吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (5): 1934-1940.doi: 10.13229/j.cnki.jdxbgxb20191072

• 农业工程·仿生工程 • 上一篇

低温等离子体处理功率对酱牛肉贮藏品质的影响

- 1.吉林大学 食品科学与工程学院,长春 130062

2.吉林大学 生物与农业工程学院,长春 130022

Effect of low⁃temperature plasma treatment power on storage quality of spiced beef

Xin-xin LI1( ),Da-yu LI1,Zi-rui ZHAO2,Ya-jun ZHOU1(

),Da-yu LI1,Zi-rui ZHAO2,Ya-jun ZHOU1( )

)

- 1.College of Food Science and Engineering, Jilin University, Changchun 130062, China

2.College of Biological and Agricultural Engineering, Jilin University, Changchun 130022, China

摘要:

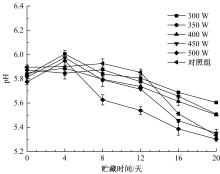

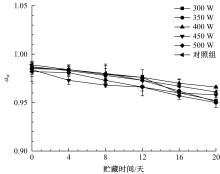

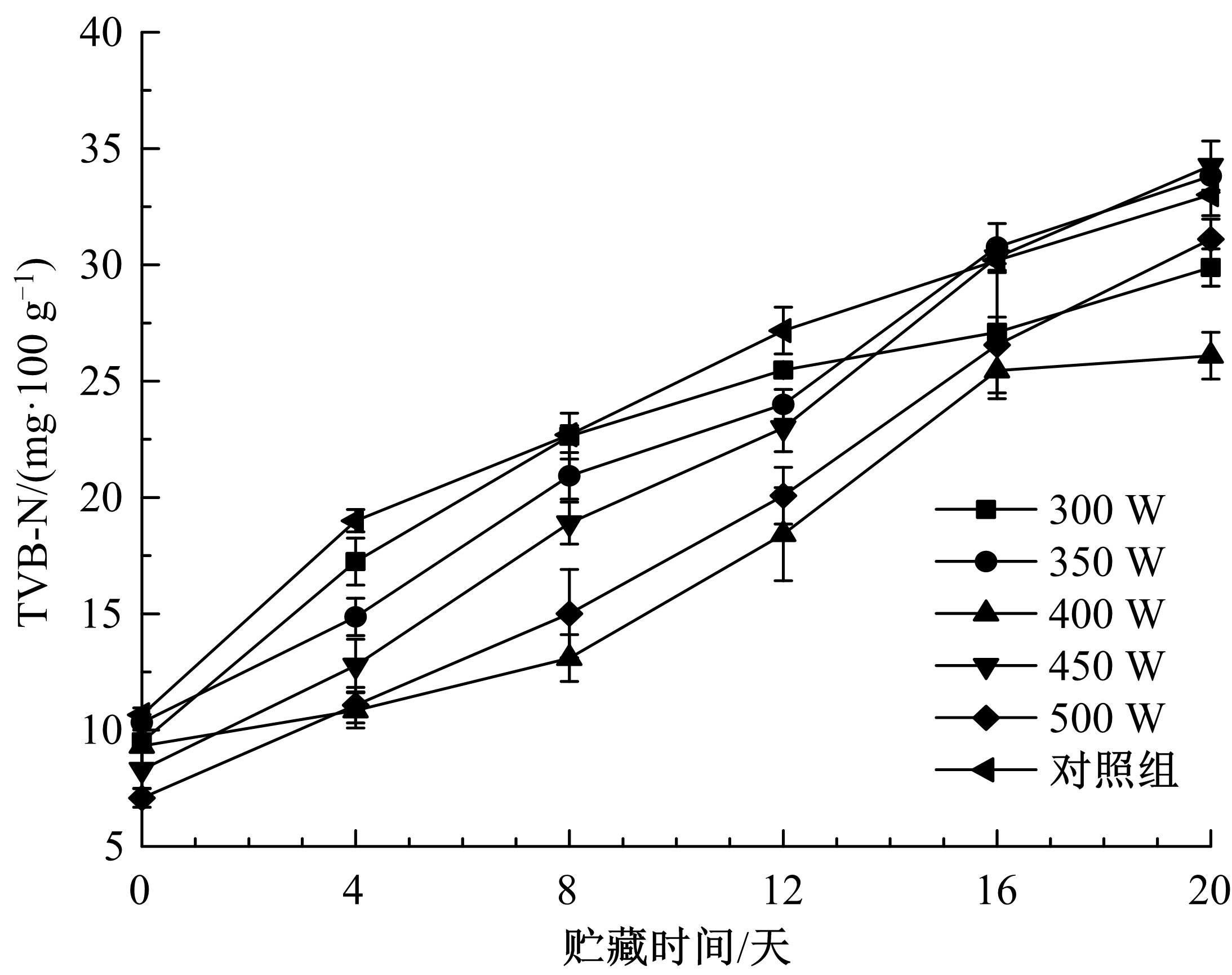

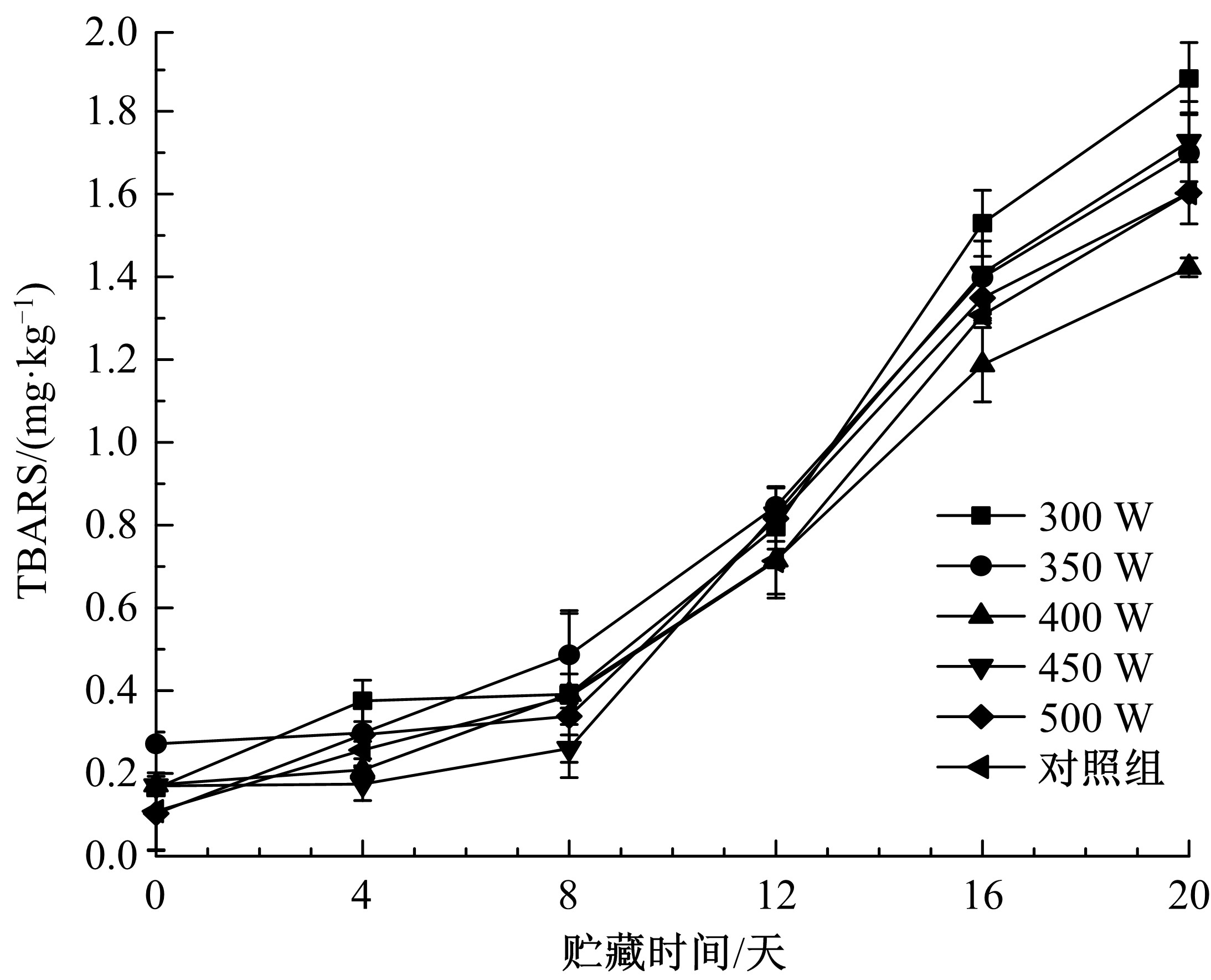

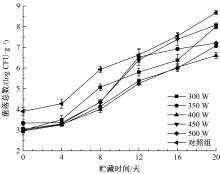

为解决酱牛肉在贮藏期间容易变质货架期短的问题,利用低温等离子体对酱牛肉进行杀菌,研究低温等离子体处理功率分别在300、350、400、450、500 W、处理时间为3 min的条件下对气调包装(75%CO2+25%N2)酱牛肉贮藏期间品质的影响。结果表明:当低温等离子体的功率为400 W、处理3 min时,对酱牛肉的pH、色泽、蛋白质和脂质氧化的影响较小,而且水分损失最少,杀菌效果最好,酱牛肉的货架期可延长约5天。

中图分类号:

- TS251.61

| 1 | 李素, 周慧敏, 张顺亮, 等. 不同加水量腌制酱牛肉中挥发性风味物质变化[J]. 食品科学, 2019, 40(10): 199-205. |

| Li Su, Zhou Hui-min, Zhang Shun-liang, et al. Changes of volatile flavor compounds in spiced beef marinated with different water contents[J]. Food Science, 2019, 40(10): 199-205. | |

| 2 | Attri P, Kim Y H, Park D H, et al. Generation mechanism of hydroxyl radical species and its lifetime prediction during the plasma-initiated ultraviolet(UV) photolysis[J]. Scientific Reports, 2015(5): 1-8. |

| 3 | Dasan B G, Boyaci I H, Mutlu M. Nonthermal plasma treatment of Aspergillus spp. spores on hazelnuts in an atmospheric pressure fluidized bed plasma system: impact of process parameters and surveillance of the residual viability of spores[J]. Journal of Food Engineering, 2017, 196: 139-149. |

| 4 | Zhu F. Plasma modification of starch[J]. Food Chemistry, 2017, 232: 476-486. |

| 5 | Toyokawa Y, Yagyu Y, Yamashiro R, et al. Roller conveyer system for the reduction of pesticides using non-thermal gas plasma—a potential food safety control measure?[J]. Food Control, 2018, 87: 211-217. |

| 6 | Bauer A, Ni Y, Bauer S, et al. The effects of atmospheric pressure cold plasma treatment on micro-biological, physical-chemical and sensory characteristics of vacuum packaged beef loin[J]. Meat Science, 2017, 128: 77-87. |

| 7 | 黄现青, 宋莲军, 赵秋艳, 等. 300W低温等离子体处理对真空包装酱卤鸭腿货架期的影响[J]. 肉类工业, 2017(10): 31-33, 36. |

| Huang Xian-qing, Song Lian-jun, Zhao Qiu-yan, et al. Effect of 300W low temperature plasma treatment on the shelf life of vacuum packaged sauced stewed duck leg[J]. Meat Industry, 2017(10): 31-33, 36. | |

| 8 | 张建友, 赵瑜亮, 张梦雨, 等. 不同贮藏温度酱鸭品质变化及其货架期预测[J]. 食品科学, 2019, 40(5): 250-257. |

| Zhang Jian-you, Zhao Yu-liang, Zhang Meng-yu, et al. Quality changes and predictive modeling of shelf life of sauced duck stored at different temperatures[J]. Food Science, 2019, 40(5): 250-257. | |

| 9 | GB 4789.2—2016. 食品微生物学检验 菌落总数测定[S]. |

| 10 | GB/T16860. 感官分析方法质地剖面检验[S]. |

| 11 | Kim H J, Yong H I, Park S, et al. Effects of dielectric barrier discharge plasma on pathogen inactivation and the physicochemical and sensory characteristics of pork loin[J]. Current Applied Physics, 2013, 13(7): 1420-1425. |

| 12 | Stoffels E, Sakiyama Y, Grave D B. Cold atmospheric plasma: charged species and their interactions with cells and tissues[J]. IEEE Transactions on Plasma Science, 2008, 36(4): 1441-1457. |

| 13 | Yadav B, Spinelli A C, Govindan B N, et al. Cold plasma treatment of ready-to-eat ham: influence of process conditions and storage on inactivation of Listeria innocua[J]. Food Research International, 2019, 123: 276-285. |

| 14 | Shintani H, Sakudo A, Burke P, et al. Gas plasma sterilization of microorganisms and mechanisms of action[J]. Experimental and Therapeutic Medicine, 2010, 1(5): 731-738. |

| 15 | Thirumdas R, Sarangapani C, Annapure U S. Cold plasma: a novel non-thermal technology for food processing[J]. Food Biophysics, 2015, 10(1): 1-11. |

| 16 | GB 2726—2016. 食品安全国家标准 熟肉制品[S]. |

| 17 | Jayasena D D, Kim H J, Yong H I, et al. Flexible thin-layer dielectric barrier discharge plasma treatment of pork butt and beef loin: effects on pathogen inactivation and meat-quality attributes[J]. Food Microbiology, 2015, 46: 51-57. |

| [1] | 徐梦蕾, 高宇, 刘静波, 熊晋锋, 赵颂宁, 黄延军. 基于抗氧化的大豆异黄酮对PC12细胞的神经保护作用[J]. 吉林大学学报(工学版), 2017, 47(1): 332-336. |

| [2] | 张铁华, 姜楠, 刘迪茹, 郝锦峰, 毛春玲, 郭明若. 乳清蛋白基质脂肪替代物的制备及其在低脂液态奶中的应用效果[J]. 吉林大学学报(工学版), 2015, 45(3): 1024-1028. |

| [3] | 袁媛, 张焕杰, 苗雨田, 吴思佳, 林松毅, 刘静波. 鲜切薯片油炸过程中丙烯酰胺形成的贡献率[J]. 吉林大学学报(工学版), 2014, 44(5): 1525-1530. |

| [4] | 赵谋明, 龙肇, 赵强忠, 徐巨才. 蛋白质用量和比例对淡奶油理化性质的影响[J]. 吉林大学学报(工学版), 2014, 44(5): 1531-1536. |

| [5] | 金声琅, 王莹, 殷涌光. 高压脉冲电场对淀粉和肌原纤维蛋白混合凝胶强度的影响[J]. 吉林大学学报(工学版), 2014, 44(2): 573-578. |

| [6] | 徐艳阳, 蔡森森, 吴海成. 玉米热风与微波联合干燥特性[J]. 吉林大学学报(工学版), 2014, 44(2): 579-584. |

| [7] | 张铁华, 李玺, 叶海青, 车宇飞, 田路, 于亚莉. 发酵林蛙油饮品的研制及工艺优化[J]. 吉林大学学报(工学版), 2013, 43(06): 1719-1724. |

| [8] | 王利民, 肖志刚, 刘宇欣, 李杰, 孙旭, 申勋业, 李佳栋. 响应面法优化板栗基营养米挤压加工参数[J]. 吉林大学学报(工学版), 2013, 43(02): 550-556. |

| [9] | 刘静波, 常皓, 王二雷, 宫新统, 姜轶群. 高效液相色谱法检测蛋黄卵磷脂中的磷脂酰胆碱[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 449-453. |

| [10] | 刘静波, 陶旭, 姜玮, 丁龙, 王二雷. 利用二次回归正交旋转组合设计优化鸡蛋壳膜唾液酸提取工艺[J]. , 2012, 42(04): 1071-1076. |

| [11] | 孙钟雷, 孙永海, 李宇, 刘晶晶. 基于仿齿压头的物料脆裂力学模型建立及验证[J]. 吉林大学学报(工学版), 2012, 42(02): 510-514. |

| [12] | 赵文竹, 殷涌光, 于志鹏, 于一丁, 刘静波. 玉米须多糖微波提取工艺及其红外光谱结构分析[J]. 吉林大学学报(工学版), 2012, 42(02): 515-520. |

| [13] | 刘静波, 王菲, 王翠娜, 刘军, 王作昭, 王二雷, 张燕, 林松毅. Alcalase酶解蛋清粉制备抗凝血肽的工艺优化[J]. 吉林大学学报(工学版), 2012, 42(01): 250-255. |

| [14] | 庄红, 陈乐群, 张婷, 朱媛媛, 唐宁, 袁媛. 亚铁血红素肽复合型保护剂的性能[J]. 吉林大学学报(工学版), 2012, 42(01): 256-260. |

| [15] | 常志勇, 陈东辉, 门海涛, 佟金, 谢军. 基于圆锥形仿生气体室的鸡肉新鲜度电子鼻检测技术[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 334-337. |

|

||