吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 392-399.doi: 10.13229/j.cnki.jdxbgxb20211154

• 车辆工程·机械工程 • 上一篇

基于PSO-SVM及时序环节的数控刀架故障诊断方法

- 1.吉林大学 数控装备可靠性教育部重点实验室,长春 130022

2.吉林大学 机械与航空航天工程学院,长春 130022

3.长春设备工艺研究所,长春 130012

4.深圳技术大学 中德智能制造学院,深圳 518118

Fault diagnosis method of NC turret based on PSO⁃SVM and time sequence

Wei LUO1,2( ),Bo LU3,Fei CHEN4(

),Bo LU3,Fei CHEN4( ),Teng MA1,2

),Teng MA1,2

- 1.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

3.Changchun Equipment & Technology Research Institute,Changchun 130012,China

4.Sino-German College of Intelligent Manufacturing,Shenzhen Technology University,Shenzhen 518118,China

摘要:

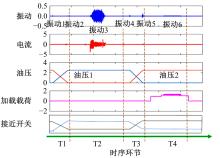

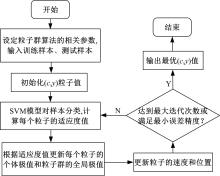

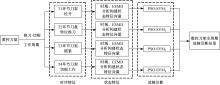

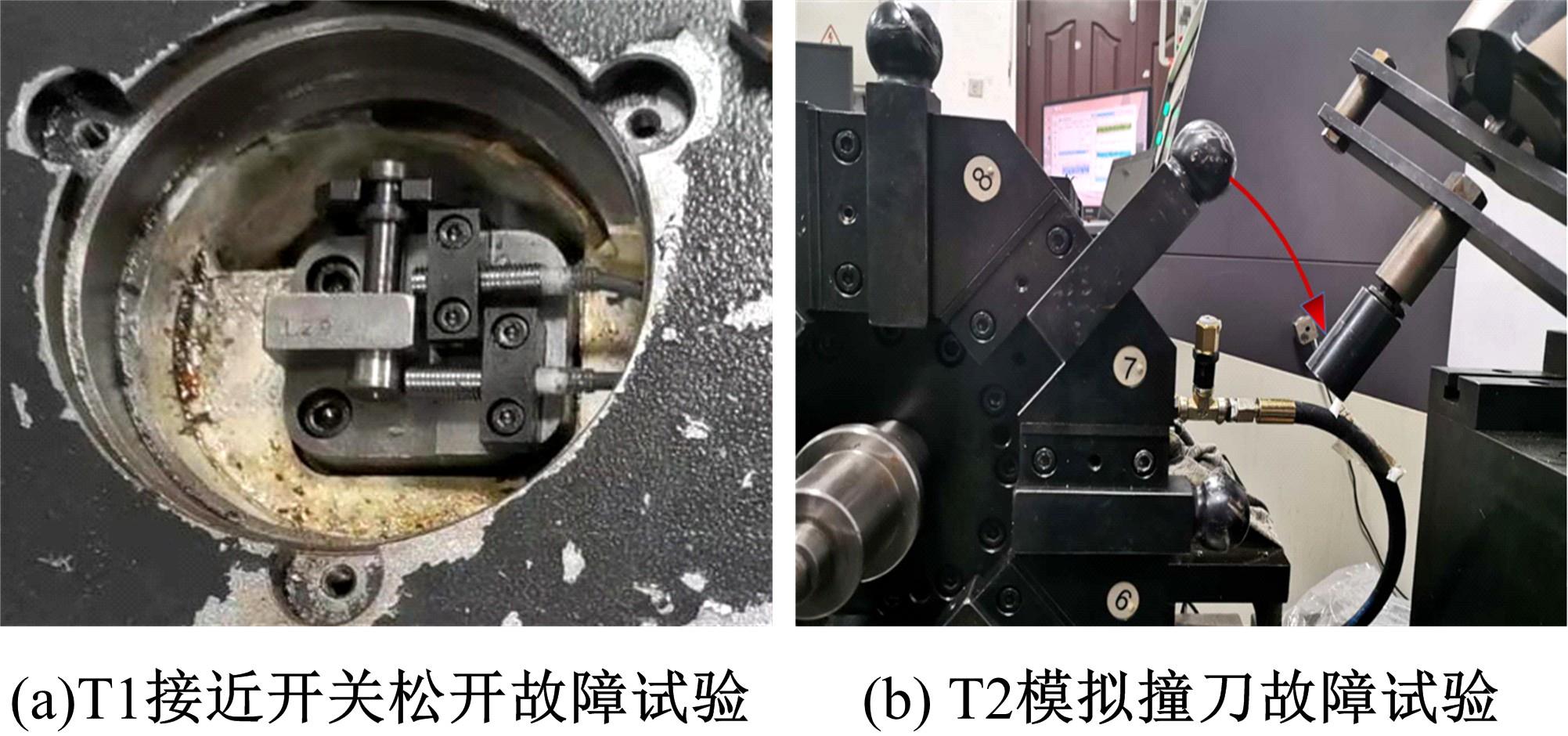

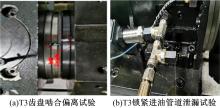

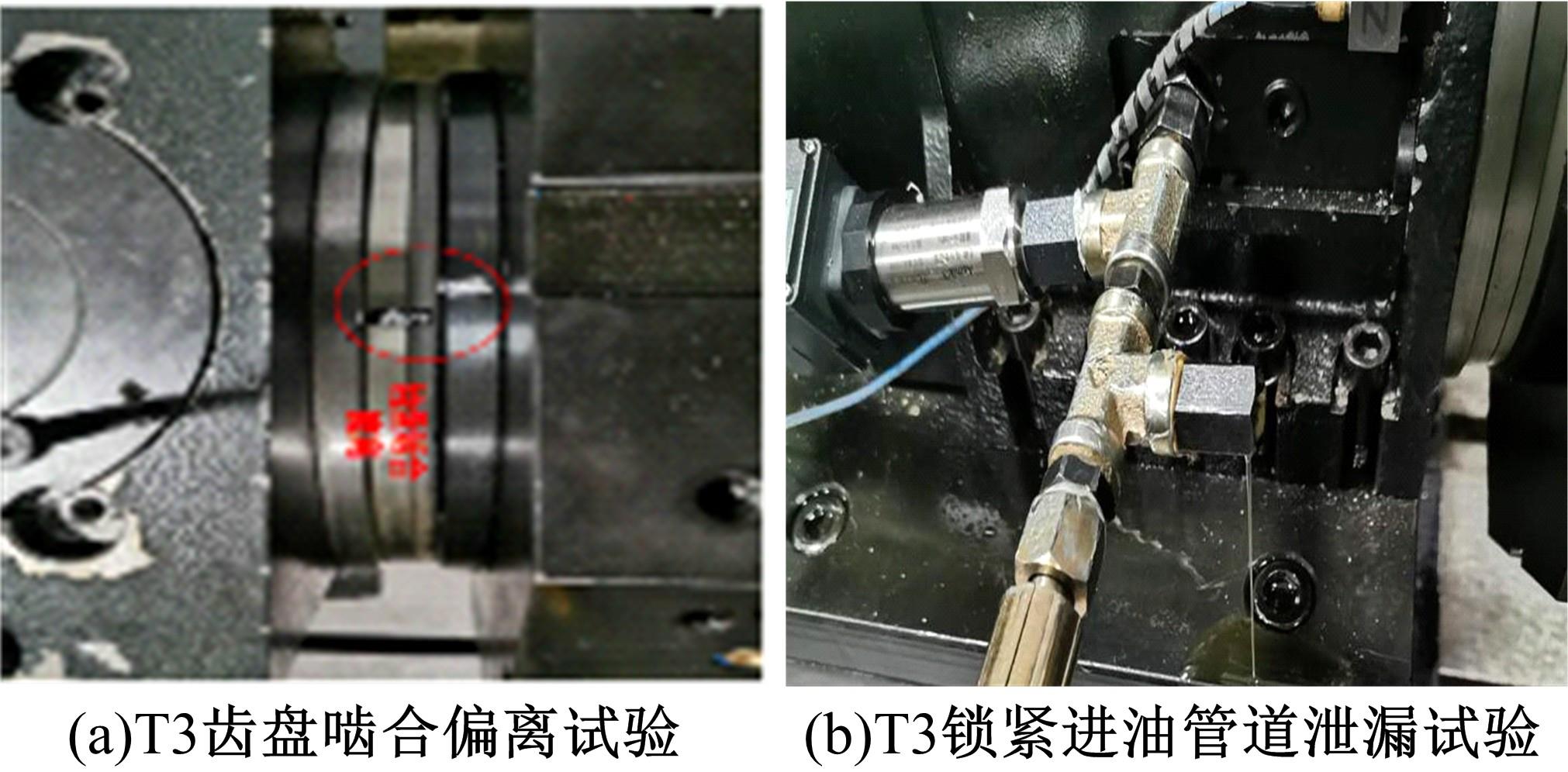

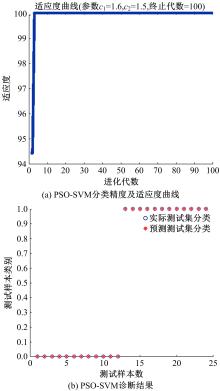

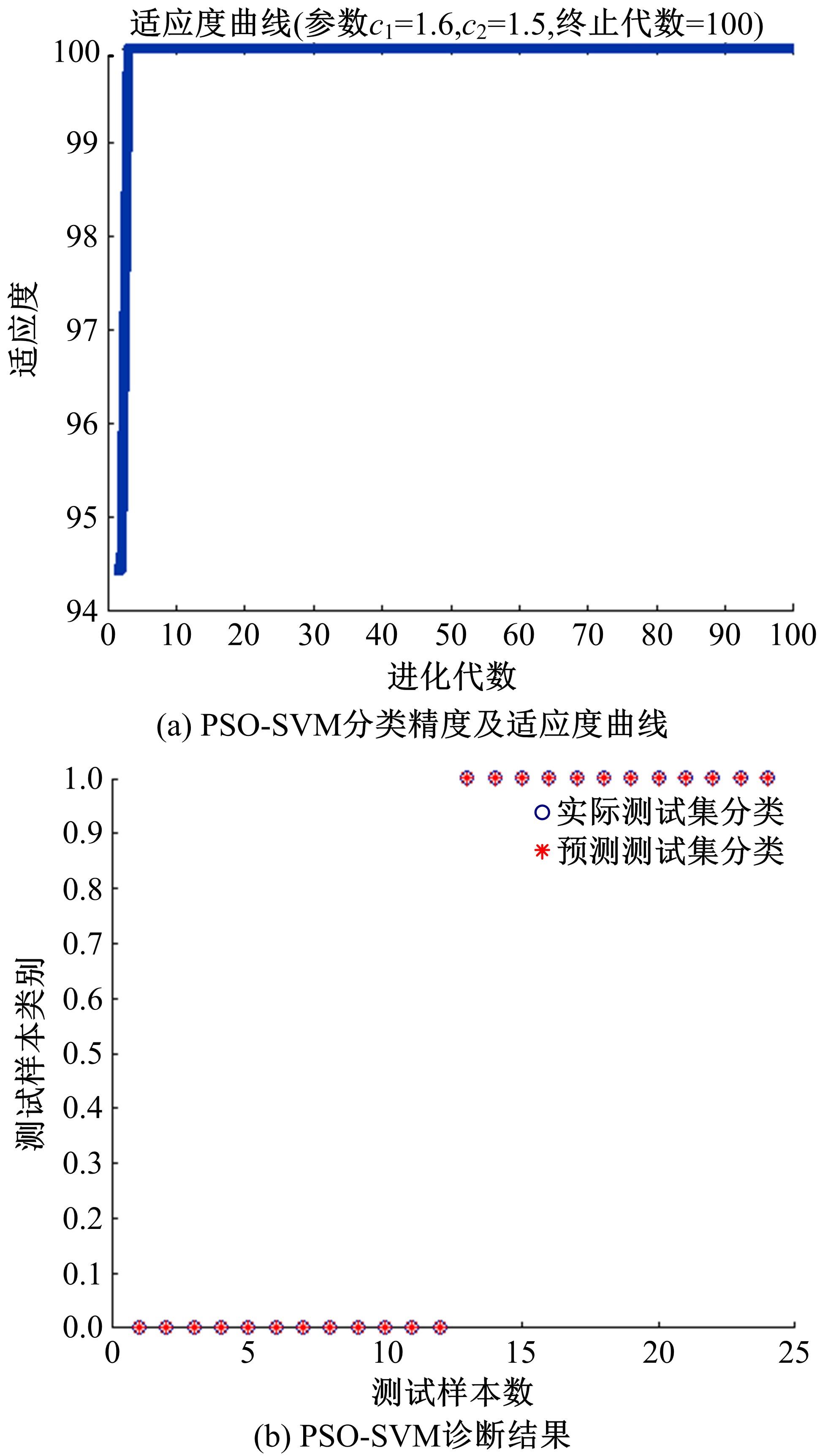

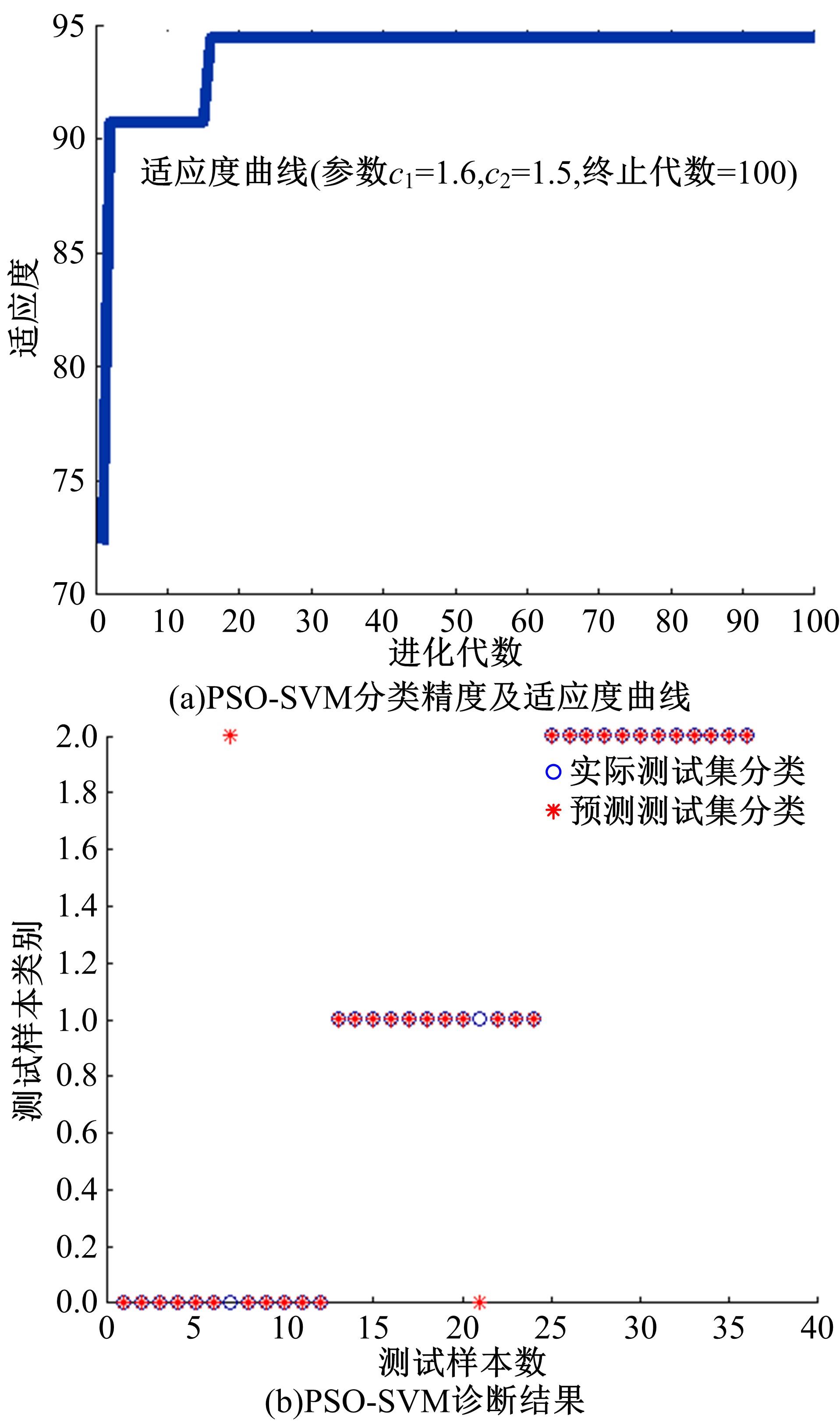

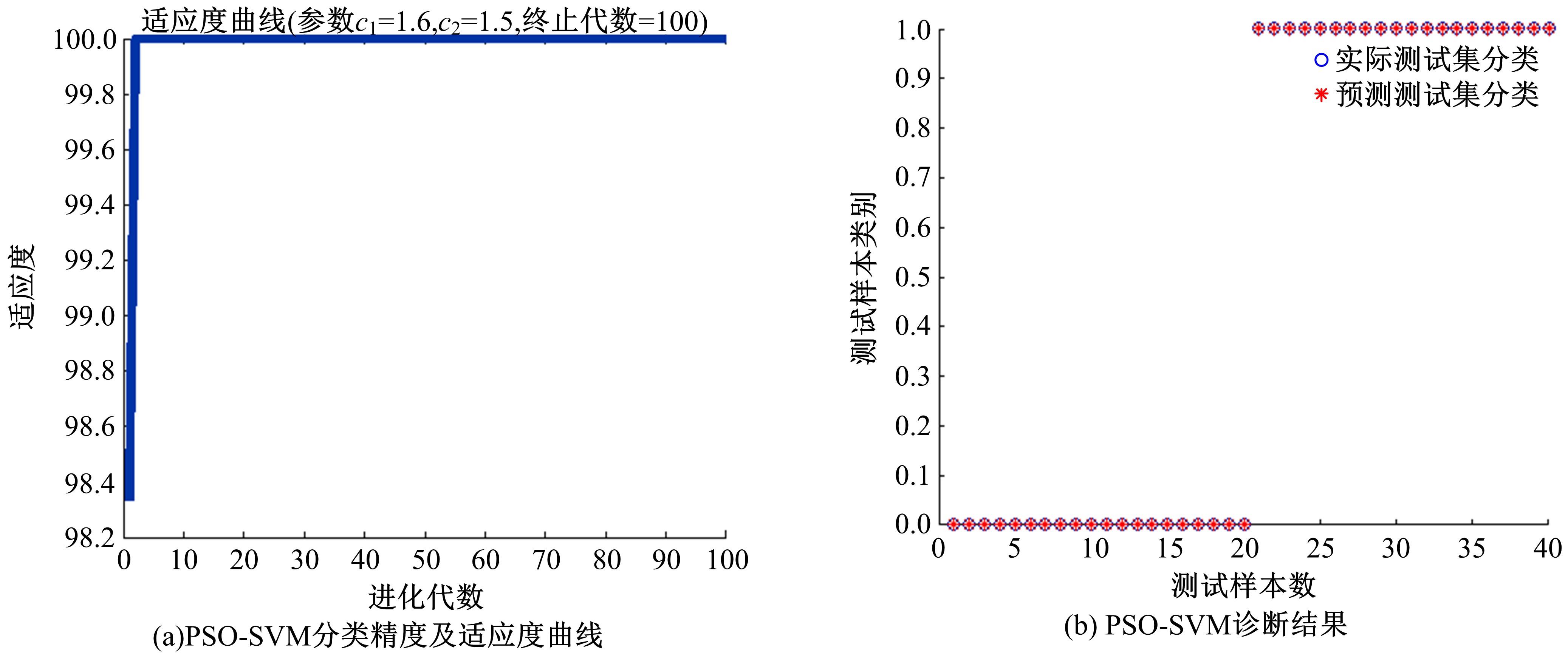

提出了一种基于粒子群-支持向量机(PSO-SVM)及时序环节的数控刀架故障诊断方法。首先,将数控刀架划分为5个子系统,并将一个工作周期划分为4个时序环节(T1、T2、T3、T4);其次,探索了数控刀架不同时序环节振动、电机电流、油压以及接近开关等信号的特征提取方法;最后,提出了基于PSO-SVM的数控刀架故障诊断方法,并开展了不同时序环节的数控刀架故障试验。根据故障数据对支持向量机(SVM)和PSO-SVM两种故障诊断方法进行了对比验证。结果表明:时序环节T2、T3和T4的故障诊断准确率分别提高了28%、23%和5%,验证了该故障诊断方法的有效性。本文方法不仅适用于数控刀架,还为其他复杂机电系统的故障诊断研究提供了一个新思路。

中图分类号:

- TH133.33

| 1 | Sun B, Balakrishnan N, Chen F, et al. Reliability evaluation of the NC turret with accurate failure data and interval censored data based on EM algorithm[J]. Journal of Mechanical Science and Technology, 2020, 34(4): 1503-1513. |

| 2 | Li Chang-you, Wang Wei, Zhang Yi-min, et al. Indexing accuracy reliability sensitivity analysis of power tool turret[J]. Eksploatacja I Niezawodność, 2015, 17(1): 27-34. |

| 3 | Wang Y Q, Yam R C M, Zuo M J,et al.A comprehensive reliability allocation method for design of CNC lathes[J]. Reliability Engineering & System Safety, 2001, 72 (3): 247-252. |

| 4 | Yan C F, Li J W, Liu J. Study on CNC lathe electric turret fault diagnosis[J]. Applied Mechanics and Materials, 2012, 220-223: 381-384. |

| 5 | Yuan L, Fu F U, Li H B. CNC Lathe turret typical failure analysis and resolution[J]. Manufacturing Technology & Machine Tool, 2010(1): 128-130. |

| 6 | Su Z, Wei W, Zhang C, et al. Fault diagnosis of general turret electrically controlled system based on fuzzy neutral network optimized by genetic algorithm[C]∥IEEE 2011 10th International Conference on Electrically Mersurement Instruments, Chengdu, 2011: 275-278. |

| 7 | 田致富. 基于贝叶斯网络的刀架系统故障预测[D]. 长春: 吉林大学机械与航空航天工程学院, 2020. |

| Tian Zhi-fu. Turret system fault prediction based on bayesian network[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2020. | |

| 8 | Chen W Z, Wei H, Fei C, et al. Designing of condition monitoring system for NC turret test platform[C]∥6th International Conference on Mechanical, Automotive and Materials Engineering, Hong Kong2018: 61-65. |

| 9 | 胡炜. 面向数控刀架可靠性试验的CPS研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2019. |

| Hu Wei. Research on CPS of NC turret reliability test[D] .Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2019. | |

| 10 | Basir O, Yuan X. Engine fault diagnosis based on multi-sensor information fusion using dempster-shafer evidence theory[J]. Information Fusion, 2007, 8(4): 379-386. |

| 11 | Stavropoulos P, Papacharalampopoulos A, Vasiliadis E, et al. Tool wear predictability estimation in milling based on multi-sensorial data[J]. International Journal of Advanced Manufacturing Technology, 2016, 82: 509-521. |

| 12 | Praveenkumar T, Saimurugan M, Rb H H, et al. A multi-sensor information fusion for fault diagnosis of gearbox utilizing discrete wavelet features[J]. Measurement Science & Technology, 2019, 30: 085101. |

| 13 | Saravanan N, Siddabattuni V, Ramachandran K I. A comparative study on classification of features by SVM and PSVM extracted using morlet wavelet for fault diagnosis of spur bevel gear box[J]. Expert Systems with Applications, 2008, 35(3): 1351-1366. |

| 14 | Fernández-Francos D, Martínez-Rego D, Fontenla-Romero O, et al. Automatic bearing fault diagnosis based on one-class ν -SVM[J]. Computers & Industrial Engineering, 2013, 64(1): 357-365. |

| 15 | Abbasion S, Rafsanjani A, Farshidianfar A, et al. Rolling element bearings multi-fault classification based on the wavelet denoising and support vector machine[J]. Mechanical System and Signal Processing, 2007, 21(7): 2933-2945. |

| 16 | Wang D J, Meng L, Chao L, et al. Fault diagnosis of automobile engine based on support vector machine[J]. Applied Mechanics and Materials, 2011, 80/81:1060-1064. |

| 17 | Ji Jun-jie, Qu Jian-feng, Chai Yi, et al. An algorithm for sensor fault diagnosis with EEMD-SVM[J]. Transactions of the Institute of Measurement and Control, 2018, 40(6): 1746-1756. |

| 18 | Wen Shuo, Wang Jie-sheng, Gao Jie. Fault diagnosis strategy of polymerization kettle equipment based on support vector machine and cuckoo search algorithm[J]. Engineering Letters, 2017, 25(4): EL-25-4-15. |

| 19 | Liu Z, Chen X, He Z, et al. LMD method and multi-class RWSVM of fault diagnosis for rotating machinery using condition monitoring information[J]. Sensors(Basel, Switzerland), 2013, 13(7): 8679-8694. |

| 20 | Luo S, Cheng J, Ao H L. Application of LCD-SVD technique and CRO-SVM method to fault diagnosis for roller bearing[J]. Shock and Vibration, 2015(2): 847802. |

| [1] | 董绍江,朱朋,裴雪武,李洋,胡小林. 基于子领域自适应的变工况下滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 288-295. |

| [2] | 王进花,胡佳伟,曹洁,黄涛. 基于自适应变分模态分解和集成极限学习机的滚动轴承多故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 318-328. |

| [3] | 胡炜,陈传海,郭劲言,刘志峰,申桂香,于春明. 考虑工况变化的数控刀架运行状态异常检测方法[J]. 吉林大学学报(工学版), 2022, 52(2): 329-337. |

| [4] | 陈晓雷,孙永峰,李策,林冬梅. 基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 296-309. |

| [5] | 张龙,徐天鹏,王朝兵,易剑昱,甄灿壮. 基于卷积门控循环网络的齿轮箱故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 368-376. |

| [6] | 欧阳丹彤,张必歌,田乃予,张立明. 结合格局检测与局部搜索的故障数据缩减方法[J]. 吉林大学学报(工学版), 2021, 51(6): 2144-2153. |

| [7] | 侯春萍,赵春月,王致芃,田海瑞. 基于有效异常样本构造的视频异常检测算法[J]. 吉林大学学报(工学版), 2021, 51(5): 1823-1829. |

| [8] | 院老虎,连冬杉,张亮,刘义. 基于密集连接卷积网络和支持向量机的飞行器机械部件故障诊断[J]. 吉林大学学报(工学版), 2021, 51(5): 1635-1641. |

| [9] | 王康,姚猛,李立犇,李建桥,邓湘金,邹猛,薛龙. 基于月面表取采样触月压痕的月壤力学状态分析[J]. 吉林大学学报(工学版), 2021, 51(3): 1146-1152. |

| [10] | 李伟,陈剑,陶善勇. 自适应耦合周期势系统随机共振信号增强方法[J]. 吉林大学学报(工学版), 2021, 51(3): 1091-1096. |

| [11] | 欧阳丹彤,刘扬,刘杰. 故障响应指导下基于测试集的故障诊断方法[J]. 吉林大学学报(工学版), 2021, 51(3): 1017-1025. |

| [12] | 潘凤文,弓栋梁,高莹,徐明伟,麻斌. 基于锂离子电池线性化模型的电流传感器故障诊断[J]. 吉林大学学报(工学版), 2021, 51(2): 435-441. |

| [13] | 杜常清,曹锡良,何彪,任卫群. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报(工学版), 2020, 50(5): 1556-1564. |

| [14] | 马芳武,韩丽,吴量,李金杭,杨龙帆. 基于遗传与粒子群算法的隔振平台减振性能优化[J]. 吉林大学学报(工学版), 2020, 50(5): 1608-1616. |

| [15] | 张根保,李浩,冉琰,李裘进. 一种用于轴承故障诊断的迁移学习模型[J]. 吉林大学学报(工学版), 2020, 50(5): 1617-1626. |

|

||