吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (3): 836-841.doi: 10.13229/j.cnki.jdxbgxb20180202

6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场

- 1. 吉林大学 材料科学与工程学院,长春 130022

2. 吉林大学 汽车材料教育部重点实验室,长春 130022

3. 长春工业大学 材料科学与工程学院,长春 130012

Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet

Yu⁃peng LI1,2,3( ),Da⁃qian SUN1,2,Wen⁃biao GONG3

),Da⁃qian SUN1,2,Wen⁃biao GONG3

- 1. School of Materials Science and Engineering, Jilin University, Changchun 130022, China

2. Key Laboratory of Automobile Materials, Ministry of Education, Jilin University, Changchun 130022, China

3. School of Materials Science and Engineering, Changchun University of Technology, Changchun 130012, China

摘要:

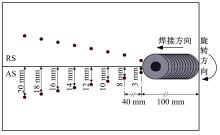

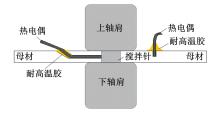

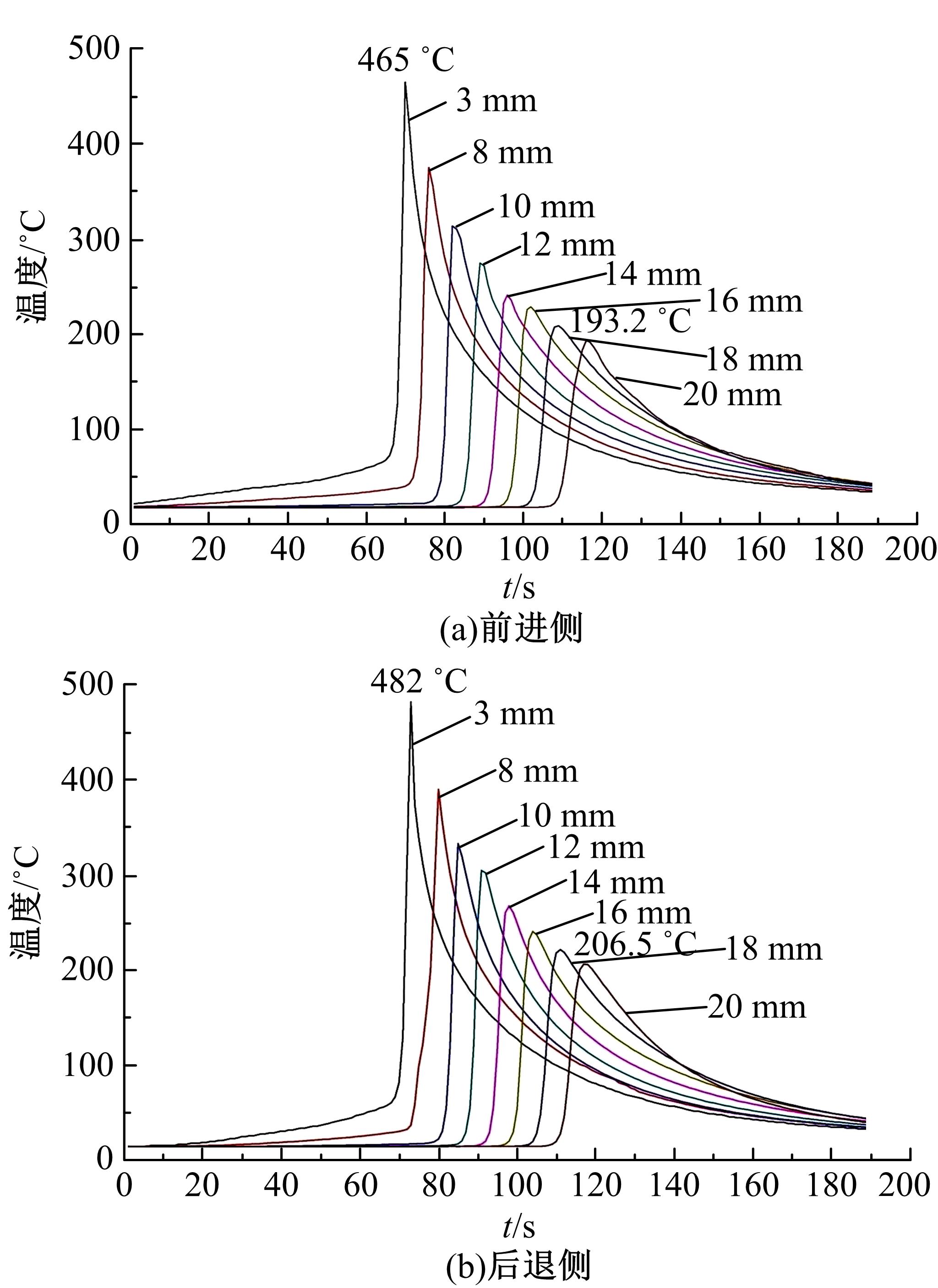

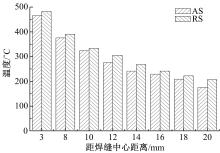

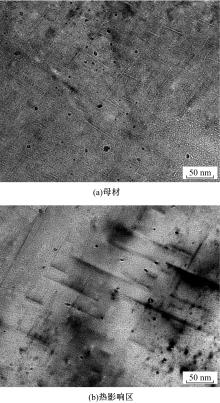

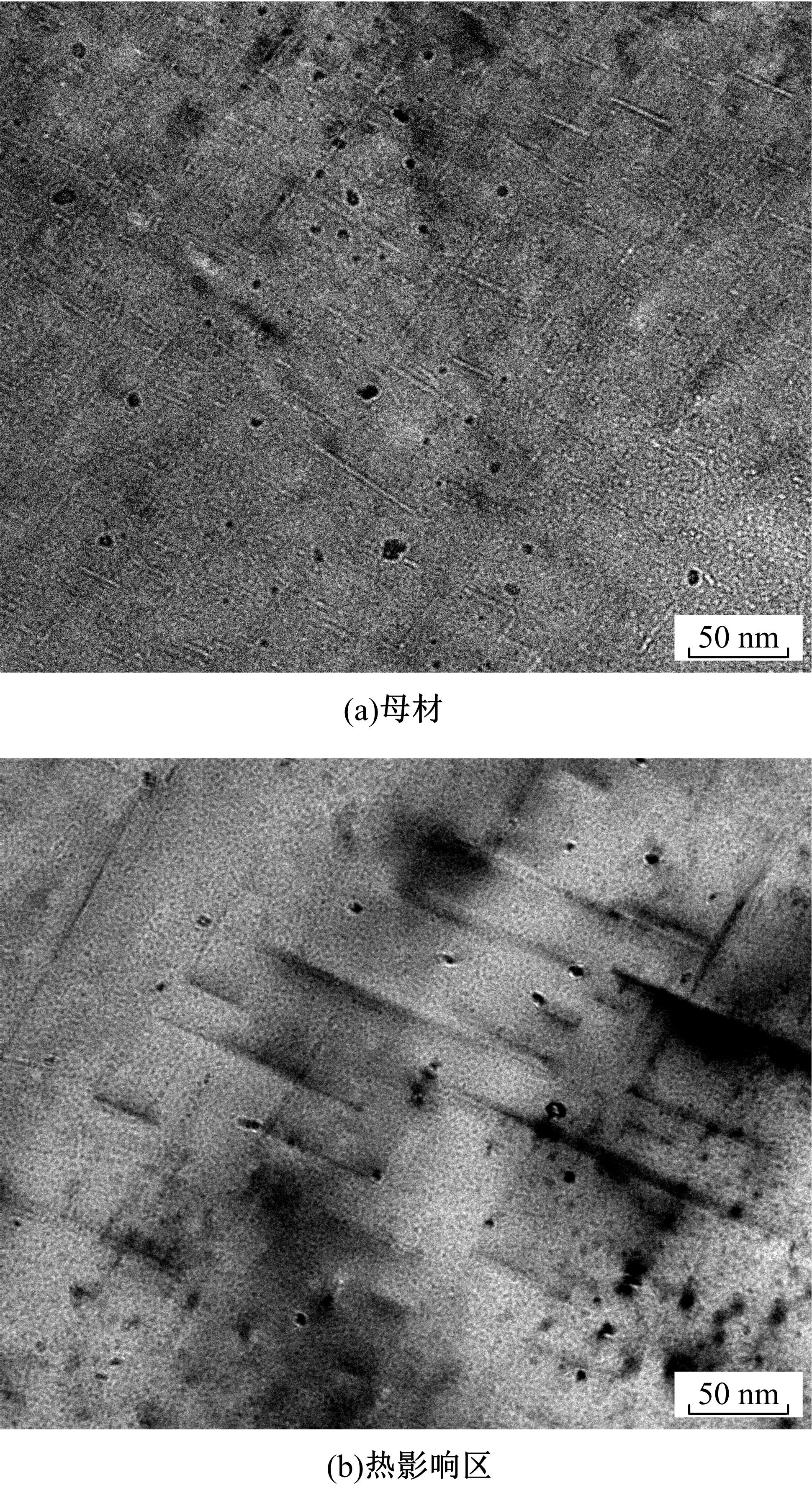

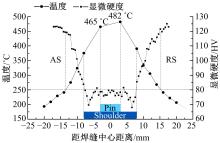

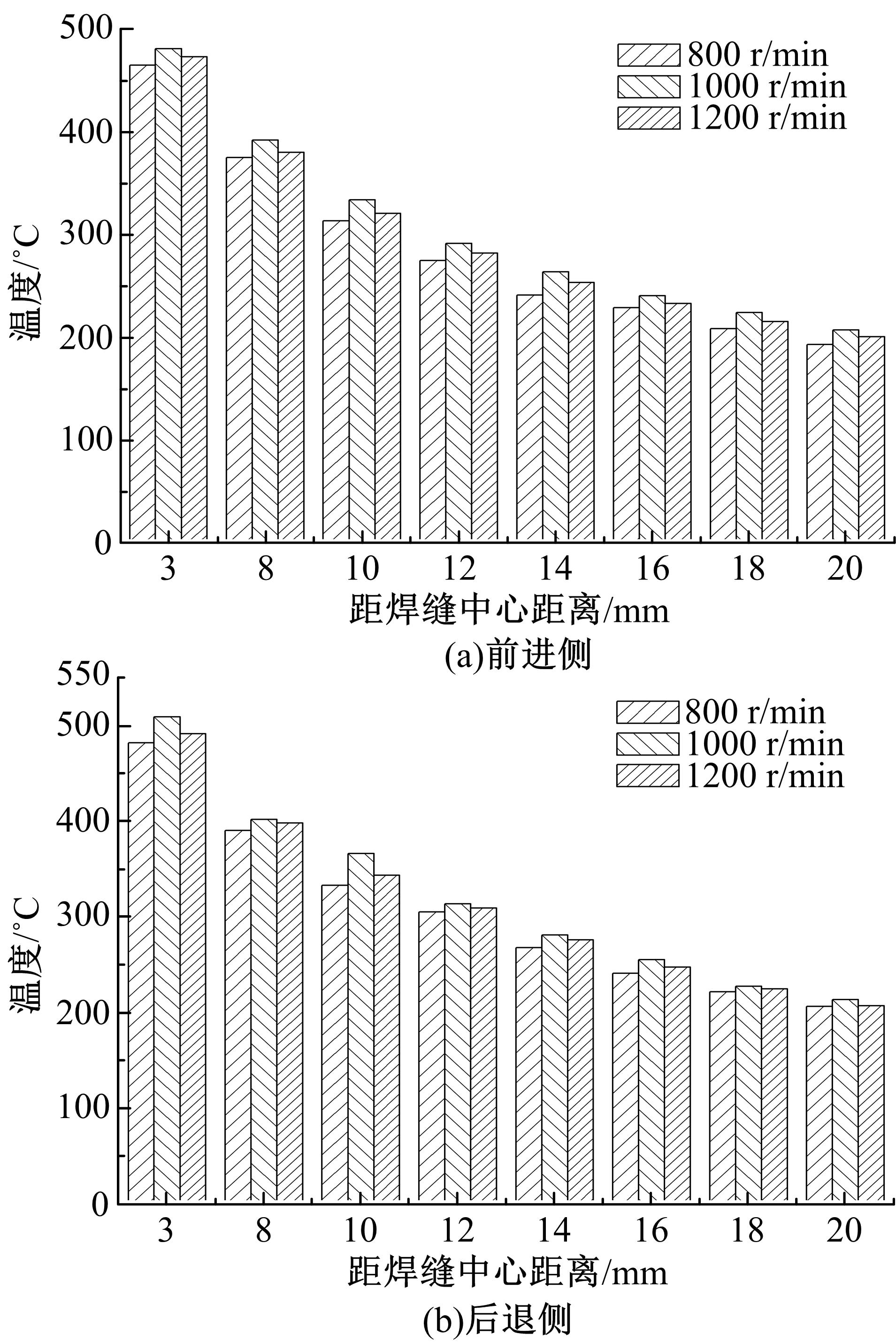

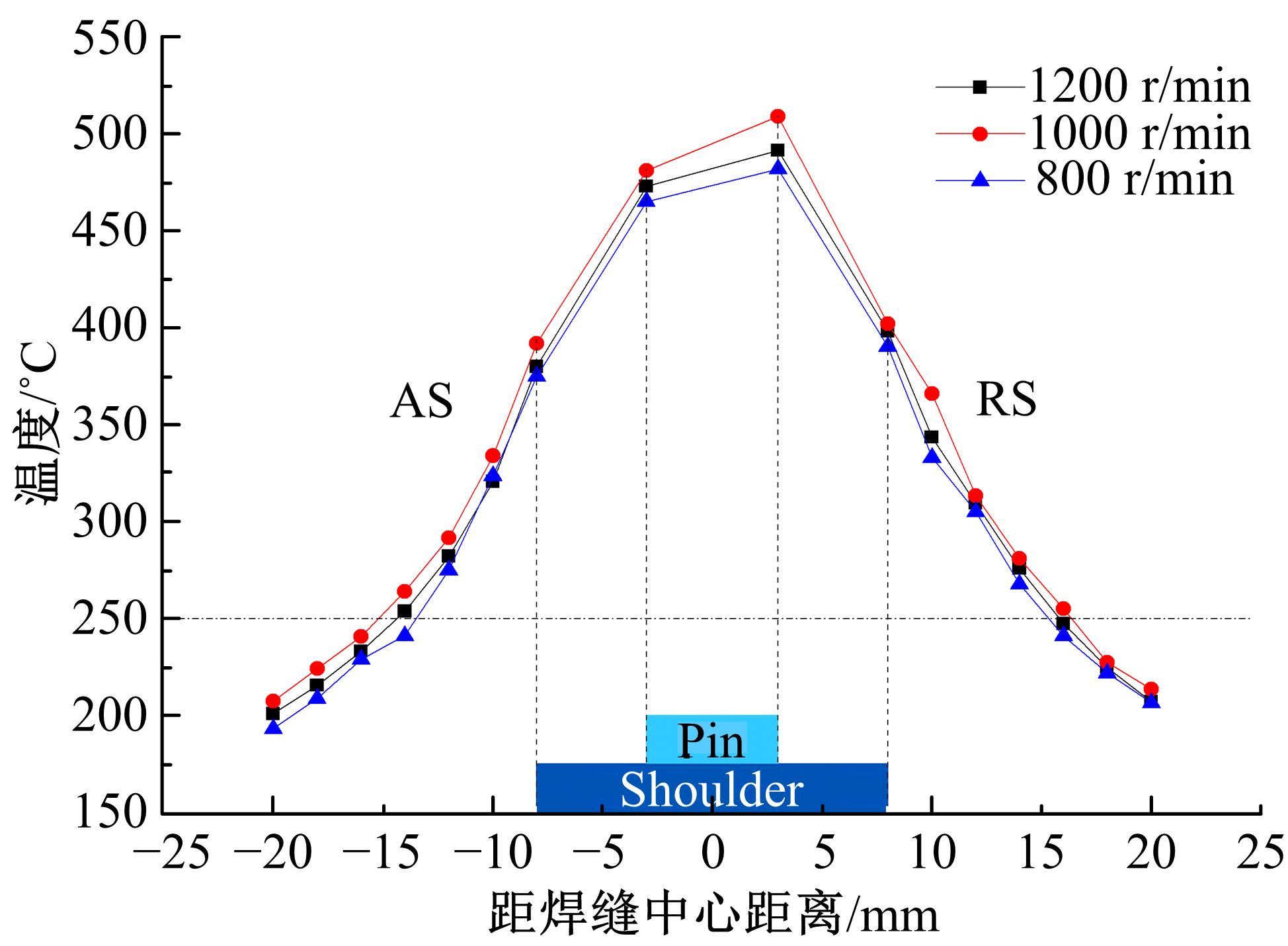

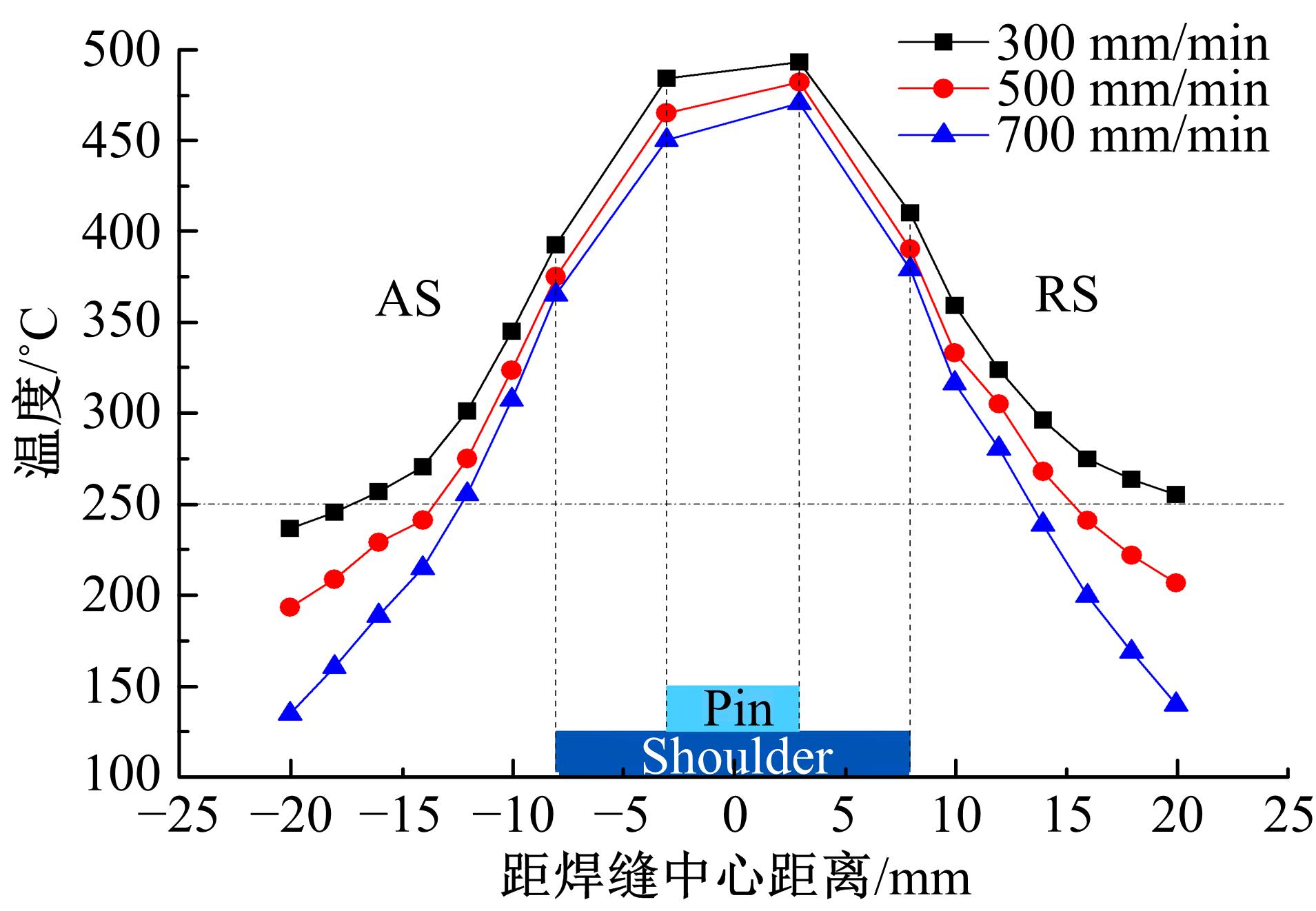

采用热电偶对4 mm厚6082?T6铝合金薄板双轴肩搅拌摩擦焊不同工艺焊接过程中各特征点的温度进行测定,绘制各点的热循环曲线,分析焊接过程中接头各区域温度场分布特征。研究表明:6082?T6铝合金薄板双轴肩搅拌摩擦焊时,后退侧各点的峰值温度均高于前进侧,温度差值在20 ℃左右;当热影响区温度超过250 ℃时出现β''相溶解,硬度开始呈现下降趋势;焊速不变、转速增大时,热输入量呈先增大后减小的趋势,在转速为1000 r/min时各测温点温度均达到最大值,当转速为1200 r/min时出现下降;转速不变、焊速增大时,单位热输入量降低,前进侧与后退侧的峰值温度差值由小变大,温度场250 ℃等温线分布宽度明显缩小。

中图分类号:

- TG456.9

| 1 | ThomasW M, NicholasE D, NeedhamJ C, et al. Improvements relating of friction welding[P]. PCT/GB1992/002203,1992⁃11⁃27. |

| 2 | 温泉,李文亚,王非凡, 等. 双轴肩搅拌摩擦焊接方法研究进展[J]. 航空制造技术,2017(12):16⁃23. |

| WenQuan,LiWen⁃ya,WangFei⁃fan,et al. Research progress on bobbin tool friction stir welding[J]. Aeronautical Manufacturing Technology,2017(12):16⁃23. | |

| 3 | LiuH J,HouJ C, GuoH. Effect of welding speed on microstructure and mechanical properties of self⁃reacting friction stir welded 6061⁃T6 aluminum alloy[J]. Materials & Design,2013(50):872⁃878. |

| 4 | 赵秋颖,吴志生,刘翠荣,等. 铝合金搅拌摩擦焊研究现状[J]. 焊接技术,2016(1):1⁃5. |

| ZhaoQiu⁃ying,WuZhi⁃sheng,LiuCui⁃rong, et al. Research status about friction stir welding of aluminum alloy[J]. Welding Technology,2016(1):1⁃5. | |

| 5 | 刘杰,邓刚,韩凤武,等. 双轴肩搅拌摩擦焊技术在铝合金车体制造中的应用发展[J].焊接,2015(1):17⁃20. |

| LiuJie, DengGang, HanFeng⁃wu, et al. The application and development of the friction stir welding technology in the manufacture of aluminum alloy body[J]. Welding & Jointing,2015(1):17⁃20. | |

| 6 | ThreadgillP L, LeonardA J, ShercliffH R, et al. Friction stir welding of aluminum alloys[J]. International Materials Reviews,2009,54(2):49⁃93. |

| 7 | SongM, KovacevicR. Thermal modeling of friction stir welding in a moving coordinate system and its validation[J]. International Journal of Machine Tools and Manufacture,2003,43(6):605⁃615. |

| 8 | SongM, KovacevicR. Numerical and experimental study of the heat transfer process in friction stir welding[J]. Proceedings of the Institution of Mechanical Engineers Part B:Journal of Engineering Manufacture,2003,217(1):73⁃85. |

| 9 | OerteltG, BabuS S,DabidS A, et al. Effect of thermal cycling on friction stir welds of 2195 aluminum alloy[J]. Welding Journal,2001,80(3):71⁃79. |

| 10 | HilgertJ, SchmidtH N B, SantosJ F, et al. Thermal models for bobbin tool friction stir welding[J]. Jounral of Materials Processing Technology,2011,211(2):197⁃204. |

| 11 | TangW, GuoX, McClureJ C, et al. Heat input and temperature distribution in friction stir welding[J]. Journal of Materials Processing and Manufacturing Science,1998,7(2):163⁃172. |

| 12 | HwangY M, KangZ W, ChiouY C, et al. Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys[J]. International Journal of Machine Tools and Manufacture,2008,48(7):778⁃787. |

| 13 | 张骁,王敏,张会杰,等. 2A14铝合金双轴肩搅拌摩擦焊的温度场模拟与测定[J]. 焊接,2015(9):16⁃19. |

| ZhangXiao, WangMin, ZhangHui⁃jie, et al. Simulation and test of bobbin tool friction stir welding temperature feld of 2A14 aluminum alloy[J]. Welding & Joining,2015(9):16⁃19. | |

| 14 | ChenShun⁃jin, LiHao,LuSheng, et al. Temperature measurement and control of bobbin tool friction stir welding[J]. The International Journal of Advanced Manufacturing Technology,2016,86(1⁃4):337⁃346. |

| 15 | 李敬勇,周小平,董春林,等. 6082铝合金双轴肩搅拌摩擦焊试板温度场研究[J].航空材料学报,2013,33(5):36⁃40. |

| LiJing⁃yong,ZhouXiao⁃ping,DongChun⁃lin,et al. Temperature fields in 6082 Aluminum alloy samples bobbin⁃tool friction stir welded[J]. Journal of Aeronautical Materials,2013,33(5):36⁃40. | |

| 16 | 王冰. 6082⁃T6铝合金搅拌摩擦焊接头微观组织及力学性能的研究[D]. 长春: 吉林大学材料科学与工程学院,2015. |

| WangBing. Study on microstructures and mechanical properties of friction stir welding joints of 6082⁃T6 aluminum alloy[D]. Changchun: College of Materials Science and Engineering, Jilin University,2015. | |

| 17 | AndersenS J, ZandbergenH W, JansenJ, et al. The crystal structure of the β'' phase in Al⁃Mg⁃Si alloys[J]. Acta Materialia,1998,46(2):3238⁃3298. |

| 18 | EdwardsG A, StillerK, DunlopG L, et al. The precipitation sequence in Al⁃Mg⁃Si alloys[J]. Acta Materialia,1998,46(11):3893⁃3904. |

| [1] | 关庆丰,张福涛,彭韬,吕鹏,李姚君,许亮,丁佐军. 含硼、钴9%Cr耐热钢的热变形行为[J]. 吉林大学学报(工学版), 2018, 48(6): 1799-1805. |

| [2] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [3] | 刘志峰, 赵代红, 王语莫, 浑连明, 赵永胜, 董湘敏. 重载静压转台承载力与油垫温度场分布的关系[J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

| [4] | 赵宇光, 杨雪慧, 徐晓峰, 张阳阳, 宁玉恒. Al-10Sr变质剂状态、变质温度及变质时间对ZL114A合金组织的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [5] | 汤华国, 马贤锋, 赵伟, 刘建伟, 赵振业. 高性能金属铝的制备、微观结构及其热稳定性[J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [6] | 关庆丰, 张远望, 孙潇, 张超仁, 吕鹏, 张从林. 强流脉冲电子束作用下铝钨合金的表面合金化[J]. 吉林大学学报(工学版), 2017, 47(4): 1171-1178. |

| [7] | 杨晓红, 杭文先, 秦绍刚, 刘勇兵, 刘利萍. H13钢激光熔覆钴基复合涂层的组织及耐磨性[J]. 吉林大学学报(工学版), 2017, 47(3): 891-899. |

| [8] | 王国林, 孙砚田, 梁晨, 杨建, 周海超. 应用满应力理论的轮胎轮廓设计[J]. 吉林大学学报(工学版), 2017, 47(2): 365-372. |

| [9] | 邵晴, 徐涛, 徐从占, 郭昊添, 郭桂凯, 张海博. 基于聚醚醚酮保持架的角接触球轴承特性仿真[J]. 吉林大学学报(工学版), 2017, 47(1): 163-168. |

| [10] | 关庆丰, 黄尉, 李怀福, 龚晓花, 张从林, 吕鹏. 强流脉冲电子束诱发的Cu-C扩散合金化[J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

| [11] | 张学广, 刘纯国, 郑愿, 江仲海, 李湘吉. 基于延性损伤和剪切损伤的铝合金成形极限预测[J]. 吉林大学学报(工学版), 2016, 46(5): 1558-1566. |

| [12] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [13] | 李春玲, 樊丁, 王斌, 余淑荣. 5A06铝合金/镀锌钢预置涂粉对接激光熔钎焊组织与性能[J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [14] | 张家陶, 赵宇光, 谭娟. 初始组织对电脉冲处理逆变奥氏体晶粒细化效果的影响[J]. 吉林大学学报(工学版), 2016, 46(1): 193-198. |

| [15] | 张志强, 贾晓飞, 袁秋菊. 基于Yoshida-Uemori模型的TRIP800高强钢回弹分析[J]. 吉林大学学报(工学版), 2015, 45(6): 1852-1856. |

|

||