吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (6): 1826-1835.doi: 10.13229/j.cnki.jdxbgxb20181075

钢铝异质自冲铆接头剥离失效仿真

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Simulation on peeling failure of self⁃piercing riveted joints insteel and aluminum alloy dissimilar sheets

Wei-min ZHUANG( ),Yang LIU,Peng-yue WANG,Hong-da SHI,Ji-shuan XU

),Yang LIU,Peng-yue WANG,Hong-da SHI,Ji-shuan XU

- State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022,China

摘要:

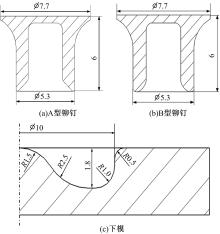

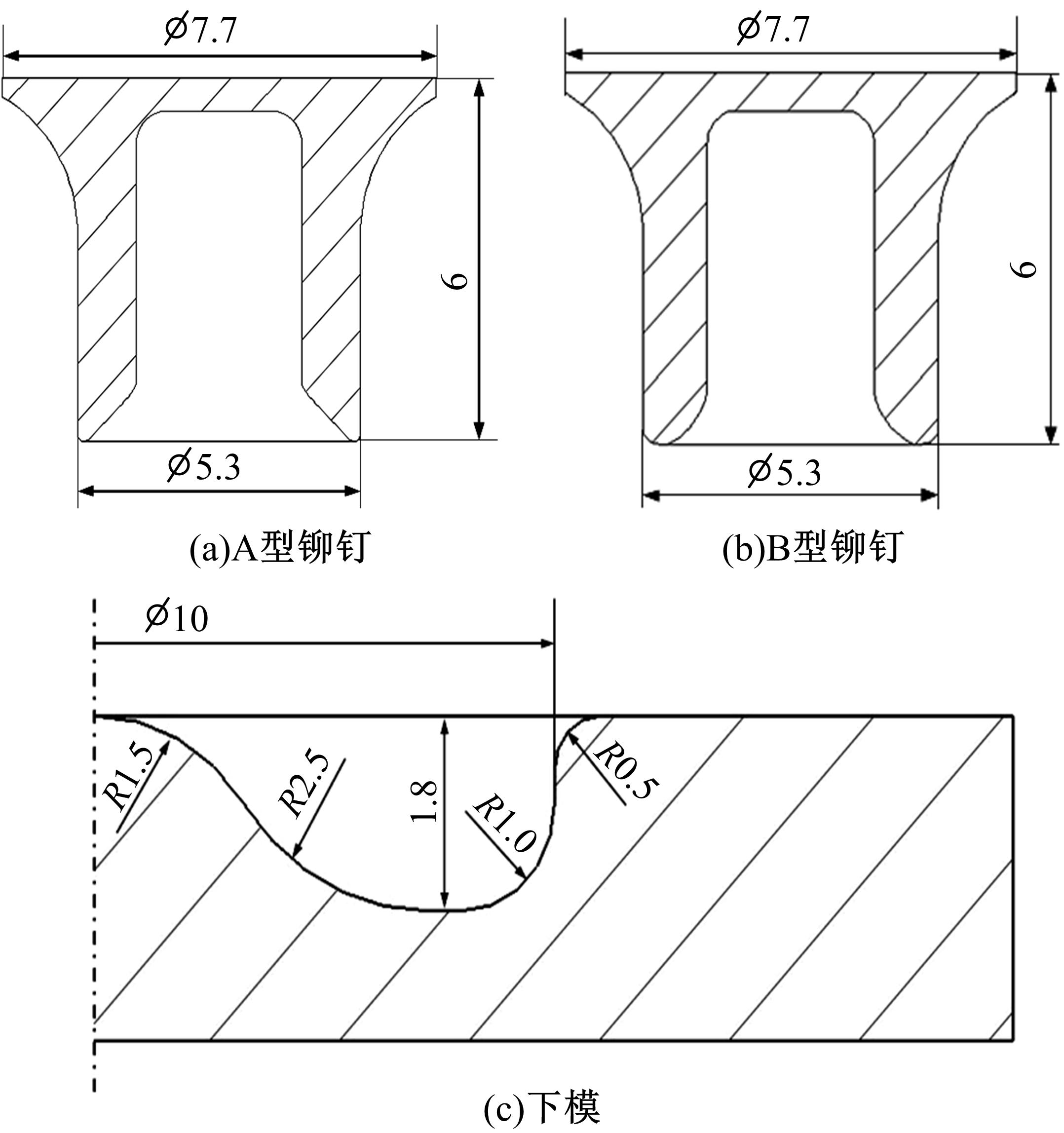

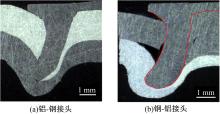

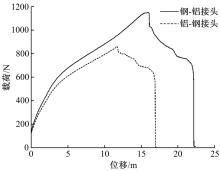

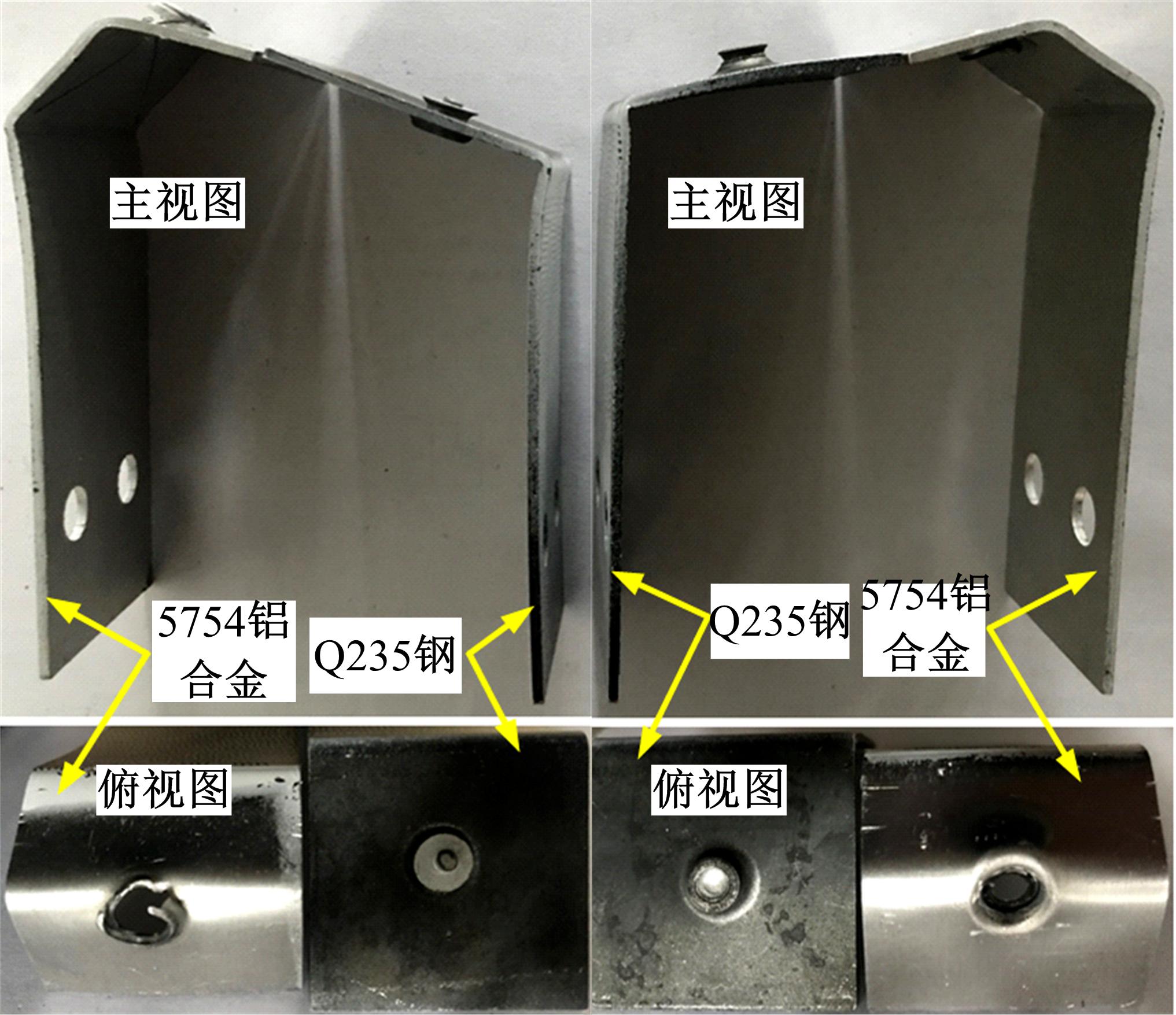

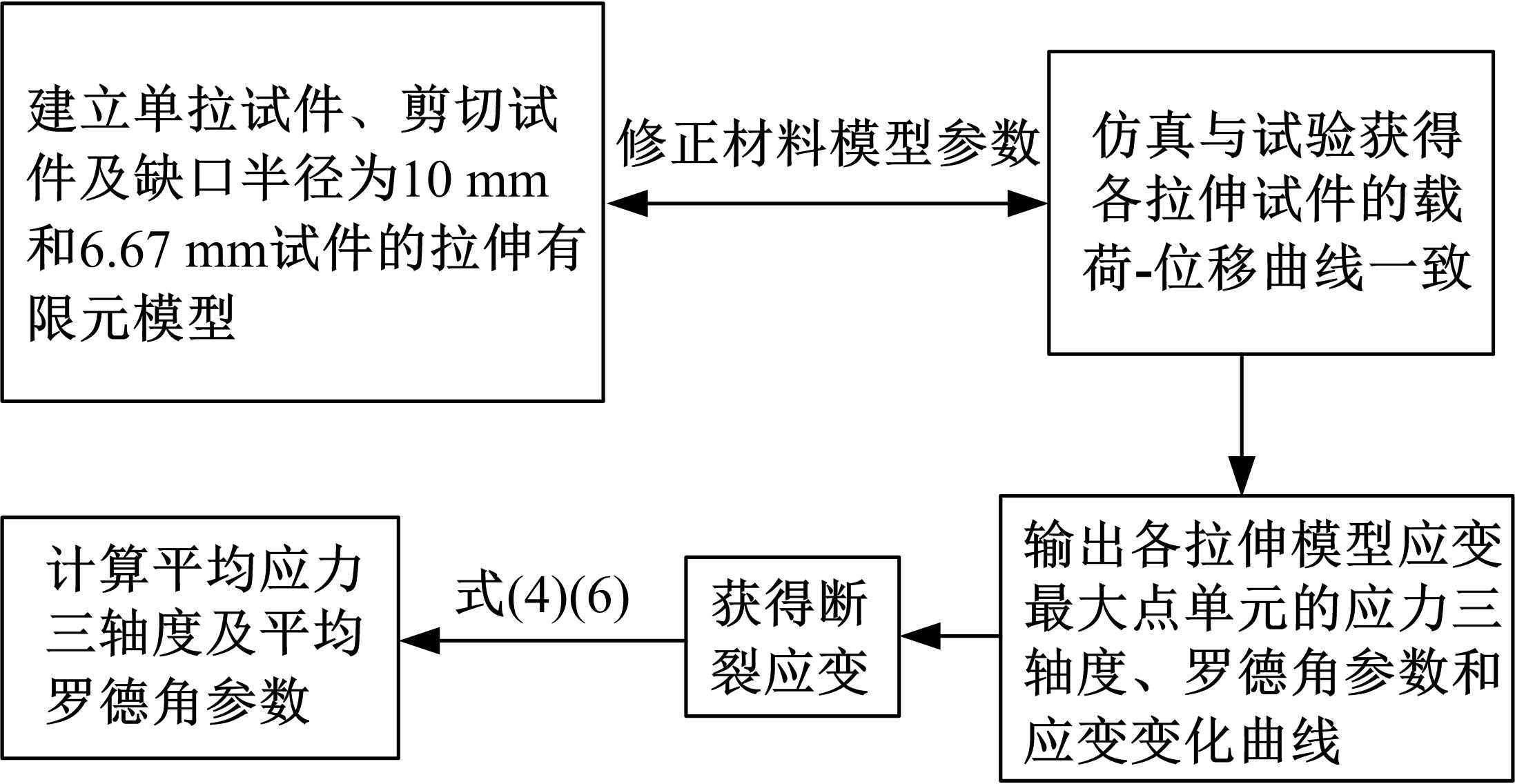

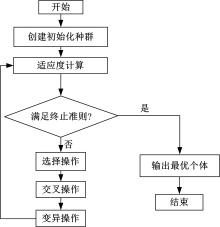

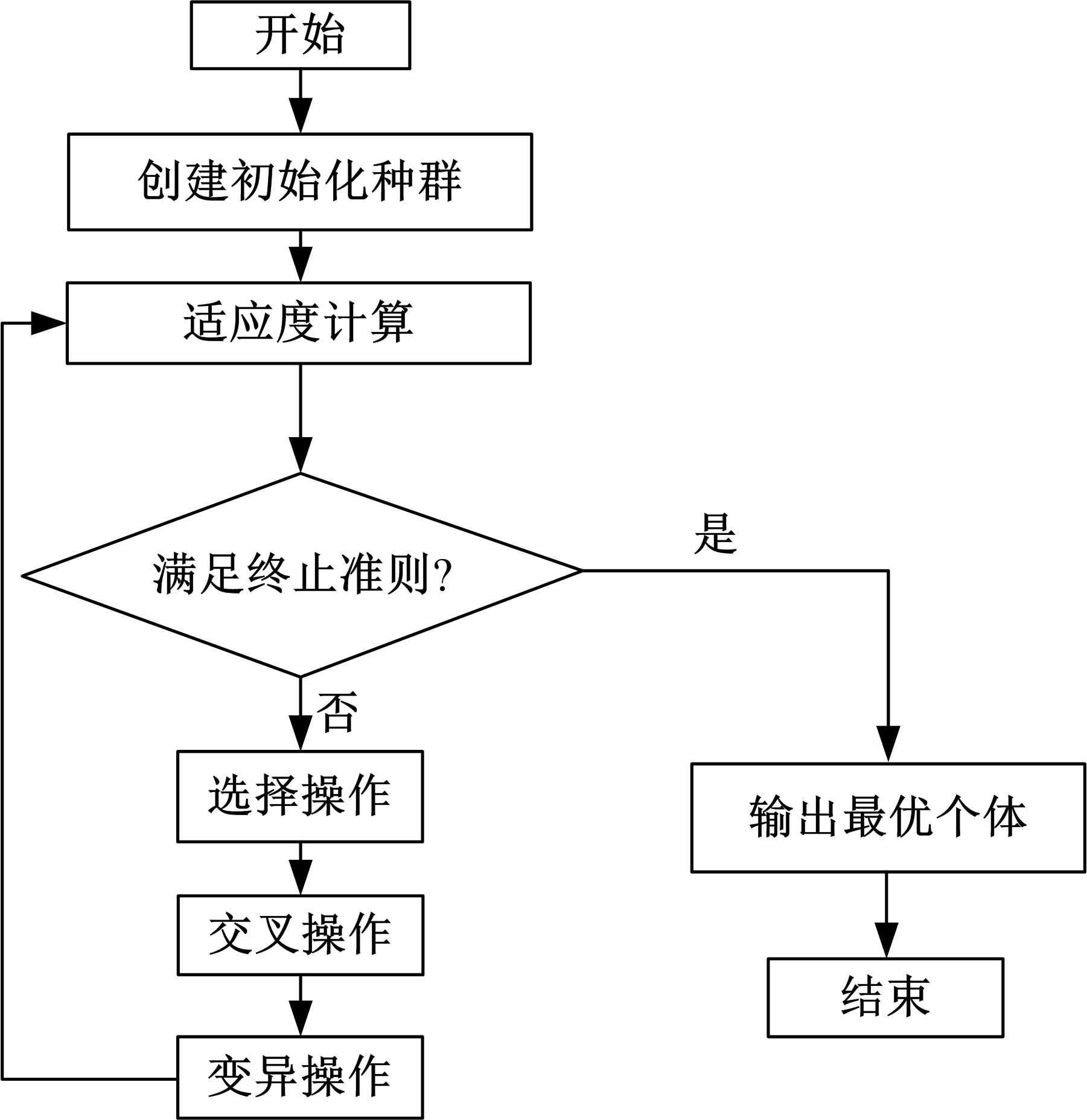

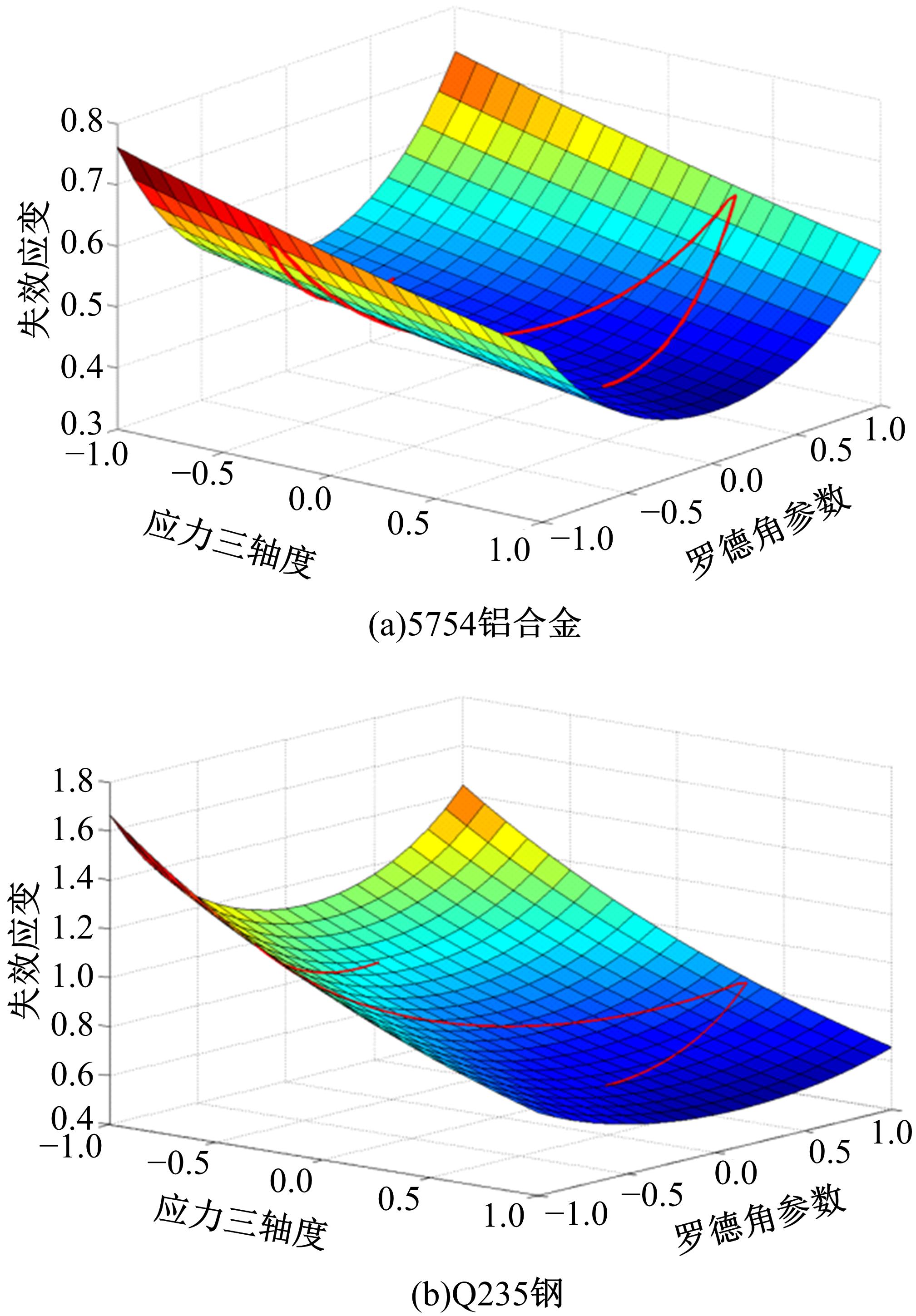

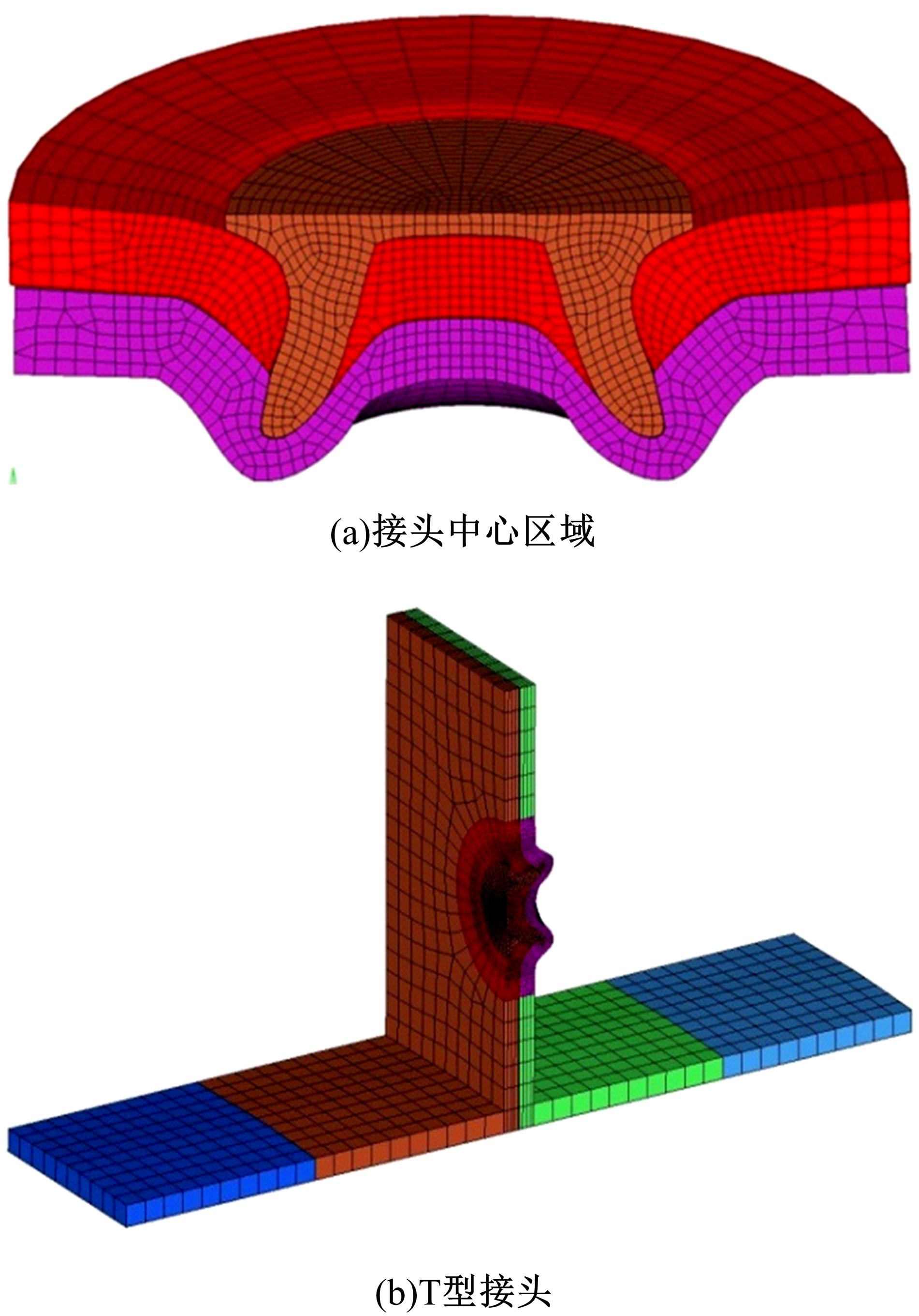

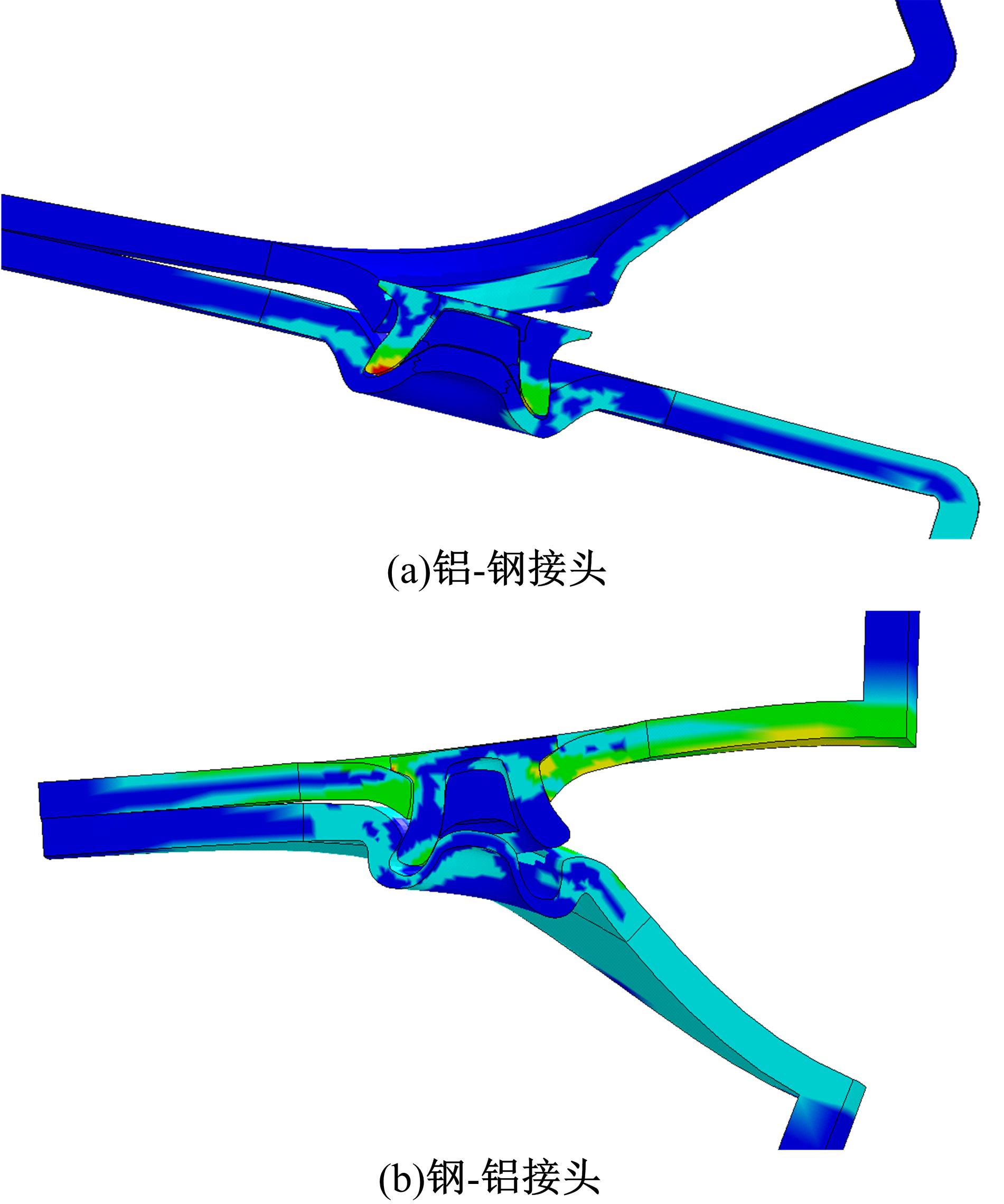

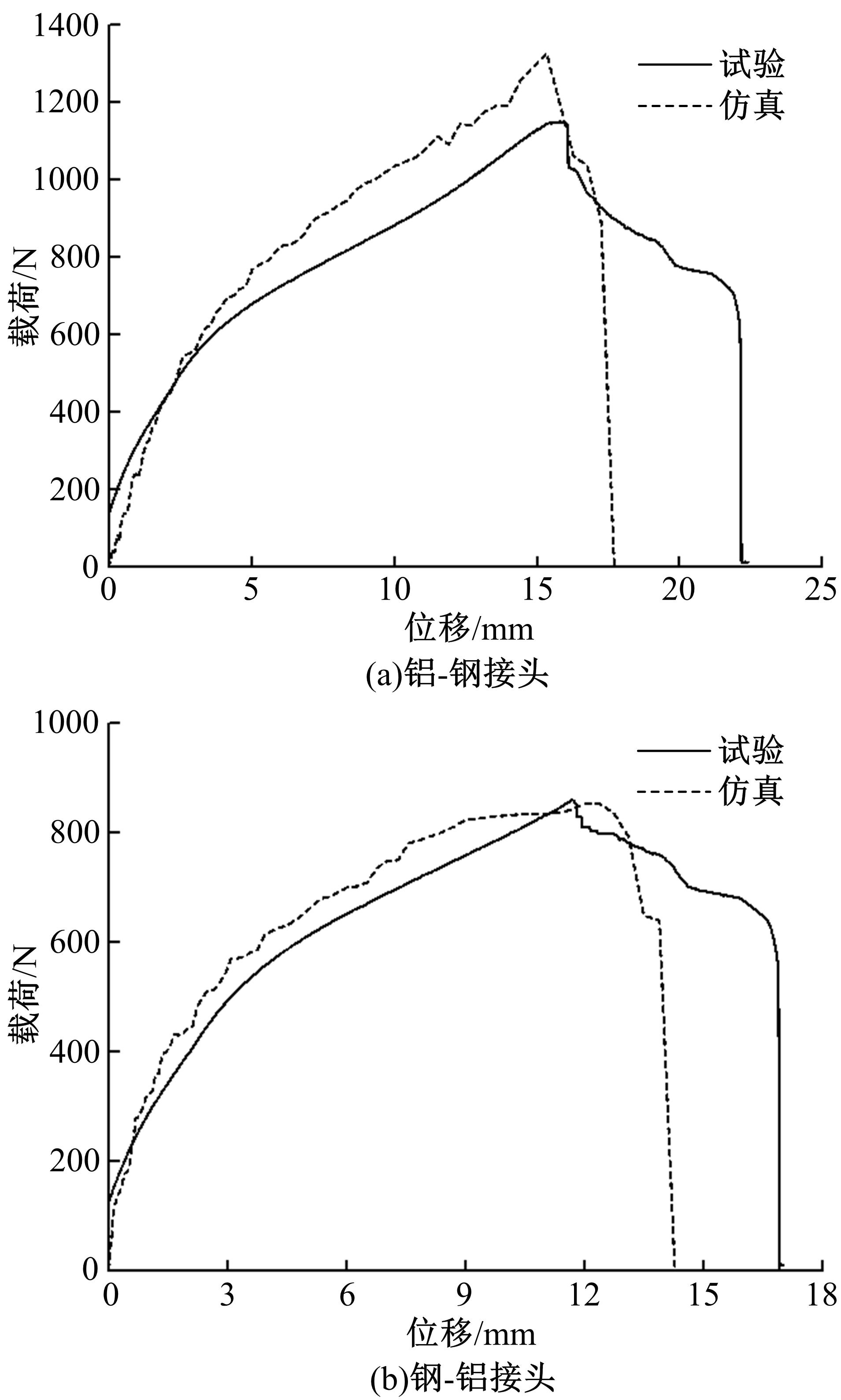

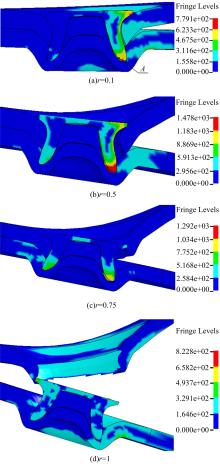

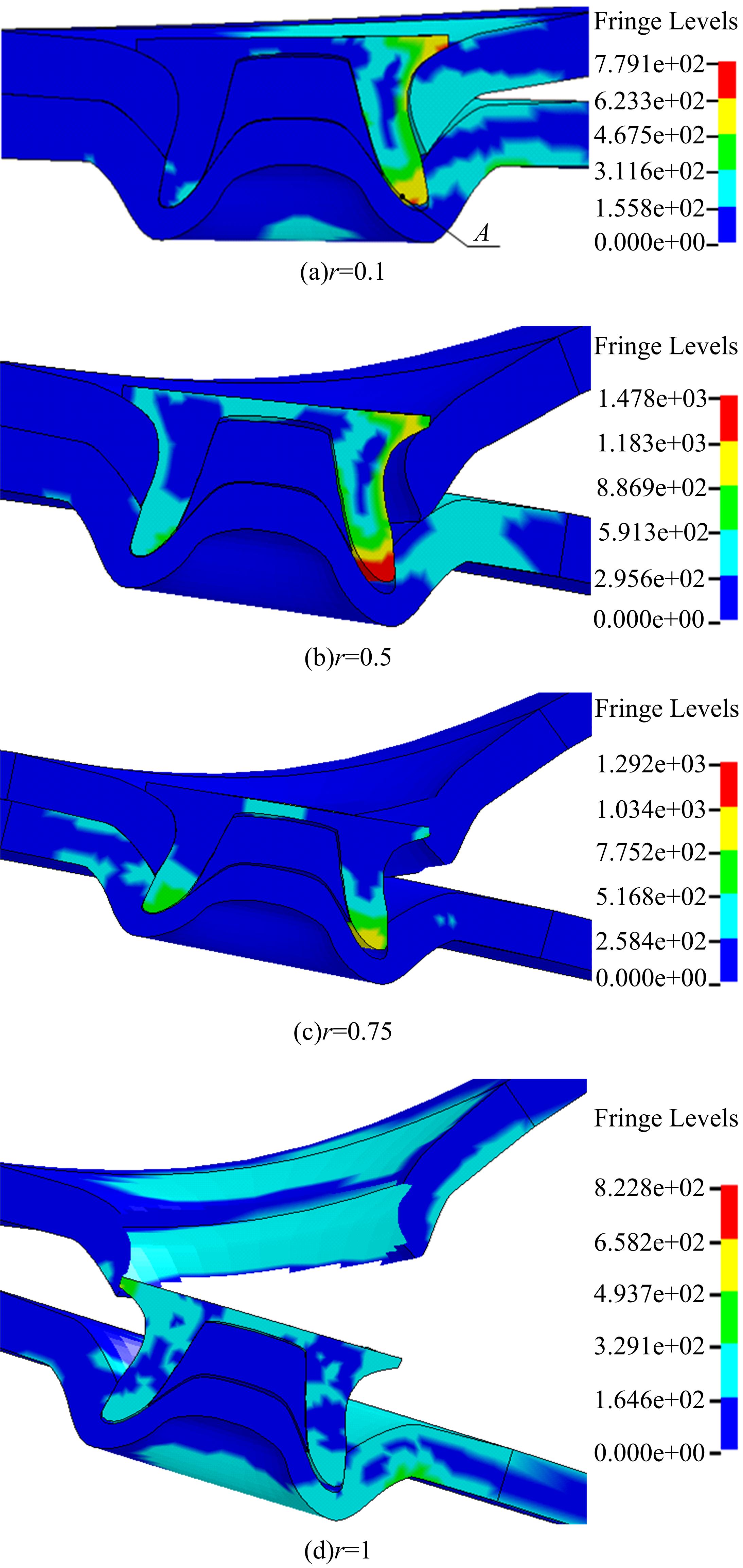

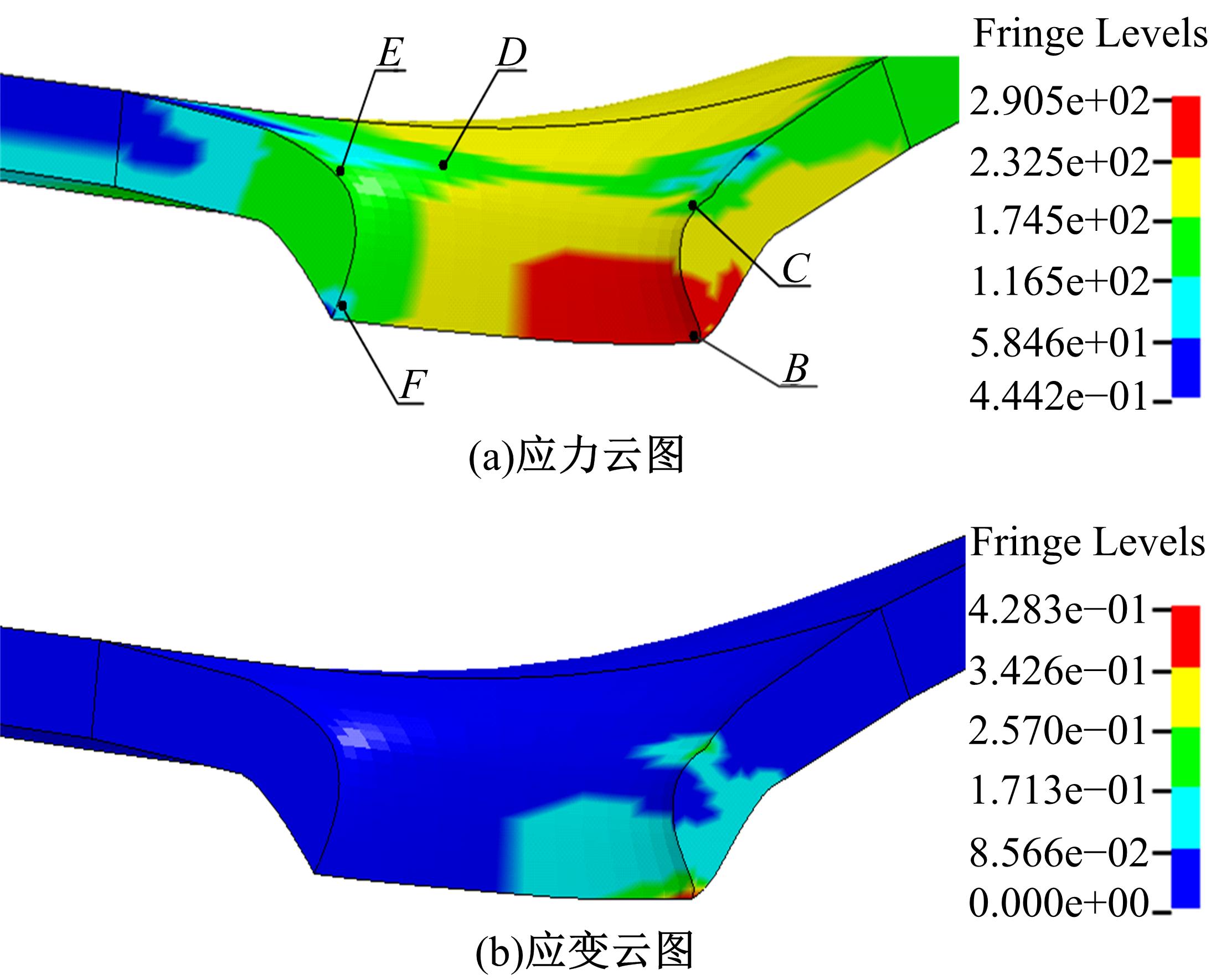

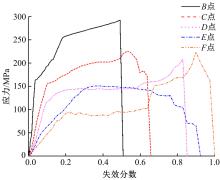

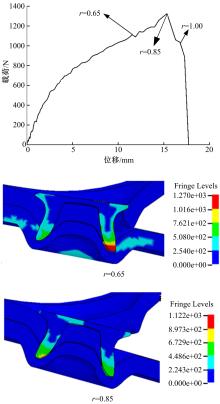

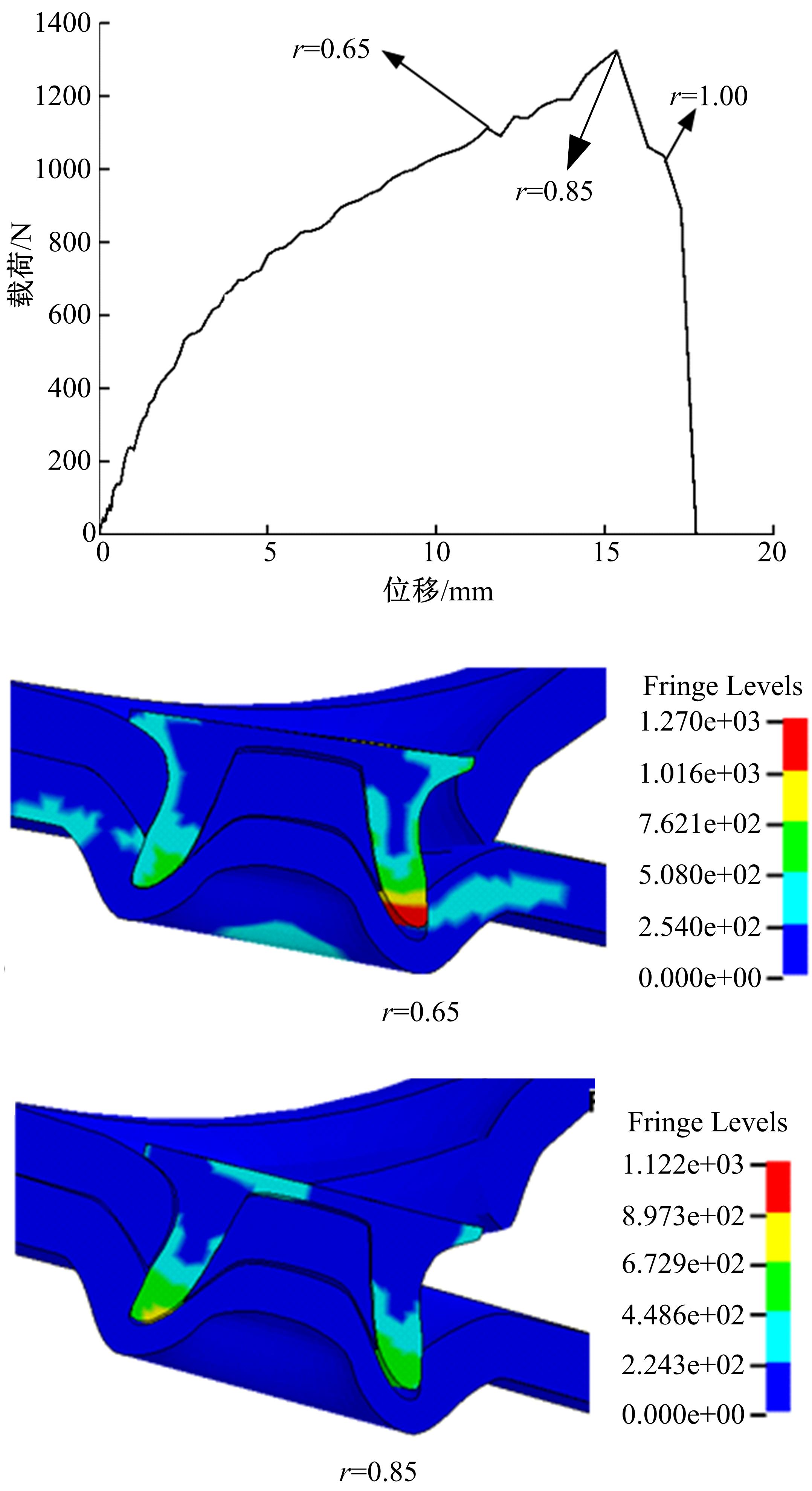

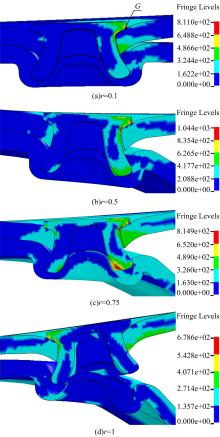

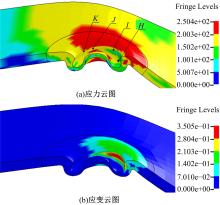

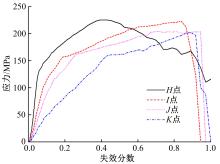

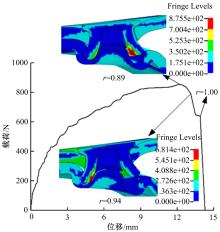

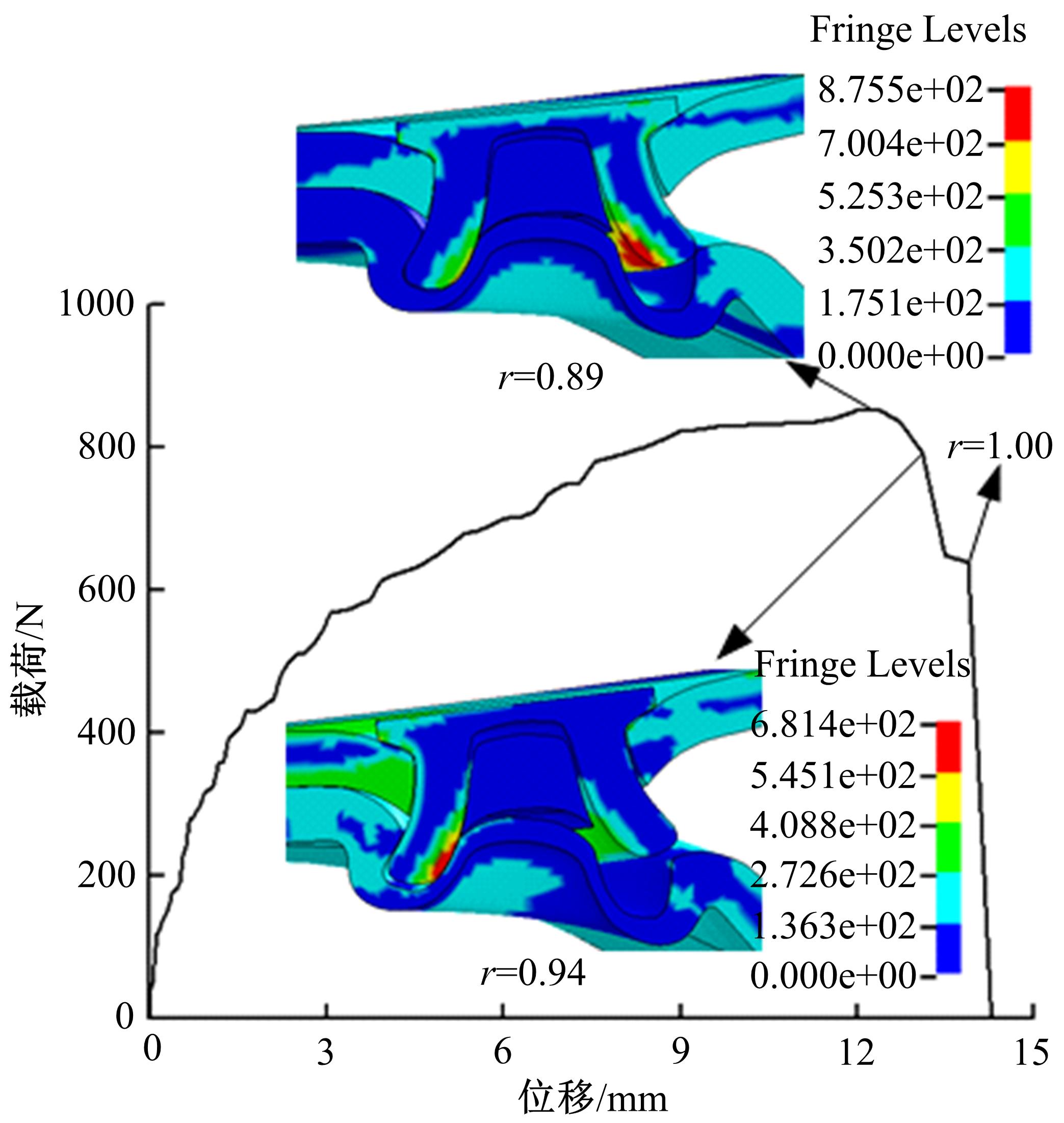

为了研究钢铝自冲铆接头剥离失效行为,对5754铝合金和Q235钢异质自冲铆接头进行了剥离试验及仿真研究。建立了基于MMC失效准则的T型自冲铆接头有限元模型,对两种接头在剥离工况下的拉伸失效过程进行仿真,对比试验结果验证了有限元模型的可靠性,并对接头的剥离失效行为进行了分析。研究结果表明:建立的有限元模型能表征接头在剥离工况下的失效形式及力学性能;铝-钢接头因上板与铆钉分离失效,剥离过程中加载侧钉脚和钉头区域易产生应力集中,上板加载侧铆孔区域最先发生失效;钢-铝接头失效形式为铆钉与下板分离,剥离过程中加载侧钉头边缘及钉脚内壁区域易出现应力集中,下板铆扣区域发生脱层损伤,脱层损伤区域向非加载侧铆扣区域扩展。

中图分类号:

- U270.4

|

| [1] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [2] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [3] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [4] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [5] | 李杰, 郭文翠, 赵旗, 谷盛丰. 基于车辆响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1810-1817. |

| [6] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [7] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

| [8] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [9] | 陈百超,邹猛,党兆龙,黄晗,贾阳,石睿杨,李建桥. CE-3月球车筛网轮月面沉陷行为试验[J]. 吉林大学学报(工学版), 2019, 49(6): 1836-1843. |

| [10] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [11] | 高振海,孙天骏,何磊. 汽车纵向自动驾驶的因果推理型决策[J]. 吉林大学学报(工学版), 2019, 49(5): 1392-1404. |

| [12] | 张博,张建伟,郭孔辉,丁海涛,褚洪庆. 路感模拟用永磁同步电机电流控制[J]. 吉林大学学报(工学版), 2019, 49(5): 1405-1413. |

| [13] | 王鹏宇,赵世杰,马天飞,熊晓勇,程馨. 基于联合概率数据关联的车用多传感器目标跟踪融合算法[J]. 吉林大学学报(工学版), 2019, 49(5): 1420-1427. |

| [14] | 胡兴军,惠政,郭鹏,张扬辉,张靖龙,王靖宇,刘飞. 基于流固耦合的汽车气动特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1414-1419. |

| [15] | 韩小健,赵伟强,陈立军,郑宏宇,刘阳,宗长富. 基于区域采样随机树的客车局部路径规划算法[J]. 吉林大学学报(工学版), 2019, 49(5): 1428-1440. |

|