吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 253-266.doi: 10.13229/j.cnki.jdxbgxb20211173

• 综述 •

数控机床可靠性建模研究现状及发展动态分析

陈传海1,2( ),王成功1,2,杨兆军1,2,刘志峰1,2,田海龙2(

),王成功1,2,杨兆军1,2,刘志峰1,2,田海龙2( )

)

- 1.吉林大学 数控装备可靠性教育部重点实验室,长春 130022

2.吉林大学 机械与航空航天工程学院,长春 130022

Research status and development trend analysis of reliability modeling of CNC machine tools

Chuan-hai CHEN1,2( ),Cheng-gong WANG1,2,Zhao-jun YANG1,2,Zhi-feng LIU1,2,Hai-long TIAN2(

),Cheng-gong WANG1,2,Zhao-jun YANG1,2,Zhi-feng LIU1,2,Hai-long TIAN2( )

)

- 1.Key Laboratory of Reliability of Numerical Control Equipment Ministry of Education,Jilin University,Changchun 130022,China

2.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

数控机床是装备制造业的工作母机,是国家综合国力的象征,其可靠性已成为制约行业发展的瓶颈。数控机床可靠性建模是可靠性工程的基础,主要对数控机床可靠性建模方法和技术的研究进展进行综合评述。可靠性建模方法主要分为基于故障时间数据的可靠性建模方法、基于多源层次信息集的可靠性建模方法、基于性能退化数据的可靠性建模方法、基于动态特性参数的工艺可靠性建模方法四种,分析了各类可靠性建模方法的研究历程和技术进展。在数控机床可靠性建模方法取得明显进展的基础上,指出现有可靠性建模方法存在的不足,然后对数控机床可靠性建模方法研究的动态和热点进行论述。最后,从可靠性建模方法的发展规律、技术应用以及行业需求的角度对数控机床可靠性建模方法和技术的发展趋势进行展望。

中图分类号:

- TH164

| 1 | 彭卫文. 重型数控机床可靠性建模与评估技术研究[D]. 成都: 电子科技大学机械与电气工程学院, 2016. |

| Peng Wei-wen. Research on methods for reliability modeling and assessment of heavy-duty CNC machine tools[D]. Chengdu: School of Mechanical and Electrical Engineering, University of Electronic Science and Technology of China, 2016. | |

| 2 | 祝洪祥. 考虑工况载荷影响的数控机床可靠性评估方法[D]. 长春: 吉林大学机械与航空航天工程学院, 2020. |

| Zhu Hong-xiang. Reliability evaluation method of NC machine tools considering the influence of working load[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2020. | |

| 3 | 朱孟兵. 基于小样本数据的数控机床MTBF评估[D]. 沈阳: 东北大学机械工程与自动化学院, 2012. |

| Zhu Meng-bing. MTBF evaluation for CNC system based on small sample data[D]. Shenyang: School of Mechanical Engineering and Automation Northeastern University, Northeastern University, 2012. | |

| 4 | Charles E E. An Introduction to Reliability and Maintainability Engineering[M]. Illinois: Waveland Press Inc, 2005. |

| 5 | Keller A Z, Kamath A R R, Perera U D. Reliability analysis of CNC machine tools[J]. Reliability Engineering, 1982, 3(6): 449-473. |

| 6 | 贾亚洲. 急需提高机床可靠性的紧迫感[J]. 机床, 1992(4): 27-30. |

| Jia Ya-zhou. The urgent need to improve the reliability of machine tools[J]. Manufacturing Technology & Machine Tool, 1992(4): 27-30. | |

| 7 | 贾志新, 艾冬梅, 贾亚洲, 等. 数控车床可靠性数据的采集及数据库建立[J]. 制造技术与机床, 2000(1): 3,14-16. |

| Jia Zhi-xin, Ai Dong-mei, Jia Ya-zhou, et al. Reliability data collection and database establishment of CNC lathes[J]. Manufacturing Technology and Machine Tools, 2000(1): 3,14-16. | |

| 8 | 张海波, 贾亚洲, 周广文, 等. 数控系统故障模式、影响及危害度分析(FMECA)[J]. 中国机械工程, 2004(6): 23-26. |

| Zhang Hai-bo, Jia Ya-zhou, Zhou Guang-wen, et al. Failure mode,effects and criticality analysis(FMECA) of CNC system[J]. China Mechanical Engineering, 2004(6): 23-26. | |

| 9 | 程晓民, 贾亚洲, 舒赜. 数控机床维修时间的统计研究[J]. 机床与液压, 1999(2): 83-85. |

| Cheng Xiao-min, Jia Ya-zhou, Shu Yu. Statistical study on maintenance time of CNC machine tools[J]. Machine Tools And Hydraulics, 1999(2): 83-85. | |

| 10 | Wang Y, Jia Y, Yu J, et al. Failure probabilistic model of CNC lathes[J]. Reliability Engineering & System Safety, 1999, 65(3): 307-314. |

| 11 | Wang Y, Jia Y, Jiang W. Early failure analysis of machining centers: a case study[J]. Reliability Engineering & System Safety, 2001, 72(1): 91-97. |

| 12 | 张英芝, 申桂香, 吴甦, 等. 随机截尾数控机床三参数威布尔分布模型[J]. 吉林大学学报: 工学版, 2009, 39(2): 378-381. |

| Zhang Ying-zhi, Shen Gui-xiang, Wu Su, et al. 3-Parameter weibull distribution for random truncated nc machine tool fault data[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(2): 378-381. | |

| 13 | 杨新坤, 赵宁宁, 杨嘉, 等. 基于故障时间数据下数控机床的故障模型研究[J]. 机电工程技术, 2020, 49(12): 66-68, 94. |

| Yang Xin-kun, Zhao Ning-ning, Yang Jia, et al. Research on fault model of CNC machine tools based on fault time data[J]. Electromechanical Engineering Technology, 2020, 49(12): 66-68, 94. | |

| 14 | Dai Y, Zhou Y, Jia Y. Distribution of time between failures of machining center based on type i censored data[J]. Reliability Engineering and System Safety, 2003, 79: 377-379. |

| 15 | 王继利, 杨兆军, 李国发, 等. 基于改进EM算法的多重威布尔可靠性建模[J]. 吉林大学学报: 工学版, 2014, 44(4): 1010-1015. |

| Wang Ji-li, Yang Zhao-jun, Li Guo-fa, et al. Reliability modeling of finite weibull distribution based on improved EM algorithm[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(4): 1010-1015. | |

| 16 | 杨兆军, 杨川贵, 陈菲, 等. 基于PSO算法和SVR模型的加工中心可靠性模型参数估计[J]. 吉林大学学报: 工学版, 2015, 45(3): 829-836. |

| Yang Zhao-jun, Yang Chuan-gui, Chen Fei, et al. Parameter estimation of reliability model of machining center based on particle swarm optimization and support vector regression[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(3): 829-836. | |

| 17 | 杨若霁. 基于幂律模型的数控机床可靠性评估[J]. 精密制造与自动化, 2015(3): 18-20. |

| Yang Ruo-ji. Reliability evaluation of CNC machine tools based on power law model[J]. Precision Manufacturing and Automation, 2015(3): 18-20. | |

| 18 | 许彬彬, 杨兆军, 陈菲, 等. 非齐次泊松过程的数控机床可靠性建模[J]. 吉林大学学报: 工学版, 2011, 41(): 210-214. |

| Xu Bin-bin, Yang Zhao-jun, Chen Fei, et al. Reliability model of CNC machine tools based on non-homogenous poisson process[J]. Journal of Jilin University(Engineering and Technology Edition), 2011, 41(Sup.2): 210-214. | |

| 19 | Li H, Yang Z, Xu B, et al. Reliability evaluation of nc machine tools considering working conditions[J]. Mathematical Problems in Engineering, 2016(5): 1-11. |

| 20 | 姜京男. 基于工况因素聚类分析的数控机床小样本可靠性建模[D]. 长春: 吉林大学机械与航空航天工程学院, 2019. |

| Jiang Jing-nan. Reliability modeling of nc machine tools with small samples based on clustering analysis of working conditions[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2019. | |

| 21 | 杨兆军, 李小兵, 许彬彬, 等. 加工中心时间动态可靠性建模[J]. 机械工程学报, 2012, 48(2): 16-22. |

| Yang Zhao-jun, Li Xiao-bing, Xu Bin-bin, et al. Time dynamic reliability modelling of machining center[J]. Journal of Mechanical Engineering, 2012, 48(2): 16-22. | |

| 22 | 张强, 艾兴, 贾亚洲. 数控机床可靠性信息系统信息建模[J]. 山东大学学报: 工学版, 2005(4): 14-18. |

| Zhang Qiang, Ai Xing, Jia Ya-zhou. Study on reliability information system modeling of CNC machine tools[J]. Journal of Shandong University(Engineering Edition), 2005(4): 14-18. | |

| 23 | 王国强, 张根保, 洪涛, 等. 基于任务的数控机床加工过程可靠性建模技术研究[J]. 中国机械工程, 2013, 24(10): 1296-1302. |

| Wang Guo-qiang, Zhang Gen-bao, Hong Tao, et al. Research on reliability modeling technology for machining process of CNC machine tools based on task[J]. China Mechanical Engineering, 2013, 24(10): 1296-1302. | |

| 24 | 刘英, 康丽娜, 王扬, 等. 数控机床马尔可夫过程下的超单元可靠性建模技术[J]. 机械科学与技术, 2016, 35(2): 247-252. |

| Liu Ying, Kang Li-na, Wang Yang, et al. Reliability modeling technology of superelements for CNC machine tools with markov process[J]. Mechanical Science and Technology for Aerospace Engineering, 2016, 35(2): 247-252. | |

| 25 | 张根保, 王扬. 基于元动作链理论的数控机床故障分析[J]. 中国机械工程, 2019, 30(16): 1950-1958, 1966. |

| Zhang Gen-bao, Wang Yang. Analysis for failures of CNC machine tools based on meta-action chain methodology[J]. China Mechanical Engineering, 2019, 30(16): 1950-1958, 1966. | |

| 26 | Das K, Lashkari R S, Sengupta S. Machine reliability and preventive maintenance planning for cellular manufacturing systems[J]. European Journal of Operational Research, 2007, 183(1): 162-180. |

| 27 | 申桂香, 陈炳锟, 张英芝, 等. 数控机床小样本类型子系统的可靠性建模[J]. 重庆大学学报, 2011, 34(8): 55-59. |

| Shen Gui-xiang, Chen Bing-kun, Zhang Ying-zhi, et al. Reliability model for subsystems of CNC machine tool with small samples[J]. Journal of Chongqing University, 2011, 34(8): 55-59. | |

| 28 | Merrick J R W, Soyer R, Mazzuchi T A. A bayesian semiparametric analysis of the reliability and maintenance of machine tools[J]. Technometrics, 2003, 45(1): 58-69. |

| 29 | 张雷. 基于Bayes理论的重型数控机床可靠性评定方法研究[D]. 秦皇岛: 燕山大学机械工程学院, 2013. |

| Zhang Lei. Research on reliability evaluation method of Heavy CNC machine tools based on Bayes theory[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University, 2013. | |

| 30 | 蒋喜, 刘宏昭, 訾佼佼, 等. 基于Bayes法的电主轴极小子样可靠性研究[J]. 振动与冲击, 2015, 34(4): 121-127. |

| Jiang Xi, Liu Hong-zhao, Zi Jiao-jiao, et al. Extremely small sample's reliability of a motorized spindle based on bayes method[J]. Journal of Vibration and Shock, 2015, 34(4): 121-127. | |

| 31 | 陈传海, 杨兆军, 陈菲, 等. 基于Bootstrap-Bayes的加工中心主轴可靠性建模[J]. 吉林大学学报: 工学版, 2014, 44(1): 95-100. |

| Chen Chuan-hai, Yang Zhao-jun, Chen Fei, et al. Reliability modeling of machining center spindle based on bootstrap Bayes[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(1): 95-100. | |

| 32 | 王学姚. 基于RBF神经网络及非线性约束的数控机床Bayes可靠性评估研究[D]. 秦皇岛: 燕山大学机械工程学院, 2017. |

| Wang Xue-yao. Research on Bayes reliability evaluation of CNC machine tools based on RBF neural network and nonlinear constraints[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University, 2017. | |

| 33 | 聂萌, 张海波. 基于自助扩充法的数控机床可靠性建模研究[J]. 制造技术与机床, 2019(3): 17-20. |

| Nie Meng, Zhang Hai-bo. Study on reliability modeling of NC machine tool based on self-expansion method[J]. Manufacturing Technology & Machine Tool, 2019(3): 17-20. | |

| 34 | 张海波, 王妍. 基于回归折算法的小样本数控机床可靠性建模[J]. 组合机床与自动化加工技术, 2018(5): 165-167, 172. |

| Zhang Hai-bo, Wang Yan. Reliability modeling under NC machine in small sample based on regression conversion method[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2018(5): 165-167, 172. | |

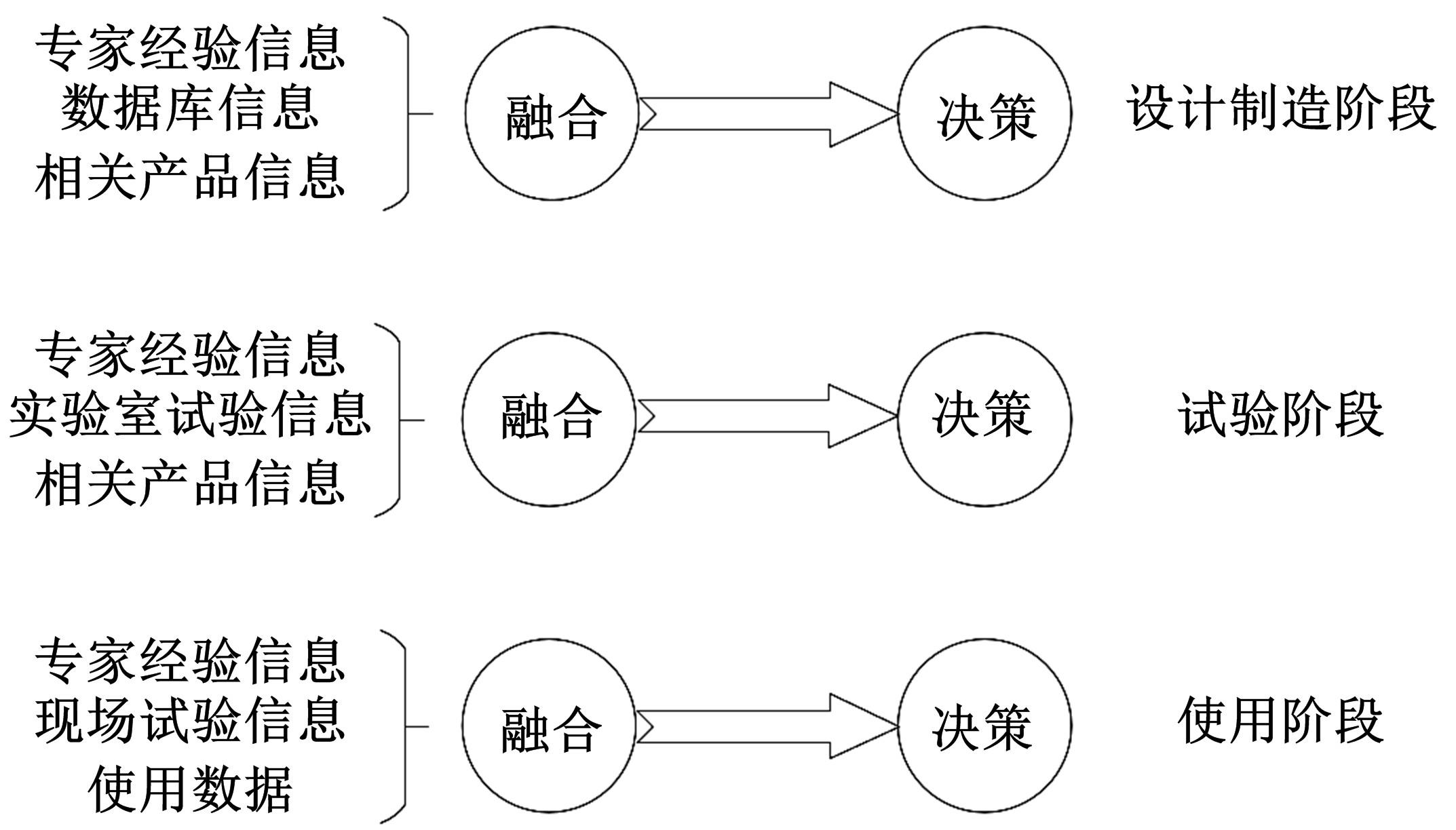

| 35 | 方艮海. 产品可靠性评估中的多源信息融合技术研究[D]. 合肥: 合肥工业大学机械工程学院, 2006. |

| Fang Gen-hai. Research on the multi-source information fusion techniques in the process of reliability assessment[D]. Hefei: School of Mechanical Engineering, Hefei University of Technology, 2006. | |

| 36 | 吴晓辉, 蔡忠义, 李全祥. 融合内外场退化数据的可靠性评估方法[J]. 合肥工业大学学报: 自然科学版, 2017, 40(12): 1589-1593. |

| Wu Xiao-hui, Cai Zhong-yi, Li Quan-xiang. Reliability assessment method with integration of infield and outfield degradation data[J]. Journal of Hefei University of Technology(Natural Science), 2017, 40 (12): 1589-1593. | |

| 37 | 彭卫文, 黄洪钟, 李彦锋, 等. 基于数据融合的加工中心功能铣头贝叶斯可靠性评估[J]. 机械工程学报, 2014, 50(6): 185-191. |

| Peng Wei-wen, Huang Hong-zhong, Li Yan-feng, et al. Bayesian information fusion method for reliability assessment of milling head[J]. Journal of Mechanical Engineering, 2014, 50(6): 185-191. | |

| 38 | 郭骏宇. 多源信息下数控机床关键子系统可靠性建模与评估研究[D]. 成都: 电子科技大学机械与电气工程学院, 2019. |

| Guo Jun-yu. Research on reliability modeling and assessment of critical subsystems of CNC machine tools under multi-source information[D]. Chengdu: School of Mechanical and Electrical Engineering, University of Electronic Science and technology, 2019. | |

| 39 | Yang Z, Kan Y, Chen F, et al. Bayesian reliability modeling and assessment solution for NC machine tools under small-sample data[J]. University of Electronic Science and Technology of China, 2015, 28(6): 1229-1239. |

| 40 | Peng W, Li Y F, Yang Y J, et al. Leveraging degradation testing and condition monitoring for field reliability analysis with time-varying operating missions[J]. IEEE Transactions on Reliability, 2015, 64(4): 1367-1382. |

| 41 | 黄洪钟, 刘征, 米金华, 等. 混合不确定性下机床主轴可靠性建模与分析[J]. 中国科学: 物理学, 力学, 天文学, 2018, 48(1): 42-53. |

| Huang Hong-zhong, Liu Zheng, Mi Jin-hua, et al. Reliability modeling and analysis of heavy-duty CNC machine tool spindle under hybrid uncertainty[J]. Scientia Sinica(Physica Mechanica & Astronomica), 2018, 48(1): 42-53. | |

| 42 | 刘征. 混合不确定性下的重型数控机床主轴系统可靠性建模与分析方法研究[D]. 成都: 电子科技大学机械与电气工程学院, 2016. |

| Liu Zheng. Research on methods for reliability modeling and analysis for heavy-duty CNC machine tools spindle system under hybrid uncertainties[D]. Chengdu: School of Mechanical and Electrical Engineering, University of Electronic Science and Technology of China, 2016. | |

| 43 | Zhang X, Zhang G, Gong X, et al. Reliability fuzzy comprehensive evaluation of all factors in CNC machine tool assembly process[C]∥Lecture Notes in Electrical Engineering, Singapore, 2018: 115-124. |

| 44 | 曾声奎. 可靠性设计与分析3[M]. 北京: 国防工业出版社, 2013. |

| 45 | 陈真. 基于性能参数的数控机床系统可靠性评估及应用[D]. 武汉: 华中科技大学能源与动力工程学院, 2017. |

| Chen Zhen. Methods and applications of reliability estimation of CNC equipment based on performance parameters[D]. Wuhan: School of Energy and Power Engineering, Huazhong University of Science and Technology, 2017. | |

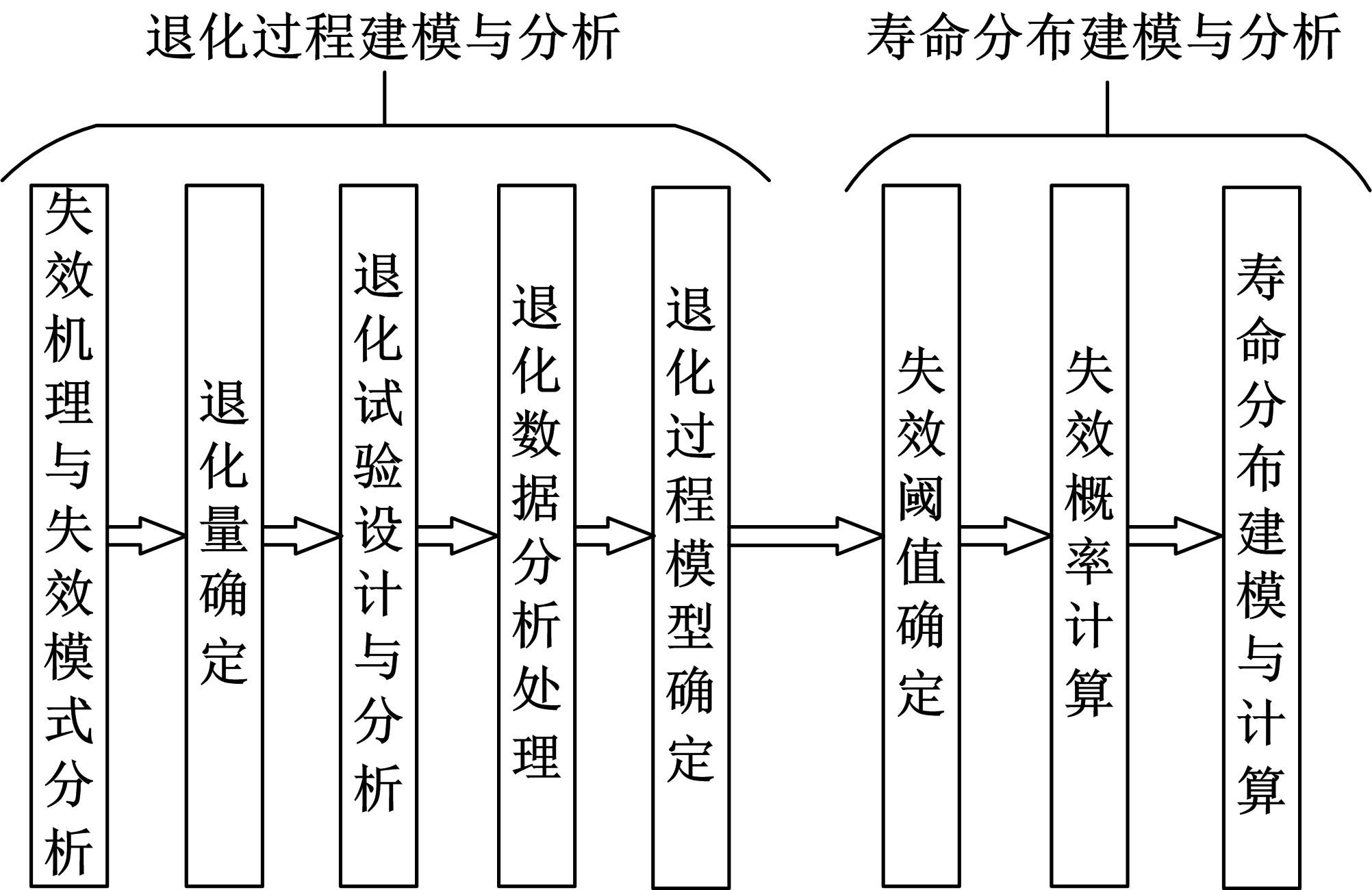

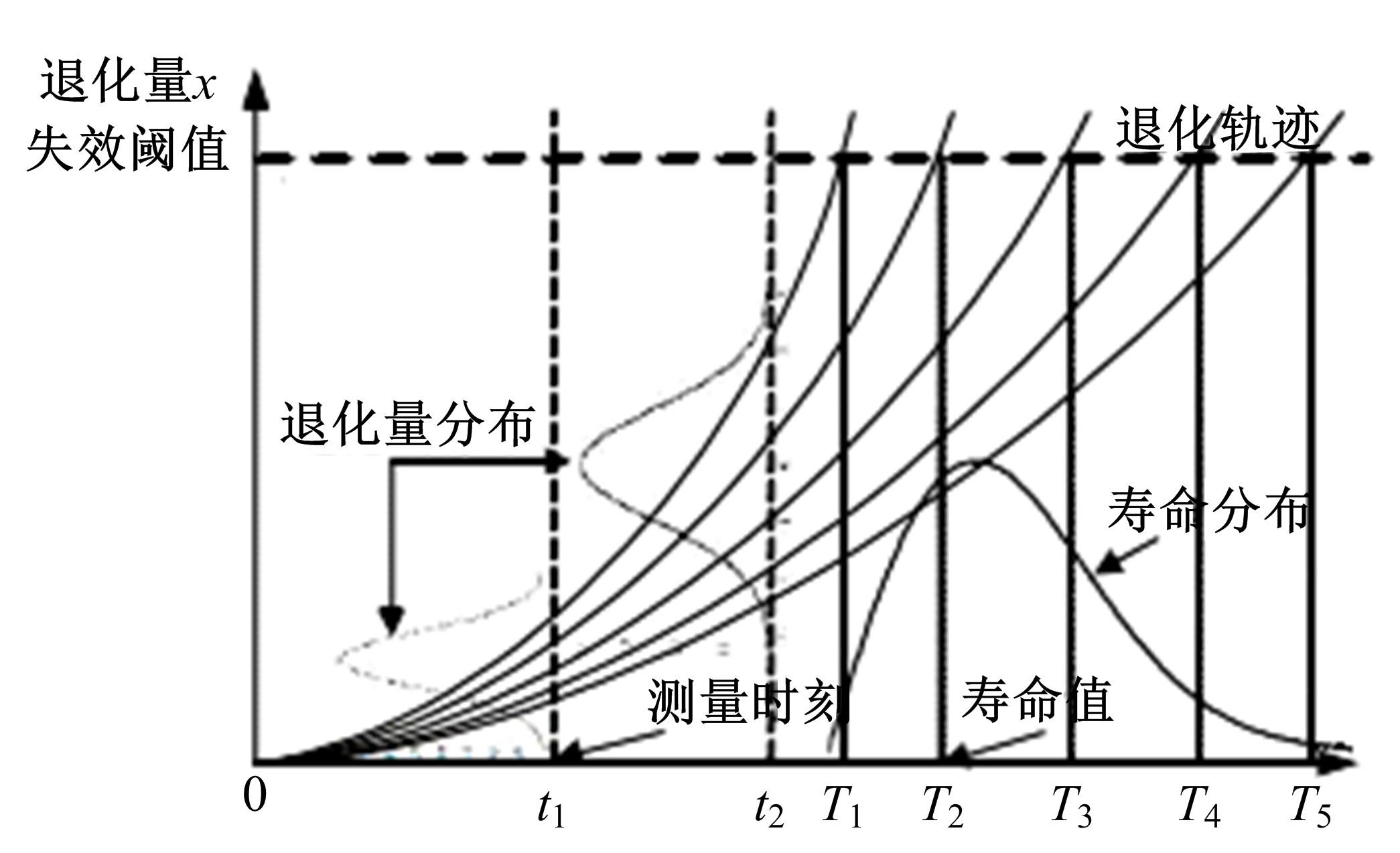

| 46 | 贺英政, 王浩伟, 杨坤. 基于退化量分布的可靠性建模方法[J]. 海军航空工程学院学报, 2014, 29(2): 178-182. |

| He Ying-zheng, Wang Hao-wei, Yang Kun. Reliability modeling method based on degradation data distribution[J]. Journal of Naval Aeronautical and Astronautical. 2014, 29(2): 178-182. | |

| 47 | Lu C J, Meeker W O. Using degradation measures to estimate a time-to-failure distribution[J]. Technometrics, 1993, 35(2): 161-174. |

| 48 | Lu S, Lu H, Kolarik W J. Multivariate performance reliability prediction in real-time[J]. Reliability Engineering and System Safety, 2001, 72(1): 39-45. |

| 49 | 吴鹏, 吴军, 邓超. 基于SVR的数控机床性能退化分析与可靠性评估[C]∥智能信息技术应用学会, 亚庇, 2011: 602-607. |

| 50 | 訾佼佼, 刘宏昭, 蒋喜, 等. 基于退化量分布的电主轴可靠性评估[J]. 中国机械工程, 2014, 25(6): 807-812. |

| Zi Jiao-jiao, Liu Hong-zhao, Jiang Xi, et al. Reliability assessment of electric spindle based on degradation values distribution[J]. China Mechanical Engineering, 2014, 25(6): 807-812. | |

| 51 | 蒋喜, 刘宏昭, 刘丽兰, 等. 基于伪寿命分布的电主轴极小子样可靠性研究[J]. 振动与冲击, 2013, 32(19): 80-85. |

| Jiang Xi, Liu Hong-zhao, Liu Li-lan, et al. Extremely small-scale sample's reliability of an electric spindle based on distribution of false lifetime[J]. Journal of Vibration and Shock, 2013, 32(19): 80-85. | |

| 52 | 邱荣华, 张敏, 王锦, 等. 小子样高速电主轴的Bayes可靠性分析[J]. 机械设计, 2018, 35(2): 67-71. |

| Qiu Rong-hua, Zhang Min, Wang Jin, et al. Reliability analysis of small sample high-speed motorized spindle base on bayes[J]. Journal of Machine Design, 2018, 35 (2): 67-71. | |

| 53 | 蒋喜, 刘宏昭, 訾佼佼, 等. 基于伪寿命分布和Bayes法的电主轴可靠性对比[J]. 机械科学与技术, 2014, 33(11): 1694-1699. |

| Jiang Xi, Liu Hong-zhao, Zi Jiao-jiao, et al. Comparative study on the reliability of motorized spindle based on false life distribution and bayes method[J]. Mechanical Science and Technology for Aerospace Engineering, 2014, 33(11): 1694-1699. | |

| 54 | 葛玉华, 韩军, 冯虎田. 刀库及机械手多态可靠性建模与分析[J]. 组合机床与自动化加工技术, 2013(9): 21-24. |

| Ge Yu-hua, Han Jun, Feng Hu-tian. Muti-state reliability modeling and analysis of tool magazine & manipulator[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2013(9): 21-24. | |

| 55 | 朱晓. 基于元动作单元依赖特性建模的机械系统多态可靠性评估方法研究[D]. 重庆: 重庆大学机械与运载工程学院, 2019. |

| Zhu Xiao. Research on reliability evaluation of multi-state mechanical system based on the meta-action units dependence modeling[D]. Chongqing: College of Mechanical and Vehicle Engineering, Chongqing University, 2019. | |

| 56 | 黄金波. 系统退化建模与可靠性评估方法研究[D]. 北京: 北京理工大学管理与经济学院, 2016. |

| Huang Jin-bo. Research on system degradation modeling and reliability assessment methods[D]. Beijing: School of Management and Economics, Beijing Institute of Technology, 2016. | |

| 57 | Ye Z S, Xie M. Stochastic modelling and analysis of degradation for highly reliable products[J]. Applied Stochastic Models in Business and Industry, 2015, 31(1): 33-34. |

| 58 | 夏爽. 基于维纳过程的机电装备性能退化建模与健康状态评估[D]. 武汉: 华中科技大学机械科学与工程学院, 2016. |

| Xia Shuang. Performance degradation modeling and health assessment for mechanical and electrical equipment based on wiener process[D]. Wuhan: School of Mechanical Science & Engineering, Huazhong University of Science and Technology, 2016. | |

| 59 | 杨斌. 基于性能退化的电主轴可靠性评估[D]. 长春: 吉林大学机械与航空航天工程学院, 2018. |

| Yang Bin. Reliability assessment of motorized spindle based on performance degradation[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2018. | |

| 60 | 张根保, 张定飞, 冉琰, 等. 基于Gamma和混合Copula的元动作单元性能可靠性分析[J]. 湖南大学学报: 自然科学版, 2021, 48(4): 113-125. |

| Zhang Gen-bao, Zhang Ding-fei, Ran Yan, et al. Performance reliability analysis of meta-action unit based on gamma process and hybrid copula function[J]. Journal of Hunan University(Natural Sciences), 2021, 48(4): 113-125. | |

| 61 | 邓超, 孙耀宗, 李嵘, 等. 基于隐Markov模型的重型数控机床健康状态评估[J]. 计算机集成制造系统, 2013, 19(3): 552-558. |

| Deng Chao, Sun Yao-zong, Li Rong, et al. Hidden markov model based on the heavy-duty CNC health state estimate[J]. Computer Integrated Manufacturing Systems, 2013, 19(3): 552-558. | |

| 62 | 钟珂珂, 吴晓东, 金永乔, 等. 面向性能退化的数控机床服役可靠性评估方法[J]. 装备制造技术, 2019(12): 154-158, 167. |

| Zhong Ke-ke, Wu Xiao-dong, Jin Yong-qiao, et al. An operational reliability evaluation method for CNC machine tools based on performance degradation[J]. Equipment Manufacturing Technology, 2019(12): 154-158, 167. | |

| 63 | 王明磊, 原大宁, 刘宏昭. 二元Wiener过程下的小样本电主轴可靠性分析[J]. 机械科学与技术, 2017, 36(2): 279-285. |

| Wang Ming-lei, Yuan Da-ning, Liu Hong-zhao. Reliability analysis of motorized spindle with small sample based on two-dimensional wiener process[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(2): 279-285. | |

| 64 | 鲍俊. 基于步进双应力加速退化试验的电主轴可靠性建模研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2018. |

| Bao Jun. Reliability modeling of motorized spindle based on step-stress accelerated degradation test with two accelerating stresses[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2018. | |

| 65 | 李睿智. 基于多性能退化的数控装备可靠性建模与评估[D]. 成都: 电子科技大学机械与电气工程学院, 2017. |

| Li Rui-zhi. Reliability modeling and assessment for numerical control equipment with multi-degradation[D]. Chengdu: School of Mechanical and Electrical Engineering, University of Electronic Science and Technology of China, 2017. | |

| 66 | 四川省机械工程学会设备维修专业委员会. 机器可靠性[M]. 成都: 四川人民出版社, 1983. |

| 67 | 邓超, 吴军, 毛宽民, 等. 面向大型数控机床的工艺可靠性评估[J]. 计算机集成制造系统, 2010, 16(10): 2250-2256. |

| Deng Chao, Wu Jun, Mao Kuan-min, et al. Process reliability evaluation for large-sized NC machine tools[J]. Computer Integrated Manufacturing Systems, 2010, 16(10): 2250-2256. | |

| 68 | 吴军, 邓超, 邵新宇, 等. 基于加工动力学模型的工艺可靠性仿真方法[J]. 系统工程理论与实践, 2011, 31(7): 1403-1408. |

| Wu Jun, Deng Chao, Shao Xin-yu, et al. Process reliability simulation method based on machining dynamics model[J]. Systems Engineering-Theory & Practice, 2011, 31(7): 1403-1408. |

| [1] | 樊学平,杨光红,尚志鹏,赵小雄,肖青凯,刘月飞. 考虑适用性的大跨桥梁主梁动态可靠性融合预测[J]. 吉林大学学报(工学版), 2022, 52(1): 144-153. |

| [2] | 李国发,陈泽权,何佳龙. 新型结构可靠性分析自适应加点策略[J]. 吉林大学学报(工学版), 2021, 51(6): 1975-1981. |

| [3] | 杜尊令,张义民. 基于随机流量下柱塞泵的可靠性分析[J]. 吉林大学学报(工学版), 2021, 51(6): 1967-1974. |

| [4] | 樊学平,杨光红,肖青凯,刘月飞. 大跨桥梁主梁失效概率分析的最优R-Vine Copula[J]. 吉林大学学报(工学版), 2021, 51(4): 1296-1305. |

| [5] | 李国龙,陶小会,徐凯,李喆裕. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报(工学版), 2021, 51(2): 458-467. |

| [6] | 吴昊天,郭锐锋,彭阿珍,王品. 一种考虑可靠性的常带宽服务器低功耗调度算法[J]. 吉林大学学报(工学版), 2020, 50(5): 1802-1808. |

| [7] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [8] | 于繁华, 刘仁云, 张义民, 张晓丽, 孙秋成. 机械零部件动态可靠性稳健优化设计的群智能算法[J]. 吉林大学学报(工学版), 2017, 47(6): 1903-1908. |

| [9] | 吴娇蓉, 王宇沁, 魏明, 林彬. 路侧公交专用道设置长度对公交线路运行可靠性的影响[J]. 吉林大学学报(工学版), 2017, 47(1): 82-91. |

| [10] | 孟广伟, 冯昕宇, 周立明, 李锋. 基于降维算法的结构可靠性分析[J]. 吉林大学学报(工学版), 2017, 47(1): 174-179. |

| [11] | 张英芝, 刘津彤, 申桂香, 戚晓艳, 龙哲. 基于故障相关性分析的数控机床系统可靠性建模[J]. 吉林大学学报(工学版), 2017, 47(1): 169-173. |

| [12] | 赵丁选, 王倩, 张祝新. 基于层次分析法的可拓学理论对舰载直升机可靠性的评估[J]. 吉林大学学报(工学版), 2016, 46(5): 1528-1531. |

| [13] | 李洪洲, 杨兆军, 许彬彬, 王彦鹍, 贾玉辉, 侯超. 数控机床可靠性评估试验周期设计[J]. 吉林大学学报(工学版), 2016, 46(5): 1520-1527. |

| [14] | 于繁华, 刘仁云, 张义民, 孙秋成, 张晓丽. 机械结构动态可靠性设计的智能计算方法[J]. 吉林大学学报(工学版), 2016, 46(4): 1269-1275. |

| [15] | 潘义勇, 马健霄, 孙璐. 基于可靠度的动态随机交通网络耗时最优路径[J]. 吉林大学学报(工学版), 2016, 46(2): 412-417. |

|

||