吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 425-432.doi: 10.13229/j.cnki.jdxbgxb20211116

• 车辆工程·机械工程 • 上一篇

薄壁件铣削加工颤振的图像特征提取与识别

- 哈尔滨理工大学 先进制造智能化技术教育部重点实验室,哈尔滨 150080

Image feature extraction and recognition of milling chatter of thin walled parts

Mao-yue LI( ),Shuo LIU,Shuai TIAN,Gui-feng XIAO

),Shuo LIU,Shuai TIAN,Gui-feng XIAO

- Key Laboratory of Advanced Manufacturing and Intelligent Technology,Ministry of Education,Harbin University of Science and Technology,Harbin 150080,China

摘要:

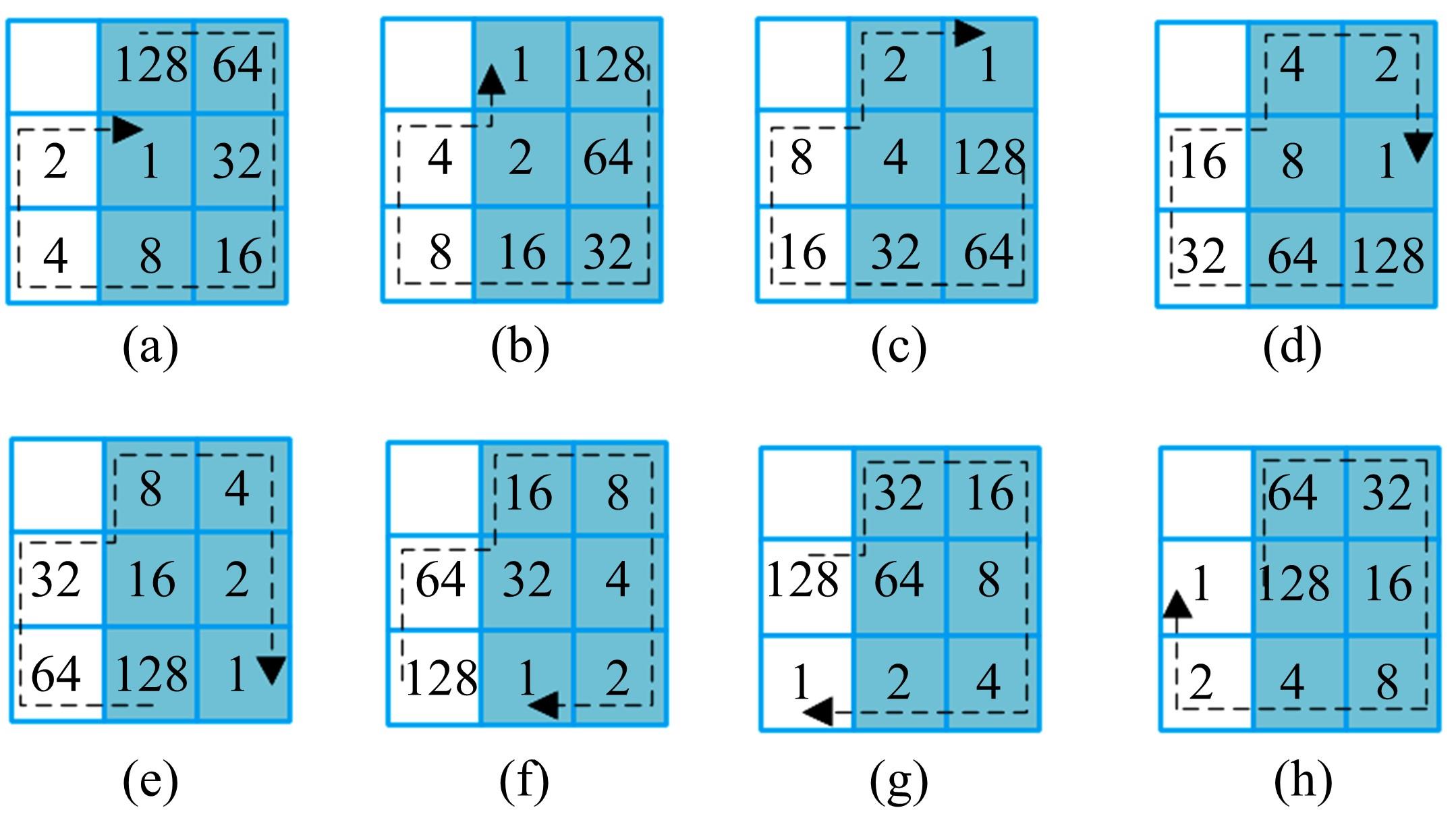

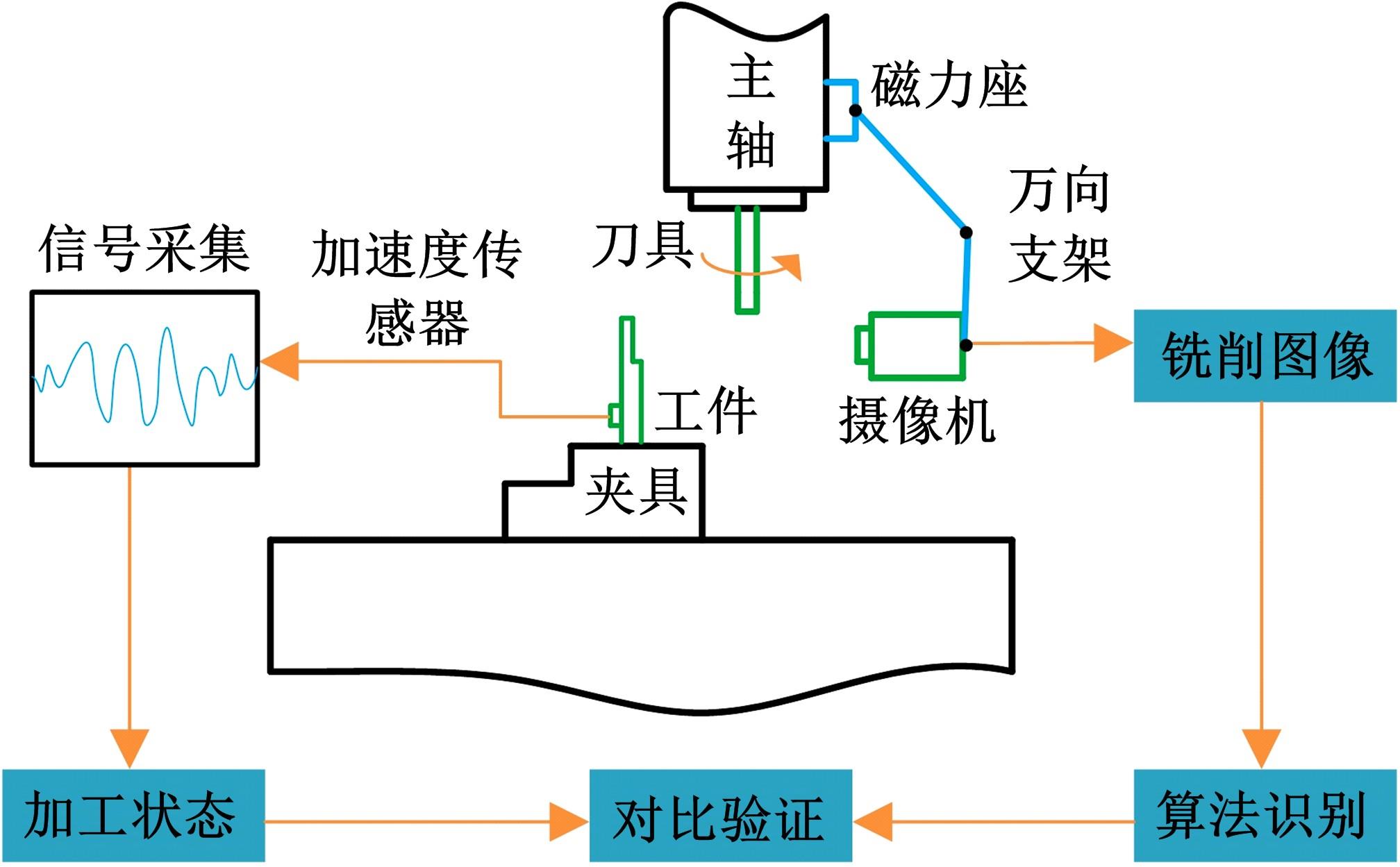

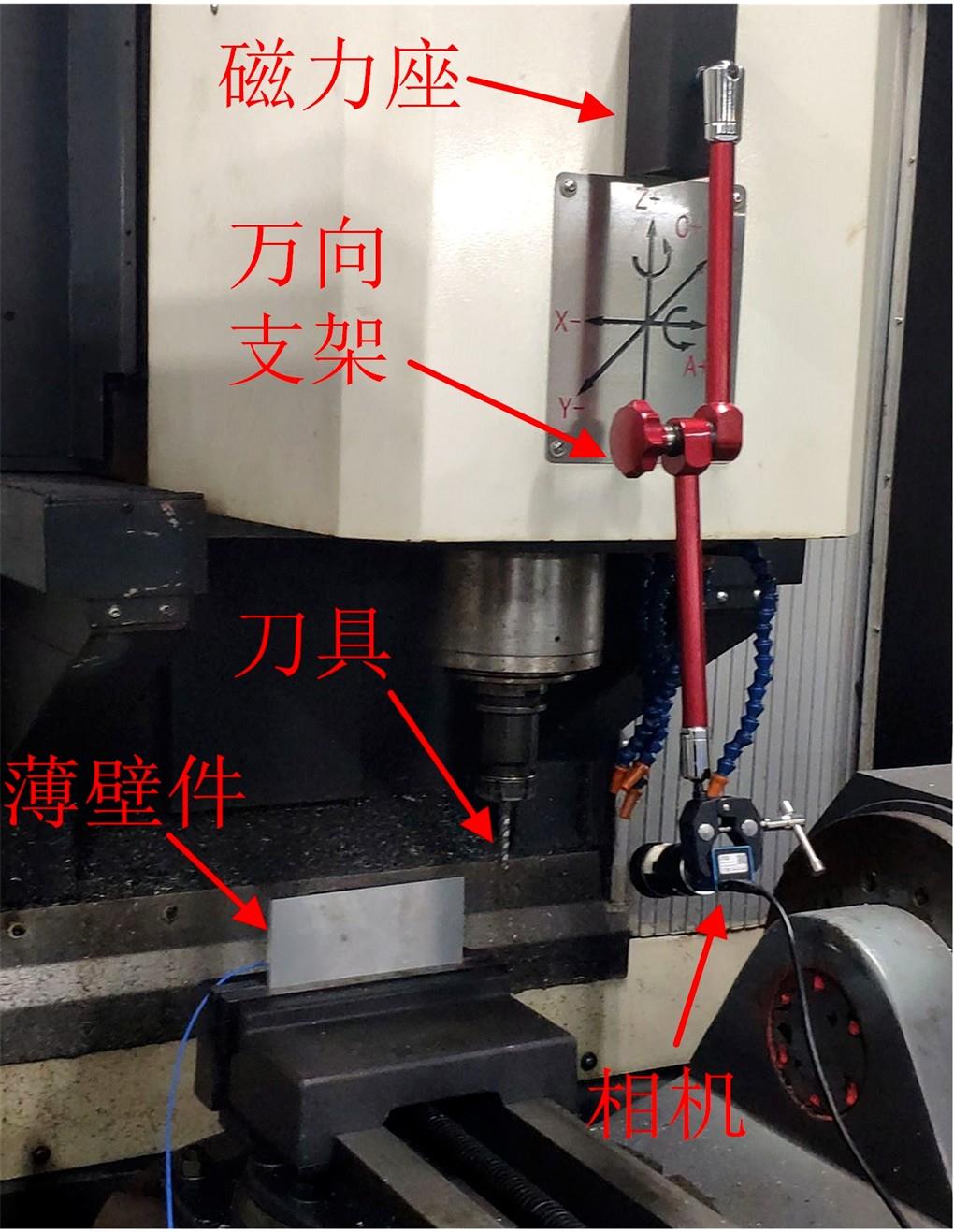

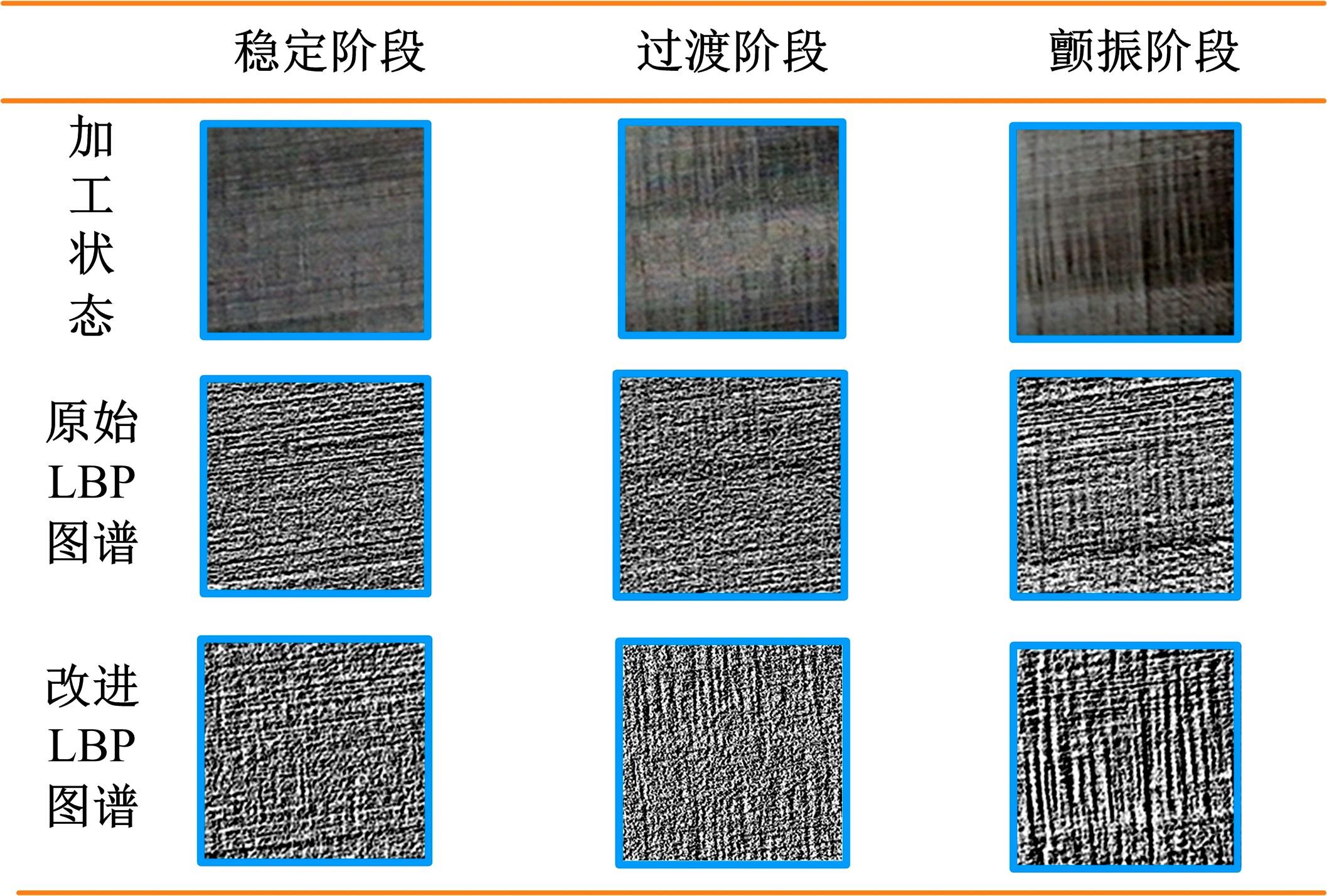

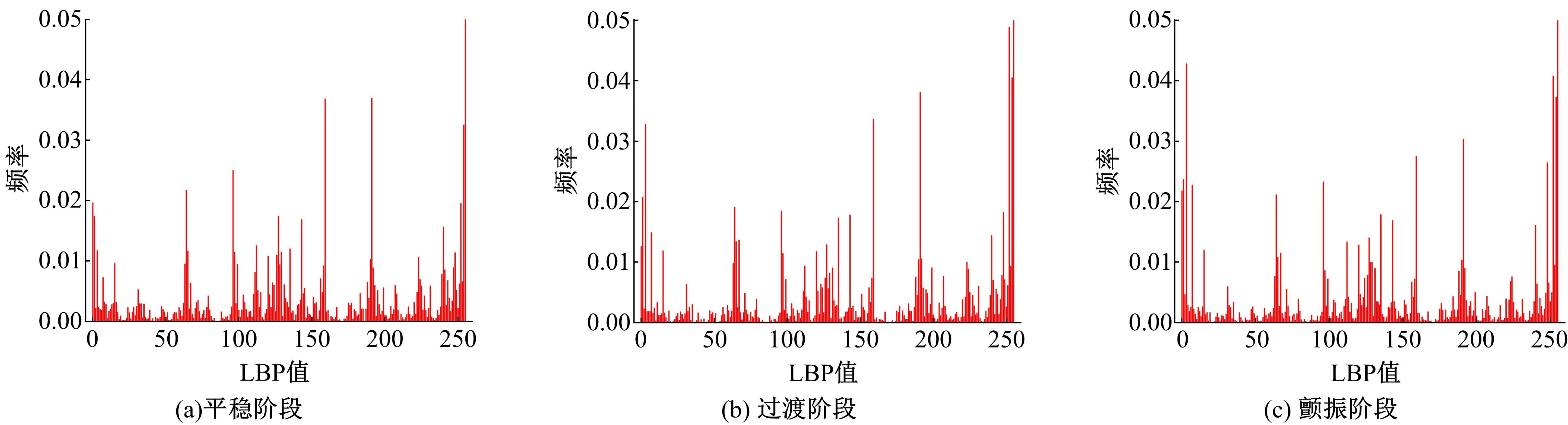

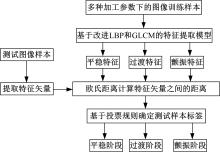

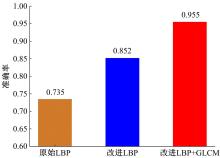

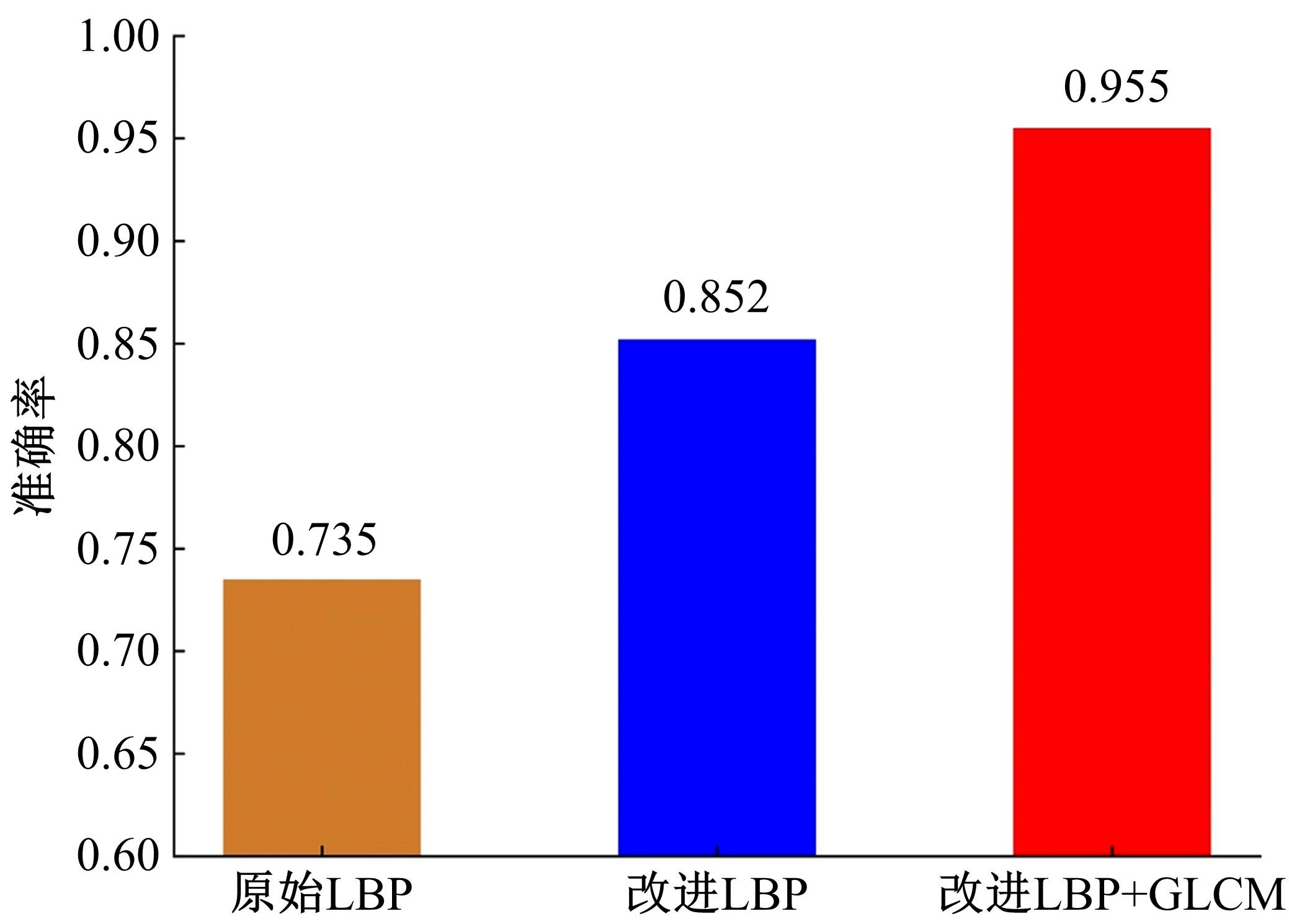

目前,针对薄壁件铣削加工过程中的颤振识别问题,普遍采用传感器信号进行判别与预测,而没有建立颤振特征与加工表面的相关联系。本文利用图像处理与模式识别技术,通过铣削表面图像实现薄壁件加工状态的精确辨识与预测。首先,设计了混合滤波方案,实现了采集图像的预处理;然后,通过改进的局部二值模式和灰度共生矩阵提取图像的颤振纹理特征,并以K近邻分类算法对铣削加工过程中采集的图像进行预测和识别。实验结果表明:该模型辨识的准确率为95.5%,算法平均运行时间为0.069 s。实验结果验证了该方法具有较高的辨识准确率,同时满足颤振预测及检测的实时性需求,对薄壁件铣削加工状态的识别及智能加工具有良好的指导意义。

中图分类号:

- TH741

| 1 | 张雪薇, 于天彪, 王宛山. 薄壁零件铣削三维颤振稳定性建模与分析[J]. 东北大学学报: 自然科学版, 2015, 36(1): 99-103. |

| Zhang Xue-wei, Yu Tian-biao, Wang Wan-shan. Modeling and analysis for 3D chatter stability of thin-walled parts in milling process[J]. Journal of Northeastern University(Natural Science), 2015, 36(1): 99-103. | |

| 2 | 王志学, 刘献礼, 李茂月, 等. 切削加工颤振智能监控技术[J]. 机械工程学报, 2020, 56(24): 1-23. |

| Wang Zhi-xue, Liu Xian-li, Li Mao-yue, et al. Intelligent monitoring and control technology of cutting chatter[J]. Journal of Mechanical Engineering, 2020,56(24): 1-23. | |

| 3 | Schmitz T. The microphone feedback analogy for chatter in machining[J/OL]. [2021-08-05]. |

| 4 | Li L H, An Q B. An in-depth study of tool wear monitoring technique based on image segmentation and texture analysis[J]. Measurement, 2016, 79(4): 44-52. |

| 5 | Lin Jian-gang, Wang Dong-xing, Tian Hong-zhi,et al. Surface defect detection of machined parts based on machining texture direction[J]. Measurement Science and Technology, 2021, 32(2): 1-12. |

| 6 | Szydlowski M, Powalka B. Chatter detection algorithm based on machine vision[J]. The International Journal of Advanced Manufacturing Technology, 2012, 62(5-8): 517-528. |

| 7 | Lei N, Soshi M. Vision-based system for chatter identification and process optimization in high-speed milling[J]. The International Journal of Advanced Manufacturing Technology, 2017, 89(9-12): 2757-2769. |

| 8 | Khalifa O, Densibali A, Faris W. Image processing for chatter identification in machining processes[J]. The International Journal of Advanced Manufacturing Technology, 2006, 31(5/6): 443-449. |

| 9 | 冯东海. 基于计算机视觉的薄壁件铣削颤振在线监测[D]. 秦皇岛: 燕山大学机械工程学院, 2018. |

| Feng Dong-hai. Chatter monitoring on-line of milling thin-walled parts based on computer vision[D]. Qinhuangdao: College of Mechanical Engineering, Yanshan University, 2018. | |

| 10 | 林洁琼, 周晓勤, 孔繁森, 等. 再生切削颤振系统动态响应谐参数辨识[J]. 吉林大学学报: 工学版, 2009, 39(4): 964-969. |

| Lin Jie-qiong, Zhou Xiao-qin, Kong Fan-sen, et al. Harmonic parameter identification of dynamic response in regenerative machining chatter system[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(4): 964-969. | |

| 11 | 李秀怡. 图像纹理检测与特征提取技术研究综述[J]. 中国管理信息化, 2017, 20(23): 175-178. |

| Li Xiu-yi. Review of image texture detection and feature extraction[J]. China Management Information, 2017, 20(23): 175-178. | |

| 12 | Ojala T, pietikainen M, Maenpaa T. Multiresolution gray-scale and rotation invariant texture classification with local binary patterns[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2002, 24(7): 971-987. |

| 13 | 戴金波, 肖霄, 赵宏伟. 基于低分辨率局部二值模式的人脸识别[J]. 吉林大学学报: 工学版, 2013, 43(2): 435-438. |

| Dai Jin-bo, Xiao Xiao, Zhao Hong-wei. Human face recognition based on low resolution local binary pattern[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(2): 435-438. | |

| 14 | Haralick R M, Shanmugam K, Dinstein I. Textural features for image classification[J]. IEEE Transactions on Systems, Man, and Cybernetics, 1973, 3(6): 610-621. |

| 15 | 鲁恒润, 王卫东, 徐志强, 等. 基于机器视觉的煤矸特征提取与分类研究[J]. 煤炭工程, 2018, 50(8): 137-140. |

| Lu Heng-run, Wang Wei-dong, Xu Zhi-qiang, et al. Research on feature extraction and classification of coal gangue based on machine vision[J]. Coal Engineering, 2018, 50(8): 137-140. | |

| 16 | Mou Wen-ping, Zhu Shao-wei, Jiang Zhen-xi, et al.Vibration signal-based chatter identification for milling of thin-walled structure[J]. Chinese Journal of Aeronautics, 2020, 35(1): 204-214. |

| 17 | 孙艺珊, 李晓洁, 赵凯. 改进LBP和HSV颜色直方图相结合的地表状态识别[J]. 测绘通报, 2020(2): 29-36, 71. |

| Sun Yi-shan, Li Xiao-jie, Zhao Kai. A combined algorithm of improved LBP and HSV for surface state recognition[J]. Bulletin of Surveying and Mapping, 2020(2): 29-36, 71. |

| [1] | 段亮,宋春元,刘超,魏苇,吕成吉. 基于机器学习的高速列车轴承温度状态识别[J]. 吉林大学学报(工学版), 2022, 52(1): 53-62. |

| [2] | 车翔玖,刘华罗,邵庆彬. 基于Fast RCNN改进的布匹瑕疵识别算法[J]. 吉林大学学报(工学版), 2019, 49(6): 2038-2044. |

| [3] | 王培智, 田地, 龙涛, 李抵非, 邱春玲, 刘敦一. 用于TOF-SIMS的锆石样品图像自动聚焦算法[J]. 吉林大学学报(工学版), 2017, 47(1): 308-315. |

| [4] | 王玉, 申铉京, 陈海鹏, 谭颖. 多角度特征融合的视频人脸纹理表示及识别[J]. 吉林大学学报(工学版), 2015, 45(6): 1954-1960. |

| [5] | 耿庆田, 于繁华, 赵宏伟, 王闯. 基于颜色特征的火焰检测新算法[J]. 吉林大学学报(工学版), 2014, 44(6): 1787-1792. |

| [6] | 李根, 李文辉. 基于思维进化的机器学习的遮挡人脸识别[J]. 吉林大学学报(工学版), 2014, 44(5): 1410-1416. |

| [7] | 李阳, 文敦伟, 王珂, 刘乐. 多核学习矩阵化最小二乘支持向量机算法及肺结节识别[J]. 吉林大学学报(工学版), 2014, 44(2): 508-515. |

| [8] | 戴金波, 肖霄, 赵宏伟. 基于低分辨率局部二值模式的人脸识别[J]. 吉林大学学报(工学版), 2013, 43(02): 435-438. |

| [9] | 王甦菁1,周春光1,张娜1,李建朋2,张利彪1. 基于形状和纹理特征的人脸年龄估计方法[J]. 吉林大学学报(工学版), 2011, 41(05): 1383-1387. |

| [10] | 郭魂,左敦稳 ,刘远伟,王珉,童国权 . 航空腔型薄壁件铣削变形的预测[J]. 吉林大学学报(工学版), 2008, 38(01): 84-88. |

| [11] | 王荣本, 王超, 初秀民. 路面破损图像识别研究进展[J]. 吉林大学学报(工学版), 2002, (4): 91-97. |

| [12] | 阚君武, 邵承会, 唐可洪, 王主玉. 基于商标识别的链板自动分选系统[J]. 吉林大学学报(工学版), 2002, (3): 65-69. |

|

||