吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1174-1185.doi: 10.13229/j.cnki.jdxbgxb20171041

• • 上一篇

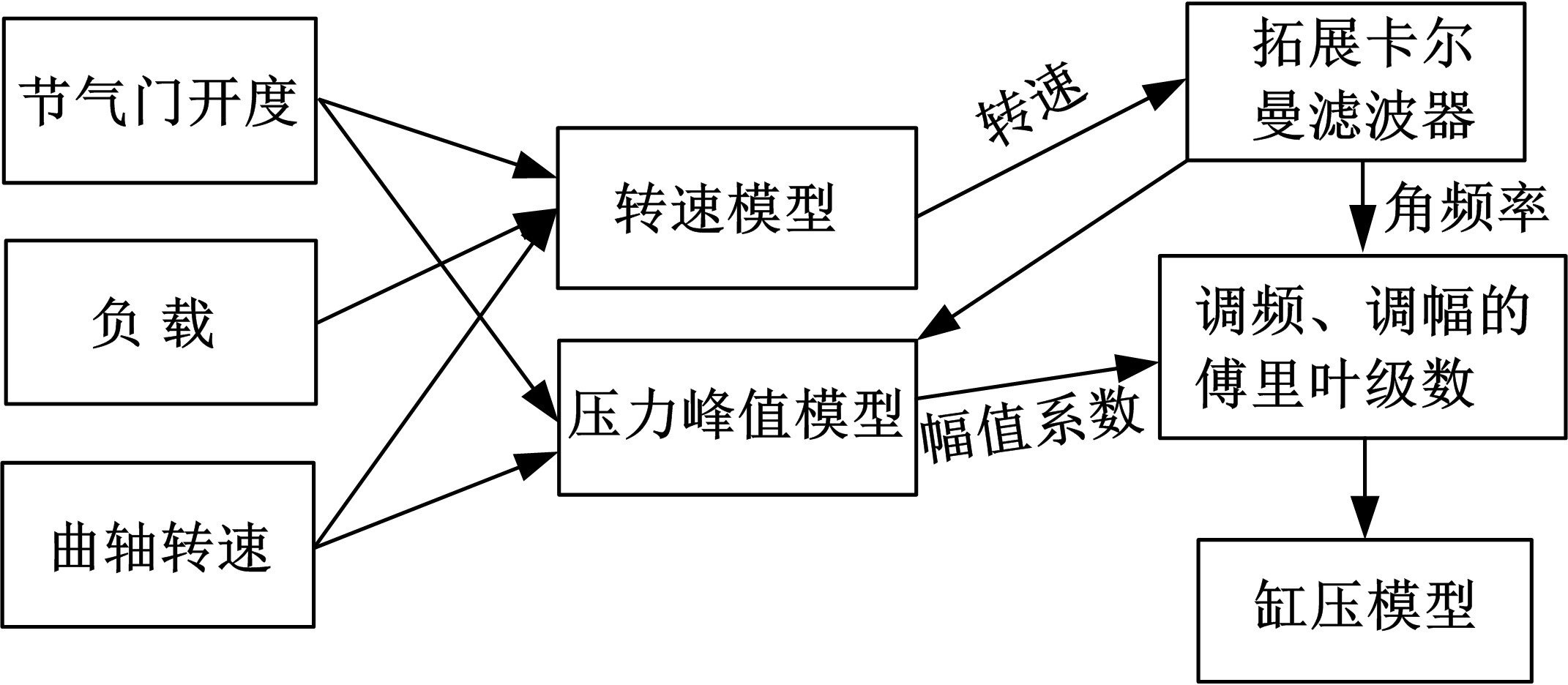

基于EKF及调制傅式级数的缸压辨识

王德军1,2( ),吕志超1,2,王启明3,张建瑞4,丁建楠2

),吕志超1,2,王启明3,张建瑞4,丁建楠2

- 1. 吉林大学 汽车仿真与控制国家重点实验室,长春130022

2. 吉林大学 通信工程学院, 长春130022

3. 吉林大学 交通学院, 长春130022

4. 中国第一汽车集团有限公司 技术中心,长春 130021

Cylinder pressure identification based on EKF and frequency⁃amplitude modulation Fourier series

De⁃jun WANG1,2( ),Zhi⁃chao LYU1,2,Qi⁃ming WANG3,Jian⁃rui ZHANG4,Jian⁃nan DING2

),Zhi⁃chao LYU1,2,Qi⁃ming WANG3,Jian⁃rui ZHANG4,Jian⁃nan DING2

- 1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2. College of Communication Engineering, Jilin University, Changchun 130022, China

3. College of Transportation, Jilin University, Changchun 130022, China

4. R&D Center, China FAW Co. , Ltd. ,Changchun 130022, China

摘要:

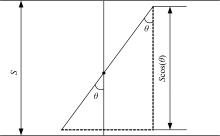

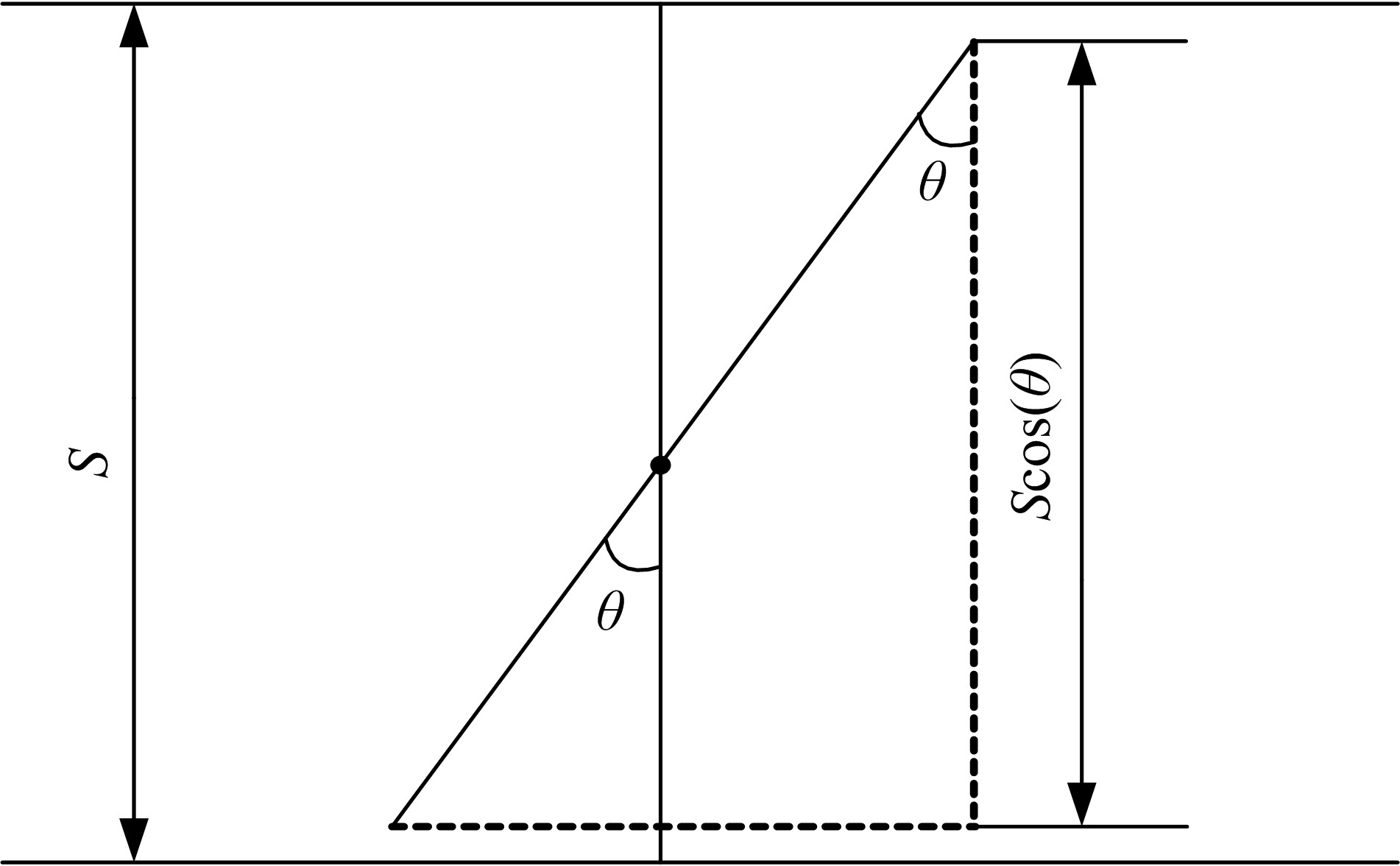

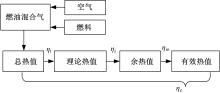

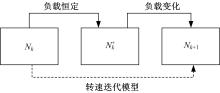

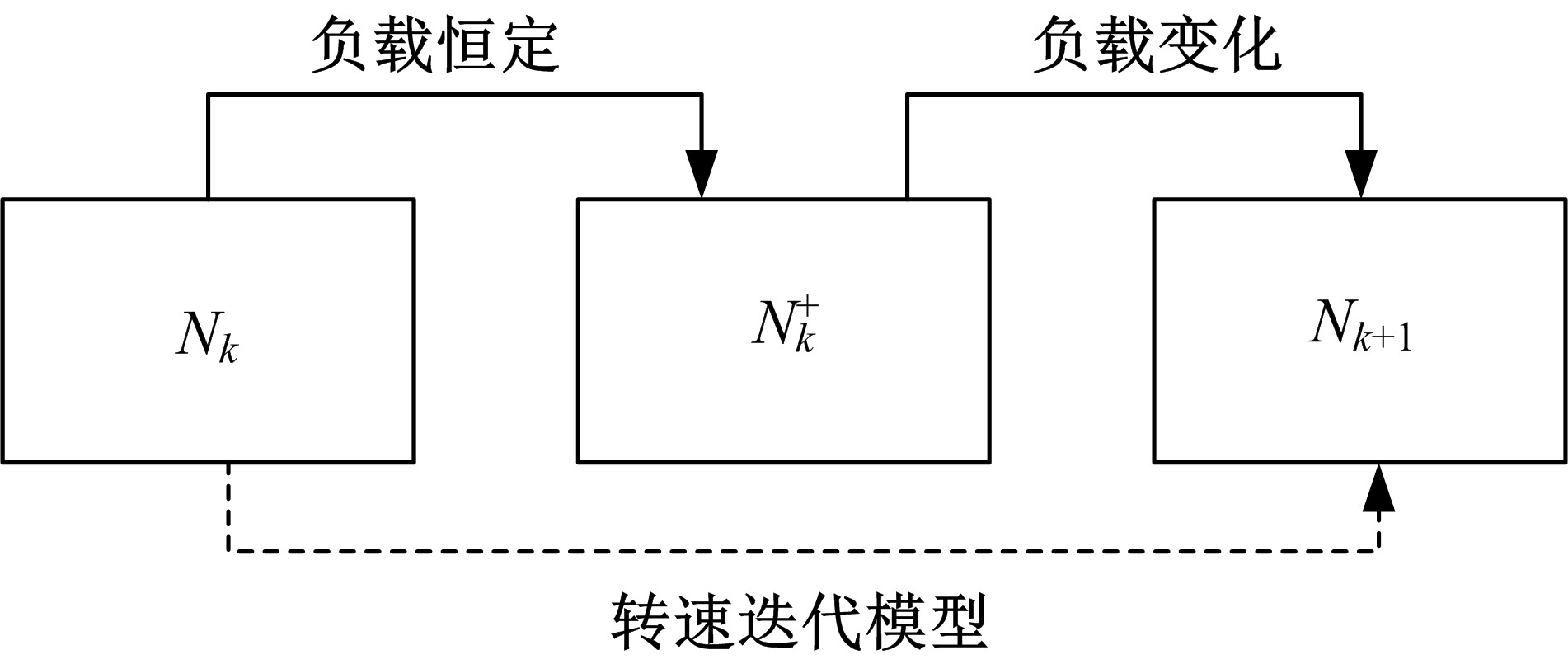

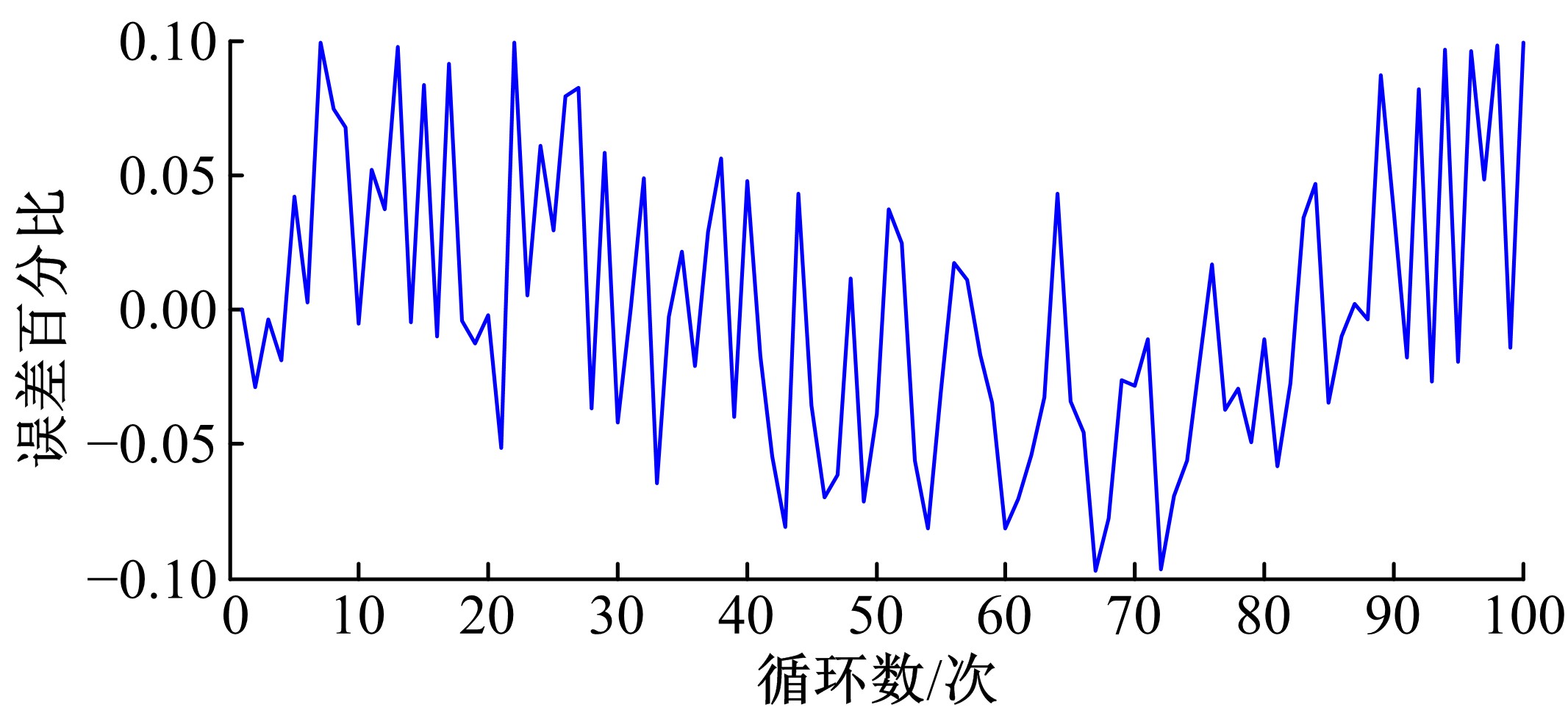

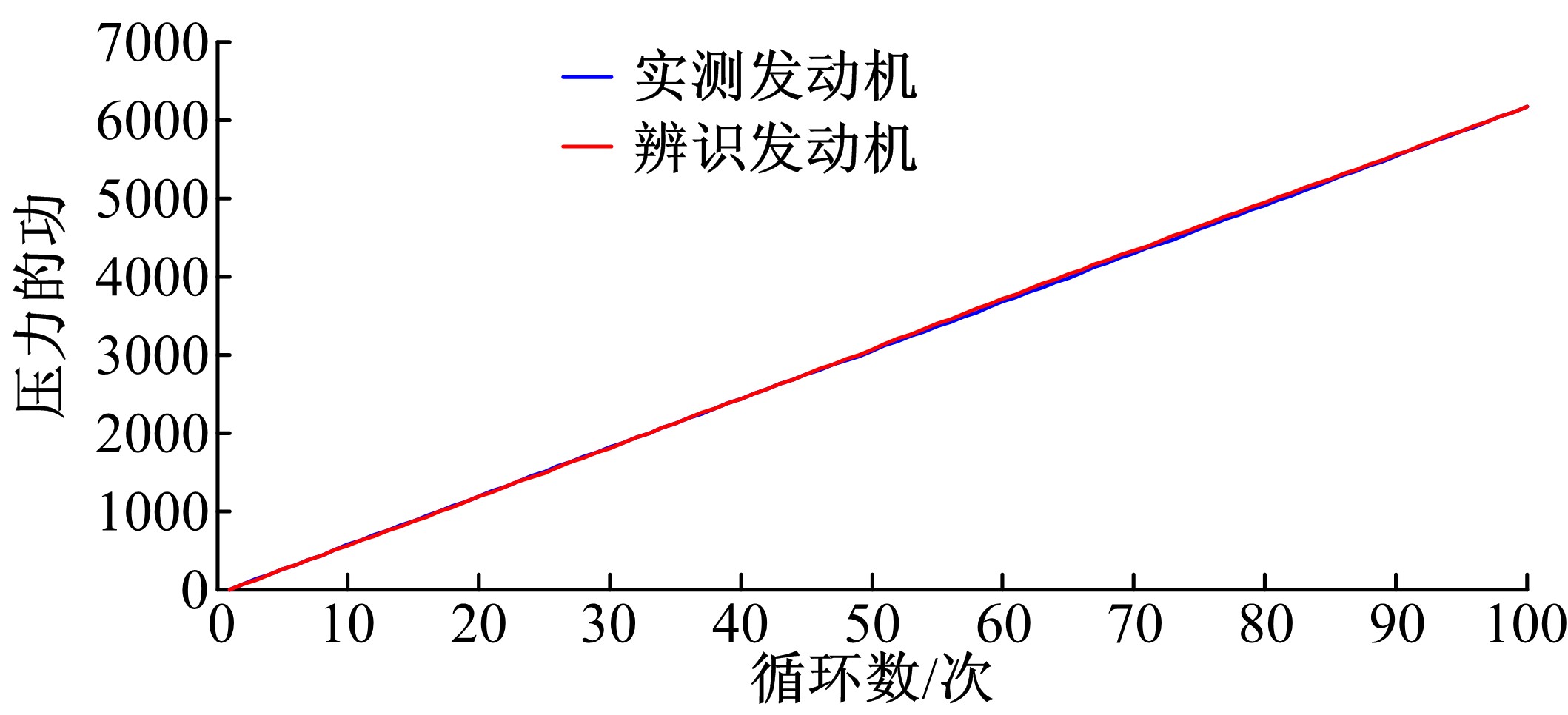

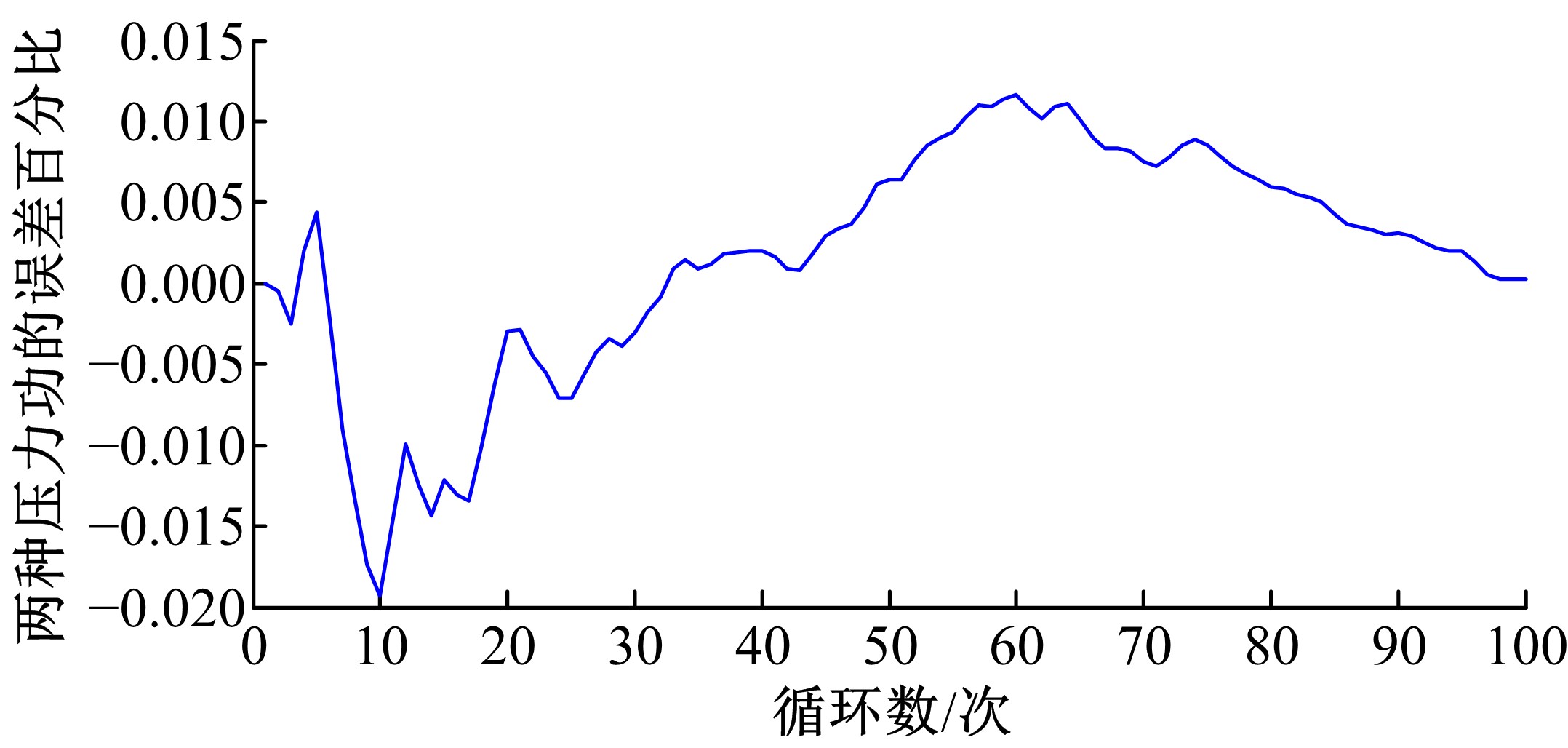

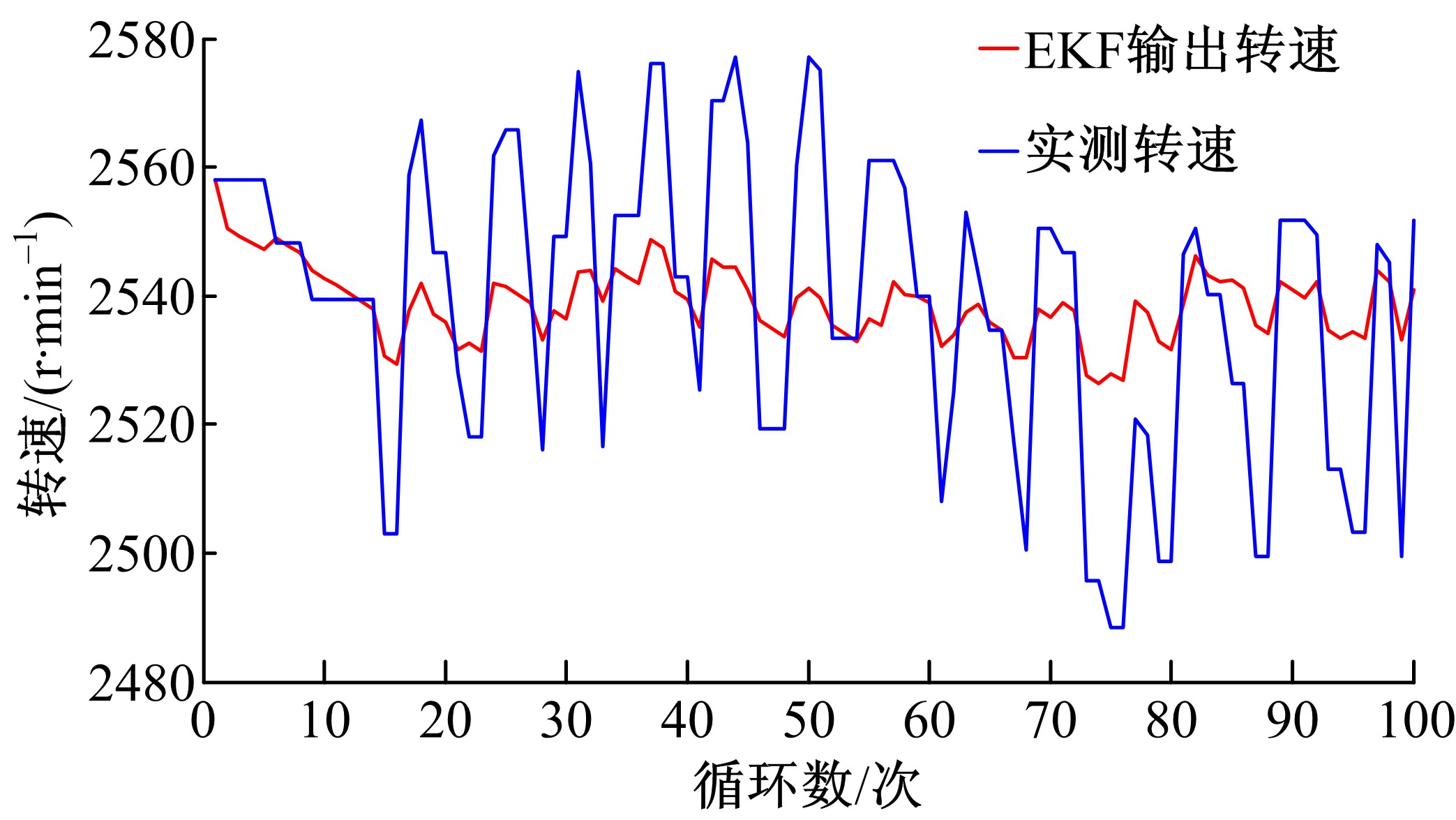

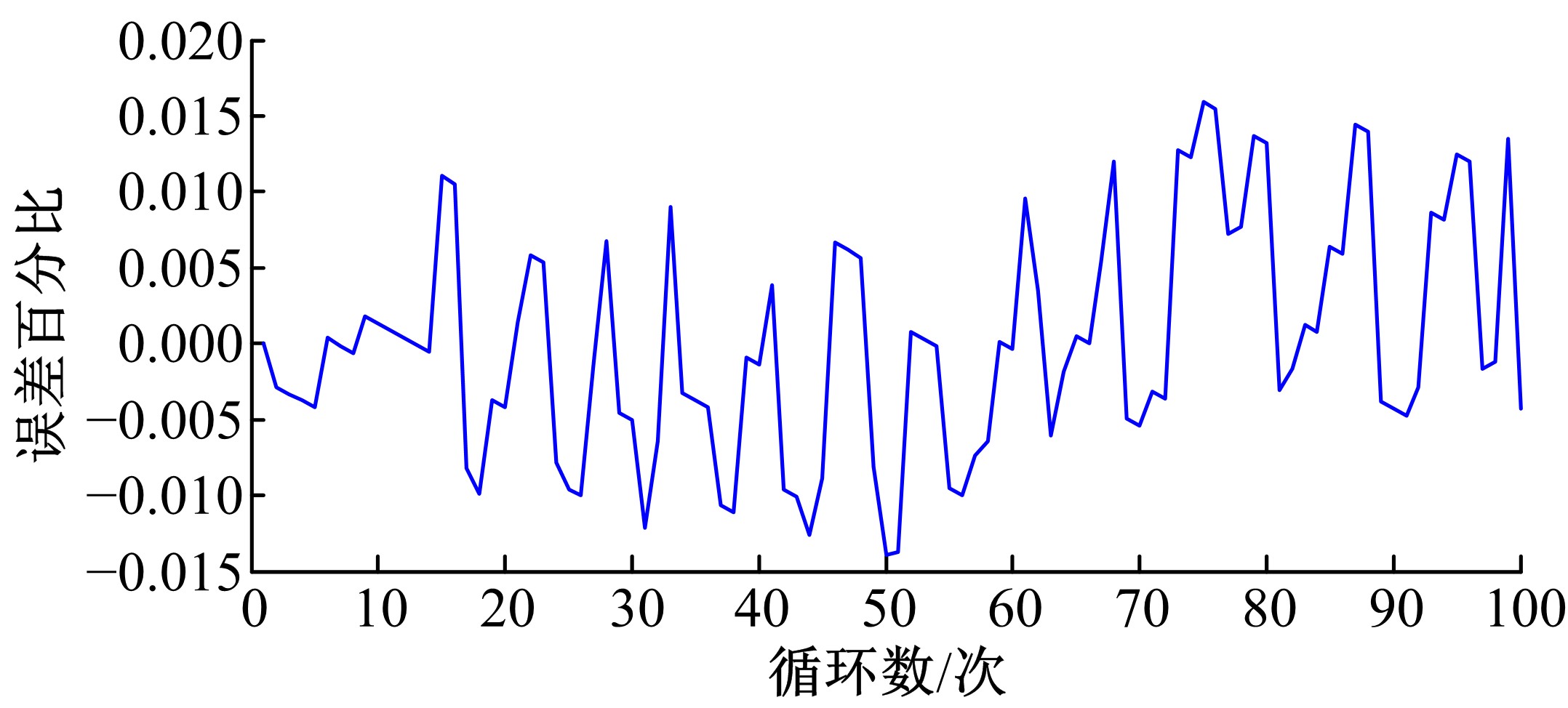

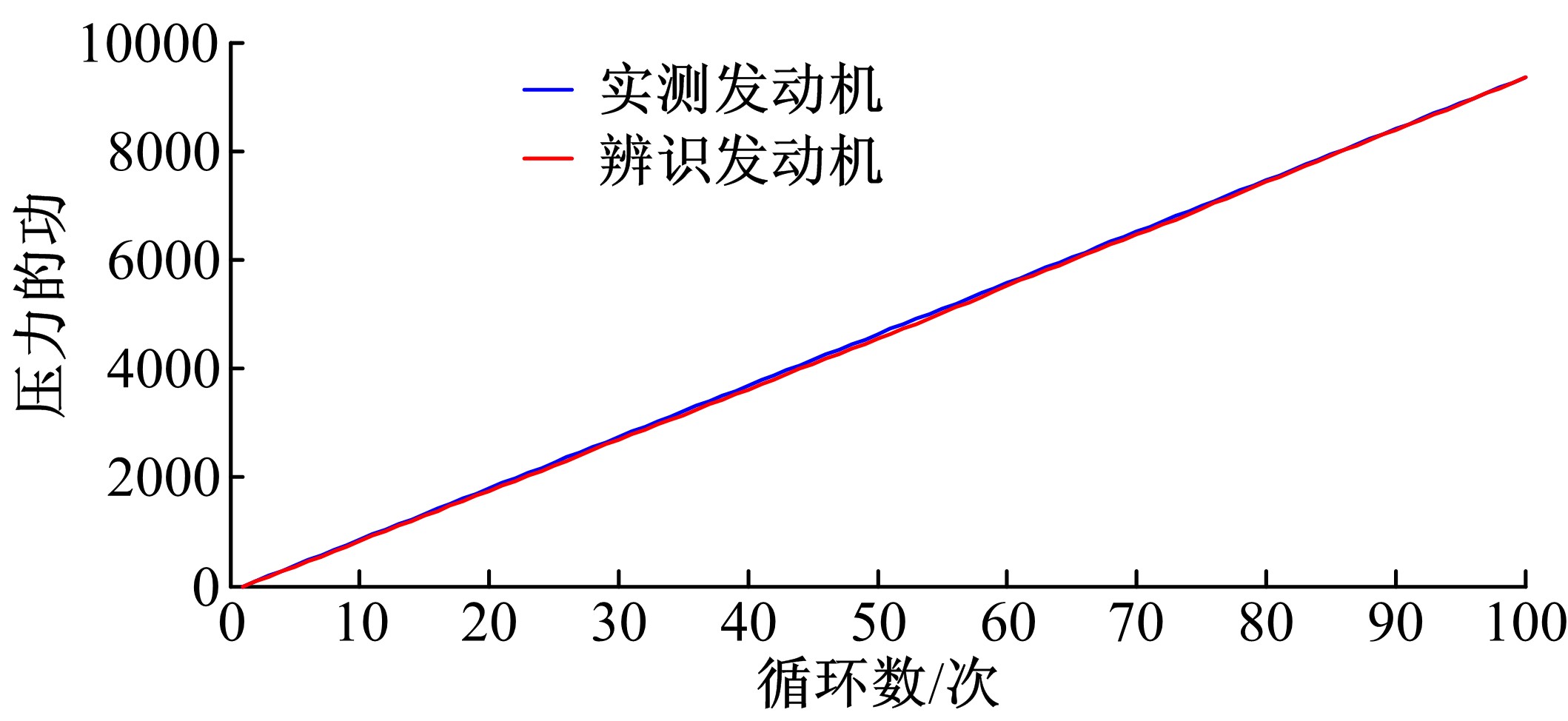

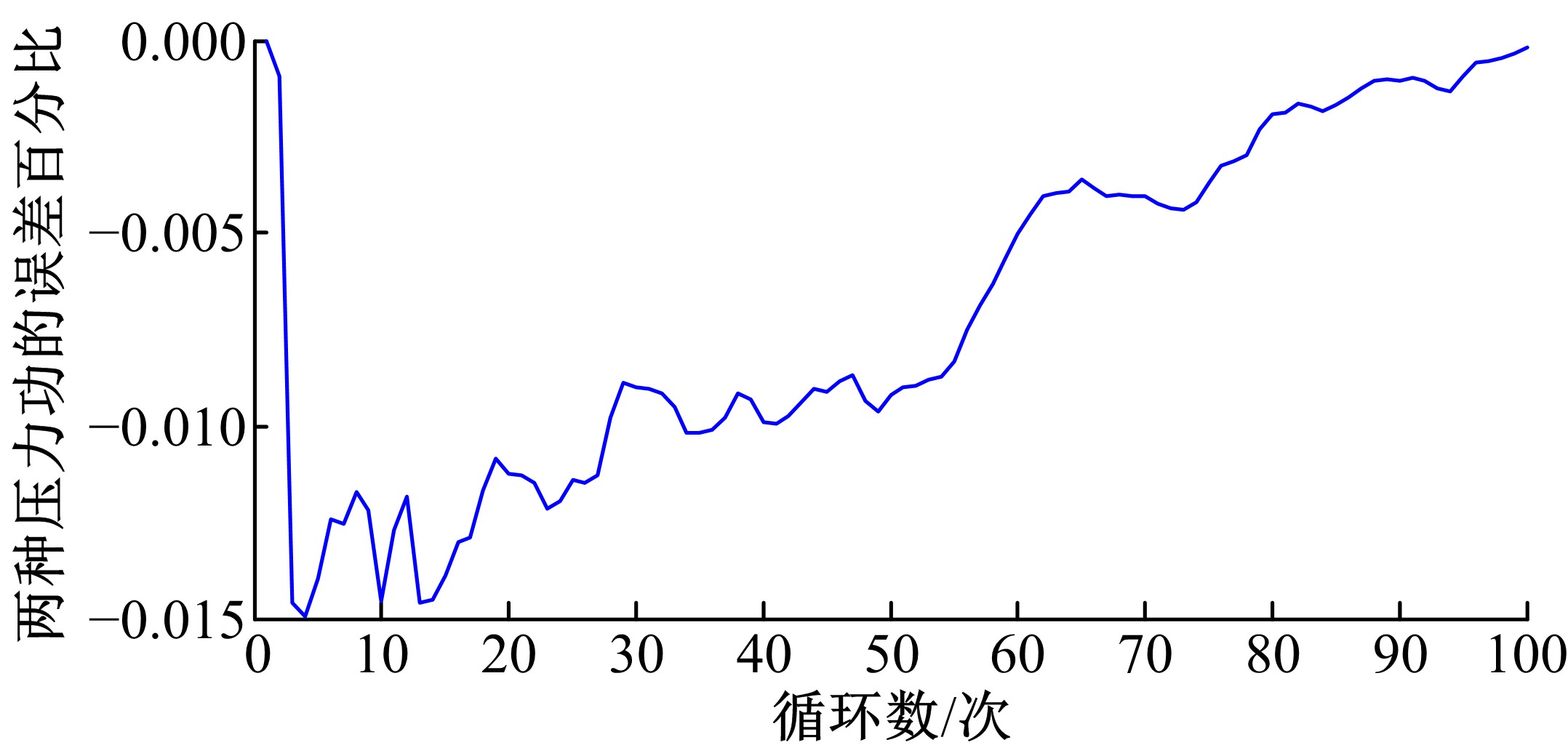

针对侵入式发动机压力传感器造价高以及运行环境恶劣导致寿命短、可靠性低的问题,利用发动机做功能量转化和牛顿运动定律对发动机做功进行建模,建立转速一步迭代模型,利用扩展卡尔曼滤波器(EKF)对转速迭代模型进行线性化处理并进行最优估计。利用奥拓循环搭建做功循环的标准模型,利用工程热力学知识对缸内压力峰值进行求取,利用压力峰值和转速最优估计分别进行24阶傅里叶级数的频率、幅值的调制,最终完成发动机汽缸压力辨识。采用大众牌EA211发动机进行试验验证,结果表明:当设定发动机空燃比系数为0.85时,转速跟踪误差在10%以内,压力功谱误差低于2%;当设定空燃比系数为0.95时,转速跟踪误差在1.5%以内,压力功谱误差低于1.5%。试验结果证明了本文模型和算法的有效性、可靠性和精确性。

中图分类号:

- TK41

| 1 | Ducek K P , Michael S . A control⁃oriented internal model for cylinder pressure in combustion engines[J]. IEEE Transactions on Automatic Control, 1989, 34(4):386⁃397. |

| 2 | Rizzoni G . A stochastic model for the indicated pressure process and the dynamics of the internal combustion engine[J]. IEEE Transactions on Vehicular Technology, 1989, 38(3):180⁃192. |

| 3 | Min K , Chung J , Sunwoo M . Torque balance control for light⁃duty diesel engines using an individual cylinder IMEP estimation model with a single cylinder pressure sensor[J]. Applied Thermal Engineering, 2016,109(Part A): 440⁃448. |

| 4 | Bennett C , Dunne J F , Trimby S , et al . Engine cylinder pressure reconstruction using crank kinematics and recurrently⁃trained neural networks[J]. Mechanical Systems and Signal Processing,2017(85):126⁃145. |

| 5 | Bodisco T , Brown R J . Inter⁃cycle variability of in⁃cylinder pressure parameters in an ethanol fumigated common rail diesel engine[J]. Energy, 2013, 52: 55⁃65. |

| 6 | Muddassar A R , Aamer I B , Qarab R B . Hybrid model of the gasoline engine for misfire detection[J]. IEEE Transactions on Industrial Electronics, 2011, 58(8):3680⁃3692. |

| 7 | Al⁃Durra A , Canova M , Yurkovich S . A real⁃time pressure estimation algorithm for closed⁃loop combustion control[J]. Mechanical Systems and Signal Processing, 2013(38):411–427. |

| 8 | Naik S . Advanced misfire detection using adaptive signal processing[J]. International Journal of Adaptive Control and Signal Processing, 2004, 18(2):181⁃198. |

| 9 | Shiao Y J , Moskwa J J . Cylinder pressure and combustion heat release estimation for SI engine diagnostics using nonlinear sliding observers[J]. IEEE Transactions on Control Systems Technology, 1995,3(1):70⁃78. |

| 10 | 濮立俊,杨建国,王志华,等 . 利用发动机瞬时转速波动诊断气门漏气故障[J]. 武汉交通科技大学学报,2000,24(1):59⁃63. |

| Pu Li⁃jun , Yang Jian⁃guo , Wang Zhi⁃hua , et al . Diagnosing leakage of valves in engines by analyzing instantaneous speed fluctuations[J]. Journal of Wuhan Transportation University,2000,24(1):59⁃63. | |

| 11 | 任卫军,贺昱曜,张卫钢 . 基于曲轴段加速度的内燃机失火故障在线诊断[J]. 汽车工程, 2010, 32(4): 339⁃342. |

| Ren Wei⁃jun , He Yi⁃yao , Zhang Wei⁃gang . On⁃line diagnosis on misfire fault of internal combustion engine based on crankshaft segment acceleration[J]. Automotive Engineering,2010,32(4):339⁃342. | |

| 12 | 栾军英,王虹,田昊,等 . 利用瞬时转速诊断站系统中原动机的失火故障[J]. 机械强度,2006(增刊1):56⁃59. |

| Luan Jun⁃ying , Wang Hong , Tian Hao ,et al . Application of transient rotational speed on diagnosing motor misfire of power station[J]. Journal of Mechanical Strength, 2006(Sup.1):56⁃59. | |

| 13 | 胡重庆,李艾华,朱春红,等 . 基于瞬时转速统计分析的内燃机失火检测[J]. 内燃机学报,2009, 27(5):446⁃451. |

| Hu Chong⁃qing , Li Ai⁃hua , Zhu Chun⁃hong ,et al . Misfire detection based on statistical analysis of instantaneous rational speed[J]. Transactions of CSICE, 2009, 27(5):446⁃451. | |

| 14 | Taglialatela F , Lavorgna M , Mancaruso E , et al . Determination of combustion parameters using engine crankshaft speed[J]. Mechanical Systems and Signal Processing, 2013,38(2):628⁃633. |

| 15 | Seuling S , Hamedovic H , Fischer W , et al . Model based engine speed evaluation for single⁃cylinder engine control[C]∥SAE Paper,2012⁃32⁃0044. |

| 16 | Al⁃Durra A , Canova M , Yurkovich S . Application of extended kalman filter to on⁃line diesel engine cylinder pressure estimation[C]∥Proceedings of the ASME Dynamic Systems and Control Conference, Hollywood, California, USA, 2009. |

| 17 | 沈刚 . 并联冗余驱动电液振动台控制系统[M].北京:科学出版社,2016:35⁃60. |

| 18 | 蔡凤英 . 化工安全工程[M]. 2版.北京:科学出版社,2009:33⁃50. |

| 19 | 林学东 . 发动机原理[M].北京:机械工业出版社,2015:55⁃88. |

| 20 | 哈尔滨工业大学理论力学研究室 .理论力学[M]. 7版.北京:高等教育出版社,2009:288⁃322. |

| 21 | Metghalchi M , Keck J C . Burning velocities of mixtures of air with methanol,isooctane,and indolene at high pressure and temperature[J]. Combustion and Flame, 1982,48:191⁃210. |

| 22 | Zhao Jun⁃bo , Marcos Netto , Lamine Mili . A robust iterated extended Kalman filter for power system dynamic state estimation[J]. IEEE Transactions on Power Systems, 2017, 32(4): 3205⁃3216. |

| 23 | Zhang Tie⁃min , Liao Yi⁃hua . Attitude measure system based on extended Kalman filter for multi⁃rotors [J]. Computers and Electronics in Agriculture, 2017(134):19⁃26. |

| 24 | 全兴信 . 内燃机学[M]. 北京.机械工业出版社,2016:30⁃99. |

| 25 | 沈维道 . 工程热力学[M]. 北京. 高等教育出版社,2000:29⁃46. |

| 26 | Yang Y , Peng Z K , Dong X J . General parameterized time⁃frequency transform[J]. IEEE Transactions on Signal Processing,2014, 62(11):2751⁃2764. |

| 27 | Oppenheim A V , Willsky A S , S Hamid Nawab . Signals & Systems[M]. 2nd ed. Upper Saddle River: Prentice Hall, 2005: 235⁃255. |

| 28 | Zhou Ke⁃min . Essentials of Robust Control[M]. Upper Saddle River:Prentice Hall, 1999:20⁃50. |

| [1] | 臧鹏飞,王哲,高洋,孙晨乐. 直线电机/发动机系统稳态运行综合控制策略[J]. 吉林大学学报(工学版), 2019, 49(3): 798-804. |

| [2] | 董伟,宋佰达,邱立涛,孙昊天,孙平,蒲超杰. 直喷汽油机暖机过程中两次喷射比例对燃烧和排放的影响[J]. 吉林大学学报(工学版), 2018, 48(6): 1755-1761. |

| [3] | 李志军, 汪昊, 何丽, 曹丽娟, 张玉池, 赵新顺. 催化型微粒捕集器碳烟分布及其影响因素[J]. 吉林大学学报(工学版), 2018, 48(5): 1466-1474. |

| [4] | 秦静, 徐鹤, 裴毅强, 左子农, 卢莉莉. 初始温度和初始压力对甲烷-甲醇裂解气预混层流燃烧特性的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1475-1482. |

| [5] | 林学东, 江涛, 许涛, 李德刚, 郭亮. 高压共轨柴油机起动工况高压泵控制策略[J]. 吉林大学学报(工学版), 2018, 48(5): 1436-1443. |

| [6] | 宫洵, 蒋冰晶, 胡云峰, 曲婷, 陈虹. 柴油机主-从双微元Urea-SCR系统非线性状态观测器设计与分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1055-1062. |

| [7] | 钟兵, 洪伟, 金兆辉, 苏岩, 解方喜, 张富伟. 进气门早关液压可变气门机构运动特性[J]. 吉林大学学报(工学版), 2018, 48(3): 727-734. |

| [8] | 席雷, 徐亮, 高建民, 赵振, 王明森. 厚壁矩形带肋通道内蒸汽流动及传热特性[J]. 吉林大学学报(工学版), 2018, 48(3): 752-759. |

| [9] | 李龙, 张幽彤, 左正兴. 变负载控制在自由活塞内燃发电机的缸压控制中的应用[J]. 吉林大学学报(工学版), 2018, 48(2): 473-479. |

| [10] | 卫海桥, 裴自刚, 冯登全, 潘家营, 潘明章. 压电喷油器多次喷射对GDI汽油机颗粒物排放的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 166-173. |

| [11] | 田径, 刘忠长, 刘金山, 董春晓, 钟铭, 杜文畅. 基于燃烧边界参数响应曲面设计的柴油机性能优化[J]. 吉林大学学报(工学版), 2018, 48(1): 159-165. |

| [12] | 李志军, 何丽, 姜瑞, 申博玺, 孔祥金, 刘世宇. 柴油机微粒捕集器灰分分布对其压降的影响评价[J]. 吉林大学学报(工学版), 2017, 47(6): 1760-1766. |

| [13] | 郭亮, 杨文昭, 王云开, 孙万臣, 程鹏, 李国良. 废气再循环对丁醇/柴油混合燃料发动机的影响[J]. 吉林大学学报(工学版), 2017, 47(6): 1767-1774. |

| [14] | 虞浏, 刘忠长, 刘江唯, 杜宏飞, 许允. 直喷汽油机喷雾粒径特性[J]. 吉林大学学报(工学版), 2017, 47(5): 1482-1488. |

| [15] | 彭玮, 李国祥, 闫伟. 适用于发动机散热器的壁面函数改进[J]. 吉林大学学报(工学版), 2017, 47(3): 804-810. |

|

||