吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (6): 1967-1974.doi: 10.13229/j.cnki.jdxbgxb20200559

• 车辆工程·机械工程 • 上一篇

基于随机流量下柱塞泵的可靠性分析

- 沈阳工业大学 机械工程学院,沈阳 110870

Reliability analysis of piston pump under random flow rate

- School of Mechanical Engineering,Shenyang University of Technology,Shenyang 110870,China

摘要:

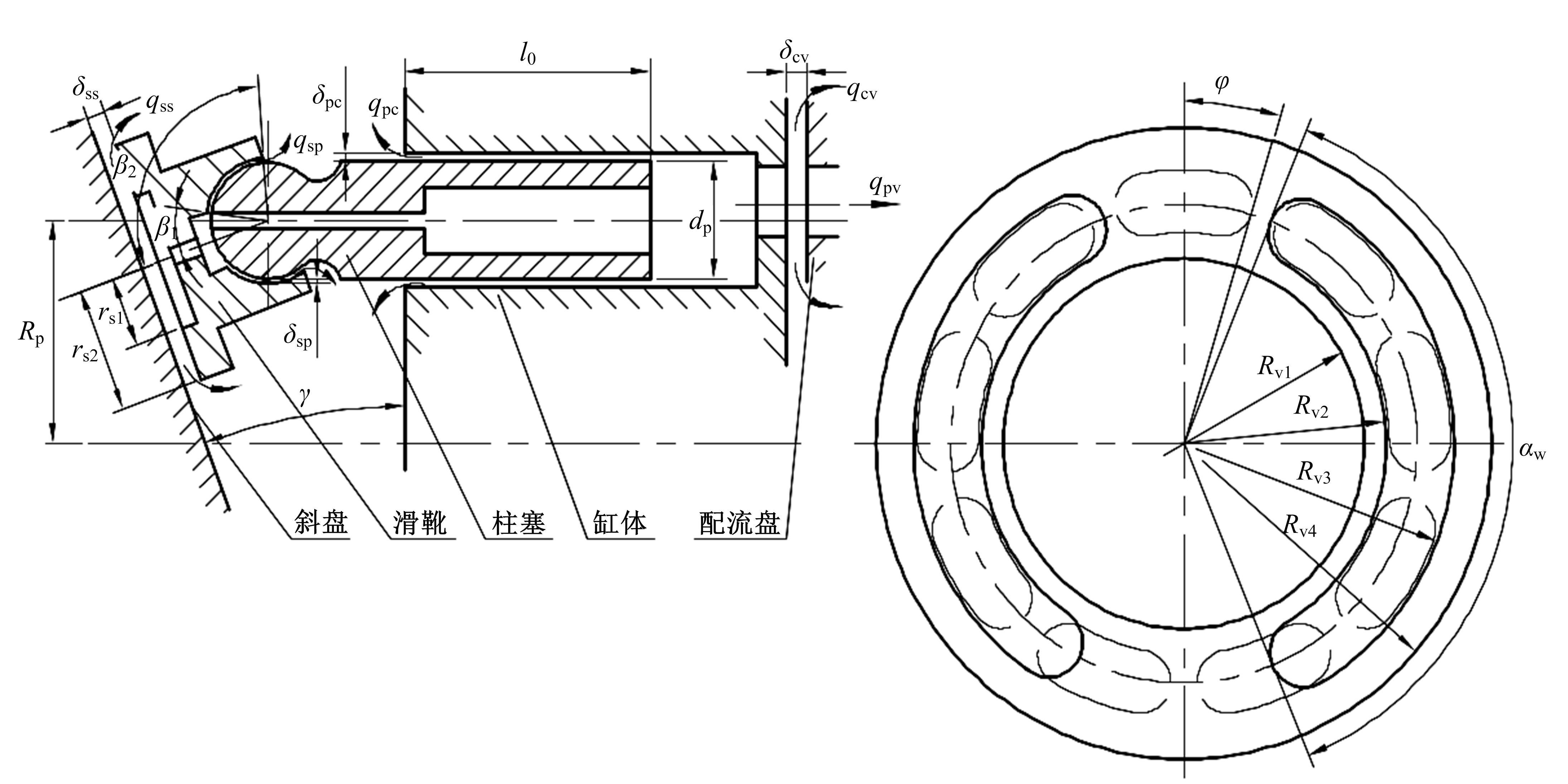

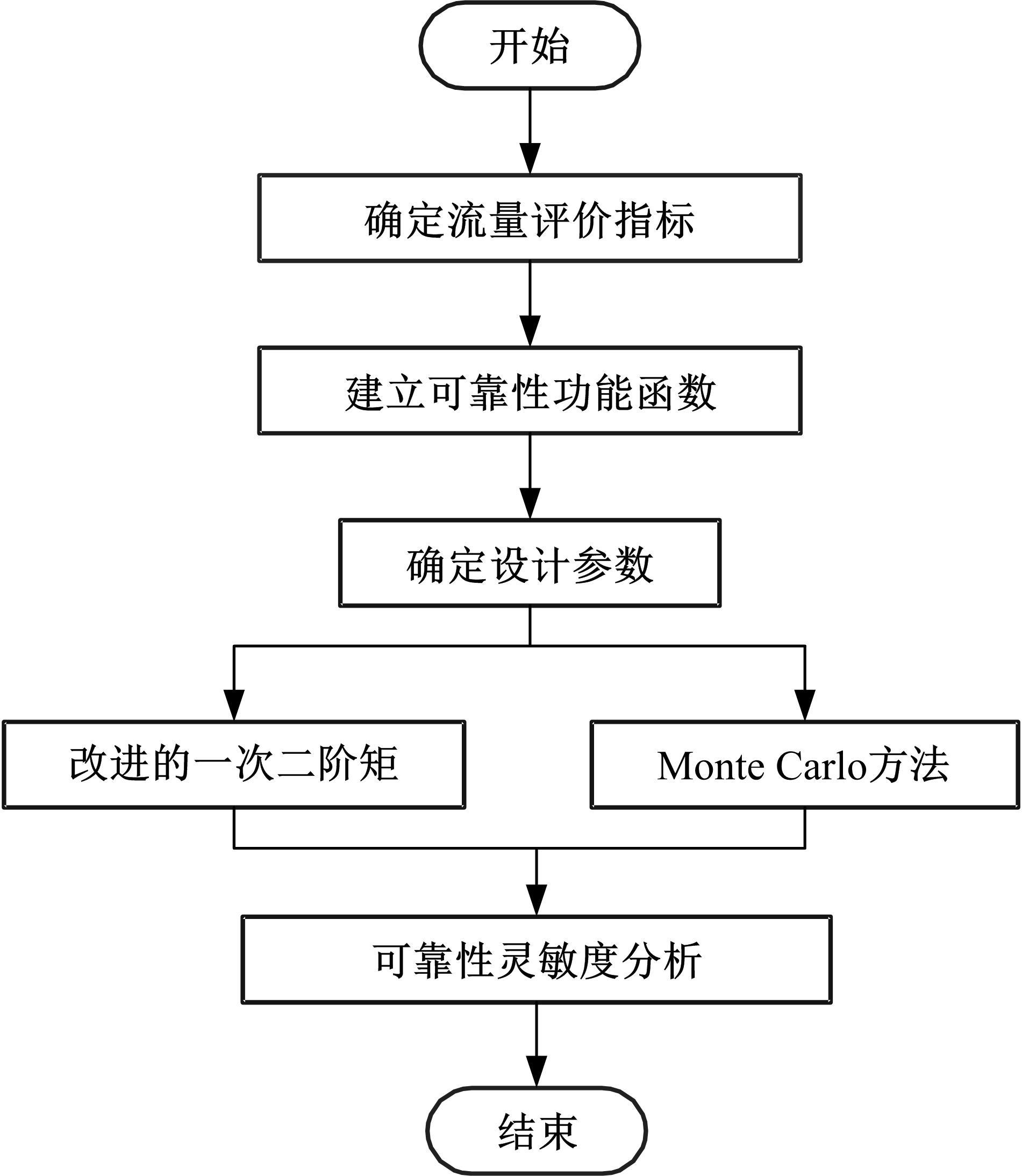

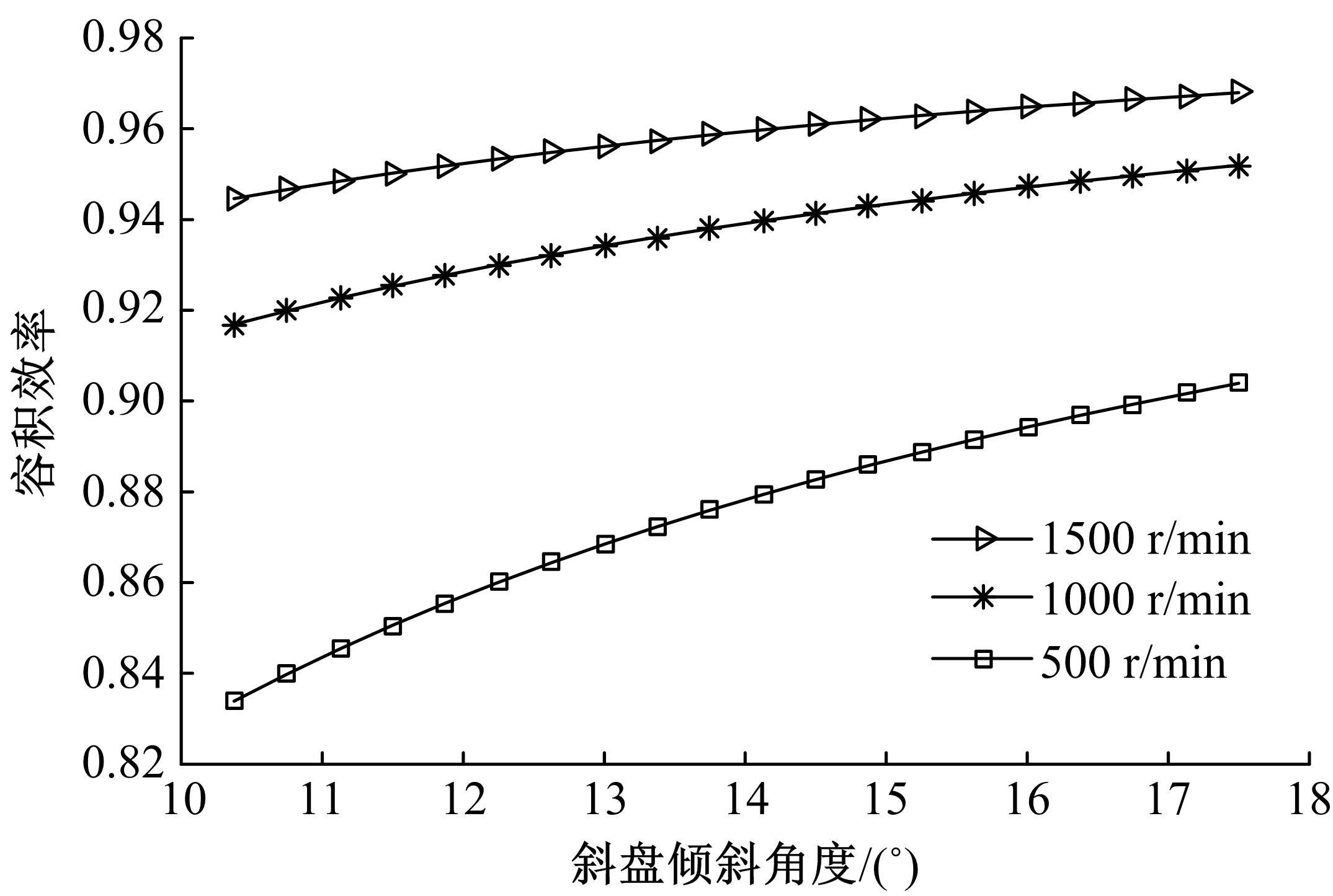

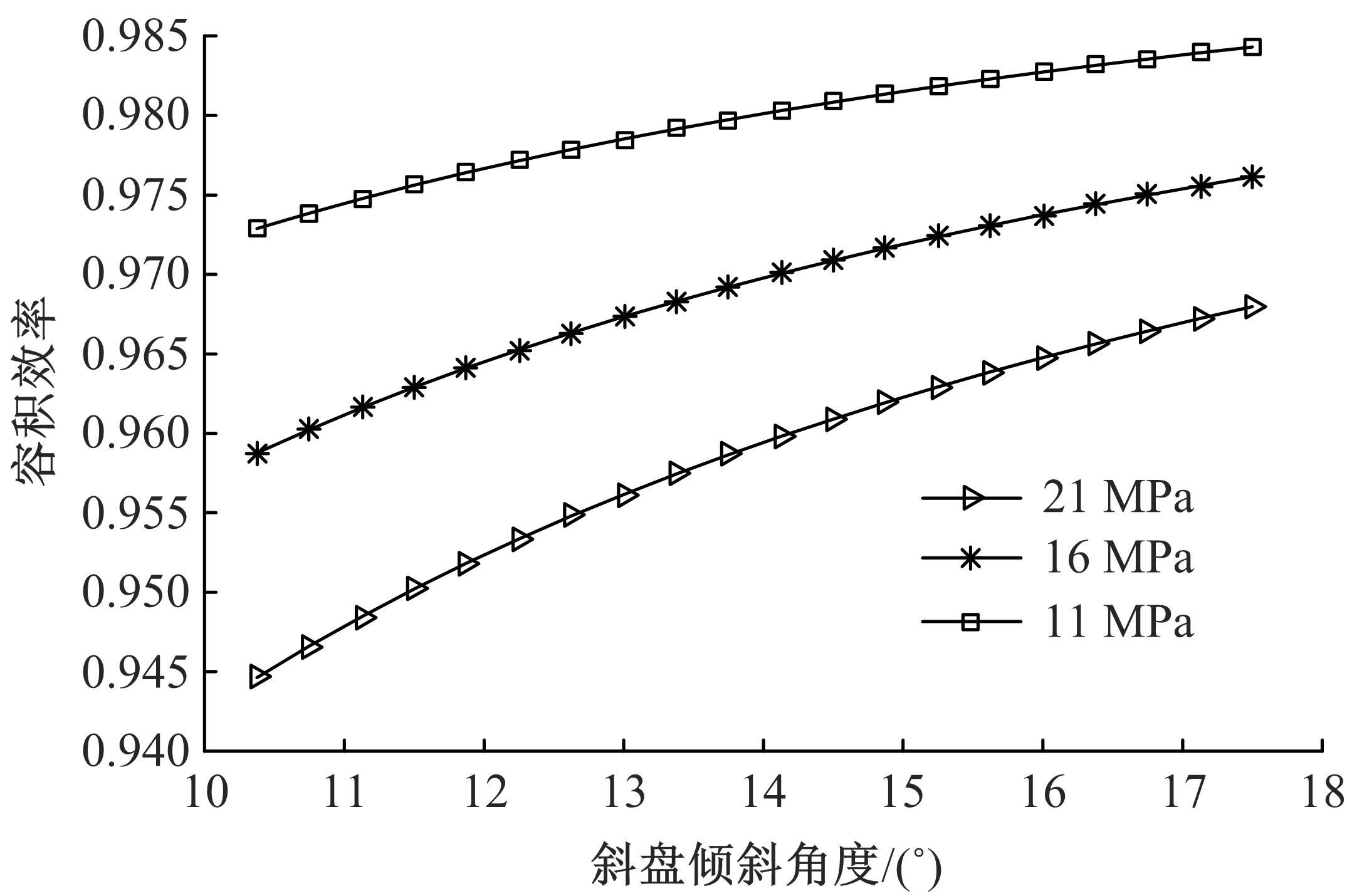

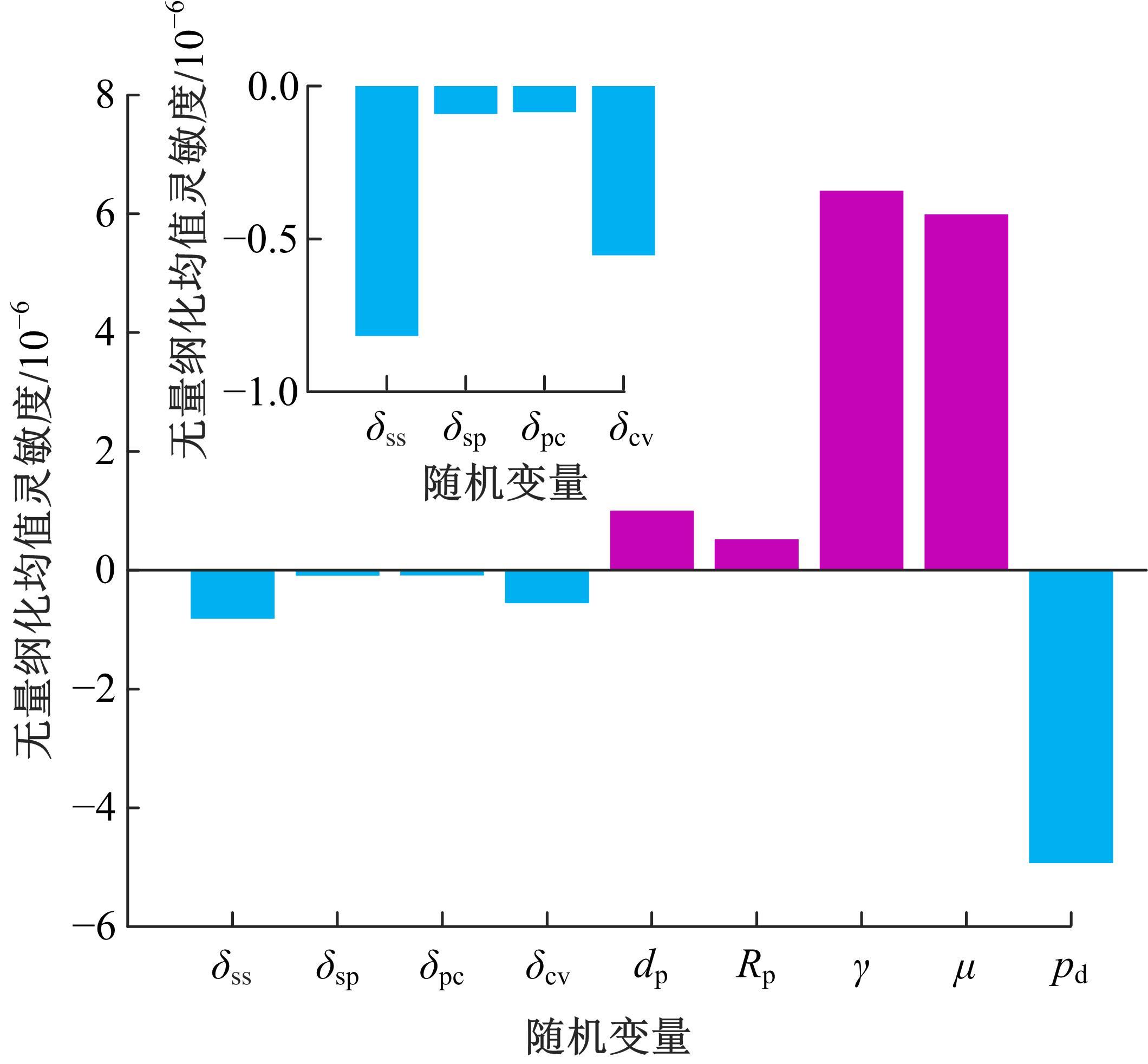

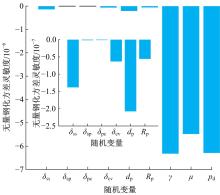

通过对柱塞泵各摩擦副单柱塞间隙泄漏流量进行分析,推导出整个柱塞泵平均间隙泄漏流量,建立了总泄漏流量及容积效率模型。由于柱塞泵在制造、运行过程中其尺寸公差和运行工况的随机不确定性致使其流量也具有随机性,选取与随机流量密切相关的容积效率作为可靠性判据,提出了一种实用的柱塞泵流量特性的可靠性及灵敏度分析方法,并用Monte-Carlo随机数值模拟法验证了本文方法的准确性。研究结果表明:柱塞泵的容积效率可靠度随斜盘倾斜角和转速的增大而提高,随排油压力的增大而降低;各基本随机变量对可靠性影响的敏感度存在明显差异,滑靴副间隙在各摩擦副间隙中对可靠性的影响最为敏感。

中图分类号:

- TH322

| 1 | 赵存然,刘伟,姜继海,等.斜盘式轴向柱塞泵加速模型[J].吉林大学学报:工学版,2016,46(4):1124-1129. |

| Zhao Cun-ran, Liu Wei, Jiang Ji-hai, et al. Accelerated model of swash-plate axial piston pump[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(4):1124-1129. | |

| 2 | 闻德生. 液压元件的创新与发展[M]. 北京:航空工业出版社,2009. |

| 3 | 姜继海,赵存然,张冠隆,等.航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报:工学版,2021,51(1):147-153. |

| Jiang Ji-hai, Zhao Cun-ran, Zhang Guang-long, et al. Tribological properties of coating materials of tribopairs for aviation kerosene piston pump[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1):147-153. | |

| 4 | Bergada J M, Kumar S, Davies D L, et al. A complete analysis of axial piston pump leakage and output flow ripples[J]. Applied Mathematical Modelling, 2012, 36(4):1731-1751. |

| 5 | Costa G K, Sepehri N. Understanding overall efficiency of hydrostatic pumps and motors[J]. International Journal of Fluid Power, 2018, 19(2):106-116. |

| 6 | Wilson W E. Performance criteria for positive displacement pumps and fluid motors[J]. ASME Transactions, 1949, 71(2):115-120. |

| 7 | McCandlish D, Dorey R E. The mathematical modelling of hydrostatic pumps and motors[J]. Proceedings of The Institution of Mechanical Engineers, Part B: Management and Engineering Manufacture, 1984, 198(10):165-174. |

| 8 | Ortwig H. New method of numerical calculation of losses and efficiencies in hydrostatic power transmissions[C]∥SAE Technical Paper, 2002-01-1418. |

| 9 | Jeong H S. A novel performance model given by the physical dimensions of hydraulic axial piston motors: model derivation[J]. Journal of Mechanical Science and Technology, 2007, 21(1):83-97. |

| 10 | Bergada J M, Haynes J M, Watton J. Leakage and groove pressure of an axial piston pump slipper with multiple lands[J]. Tribology Transactions, 2008, 51(4):469-482. |

| 11 | Gao M D, Huang H H, Li X Y, et al. A novel method to quickly acquire the energy efficiency for piston pumps[J]. Journal of Dynamic Systems Measurement and Control, 2016, 138(10):No.101004. |

| 12 | 孙毅刚,高建树,李国洪. 液压泵摩擦副可靠性设计基本方法研究[J]. 中国民航学院学报,1999,17(6):5-9. |

| Sun Yi-gang, Gao Jian-shu, Li Guo-hong. A reliability analysis and design for the friction pairs of hydraulic pumps[J]. Journal of Civil Aviation University of China, 1999,17(6):5-9. | |

| 13 | Zhang Tian-xiao, Zhang Yi-min. A new model for reliability design and reliability sensitivity analysis of a hydraulic piston pump[J]. Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, 2017, 231(1): 11-24. |

| 14 | Zhang Tian-xiao, He David. A reliability-based robust design method for the sealing of slipper-swash plate friction pair in hydraulic piston pump[J]. IEEE Transactions on Reliability, 2018, 67(2):459-469. |

| 15 | Zhang Tian-xiao. Robust reliability-based optimization with a moment method for hydraulic pump sealing design[J]. Structural and Multidisciplinary Optimization, 2018, 58(5): 1737-1750. |

| 16 | Yin F L, Nie S L, Ji H, et al. Non-probabilistic reliability analysis and design optimization for valve-port plate pair of seawater hydraulic pump for underwater apparatus[J]. Ocean Engineering, 2018, 163: 337-347. |

| 17 | 胡敏. 轴向柱塞泵摩擦副功率损失分析与表面形貌设计研究[D]. 杭州:浙江大学机械工程学院, 2017. |

| Hu Min. Study on power losses and design technology for the surface topography of friction pairs of axial piston pump[D]. Hangzhou: School of Mechanical Engineering, Zhejiang University, 2017. | |

| 18 | 吕震宙, 宋述芳, 李璐祎,等.结构/机构可靠性设计基础[M]. 西安:西北工业大学出版社, 2018. |

| 19 | . 液压轴向柱塞泵[S]. |

| [1] | 樊学平,杨光红,肖青凯,刘月飞. 大跨桥梁主梁失效概率分析的最优R-Vine Copula[J]. 吉林大学学报(工学版), 2021, 51(4): 1296-1305. |

| [2] | 张斌,程国赞,洪昊岑,赵春晓,白大鹏,杨华勇. 基于SVR的轴向柱塞泵配流盘三角槽结构优化[J]. 吉林大学学报(工学版), 2021, 51(4): 1213-1221. |

| [3] | 姜继海,赵存然,张冠隆,车明阳. 航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报(工学版), 2021, 51(1): 147-153. |

| [4] | 魏巍,刘旭,韩雪永,闫清东. 液力缓速器全充液工况下本征正交基对流场重构精度的影响规律[J]. 吉林大学学报(工学版), 2019, 49(6): 1959-1968. |

| [5] | 刘俊龙,孙冬野,刘小军,尤勇. 基于耦合特性的机电控制无级变速器速比控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1951-1958. |

| [6] | 王晓晶,刘美珍,陈帅,李嵩. 仿真转台用连续回转电液伺服马达预测滑模控制[J]. 吉林大学学报(工学版), 2019, 49(5): 1547-1557. |

| [7] | 卢秀泉,胡春玉,柴亚龙,马文星,张剑楠. 大功率液力偶合器调速工况瞬态流场特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1539-1546. |

| [8] | 闻德生,隋广东,田山恒,王少朋,冯佩坤,刘小雪. 内外啮合齿轮马达泄漏与容积效率分析及试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1186-1193. |

| [9] | 刘建芳, 王记波, 刘国君, 李新波, 梁实海, 杨志刚. 基于PMMA内嵌三维流道的压电驱动微混合器[J]. 吉林大学学报(工学版), 2018, 48(5): 1500-1507. |

| [10] | 姜继海, 葛泽华, 杨晨, 梁海健. 基于微分器的直驱电液伺服系统离散滑模控制[J]. 吉林大学学报(工学版), 2018, 48(5): 1492-1499. |

| [11] | 刘国君, 马祥, 杨志刚, 王聪慧, 吴越, 王腾飞. 集成式三相流脉动微混合芯片[J]. 吉林大学学报(工学版), 2018, 48(4): 1063-1071. |

| [12] | 刘祥勇, 李万莉. 包含蓄能器的电液比例控制模型[J]. 吉林大学学报(工学版), 2018, 48(4): 1072-1084. |

| [13] | 王佳怡, 刘昕晖, 王昕, 齐海波, 孙晓宇, 王丽. 数字二次元件变量冲击机理及其抑制[J]. 吉林大学学报(工学版), 2017, 47(6): 1775-1781. |

| [14] | 闻德生, 王京, 高俊峰, 周聪. 双定子单作用叶片泵闭死容腔的压力特性[J]. 吉林大学学报(工学版), 2017, 47(4): 1094-1101. |

| [15] | 刘国君, 张炎炎, 杨旭豪, 李新波, 刘建芳, 杨志刚. 声表面波技术在金纳米粒子可控制备中的应用[J]. 吉林大学学报(工学版), 2017, 47(4): 1102-1108. |

|

||