吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 72-81.doi: 10.13229/j.cnki.jdxbgxb20210610

机床主轴热关键点选择与典型转速热误差预测

郭世杰1,2( ),张学炜1,2,3(

),张学炜1,2,3( ),张楠1,2,乔冠1,2,唐术锋1,2

),张楠1,2,乔冠1,2,唐术锋1,2

- 1.内蒙古工业大学 机械工程学院,呼和浩特 010051

2.内蒙古自治区特殊服役智能机器人重点实验室,呼和浩特 010051

3.浙江大学 机械工程学院,杭州 310063

Thermal key point select and error prediction under typical speed of machine tool spindle

Shi-jie GUO1,2( ),Xue-wei ZHANG1,2,3(

),Xue-wei ZHANG1,2,3( ),Nan ZHANG1,2,Guan QIAO1,2,Shu-feng TANG1,2

),Nan ZHANG1,2,Guan QIAO1,2,Shu-feng TANG1,2

- 1.College of Mechanical Engineering,Inner Mongolia University of Technology,Hohhot 010051,China

2.Inner Mongolia Key Laboratory of Special Service Intelligent Robotics,Inner Mongolia Autonomous Region,Hohhot 010051,China

3.School of Mechanical Engineering,Zhejiang University,Hangzhou 310063,China

摘要:

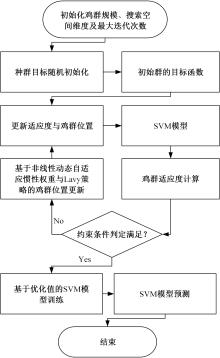

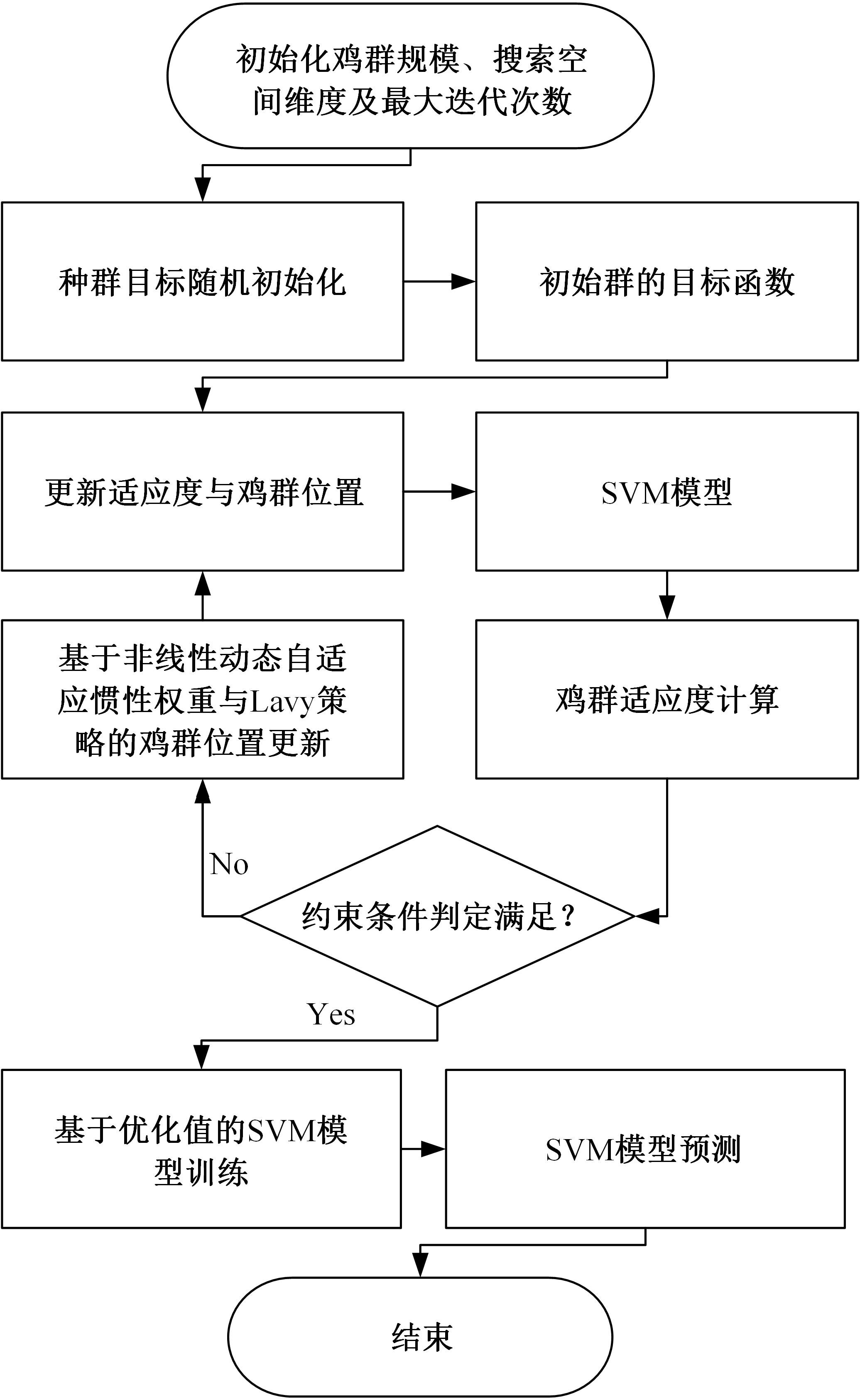

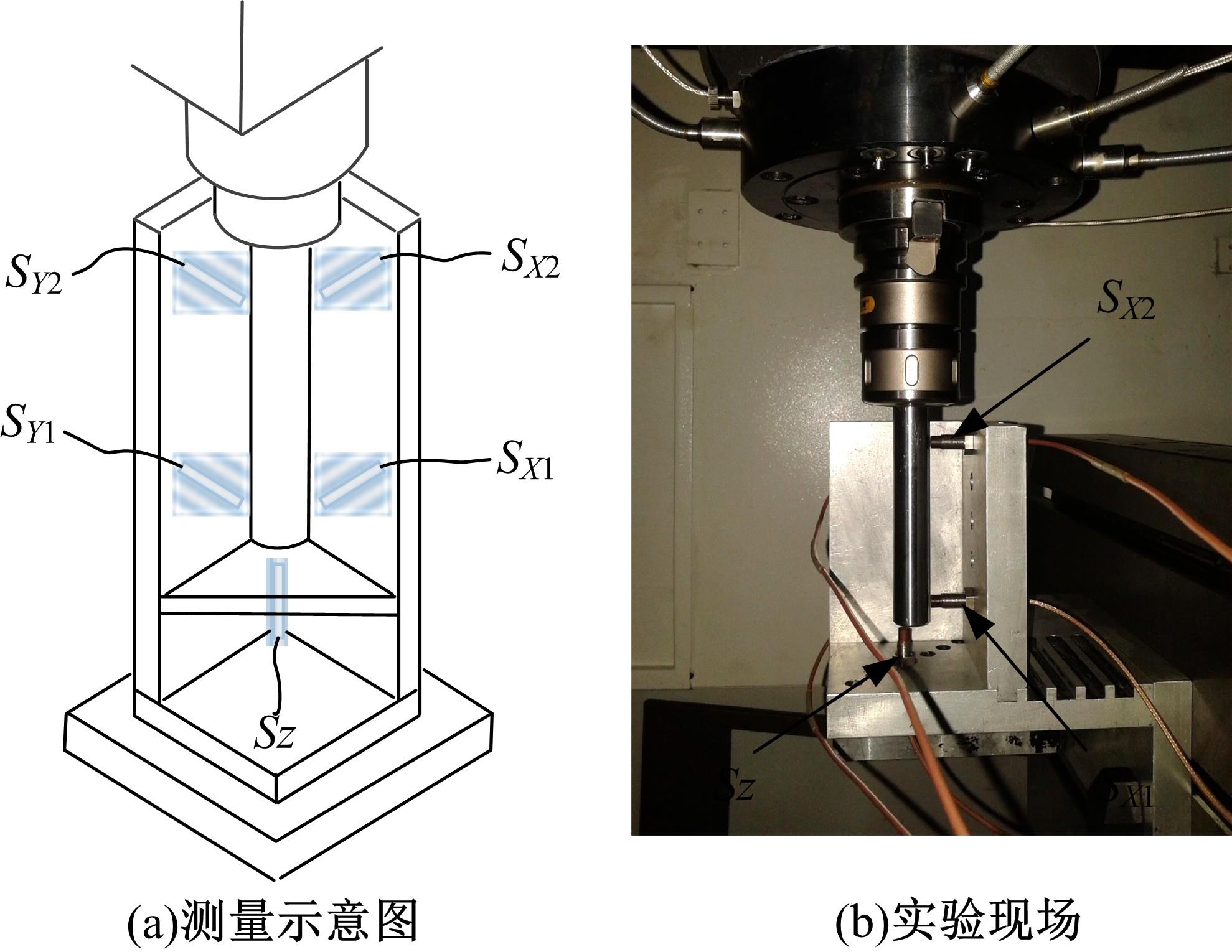

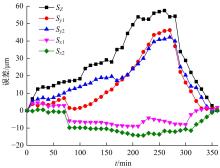

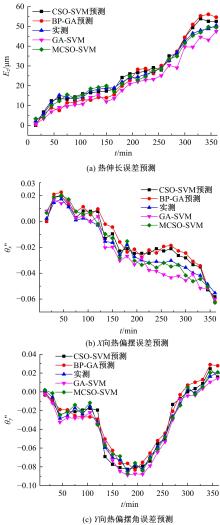

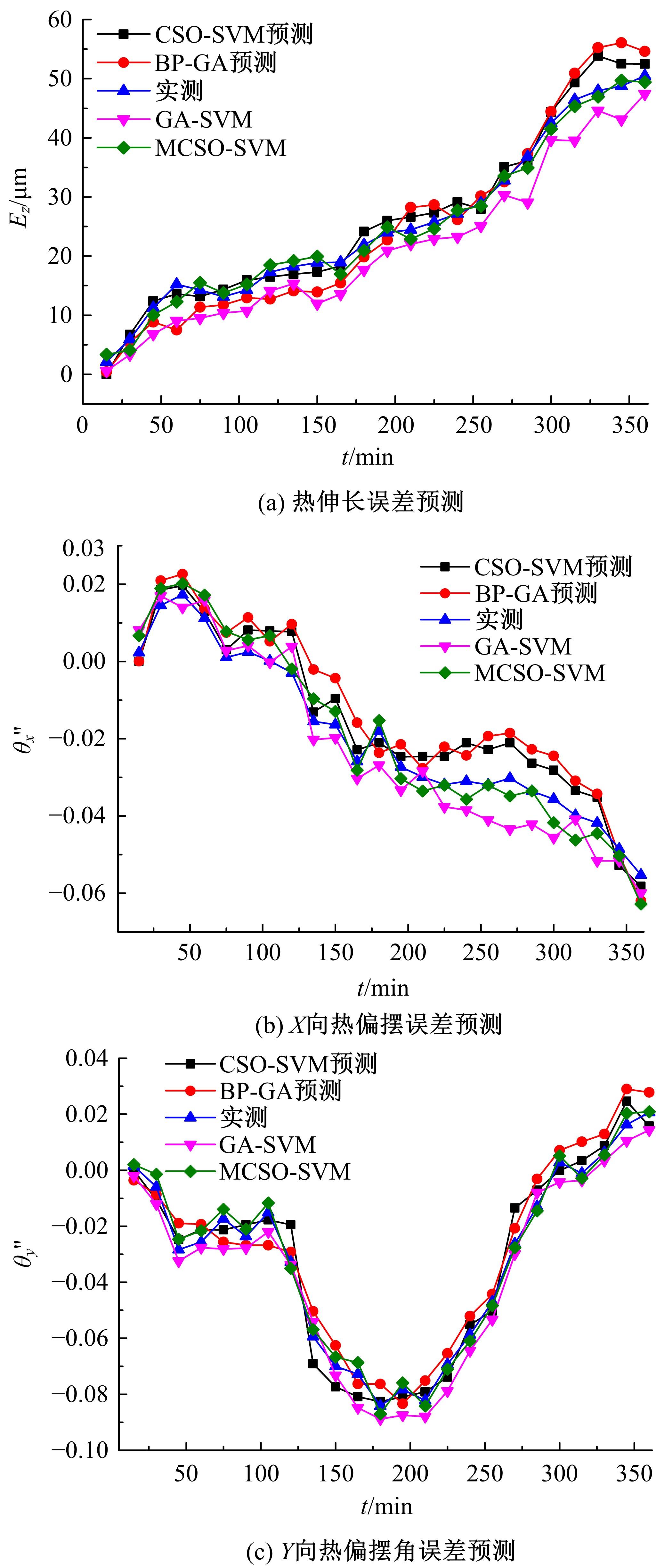

针对机床主轴热误差对准静态精度影响的关键问题,提出了一种基于改进鸡群优化(MCSO)算法及支持向量(SVM)的热误差预测模型。利用基于非监督学习的谱聚类与Spearman关联分析辨识主轴关键敏感温度测点,降低温度数据分布于数量的依赖,削弱温度变量间的多重共线性。引入Levy飞行策略至母鸡个体局部搜索过程,构建了非线性动态自适应惯性权重更新雏鸡策略,基于MCSO-SVM进行核函数、罚因子以及偏差量的全局优化,分别采用MCSO-SVM、BP-GA、GA-SVM和CSO-SVM热误差建模,同时对不同转速下的模型预测能力进行对比分析。热误差实验测量与预测结果表明:谱聚类与Spearman关联分析可有效降低温度变量共线性导致的耦合作用;MCSO-SVM可实现典型转速下主轴五项热误差的高精度预测,模型具备较好的泛化能力和鲁棒性。

中图分类号:

- TH161

| 1 | Tan Feng, Yin Guo-fu, Zheng Kai, et al. Thermal error prediction of machine tool spindle using segment fusion LSSVM[J]. The International Journal of Advanced Manufacturing Technology, 2021,116(1/2):1-16. |

| 2 | 李国龙,陶小会,徐凯,等. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报:工学版, 2021, 51(2): 458-467. |

| Li Guo-long, Tao Xiao-hui, Xu Kai, et al. Rapid measurement and identification of position dependent geometric errors of CNC machine tool turntable[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 458-467. | |

| 3 | Li Tie-jun, Sun Ting-ying, Zhang Yi-min, et al. Prediction of thermal error for feed system of machine tools based on random radial basis function neural network[J]. The International Journal of Advanced Manufacturing Technology, 2021, 114(5):1545-1553. |

| 4 | 杜柳青,李仁杰,余永维. 基于注意力机制的时空卷积数控机床热误差模型研究[J]. 农业机械学报, 2021, 52(5):404-411. |

| Du Liu-qing, Li Ren-jie, Yu Yong-wei. Spatiotemporal convolution thermal error model of CNC machine tools based on attention mechanism[J]. Transactions of the Chinese Society for Agricultural Machinery,2021, 52(5):404-411. | |

| 5 | 刘阔,韩伟,王永青,等. 数控机床进给轴热误差补偿技术研究综述[J]. 机械工程学报, 2021, 57(3):156-173. |

| Liu Kuo, Han Wei, Wang Yong-qing,et al. Review on thermal error compensation for feed axes of CNC machine tools[J]. Journal of Mechanical Engineering, 2021, 57(3):156-173. | |

| 6 | Li Yang, Shi He-xuan, Ji Shi-jun, et al. Thermal positioning error modeling of servo axis based on empirical modeling method[J]. Micromachines, 2021, 12(2):1-22. |

| 7 | Fu Guo-qiang, Tao Chun, Xie Yun-peng, et al. Temperature-sensitive point selection for thermal error modeling of machine tool spindle by considering heat source regions[J]. The International Journal of Advanced Manufacturing Technology, 2021, 112(9/10):2447⁃2460 . |

| 8 | 杜宏洋,陶涛,侯瑞生,等. 机床主轴轴向热误差一阶自回归建模方法[J].哈尔滨工业大学报,2021, 53(7):60-67. |

| Du Hong-yang, Tao Tao, Hou Rui-sheng, et al. First-order autoregressive modeling method for axial thermal error of machine tool spindle[J]. Journal of Harbin Institute of Technology, 2021, 53(7):60-67. | |

| 9 | 赵亮,雷默涵,朱星星,等.高精度数控机床主轴系统热误差的控制方法[J].上海交通大学学报, 2020, 54(11):1165-1171. |

| Zhao Liang, Lei Mo-han, Zhu Xing-xing, et al. A new thermal error control method for spindle system of high precision computer numerical control machine tools[J]. Journal of Shanghai Jiaotong University, 2020, 54(11):1165-1171. | |

| 10 | 谭峰,李成南,萧红,等.基于LSTM循环神经网络的数控机床热误差预测方法[J].仪器仪表学报,2020,41(9):79-87. |

| Tan Feng, Li Cheng-nan, Xiao Hong, et al. A thermal error prediction method for CNC machine tool based on LSTM recurrent neural network[J]. Chinese Journal of Scientific Instrument, 2020, 41(9):79-87. | |

| 11 | Huang Z, Liu Y, Du L, et al. Thermal error analysis, modeling and compensation of five-axis machine tools[J]. Journal of Mechanical Science and Technology, 2020, 34(10):4295-4305. |

| 12 | Yue Hai-tao, Guo Chen-guang, Li Qiang, et al. Thermal error modeling of CNC milling machine tool spindle system in load machining: based on optimal specific cutting energy[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2020, 42(9):4561-4568 |

| 13 | 黄智,刘永超,邓涛,等. 一种五轴数控机床热误差建模方法[J]. 中国机械工程,2020,31(13):1529-1538. |

| Huang Zhi, Liu Yong-chao, Deng Tao, et al. A method for thermal error modeling of FAMT[J]. China Mechanical Engineering, 2020, 31(13):1529-1538. | |

| 14 | Shi Hu, Jiang Chun-ping, Yan Zong-zhuo, et al. Bayesian neural network-based thermal error modeling of feed drive system of CNC machine tool[J]. The International Journal of Advanced Manufacturing Technology, 2020, 108(9): 3031-3044. |

| 15 | 马驰,杨军,梅雪松,等.基于遗传算法及BP网络的主轴热误差建模[J].计算机集成制造系统,2015,21(10):2627-2636. |

| Ma Chi, Yang Jun, Mei Xue-song, et al. High-speed spindle thermal error modeling based on genetic algorithm and BP neural network[J]. Computer Integrated Manufacturing Systems, 2015, 21(10):2627-2636. | |

| 16 | 张蕾.基于GA-SVM的数控机床热误差建模研究[D]. 桂林:桂林电子科技大学材料科学与工程学院,2015. |

| Zhang Lei. Research on thermal error modeling of NC machine tools based on GA-SVM[D]. Guilin: School of Materials Science and Engineering, Guilin University of Electronic Technology,2015. | |

| 17 | 马驰,赵亮,梅雪松,等. 基于粒子群算法与BP网络的机床主轴热误差建模[J]. 上海交通大学学报,2016, 50(5):686-695. |

| Ma Chi, Zhao Liang, Mei Xue-song, et al. Thermal error modeling of machine tool spindle based on particle swarm optimization and neural network[J]. Journal of Shanghai Jiaotong University,2016, 50(5):686-695. | |

| 18 | Meng X, Liu Y, Gao X, et al. A new bio-inspired algorithm: chicken swarm optimization[C]∥International Conference in Swarm Intelligence, Hefei,China,2014: 86-94. |

| 19 | Deb Sanchari, Gao Xiao-zhi, Tammi Kari, et al. Recent studies on chicken swarm optimization algorithm: a review (2014⁃2018)[J]. Artificial Intelligence Review, 2020, 53(4): 1737⁃1765. |

| 20 | 罗勇,邵珠峰,王立平,等. NL201HA数控卧式车床X轴热误差建模及补偿[J]. 清华大学学报:自然科学版,2021,61(1):28-35. |

| Luo Yong, Shao Zhu-feng, Wang Li-ping, et al. X-axis thermal error modeling and compensation for an NL201HA CNC horizontal lathe[J]. Journal of Tsinghua University(Science and Technology), 2021, 61(1):28-35. | |

| 21 | Ma Chi, Liu Jia-lan, Wang Shi-long. Thermal error compensation of linear axis with fixed-fixed installation[J]. International Journal of Mechanical Sciences,2020,175:No.105531. |

| 22 | Groos Lisa, Held Christian, Keller Frank, et al. Mapping and compensation of geometric errors of a machine tool at different constant ambient temperatures[J]. Precision Engineering,2020, 63:10-17. |

| 23 | Yao Xiao-dong, Du Zheng-chun, Ge Guang-yan, et al. Dynamic temperature gradient and unfalsified control approach for machine tool thermal error compensation[J]. Journal of Mechanical Science and Technology, 2020,34(2):319-331. |

| 24 | Liu Yun-sheng, Miao En-ming, Liu Hui, et al. Robust machine tool thermal error compensation modelling based on temperature-sensitive interval segmentation modelling technology[J]. The International Journal of Advanced Manufacturing Technology,2020,106(1):655⁃669. |

| 25 | . Test code for machine tools-3: determination of thermal effects [S]. |

| 26 | Yang J, Shi H, Feng B, et al. Thermal error modeling and compensation for a high-speed motorized spindle[J]. The International Journal of Advanced Manufacturing Technology, 2015, 77(5-8):1005-1017. |

| [1] | 龙恩深,班光泽. 基于小波包信包提取的空调制冷压缩机怠速噪声诊断算法[J]. 吉林大学学报(工学版), 2023, 53(7): 1929-1934. |

| [2] | 田野,李楠楠,刘君巍,姜生元,王储,张伟伟. 基于支持向量机的模拟月壤临界尺度颗粒切削负载识别[J]. 吉林大学学报(工学版), 2023, 53(7): 2143-2151. |

| [3] | 康耀龙,冯丽露,张景安,曹素娥. 基于谱聚类的不确定数据集中快速离群点挖掘算法[J]. 吉林大学学报(工学版), 2023, 53(4): 1181-1186. |

| [4] | 吴剑,许斌. 基于CEEMDAN理论的堆积层滑坡位移区间预测模型及仿真[J]. 吉林大学学报(工学版), 2023, 53(2): 562-568. |

| [5] | 王奎洋,何仁. 基于支持向量机的制动意图识别方法[J]. 吉林大学学报(工学版), 2022, 52(8): 1770-1776. |

| [6] | 康耀龙,冯丽露,张景安,陈富. 基于谱聚类的高维类别属性数据流离群点挖掘算法[J]. 吉林大学学报(工学版), 2022, 52(6): 1422-1427. |

| [7] | 章子玲,胡雄,亓寅,王微,陶志强,刘志峰. 基于向量投影响应面的数控机床几何误差分配方法[J]. 吉林大学学报(工学版), 2022, 52(2): 384-391. |

| [8] | 申桂香,郑君,张英芝,宋杰,李哲文. 基于多属性群决策的加工中心故障模式风险分析[J]. 吉林大学学报(工学版), 2022, 52(2): 338-344. |

| [9] | 罗巍,卢博,陈菲,马腾. 基于PSO-SVM及时序环节的数控刀架故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(2): 392-399. |

| [10] | 于立娟,刘昂,杨兆军,田海龙,陈传海,高景文. 基于网络层次和数据包络的数控机床可靠性分析[J]. 吉林大学学报(工学版), 2022, 52(2): 400-408. |

| [11] | 赵泓荀,杨兆军,陈传海,田海龙,王立平. 考虑参数权重的数控机床电主轴加速试验优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 409-416. |

| [12] | 蒋仁言,熊彬彬. 基于等效加工时间模型的机床退化过程建模[J]. 吉林大学学报(工学版), 2022, 52(2): 483-490. |

| [13] | 陈传海,王成功,杨兆军,刘志峰,田海龙. 数控机床可靠性建模研究现状及发展动态分析[J]. 吉林大学学报(工学版), 2022, 52(2): 253-266. |

| [14] | 侯春萍,赵春月,王致芃,田海瑞. 基于有效异常样本构造的视频异常检测算法[J]. 吉林大学学报(工学版), 2021, 51(5): 1823-1829. |

| [15] | 院老虎,连冬杉,张亮,刘义. 基于密集连接卷积网络和支持向量机的飞行器机械部件故障诊断[J]. 吉林大学学报(工学版), 2021, 51(5): 1635-1641. |

|

||