吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1266-1271.doi: 10.13229/j.cnki.jdxbgxb20180291

• • 上一篇

基于损伤修正M⁃K模型的高强度钢成形极限预测

- 1. 大连理工大学 运载工程与力学学部,辽宁 大连 116024

2. 大连理工大学 汽车工程学院,辽宁 大连 116024

Forming limit prediction of high strength steel based on damage modified M⁃K model

Wen⁃quan LIU1( ),Liang YING2,Hai RONG2,Ping HU2(

),Liang YING2,Hai RONG2,Ping HU2( )

)

- 1. Faculty of Vehicle Engineering and Mechanics, Dalian University of Technology, Dalian 116024, China

2. School of Automotive Engineering, Dalian University of Technology, Dalian 116024, China

摘要:

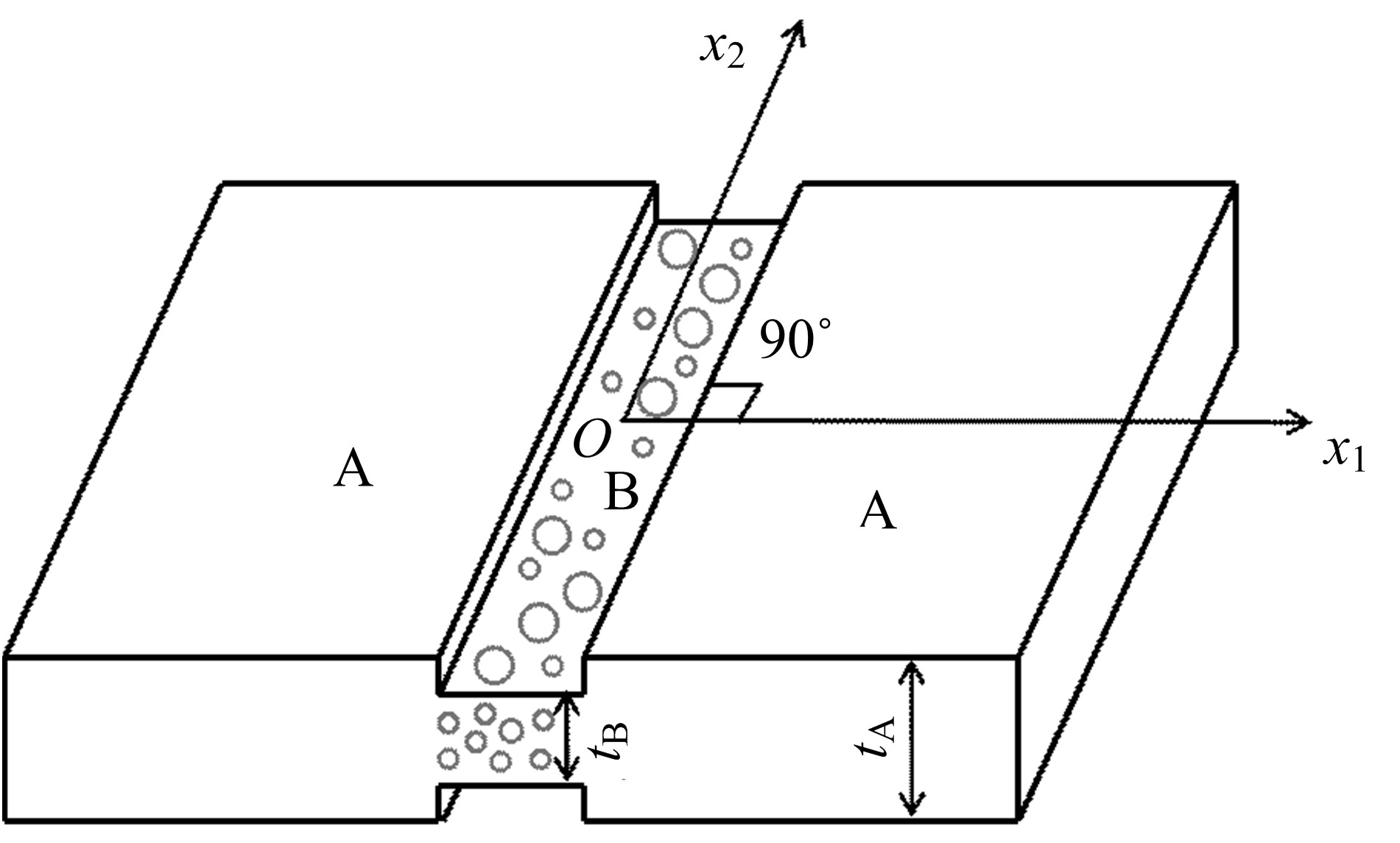

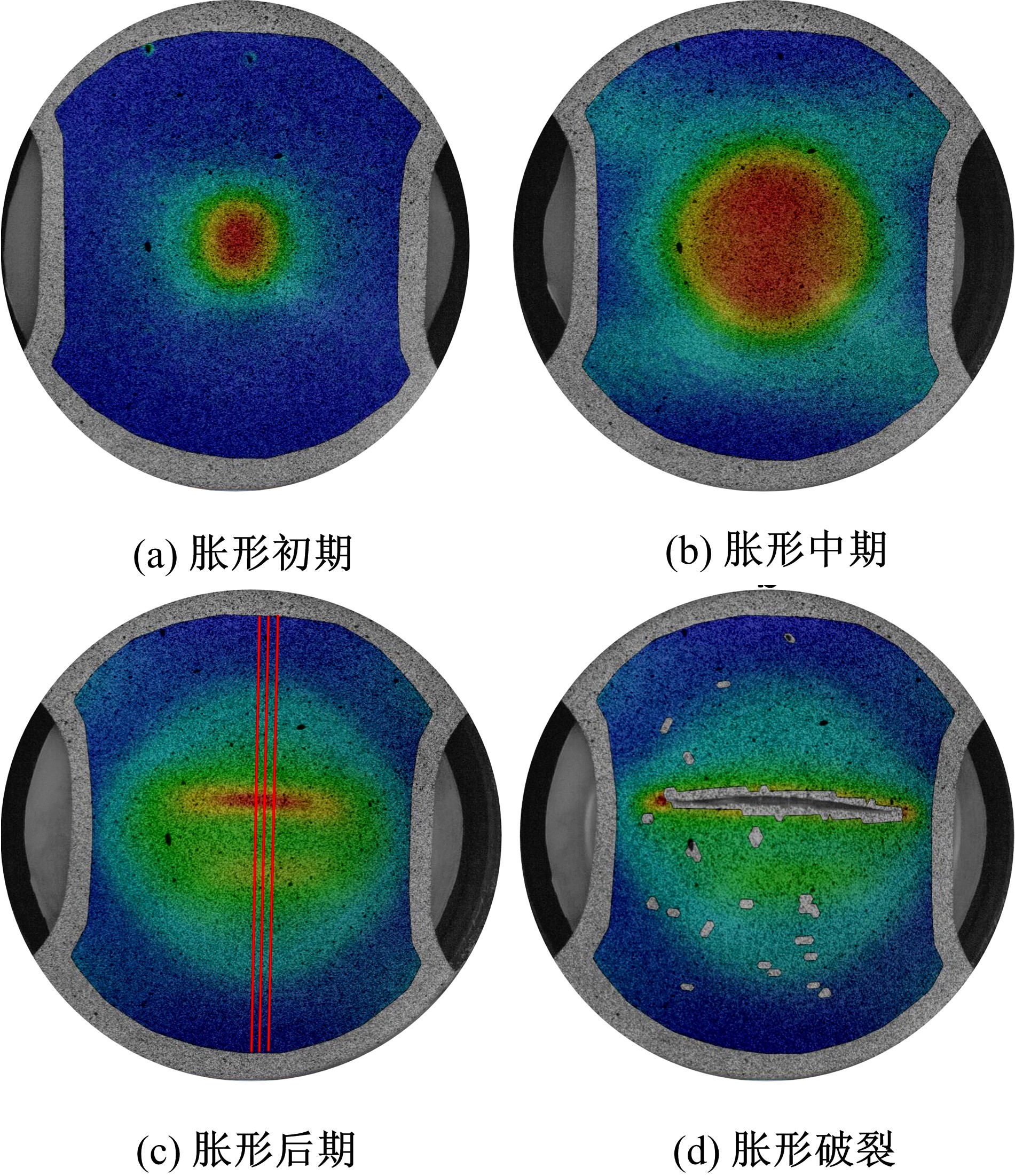

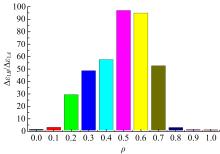

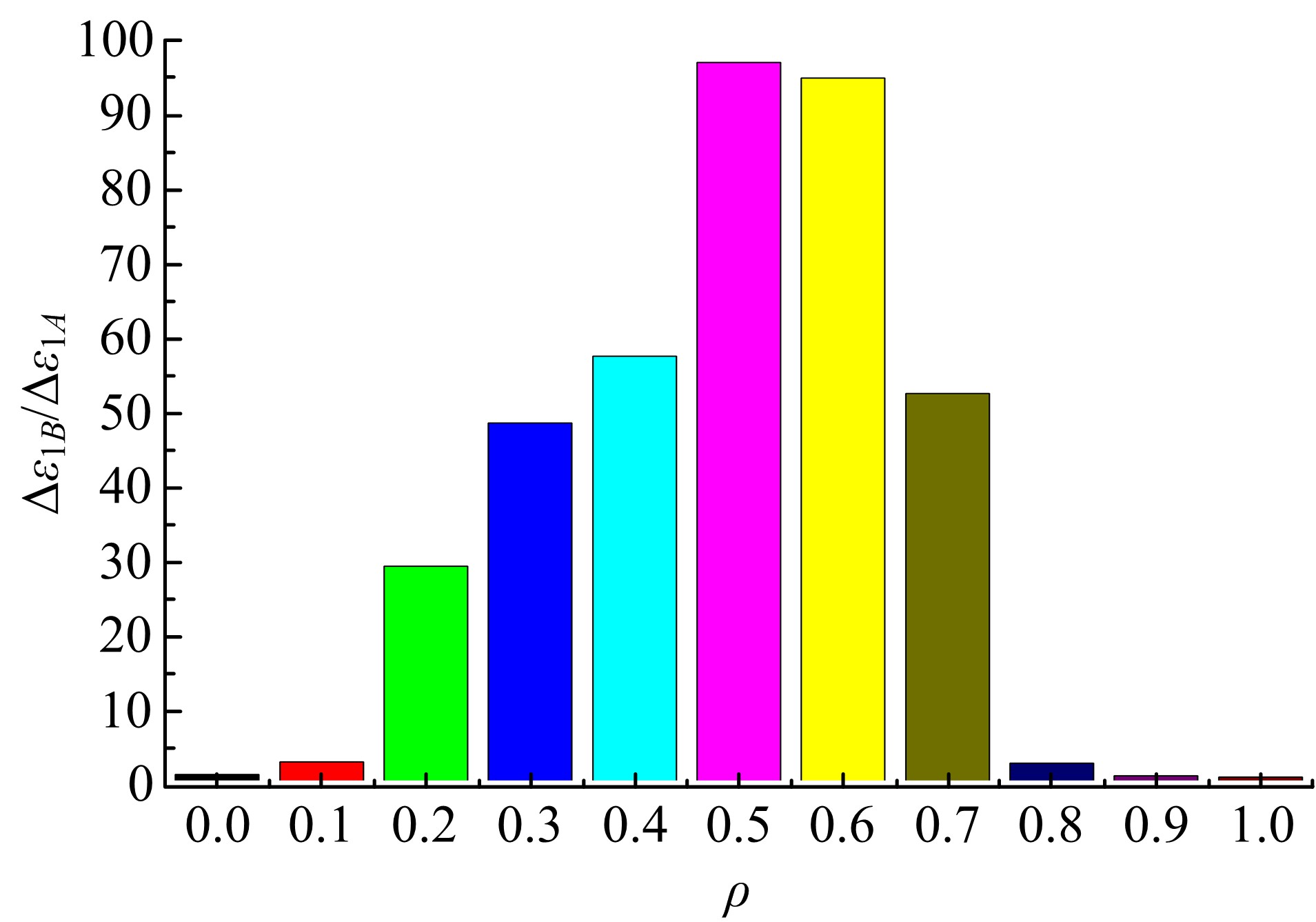

为探究材料内部损伤演化对其成形特性的影响,在M?K凹槽失稳理论的基础之上,通过引入GTN损伤模型,建立了耦合损伤的高强度钢22MnB5成形极限预测方法,并确定了相关损伤参数。该方法以临界孔洞体积分数作为失稳判据,增强了预测方法的物理意义。通过理论计算分析了变形路径对板材失稳以及损伤演化的影响。同时,通过开展NAKAZIMA实验研究,获取了22MnB5的成形极限数据并对其变形特点进行了分析。通过与实验结果的对比,验证了本文预测方法的有效性。

中图分类号:

- TG386

| 1 | 马高山,万敏,吴向东. 基于M⁃K模型的铝锂合金热态下成形极限预测[J]. 中国有色金属学报, 2008, 18(6): 980⁃984. |

| MaGao⁃shan, WanMin, WuXiang⁃dong. Theoretical prediction of FLDs for Al⁃Li alloy at elevated temperature based on M⁃K model[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 980⁃984. | |

| 2 | MarciniakZ, KuczyńskiK. Limit strains in the processes of stretch⁃forming sheet metal[J]. International Journal of Mechanical Sciences, 1967, 9(9): 609⁃620. |

| 3 | ZhangC S, LeotoingL, GuinesD, et al. Theoretical and numerical study of strain rate influence on AA5083 formability[J]. Journal of Materials Processing Technology, 2009, 209(8): 3849⁃3858. |

| 4 | 余海燕,高云凯. 基于M⁃K模型的相变诱发塑性钢板的 成形极限研究[J]. 中国机械工程, 2007, 18(1): 109⁃113. |

| YuHai⁃yan, GaoYun⁃kai. Study on forming limit diagram for transformation⁃induced plasticity sheet steel based on M⁃K model[J]. China Mechanical Engineering, 2007, 18(1): 109⁃113. | |

| 5 | 孙权,陈建钧,李晓雪,等. 剪切修正GTN模型在小冲杆试验中的应用研究[J]. 机械工程学报, 2014, 50(24): 79⁃85. |

| SunQuan, ChenJian⁃jun, LiXiao⁃xue, et al. Study on the application of shear modified GTN model to small punch test[J]. Journal of Mechanical Engineering, 2014, 50(24): 79⁃85. | |

| 6 | 陈志英,董湘怀. 基于GTN细观损伤模型的板料成形过程损伤分析[J]. 工程力学, 2009, 26(7): 238⁃244. |

| ChenZhi⁃ying,DongXiang⁃huai. Ductile damage analysis for fracture in sheet metal forming based on GTN mesoscopic damage model[J]. Engineering Mechanics, 2009, 26(7): 238⁃244. | |

| 7 | 刘文权,盈亮,王丹彤,等. 热冲压成形过程细观损伤演化机理研究[J]. 机械工程学报, 2016, 52(14): 31⁃39. |

| LiuWen⁃quan, YingLiang, WangDan⁃tong, et al. Investigation of mesoscopic damage evolution mechanism of high dtrength dteel in hot stamping process[J]. Journal of Mechanical Engineering, 2016, 52(14): 31⁃39. | |

| 8 | NeedlemanA, TriantafyllidisN. Void growth and local necking in biaxially stretched sheets[J]. Journal of Engineering Materials and Technology, 1978, 100(2): 164⁃169. |

| 9 | TvergaardV. Influence of voids on shear band instabilities under plane strain conditions[J]. International Journal of Fracture, 1981, 17(4): 389⁃407. |

| 10 | TvergaardV, NeedlemanA. Analysis of the cup⁃cone fracture in a round tensile bar[J]. Acta Metallurgica, 1984, 32(1): 157⁃169. |

| 11 | NeedlemanA, TvergaardV. An analysis of ductile rupture in notched bars[J]. Journal of the Mechanics & Physics of Solids, 1984, 32(6): 461⁃490. |

| 12 | SonH S, KimY S. Prediction of forming limits for anisotropic sheets containing prolate ellipsoidal voids[J]. International Journal of Mechanical Sciences, 2003, 45(10): 1625⁃1643. |

| 13 | ChuC C, NeedlemanA. Void nucleation effects in biaxially stretched sheets[J]. Journal of Engineering Materials and Technology, 1980, 102(3): 249⁃256. |

| 14 | BenseddiqN, ImadA. A ductile fracture analysis using a local damage model[J]. International Journal of Pressure Vessels and Piping, 2008, 85(4): 219⁃227. |

| 15 | YingLiang, WangDan⁃tong, LiuWen⁃quan, et al. On the numerical implementation of a shear modified GTN damage model and its application to small punch test[J]. International Journal of Material Forming, 2018, 11(4): 527⁃539. |

| [1] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [2] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [3] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [4] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [5] | 陈俊甫, 管志平, 杨昌海, 牛晓玲, 姜振涛, 宋玉泉. 金属棒试样拉伸和扭转试验应变范围和力学特性对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

| [6] | 梁晓波, 蔡中义, 高鹏飞. 夹芯复合板柱面成形的数值模拟及试验[J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [7] | 刘子武, 李剑峰. 叶片材料FV520B再制造熔覆层冲蚀损伤行为及评价[J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [8] | 刘纯国, 刘伟东, 邓玉山. 多点冲头主动加载路径对薄板拉形的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [9] | 张志强, 刘从豪, 何东野, 李湘吉, 李纪萱. 基于性能梯度分布的硼钢热冲压工艺对形状精度的影响[J]. 吉林大学学报(工学版), 2017, 47(6): 1829-1833. |

| [10] | 吕萌萌, 谷诤巍, 徐虹, 李欣. 超高强度防撞梁热冲压成形工艺优化[J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [11] | 王辉, 周杰, 熊煜, 陶亚平, 向荣. 基于逆向工程的复杂曲面冲压件回弹补偿[J]. 吉林大学学报(工学版), 2017, 47(6): 1842-1847. |

| [12] | 王春生, 邹丽, 杨鑫华. 基于邻域粗糙集的铝合金焊接接头疲劳寿命影响因素分析[J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

| [13] | 邢海燕, 葛桦, 李思岐, 杨文光, 孙晓军. 基于模糊隶属度最大似然估计的焊缝隐性缺陷磁记忆信号识别[J]. 吉林大学学报(工学版), 2017, 47(6): 1854-1860. |

| [14] | 谷晓燕, 刘亚俊, 孙大千, 徐锋, 孟令山, 高帅. S355钢/6005A铝合金瞬间液相扩散连接接头组织与性能[J]. 吉林大学学报(工学版), 2017, 47(5): 1534-1541. |

| [15] | 谷诤巍, 张文学, 吕萌萌, 王伟, 徐虹, 李欣. 宽翼边U型截面不锈钢型材拉弯成形缺陷控制[J]. 吉林大学学报(工学版), 2017, 47(4): 1165-1170. |

|

||