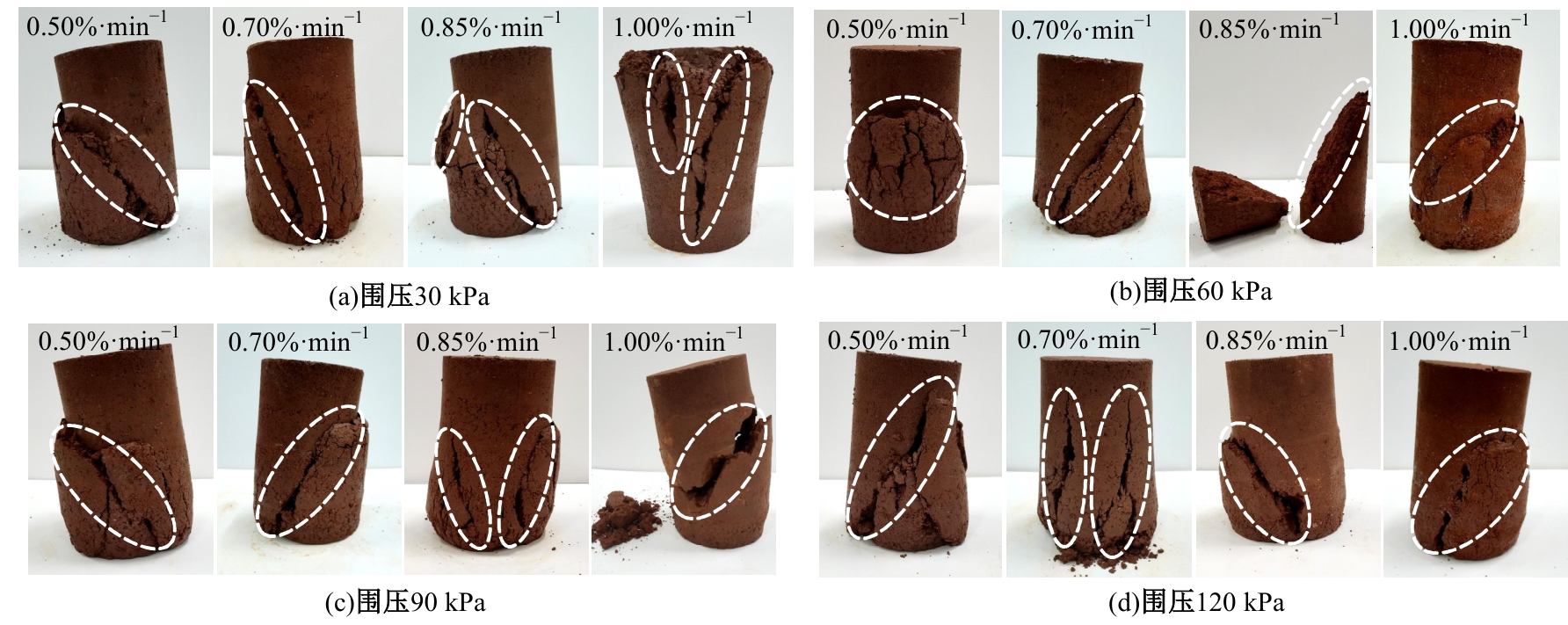

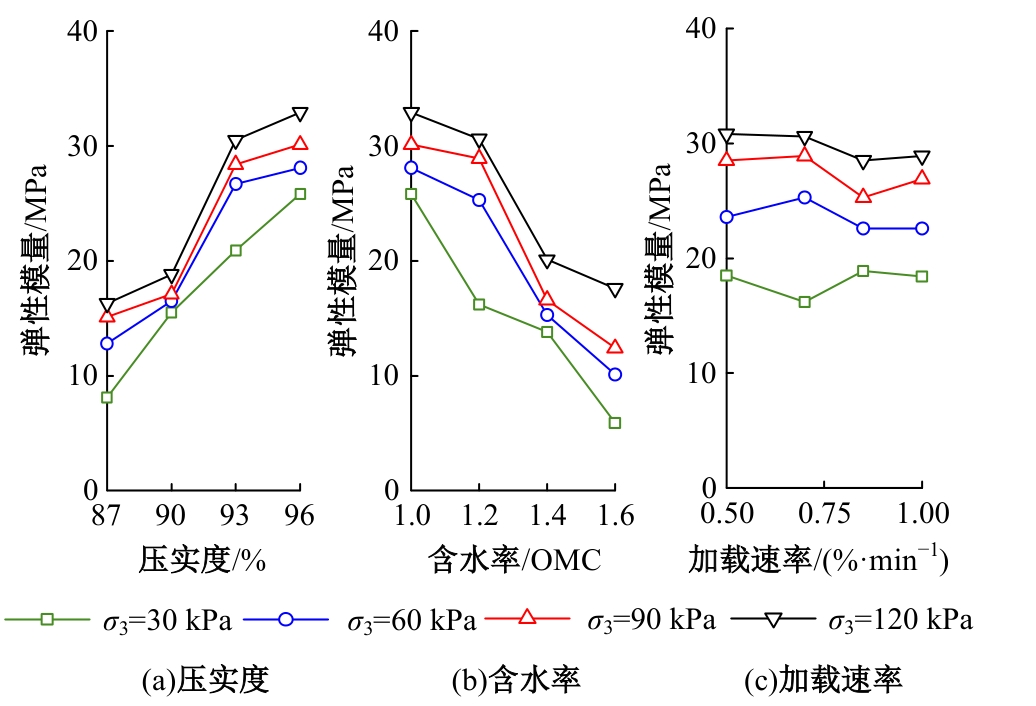

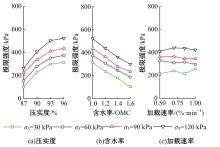

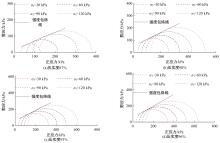

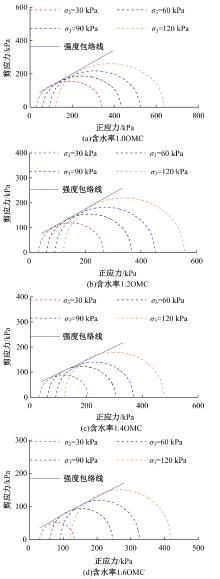

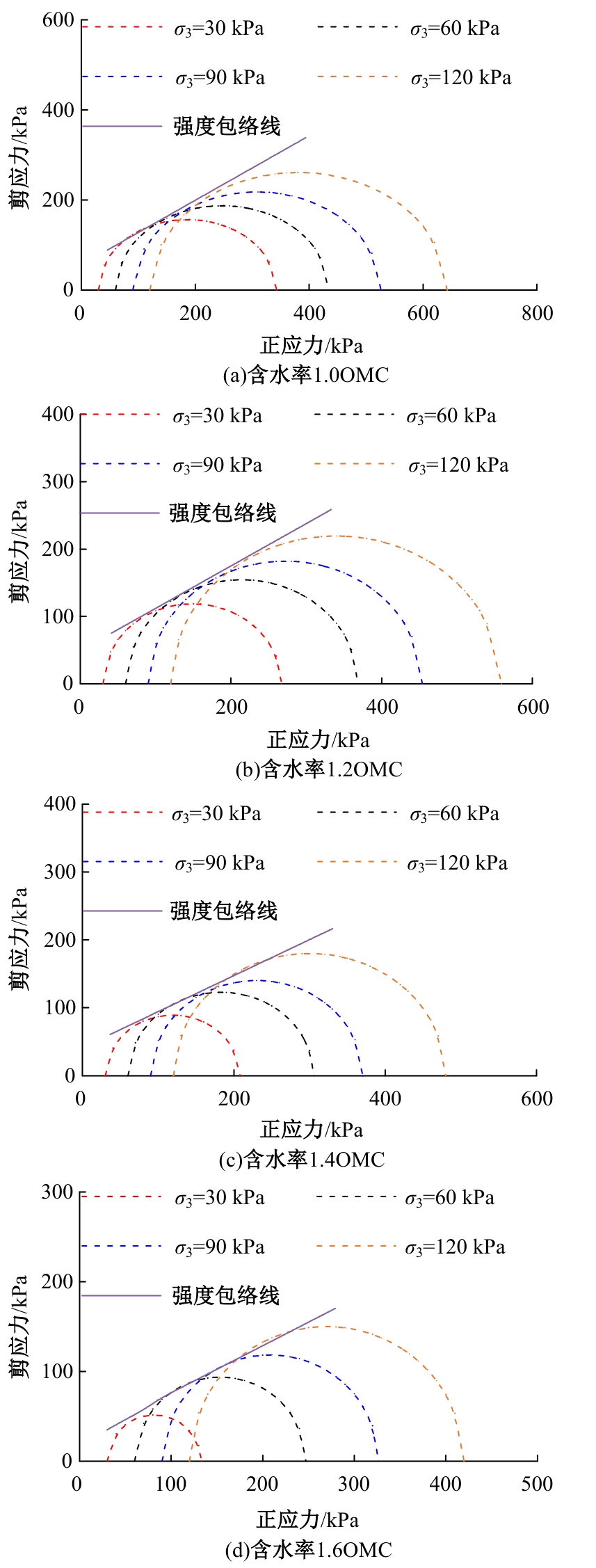

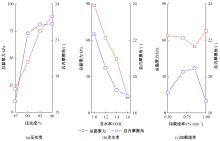

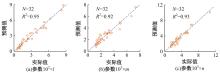

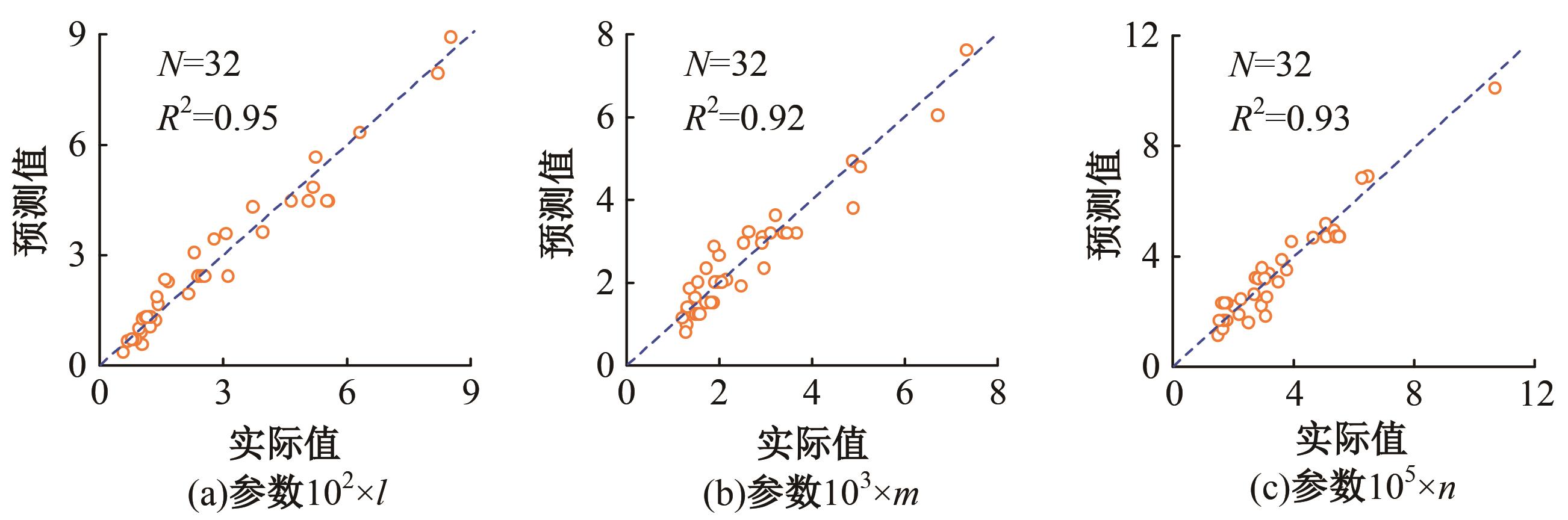

为研究路基压实黏土的剪切特性与应力-应变关系,以长沙黏土为例开展了不同压实度、含水率、加载速率、围压下的不固结不排水三轴试验。结果表明:弹性模量与极限强度均随压实度降低、含水率升高及围压减小呈衰减趋势,但与加载速率之间表现为无显著规律的小幅波动。建立了复杂条件下路基黏土的莫尔-库仑强度准则,以描述路基黏土强度随各个因素的变化规律。总黏聚力和总内摩擦角因压实度提高及含水率降低而大幅提高,且总黏聚力随加载速率的增加先减小后增大,总内摩擦角随加载速率的增加先增大后减小,但两者因加载速率改变导致的变化幅度较小。提出了长沙黏土应力-应变曲线的统一表征方法,可合理描述应变软化、稳定及硬化3种变形曲线。

中图分类号:

- TU411

| [1] | 张哲, 付伟, 张军辉, 等. 循环荷载下冻融路基黏土长期塑性行为[J]. 吉林大学学报: 工学版, 2023, 53(6): 1790-1798. |

| Zhang Zhe, Fu Wei, Zhang Jun-hui, et al. Long⁃term characterising plastic behavior of thawed subgrade clay under cyclic loads[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(6): 1790-1798. | |

| [2] | Yang K H, Uzuoka R, Thuo J, et al. Coupled hydro-mechanical analysis of two unstable unsaturated slopes subject to rainfall infiltration[J]. Engineering Geology, 2017, 216: 13-30. |

| [3] | Nhan T T, Matsuda H, Sato H, et al. Pore water pressure and settlement of clays under cyclic shear: effects of soil plasticity and cyclic shear direction[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2022, 148(2): No.04021185. |

| [4] | Zhang J H, Li F, Zeng L, et al. Numerical simulation of the moisture migration of unsaturated clay embankments in southern China considering stress state[J]. Bulletin of Engineering Geology and the Environment, 2021, 80: 11-24. |

| [5] | 李崛, 张安顺, 张军辉, 等. 级配碎石基层结构动力响应模型测试及数值分析[J]. 吉林大学学报: 工学版, 2023, 53(6): 1782-1789. |

| Li Jue, Zhang An-shun, Zhang Jun-hui, et al. Model testing and numerical analysis of dynamic response of graded crushed rock base structure[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(6): 1782-1789. | |

| [6] | 刘寒冰, 张互助, 王静. 冻融及含水率对压实黏质土力学性质的影响[J]. 岩土力学, 2018, 39(1): 158-164. |

| Liu Han-bing, Zhang Hu-zhu, Wang Jing. Effect of freeze-thaw and water content on mechanical properties of compacted clayey soil[J]. Rock and Soil Mechanics, 2018, 39(1): 158-164. | |

| [7] | Xu W B, Wang X C. Effect of freeze-thaw cycles on mechanical strength and microstructure of silty clay in the Qinghai-Tibet plateau[J]. Journal of Cold Regions Engineering, 2022, 36(1):No.04021018. |

| [8] | 龙万学, 陈开圣, 肖涛, 等. 非饱和红黏土三轴试验研究[J]. 岩土力学, 2009, 30(): 28-33. |

| Long Wan-xue, Chen Kai-sheng, Xiao Tao, et al. Research of general triaxial test for unsaturated red clay[J]. Rock and Soil Mechanics, 2009, 30(Sup.2): 28-33. | |

| [9] | 周春梅, 程月, 王勇, 等. 压实黄土抗剪强度参数影响因素研究[J]. 防灾减灾工程学报, 2018, 38(2): 258-264. |

| Zhou Chun-mei, Cheng Yue, Wang Yong, et al. Study on influencing factors of shear strength parameters of compacted loess[J]. Journal of Disaster Prevention and Mitigation Engineering, 2018, 38(2): 258-264. | |

| [10] | Wei C B, Apel D, Zhang Y H. Shear behavior of ultrafine magnetite tailings subjected to freeze-thaw cycles[J]. International Journal of Mining Science and Technology, 2019, 29: 609-616. |

| [11] | 詹良通, 孙倩倩, 郭晓刚, 等. 花岗岩风化料弃土快速堆填过程中不排水抗剪强度评估[J]. 岩土力学, 2021, 42(1): 50-58. |

| Zhan Liang-tong, Sun Qian-qian, Guo Xiao-gang, et al. Estimation of undrained shear strength of completely decomposed granite waste during rapid landfilling[J]. Rock and Soil Mechanics, 2021, 42(1): 50-58. | |

| [12] | Zhang A S, Zhang J H, Peng J H, et al. Effect of freeze-thaw cycles on mechanical properties of an embankment clay: laboratory tests and model evaluations[J]. Frontiers in Earth Science, 2022, 10: 865348. |

| [13] | 刘红玫, 钟秀梅. 黄土抗剪强度的三轴试验[J]. 地震工程学报, 2011, 33(): 243-245. |

| Liu Hong-mei, Zhong Xiu-mei. Triaxial test on the shearing strength of loess[J]. China Earthquake Engineering Journal, 2011, 33(Sup.1): 243-245. | |

| [14] | 邓亚虹, 魏宝华, 王晗, 等. 原状黄土变形与强度特性的加载速率效应[J]. 中国公路学报, 2016, 29(7): 22-29. |

| Deng Ya-hong, Wei Bao-hua, Wang Han, et al. Loading rate effect on deformation and strength characteristics of undisturbed loess[J]. China Journal of Highway and Transport, 2016, 29(7): 22-29. | |

| [15] | Toyota H, Takada S, Susami A. Rate dependence on mechanical properties of unsaturated cohesive soil with stress-induced anisotropy[J]. Soils and Foundations, 2019, 59: 1013-1023. |

| [16] | 林波, 张锋, 冯德成, 等. 冻融循环作用后饱和黏土的应变速率效应试验研究[J]. 岩土力学, 2017, 38(7): 2007-2014. |

| Lin Bo, Zhang Feng, Feng De-cheng, et al. Experimental investigation on strain rate effects of saturated clay subjected to freeze-thaw cycles[J]. Rock and Soil Mechanics, 2017, 38(7): 2007-2014. | |

| [17] | Zhang J H, Ding L, Zheng J L, et al. Deterioration mechanism and rapid detection of performances of an existing subgrade in southern China[J]. Journal of Central South University, 2020, 27(7): 2134-2147. |

| [18] | 郑健龙, 张锐. 公路膨胀土路基变形预测与控制方法[J]. 中国公路学报, 2015, 28(3): 1-10. |

| Zheng Jian-long, Zhang Rui. Prediction and control method for deformation of highway expansive soil subgrade[J]. China Journal of Highway and Transport, 2015, 28(3): 1-10. | |

| [19] | 姚占勇, 蒋红光, 孙梦林, 等. 细粒土路基平衡密度状态分析[J]. 中国公路学报, 2020, 33(9): 94-103. |

| Yao Zhan-yong, Jiang Hong-guang, Sun Meng-lin, et al. Analysis of equilibrium density state of highway subgrade with fine soils[J]. China Journal of Highway and Transport, 2020, 33(9): 94-103. | |

| [20] | Liu B H, Kong L W, Xu G F, et al. Effects of three-dimensional cyclic stresses on permanent deformation of natural undisturbed clay[J]. International Journal of Geomechanics, 2022, 22(12):04022220. |

| [21] | 臧濛, 孔令伟, 郭爱国. 静偏应力下湛江结构性黏土的动力特性[J]. 岩土力学, 2017, 38(1): 33-40. |

| Zang Meng, Kong Ling-wei, Guo Ai-guo. Effects of static deviatoric stress on dynamic characteristics of Zhanjiang structured clay[J]. Rock and Soil Mechanics, 2017, 38(1): 33-40. | |

| [22] | 王家全, 畅振超, 唐毅, 等. 循环荷载下加筋砾性土填料的动三轴试验分析[J]. 岩土力学, 2020, 41(9): 2851-2860. |

| Wang Jia-quan, Chang Zhen-chao, Tang Yi, et al. Dynamic triaxial test analysis of reinforced gravel soil under cyclic loading[J]. Rock and Soil Mechanics, 2020, 41(9): 2851-2860. | |

| [23] | Zhang J H, Li F, Zeng L, et al. Effect of cushion and cover on moisture distribution in clay embankments in Southern China[J]. Journal of Central South University, 2020, 27(7): 1893-1906. |

| [24] | 胡田飞, 刘建坤, 房建宏, 等. 冻融循环下压实度对粉质黏土力学性质影响的试验研究[J]. 岩石力学与工程学报, 2017, 36(6): 1495-1503. |

| Hu Tian-fei, Liu Jian-kun, Fang Jian-hong, et al. Experimental study on the effect of cyclic freezing-thawing on mechanical properties of silty clay with different degrees of compaction[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(6): 1495-1503. | |

| [25] | 严晗, 刘建坤, 王天亮. 冻融对粉砂土力学性能影响的试验研究[J]. 北京交通大学学报, 2013, 37(4): 73-77. |

| Yan Han, Liu Jian-kun, Wang Tian-liang. Experimental research of influences of freeze-thaw on the mechanical properties of silty soil[J]. Journal of Beijing Jiaotong University, 2013, 37(4): 73-77. | |

| [26] | Yang Y G, Gao F, Lai Y M. Modified Hoek-Brown criterion for nonlinear strength of frozen soil[J]. Cold Regions Science and Technology, 2013, 86: 98-103. |

| [27] | 李晶晶, 孔令伟, 凌贤长. 高铁堑坡粉质黏土原位强度特性与应力历史效应[J]. 湖南大学学报: 自然科学版, 2019, 46(3): 99-105. |

| Li Jing-jing, Kong Ling-wei, Ling Xian-zhang. Insitu strength characteristics and stress history effect of silty soil on high-speed railway cut slope[J]. Journal of Hunan University (Natural Sciences), 2019, 46(3): 99-105. | |

| [28] | 周葆春, 孔令伟, 马全国, 等. 压实膨胀土非饱和抗剪强度的湿度与密度效应[J]. 岩土力学, 2017, 38(): 240-246. |

| Zhou Bao-chun, Kong Ling-wei, Ma Quan-guo, et al. Effects of moisture and density states on unsaturated shear strength of compacted expansive soil[J]. Rock and Soil Mechanics, 2017, 38(Sup.1): 240-246. | |

| [29] | Prevost J, Hoeg K. Soil mechanics and plasticity analysis of strain softening[J]. Géotechnique, 1975, 25(2): 279-297. |

| [30] | 赖远明, 程红彬, 高志华, 等. 冻结砂土的应力-应变关系及非线性莫尔强度准则[J]. 岩石力学与工程学报, 2007, 187(8): 1612-1617. |

| Lai Yuan-ming, Cheng Hong-bin, Gao Zhi-hua, et al. Stress-strain relationships and nonlinear mohr strength criterion of frozen sand clay[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 187(8): 1612-1617. |

| [1] | 王黎明,宋子坤,周辉,魏文,袁浩. 超声处置石油沥青的流变学响应及响应机理[J]. 吉林大学学报(工学版), 2025, 55(4): 1346-1355. |

| [2] | 徐俊鹏,郑传峰,杜艳韬,王雨航,路政,范文军. 寒区沥青混合料在水-热-力三场耦合作用下的损伤效应[J]. 吉林大学学报(工学版), 2025, 55(3): 877-887. |

| [3] | 俞靖洋,李东钊,张志清,王真,孙海林,布海玲,李明春. 环保型蓄盐沥青混合料性能损伤演变[J]. 吉林大学学报(工学版), 2025, 55(3): 888-898. |

| [4] | 杨彦海,李百川,杨野,王崇骅,岳靓. 基于虚拟劈裂试验的集料椭球表面基构造[J]. 吉林大学学报(工学版), 2025, 55(2): 653-663. |

| [5] | 念腾飞,韩召,魏智强,王国伟,戈锦果,李萍. 考虑骨料形态的沥青混合料细观数值建模方法[J]. 吉林大学学报(工学版), 2025, 55(2): 639-652. |

| [6] | 韦万峰,孔令云,禤炜安,杨帆,郭鹏. 沥青发泡特性及温拌混合料水分敏感性综述[J]. 吉林大学学报(工学版), 2025, 55(1): 20-35. |

| [7] | 郭风春,毕海鹏,王海涛,吴树正,杨泓雨. 基于时温等效的纳米碳粉改性沥青黏弹行为[J]. 吉林大学学报(工学版), 2025, 55(1): 221-229. |

| [8] | 刘海峰,陶仁光,车佳玲,杨维武,朱立晨. 荷载和高温对沙漠砂混凝土单轴抗压性能的影响[J]. 吉林大学学报(工学版), 2024, 54(9): 2609-2619. |

| [9] | 高英力,谷小磊,廖美捷,胡新浪,谢雨彤. SiO2气凝胶/反应性弹性体三元共聚物/多聚磷酸复合改性沥青流变性能与改性机理[J]. 吉林大学学报(工学版), 2024, 54(7): 1978-1987. |

| [10] | 崔亚宁,司春棣,凡涛涛,王飞. 水-荷耦合作用下沥青桥面铺装层裂缝扩展分析[J]. 吉林大学学报(工学版), 2024, 54(7): 1988-1996. |

| [11] | 徐永丽,杨煦兰,周吉森,杨松翰,孙明刚. 温拌沥青的沥青烟成分及温拌剂抑烟性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1701-1707. |

| [12] | 孙雅珍,薛博欣,孙岩,王志臣,潘嘉伟. 考虑非均匀性的沥青混合料开裂行为细观模拟[J]. 吉林大学学报(工学版), 2024, 54(6): 1708-1718. |

| [13] | 赵晓康,胡哲,牛振兴,张久鹏,裴建中,温永. 基于非均质模型的水稳碎石材料细观开裂行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1258-1266. |

| [14] | 万铜铜,汪海年,郑文华,冯珀楠,陈玉,张琛. 级配碎石层协调沥青混合料层温度收缩变形行为[J]. 吉林大学学报(工学版), 2024, 54(4): 1045-1057. |

| [15] | 李松,石星星,司春棣,蒋继望,暴斌硕. 沥青胶浆高温流变性能及矿粉强化效应评价[J]. 吉林大学学报(工学版), 2024, 54(11): 3244-3254. |

|