吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (1): 221-229.doi: 10.13229/j.cnki.jdxbgxb.20240127

• 交通运输工程·土木工程 • 上一篇

基于时温等效的纳米碳粉改性沥青黏弹行为

- 1.中交一公局,北京 100024

2.吉林大学 交通学院,长春 130022

Viscoelastic behavior of carbon nano powder modified asphalt based on time-temperature equivalence

Feng-chun GUO1( ),Hai-peng BI2(

),Hai-peng BI2( ),Hai-tao WANG2,Shu-zheng WU2,Hong-yu YANG2

),Hai-tao WANG2,Shu-zheng WU2,Hong-yu YANG2

- 1.China First Highway Engineering Company Limited,Beijing 100024,China

2.College of Transportation,Jilin University,Changchun 130022,China

摘要:

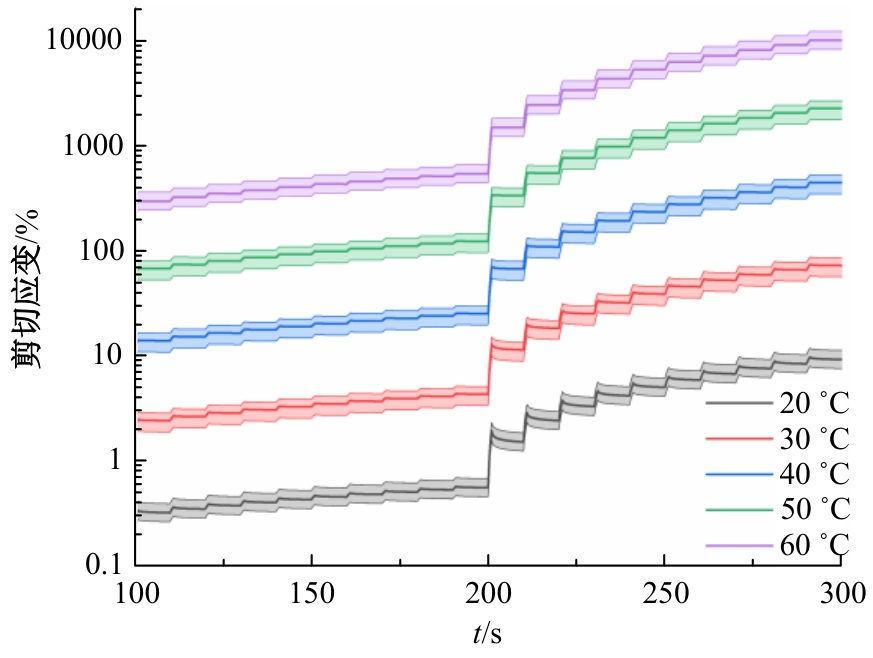

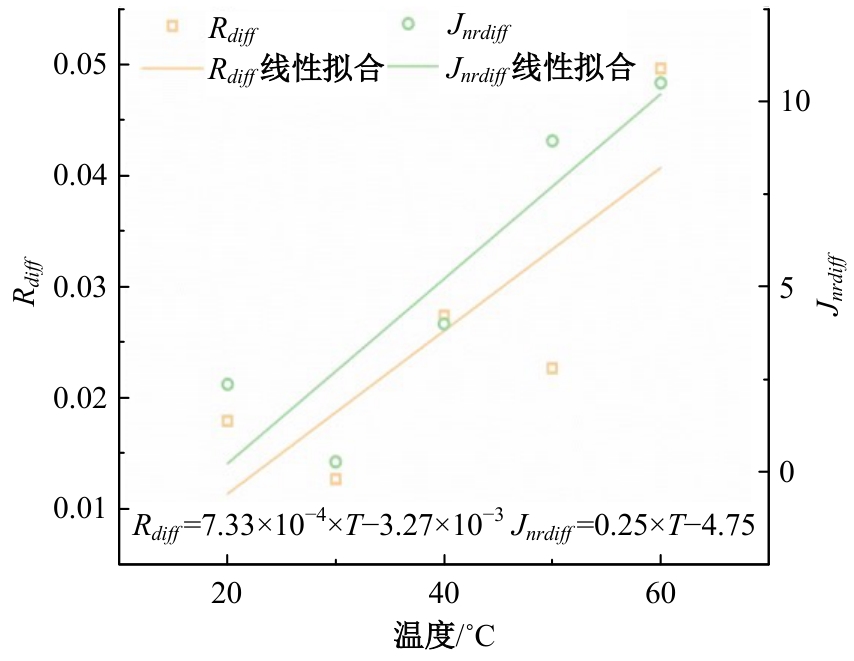

为了解纳米碳粉改性沥青的高低温黏弹行为,本文将基于多温度多重应力蠕变恢复试验及低温松弛试验,结合时温等效原理,对纳米碳粉改性沥青的蠕变及松弛行为进行分析。随后结合Laplace卷积积分,反演并验证纳米碳粉改性沥青的低温松弛行为。结果表明,在中低温环境下,纳米碳粉改性沥青弹性稳定性较强,应力敏感程度较低。短期蠕变柔量较小,长期蠕变柔量增长明显,应力松弛效应显著。本文提出的反演松弛模量方法与低温松弛试验模量曲线Pearson相关性为0.911。本文为纳米碳粉改性沥青的应用提供试验及理论参考,同时提供一种有效反演纳米碳粉改性沥青低温松弛行为的方法。

中图分类号:

- U416

| 1 | Bobbili A, Kollipara S K, Mallikarjuna V, et al. Comparative study on asphalt mixture with nano materials and polymer[J]. IOP Conference Series: Materials Science and Engineering, 2021, 1112(1): No.012019. |

| 2 | Singh B, Prasad D, Kumar A, et al.Use of nano-materials to enhance the properties of asphalt mixes[J]. Materials Today: Proceedings, 2022, 65(2): 1861-1866. |

| 3 | 徐衍青,李瑞明,郑传峰. 纳米材料在沥青路面中的应用综述[J]. 中外公路, 2021, 41(1): 206-214. |

| Xu Yan-qing, Li Rui-ming, Zheng Chuan-feng. Review on application of nanomaterials in asphalt pavement[J]. Journal of China & Foreign Highway, 2021, 41(1): 206-214. | |

| 4 | 俞才华. 碳纳米材料与SBS改性沥青相互作用及调控研究[D]. 郑州:河南工业大学土木工程学院, 2022. |

| Yu Cai-hua. Study on the interaction between carbon nanomaterials and SBS modified asphalt and the regulation method[D]. Zhengzhou: School of Civil Engineering, Henan University of Technology, 2022. | |

| 5 | Amini A, Ziari H, Saadatjoo S A, et al. Rutting resistance, fatigue properties and temperature susceptibility of nano clay modified asphalt rubber binder[J]. Construction and Building Materials, 2021, 267: No.120946. |

| 6 | Rezaei S, Khordehbinan M, Fakhrefatemi S M R. The effect of nano-SiO2 and the styrene butadiene styrene polymer on the high-temperature performance of hot mix asphalt[J]. Petroleum Science and Technology, 2017, 35(6): 553-560. |

| 7 | Xue Y, Liu C, Lyu S, et al. Research on rheological properties of CNT-SBR modified asphalt[J]. Construction and Building Materials, 2022, 361: No.129587. |

| 8 | Di H, Zhang H, Yang E, et al. Usage of nano-TiO2 or nano-ZnO in asphalt to resist aging by NMR spectroscopy and rheology technology[J]. Journal of Materials in Civil Engineering, 2023, 35(1): No.0004570. |

| 9 | 沈雪婷,王矿,张瑞芝,等. 自分散纳米碳粉的制备及性能[J]. 印染助剂, 2021, 38(6): 31-33. |

| Shen Xue-ting, Wang Kuang, Zhang Rui-zhi, et al. Preparation and properties of self-dispersing nano-carbon powder[J]. Textile Auxiliaries, 2021, 38(6): 31-33. | |

| 10 | Huang S, Liang C. Evaluation of the engineering properties of powdered activated carbon amendments in porous asphalt pavement[J]. Processes, 2021, 9(4): No.9040582. |

| 11 | 李诗琦,李闯民,李元元. 回收碳粉改性沥青制备参数及性能研究[J]. 石油沥青, 2016, 30(6): 25-30. |

| Li Shi-qi, Li Chuang-min, Li Yuan-yuan. Preparation parameters and performance study of recycled carbon powder modified asphalt[J]. Petroleum Asphalt, 2016, 30(6): 25-30. | |

| 12 | 孟旭,谢祥兵,李广慧,等. 基于正交灰关联分析的纳米碳粉/橡胶粉复合改性沥青制备工艺试验研究[J]. 硅酸盐通报, 2019, 38(8): 2642-2649. |

| Meng Xu, Xie Xiang-bing, Li Guang-hui, et al. Experimental study on preparation technology of nano-carbon powder/rubber powder composite modified asphalt based on orthogonal grey relation analysis[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(8): 2642-2649. | |

| 13 | Amirbayev Y, Yelshibayev A, Nugmanova A. Characterization of asphalt bitumens and asphalt concretes modified with carbon powder[J]. Case Studies in Construction Materials, 2022, 17: No. e01554. |

| 14 | 王明伟,谢祥兵,李广慧,等. 基于动态力学的纳米碳粉-橡胶粉-SBS改性沥青相态结构分析[J]. 硅酸盐通报, 2021, 40(7): 2444-2453. |

| Wang Ming-wei, Xie Xiang-bing, Li Guang-hui, et al. Phase structure analysis of nano carbon powder-rubber powder-SBS modified asphalt based on dynamic mechanics[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(7): 2444-2453. | |

| 15 | Wang Y F, Hong L, Liu Z M, et al. Rheological performance evaluation of activated carbon powder modified asphalt based on TOPSIS method[J]. Case Studies in Construction Materials, 2024, 20: No.e02963. |

| 16 | ASTM D7405. Standard test method for multiple stress creep and recovery(M ) of asphalt binder using a dynamic shear rheometer[S]. |

| 17 | 杨作杰. 橡胶沥青混合料性能试验研究[J]. 交通世界(建养·机械), 2015(8): 100-101. |

| Yang Zuo-jie. Experimental study on rubberized asphalt mixture performance[J]. TranspoWorld, 2015(8): 100-101. | |

| 18 | Maturana L G, López A O. Determination and assessment of the linear viscoelastic range and viscoelastic properties of modified asphalt and mastics under different temperature conditions[J]. Construction and Building Materials, 2024, 420: No.135606. |

| 19 | Abate J, Valkó P P. Multi-precision Laplace transform inversion[J]. International Journal for Numerical Methods in Engineering, 2004, 60(5): 979-993. |

| 20 | Saboo N, Sukhija M. Evaluating the suitability of nanoclay-modified asphalt binders from 10℃ to 70℃[J]. Journal of Materials in Civil Engineering, 2020, 32(12): No.04020393. |

| 21 | Park S W, Schapery R A. Methods of interconversion between linear viscoelastic material functions. Part I——a numerical method based on Prony series[J]. International Journal of Solids and Structures, 1999, 36(11): 1653-1675. |

| 22 | Schapery R A, Park S W. Methods of interconversion between linear viscoelastic material functions. Part II——an approximate analytical method[J]. International Journal of Solids and Structures, 1999, 36(11): 1677-1699. |

| 23 | 茹楠. 基于分子模拟的再生剂对热再生沥青混合料性能影响研究[D]. 重庆:重庆交通大学土木工程学院, 2023. |

| Ru Nan. Study on the influence of recycler based on molecular simulation on the performance of hot-recycled asphalt mixture[D]. Chongqing: School of Civil Engineering, Chongqing Jiaotong University, 2023. |

| [1] | 韦万峰,孔令云,禤炜安,杨帆,郭鹏. 沥青发泡特性及温拌混合料水分敏感性综述[J]. 吉林大学学报(工学版), 2025, 55(1): 20-35. |

| [2] | 崔亚宁,司春棣,凡涛涛,王飞. 水-荷耦合作用下沥青桥面铺装层裂缝扩展分析[J]. 吉林大学学报(工学版), 2024, 54(7): 1988-1996. |

| [3] | 高英力,谷小磊,廖美捷,胡新浪,谢雨彤. SiO2气凝胶/反应性弹性体三元共聚物/多聚磷酸复合改性沥青流变性能与改性机理[J]. 吉林大学学报(工学版), 2024, 54(7): 1978-1987. |

| [4] | 徐永丽,杨煦兰,周吉森,杨松翰,孙明刚. 温拌沥青的沥青烟成分及温拌剂抑烟性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1701-1707. |

| [5] | 孙雅珍,薛博欣,孙岩,王志臣,潘嘉伟. 考虑非均匀性的沥青混合料开裂行为细观模拟[J]. 吉林大学学报(工学版), 2024, 54(6): 1708-1718. |

| [6] | 赵晓康,胡哲,牛振兴,张久鹏,裴建中,温永. 基于非均质模型的水稳碎石材料细观开裂行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1258-1266. |

| [7] | 万铜铜,汪海年,郑文华,冯珀楠,陈玉,张琛. 级配碎石层协调沥青混合料层温度收缩变形行为[J]. 吉林大学学报(工学版), 2024, 54(4): 1045-1057. |

| [8] | 徐进,陈正欢,廖祺硕,郑展骥,张河山. 基于心电数据的高速公路高密度互通立交驾驶负荷[J]. 吉林大学学报(工学版), 2024, 54(10): 2807-2818. |

| [9] | 朱洪洲,苏春力,唐乃膨,魏俊尧,孙宏军. 胶粉改性沥青排放物采样及定量分析方法[J]. 吉林大学学报(工学版), 2024, 54(10): 2922-2929. |

| [10] | 陈俊,孙振浩,赵成,吴欣怡,王俊鹏. 相变沥青混凝土复合结构降温效果试验分析[J]. 吉林大学学报(工学版), 2024, 54(1): 180-187. |

| [11] | 唐乃膨,薛晨阳,刘少鹏,朱洪洲,李睿. 胶粉改性沥青老化机理及表征评价研究综述[J]. 吉林大学学报(工学版), 2024, 54(1): 22-43. |

| [12] | 王壮,冯振刚,姚冬冬,崔奇,沈若廷,李新军. 导电沥青混凝土研究进展[J]. 吉林大学学报(工学版), 2024, 54(1): 1-21. |

| [13] | 赵胜前,丛卓红,游庆龙,李源. 沥青-集料黏附和剥落研究进展[J]. 吉林大学学报(工学版), 2023, 53(9): 2437-2464. |

| [14] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [15] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

|

||