吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (12): 3468-3477.doi: 10.13229/j.cnki.jdxbgxb.20230157

激光焊接接头剪切GTN模型损伤参数识别

- 北京科技大学 机械工程学院,北京 100083

Damage parameter identification of laser welded joint shear Gurson⁃Tvergaard⁃Needleman model

Bing CHEN( ),Yang-kun ZHANG,Yang WANG,Sheng-zhe LIU,Jin-yang HAN

),Yang-kun ZHANG,Yang WANG,Sheng-zhe LIU,Jin-yang HAN

- School of Mechanical Engineering,University of Science and Technology Beijing,Beijing 100083,China

摘要:

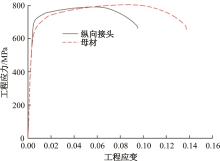

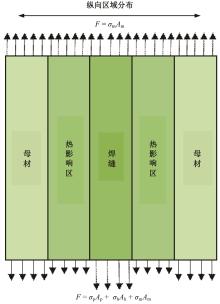

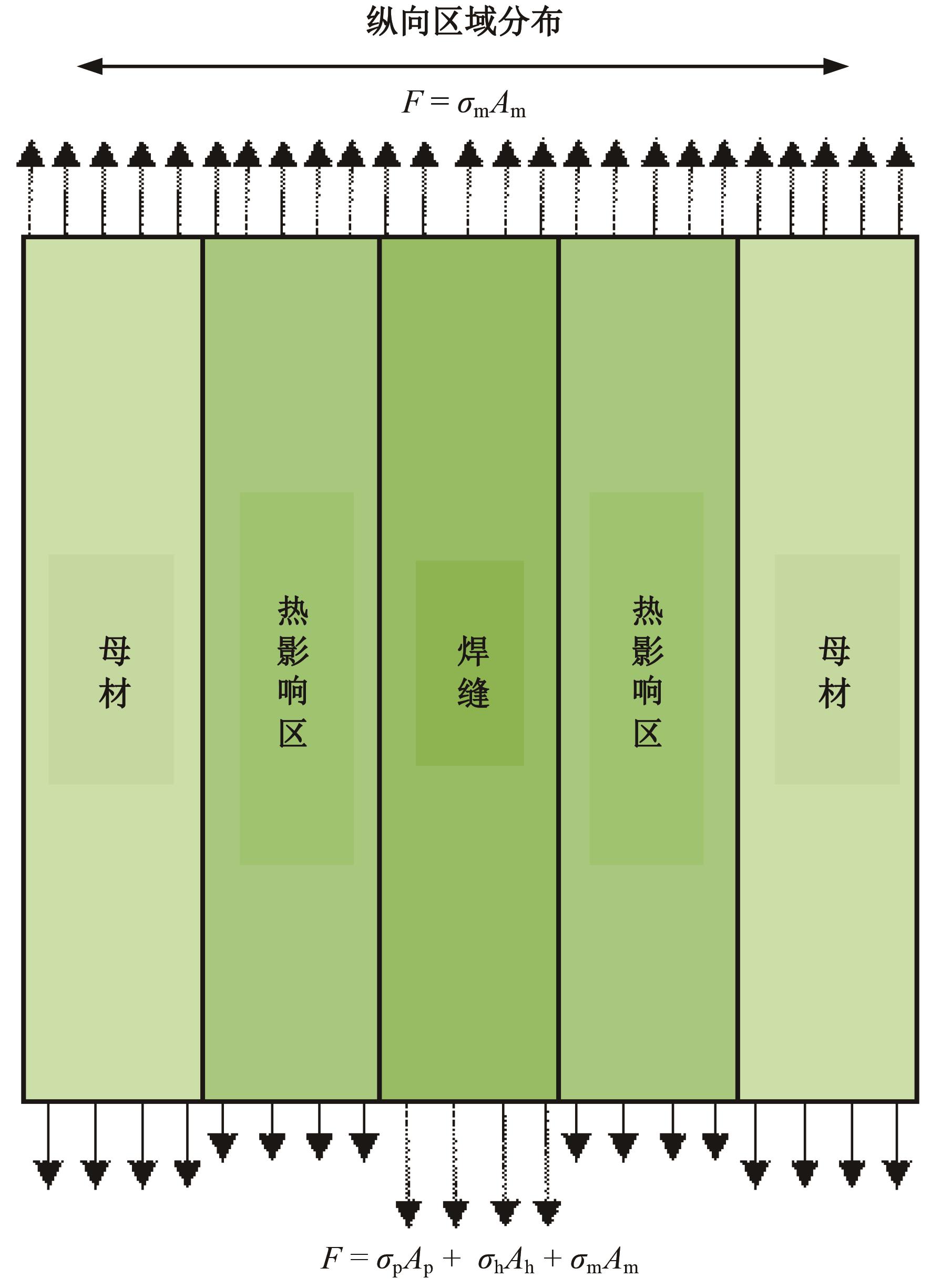

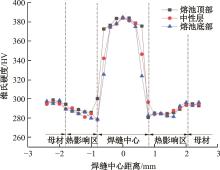

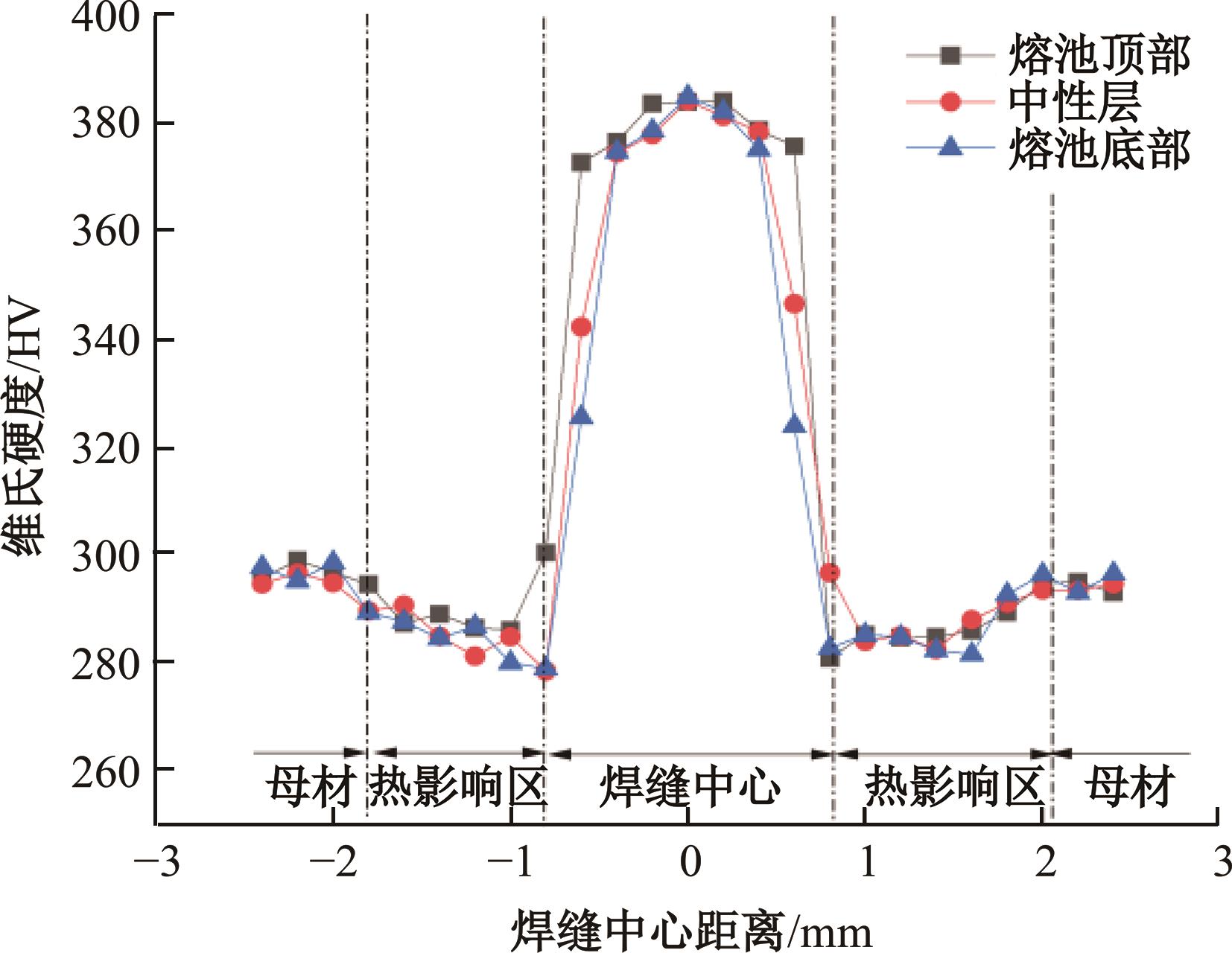

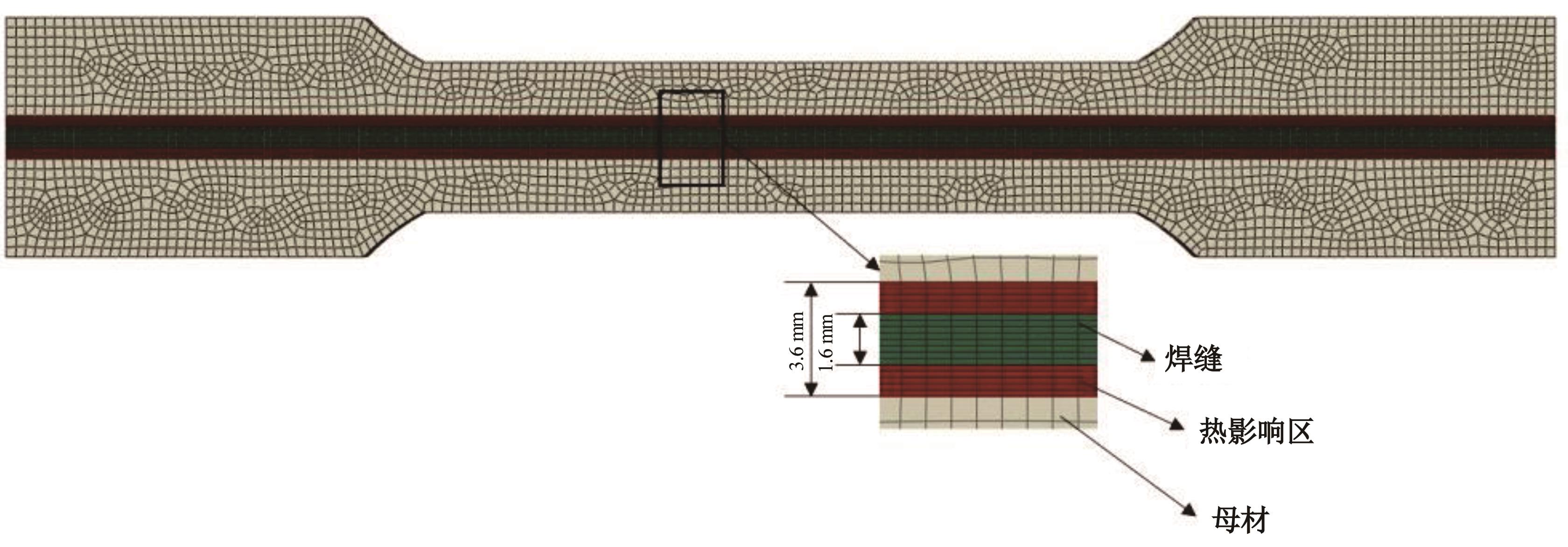

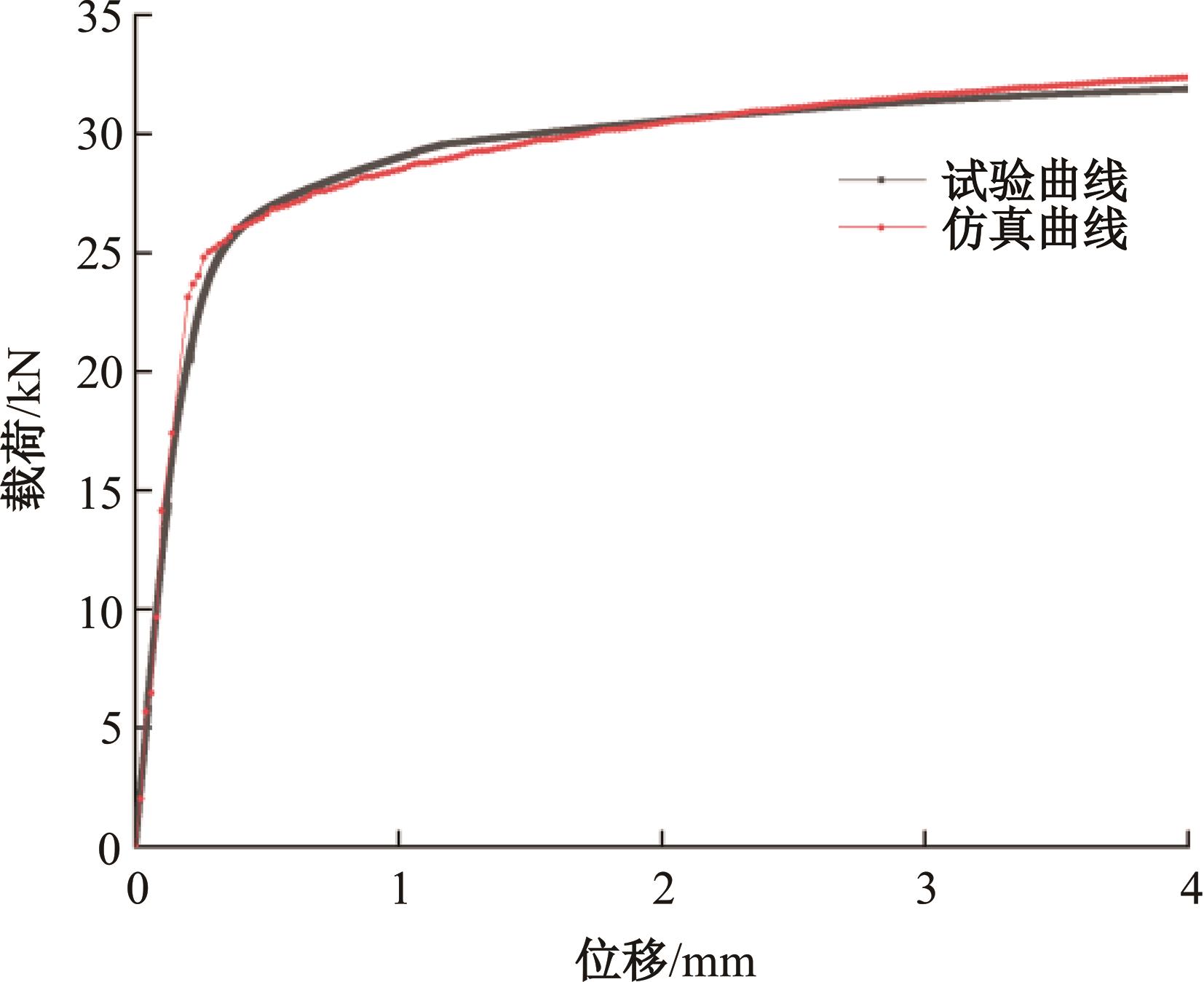

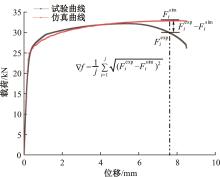

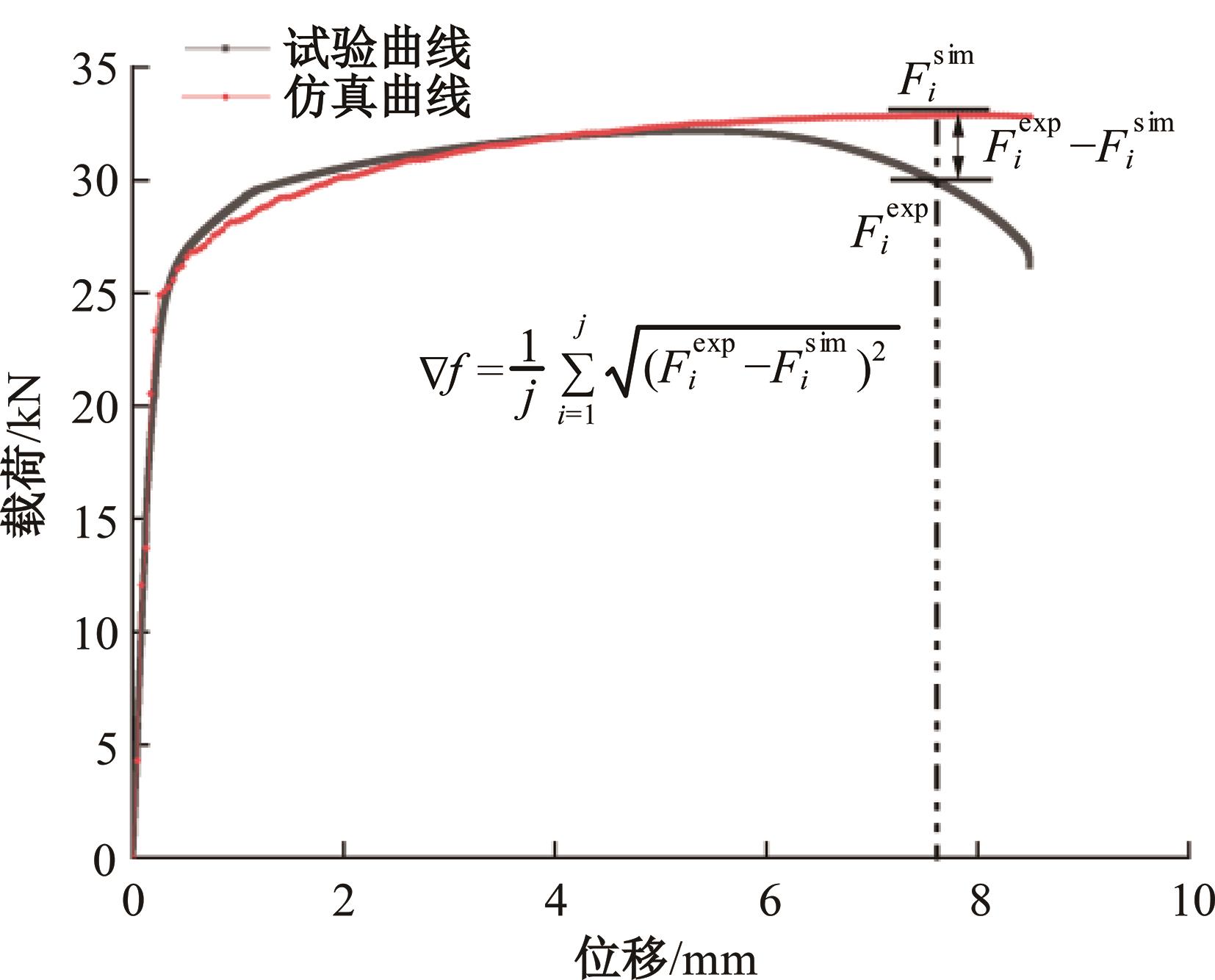

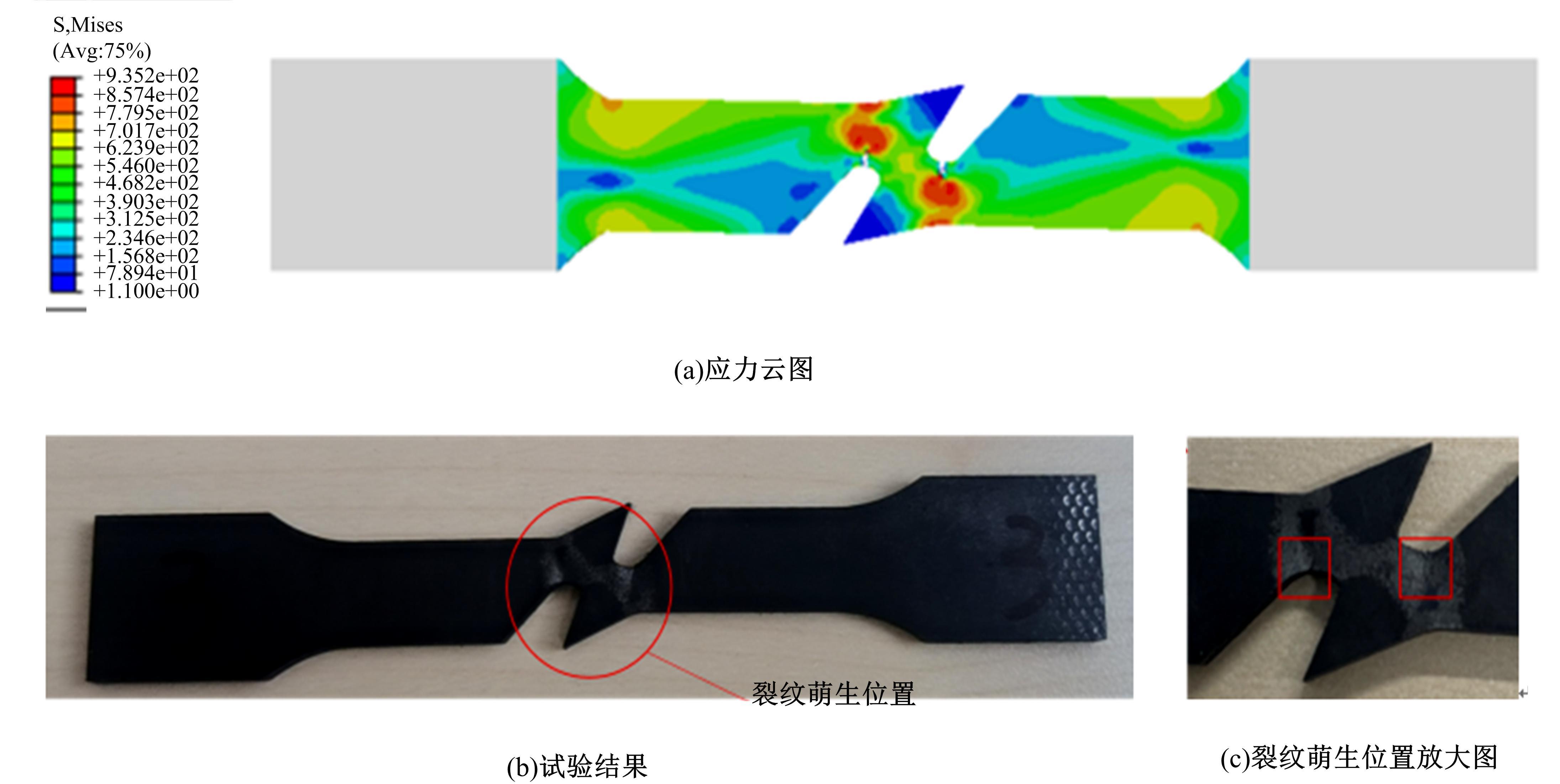

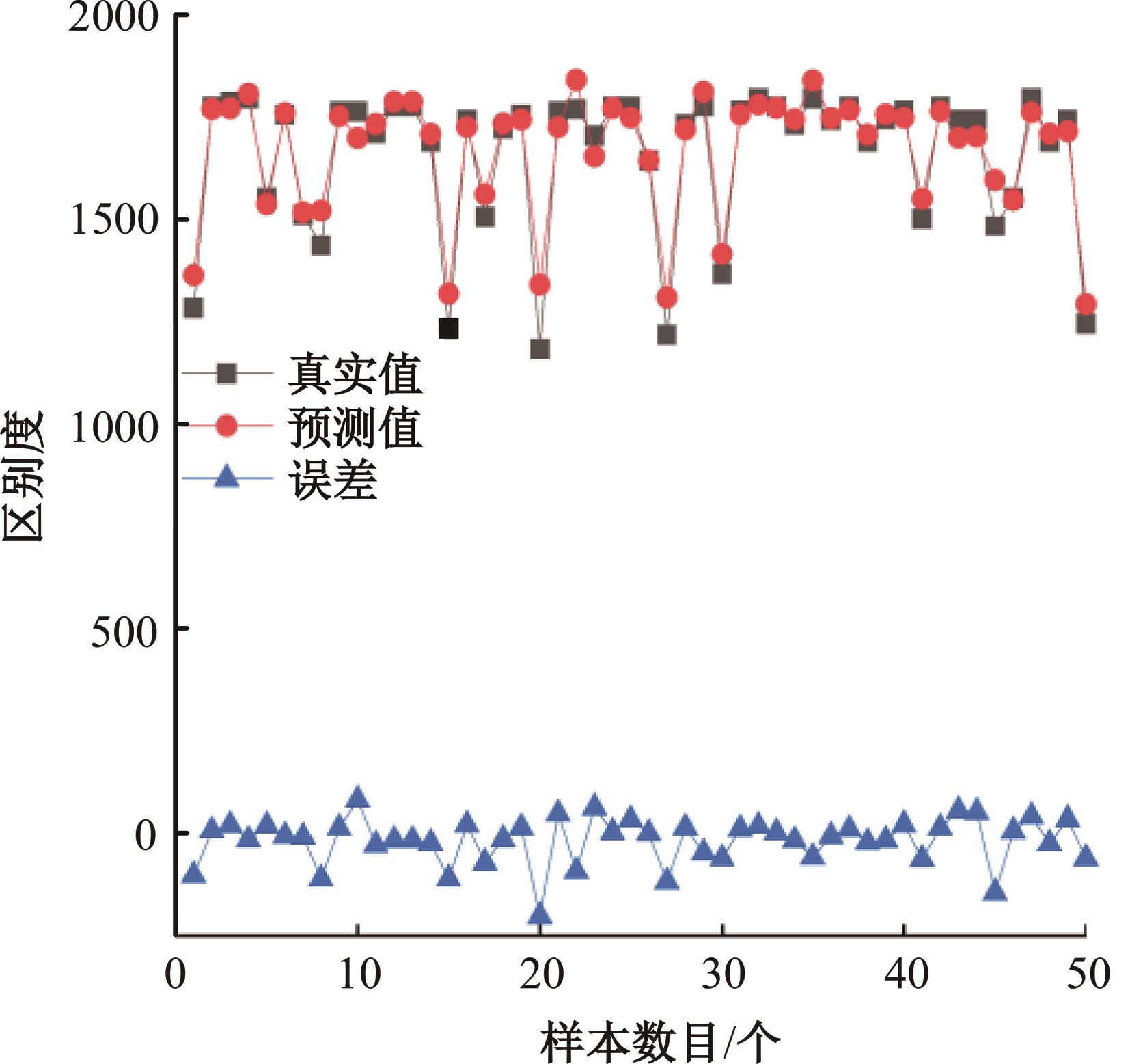

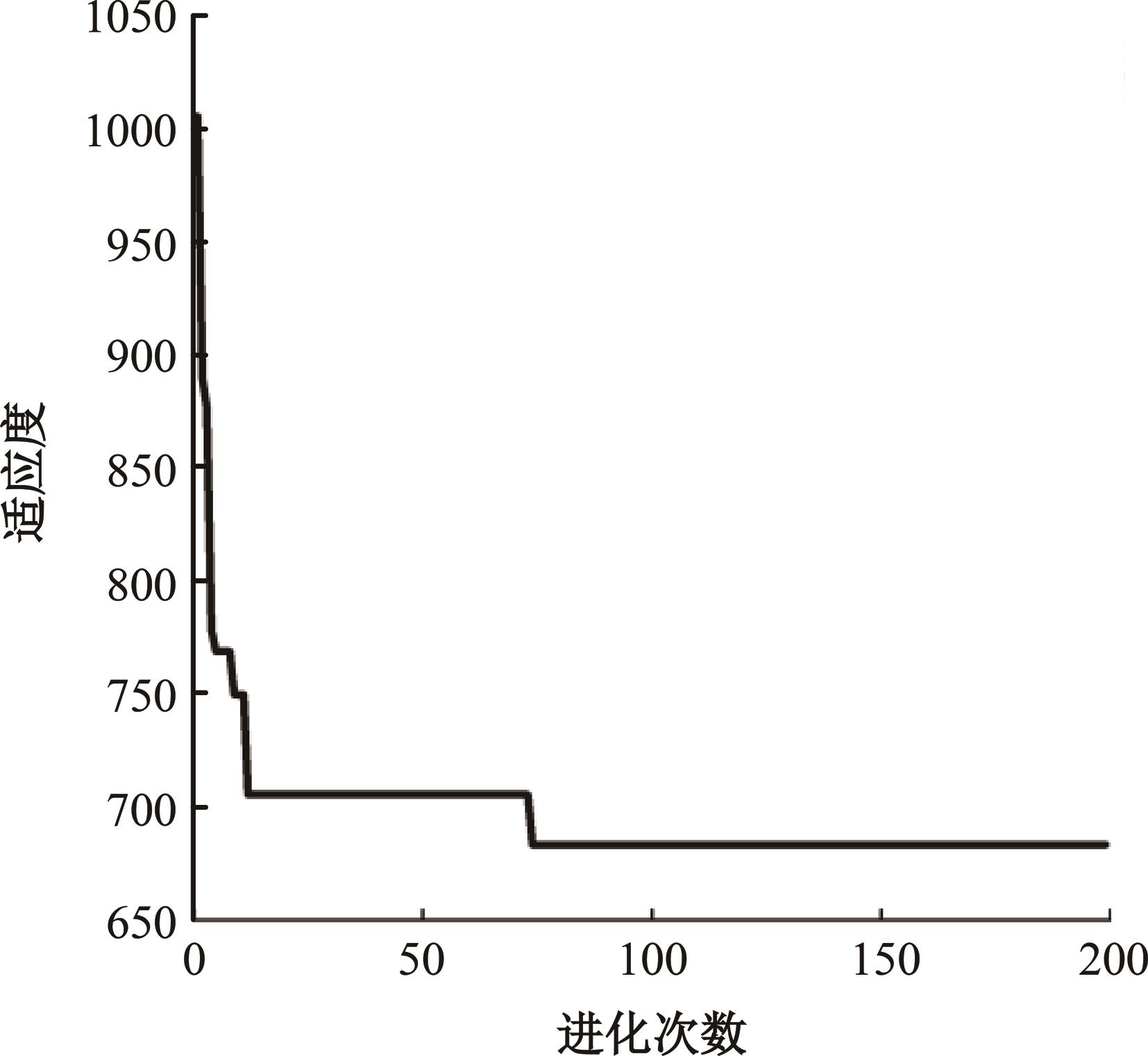

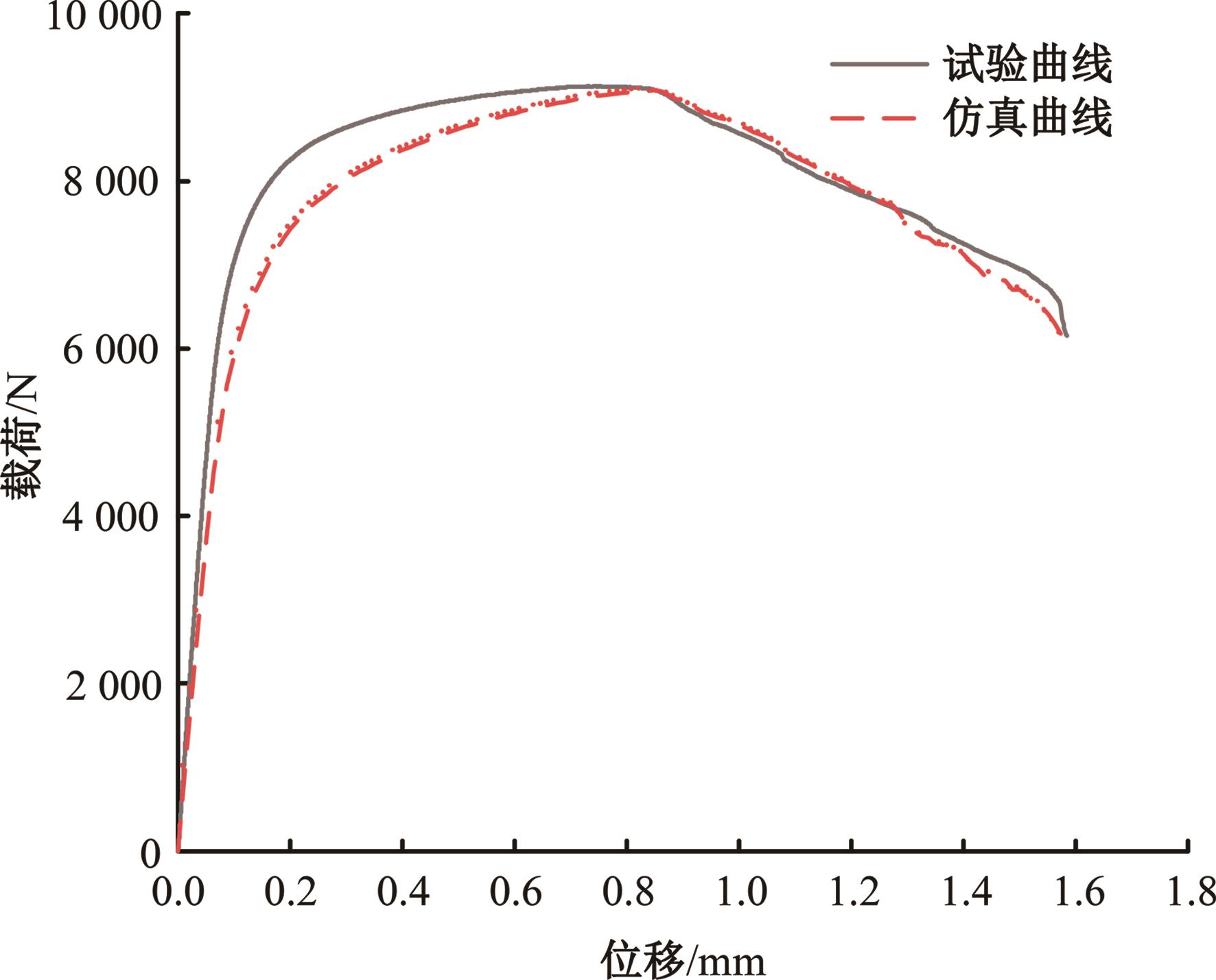

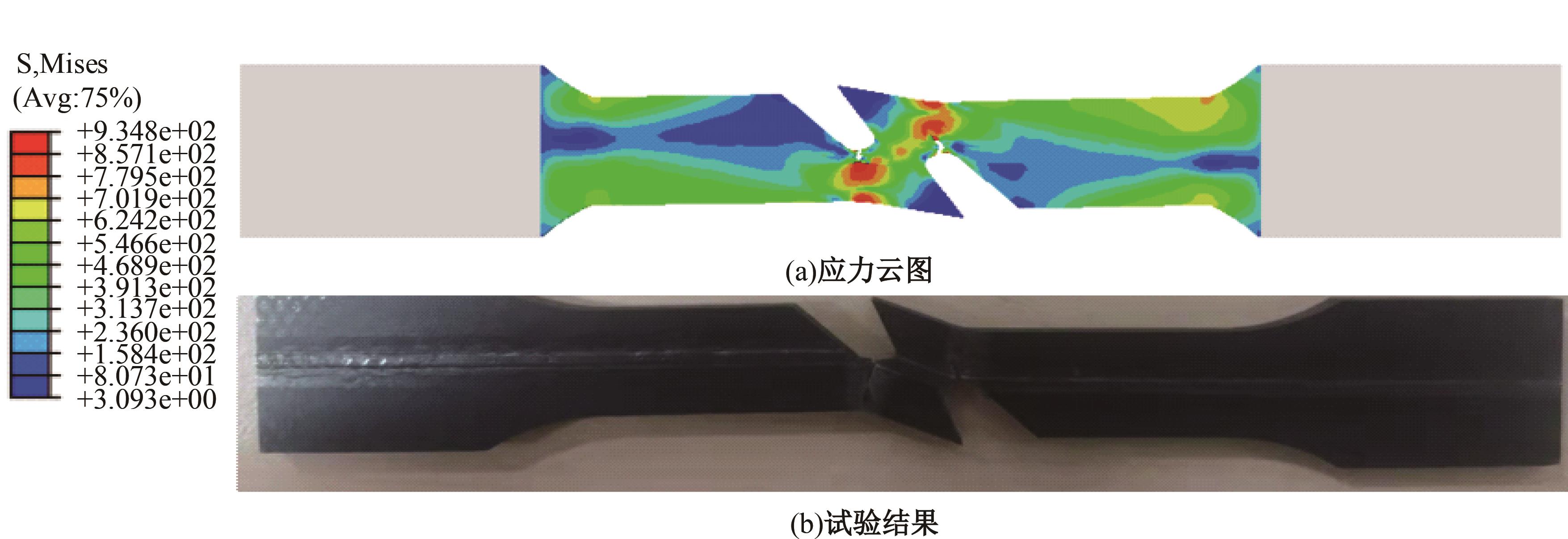

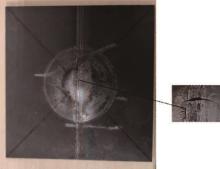

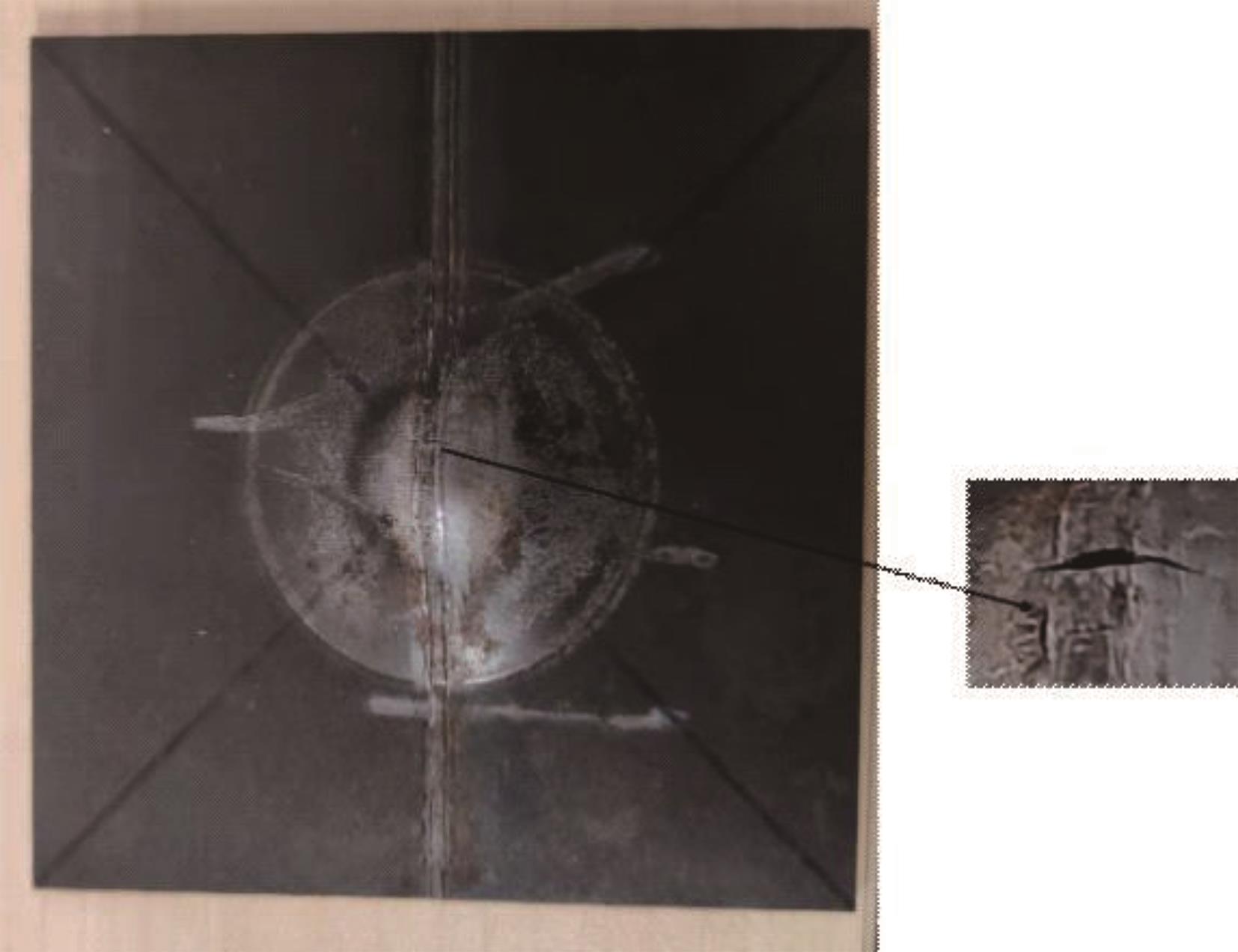

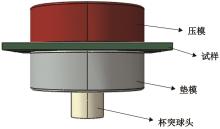

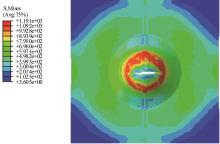

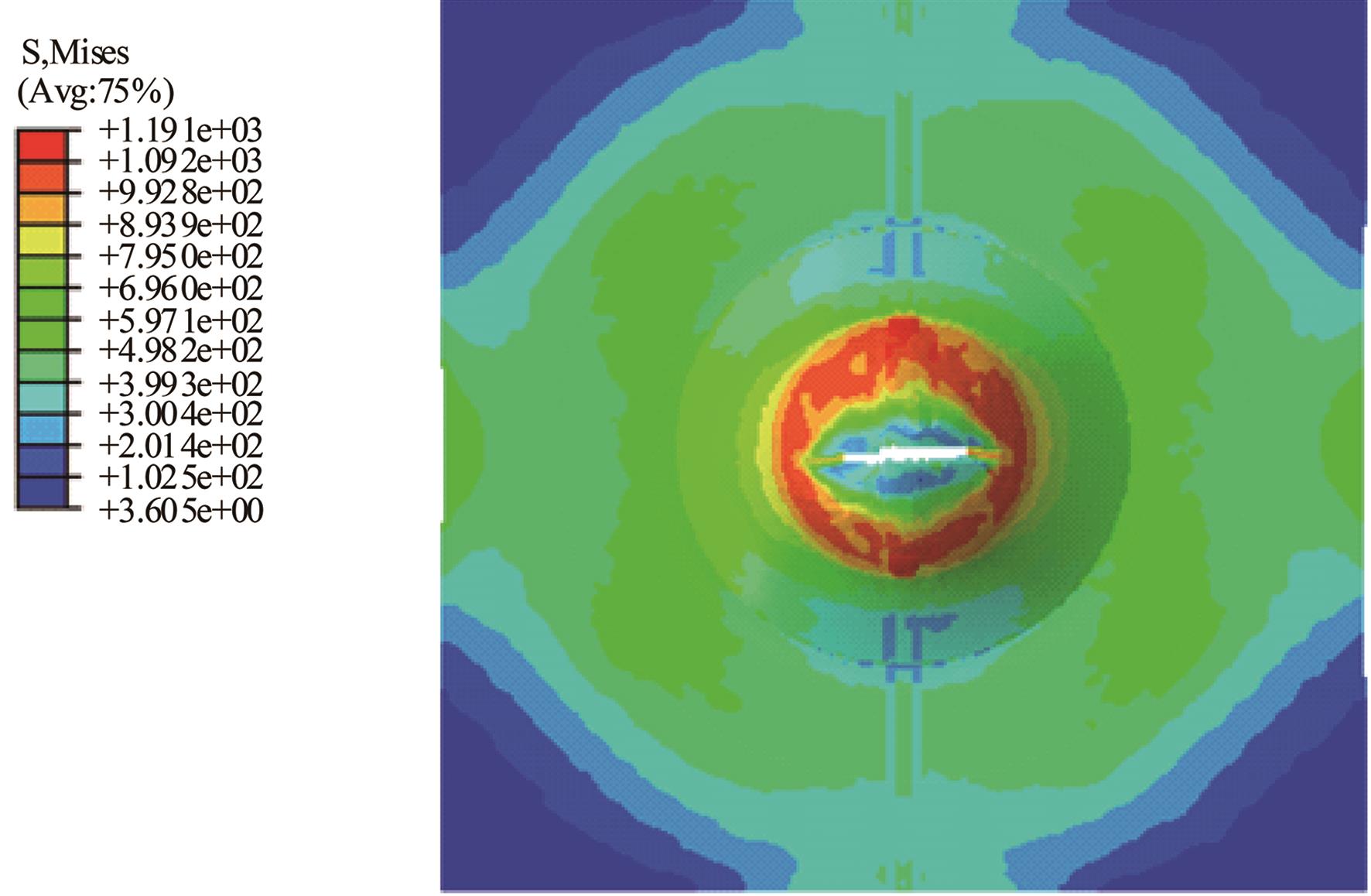

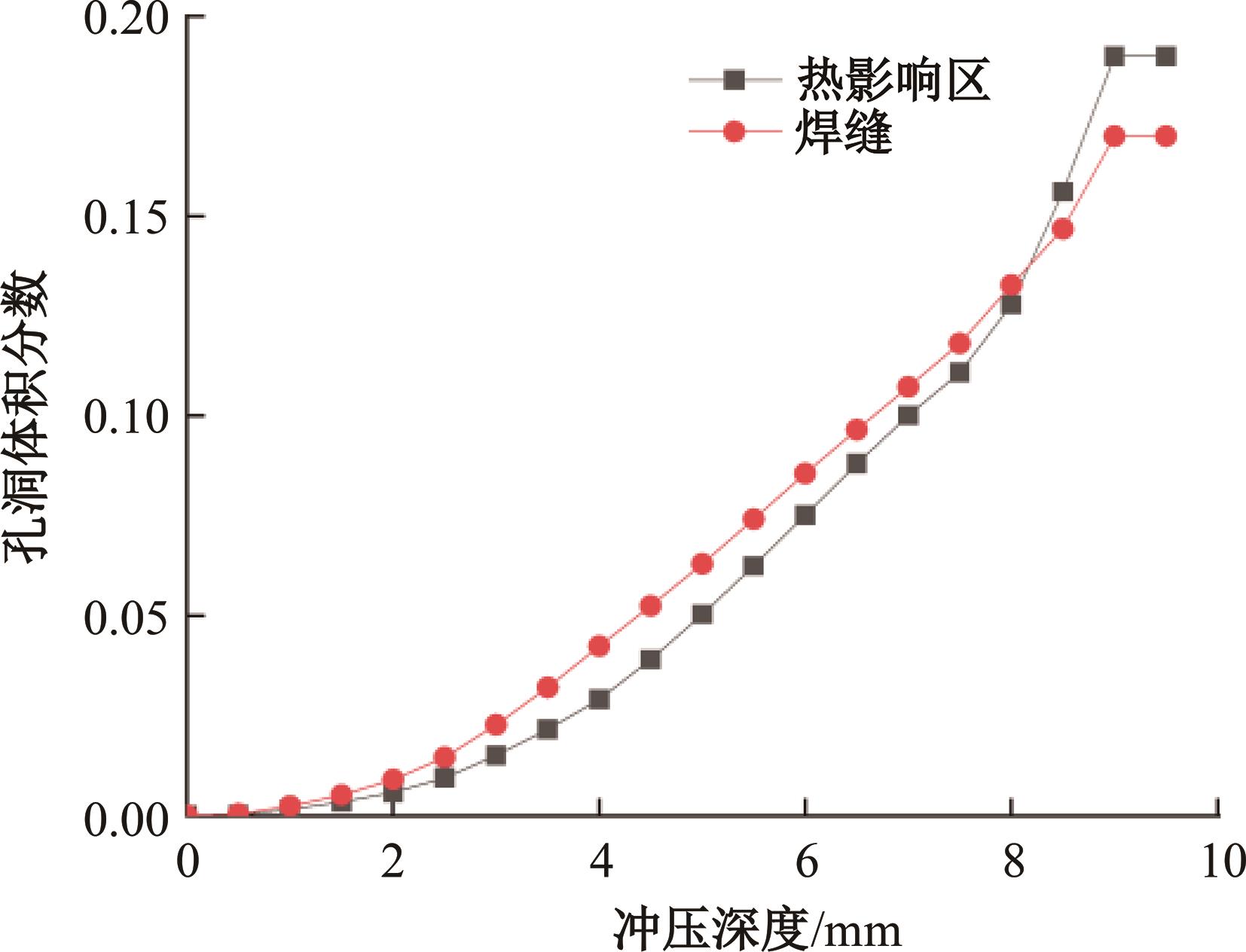

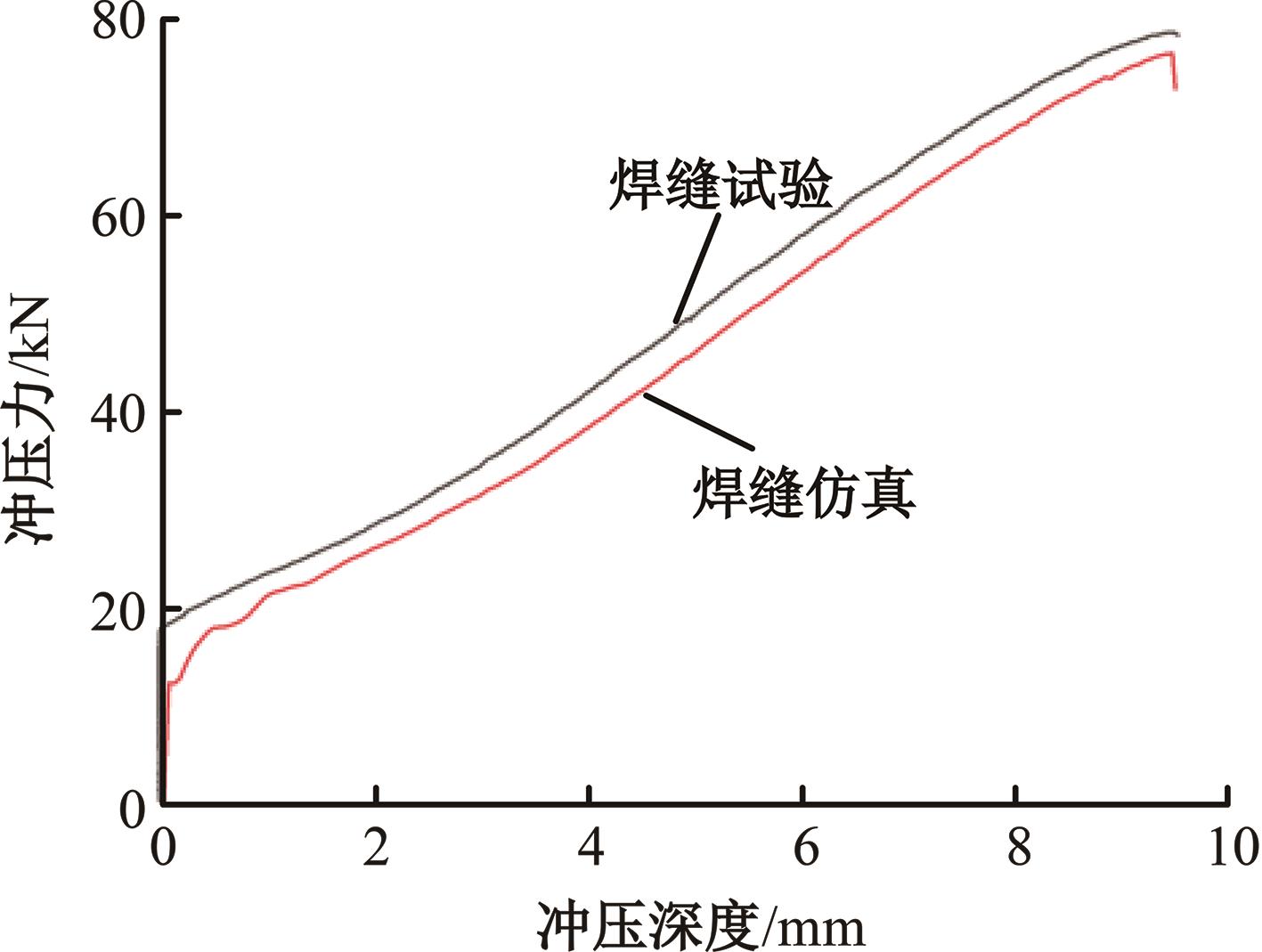

利用试验与仿真结果结合神经网络和遗传算法的方法,对DP980激光焊接接头的力学性能不均匀特性进行了研究,得到了剪切修正Gurson-Tvergaard-Needleman模型优化焊接接头的损伤参数,将优化结果代入有限元模型和试验结果进行对比以验证拟合参数的准确性,并通过孔洞体积分数变化分析杯突试样横向裂纹扩展的原因。通过以上方法获得了准确的焊接接头力学性能,可应对复杂应力状态下的焊接接头断裂损伤的分析预测。

中图分类号:

- TG407

| 1 | Merklein M, Johannes M, Lechner M, et al. A review on tailored blanks-production, applications and evaluation[J]. Journal of Materials Processing Technology, 2014, 214(2): 151-164. |

| 2 | 谷诤巍, 于思彬, 韩立军, 等. 激光焊接速度对超高强度钢焊缝微观组织和显微硬度的影响[J]. 吉林大学学报:工学版, 2012, 42(3): 656-659. |

| Gu Zheng-wei, Yu Si-bin, Han Li-jun, et al. Effect of welding speed on microstructure and micro hardness of the weld seam of laser welded ultra-high strength steel[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(3): 656-659. | |

| 3 | Gurson A L. Continuum theory of ductile rupture by void nucleation and growth: part I-yield criteria and flow rules for porous ductile media[J]. Journal of Engineering Materials and Technology, 1977, 99(1): 2-15. |

| 4 | Tvergaard V, Needleman A. Analysis of the cup-cone fracture in a round tensile bar[J]. Acta Metallurgica, 1984, 32(1): 157-169. |

| 5 | 王江超, 卓子超, 熊家炜, 等. 基于 Gurson 模型的船用属单向拉伸断裂分析[J]. 船舶与海洋工程, 2020, 36(4): 44-49, 70. |

| Wang Jiang-chao, Zhuo Zi-chao, Xiong Jia-wei. Fracture analysis of marine metal under axial tension based on Gurson model[J]. Naval Architecture and Ocean Engineering, 2020, 36(4): 44-49, 70. | |

| 6 | 肖晋, 胡玉梅, 金晓清, 等. 基于各向异性 GTN 模型的铝合金损伤参数确定[J]. 机械强度, 2018, 40(5):1189-1193. |

| Xiao Jin, Hu Yu-mei, Jin Xiao-qing, et al. Damage parametersidentification of aluminum alloy based on anisotropic GTN model[J]. Journal of Mechanical Strength, 2018, 40(5): 1189-1193. | |

| 7 | Oh Y R, Nam H S, Kim Y J, et al. Application of the GTN model to ductile crack growth simulation in through-wall cracked pipes[J]. International Journal of Pressure Vessels and Piping, 2018, 159(1): 35-44. |

| 8 | 刘文权, 盈亮, 荣海, 等. 基于损伤修正M-K模型的高强度钢成形极限预测[J]. 吉林大学学报:工学版, 2019, 49 (4): 1266-1271. |

| Liu Wen-quan, Ying Liang, Rong Hai, et al. Forming limit prediction of high strength steel based on damage modified M-K model[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1266-1271. | |

| 9 | 刘妹妹, 陈建钧, 潘红良. 低应力三轴度下孔洞行为的有限元研究[J]. 机械强度, 2017, 39(1): 85-91. |

| Liu Mei-mei, Chen Jian-jun, Pan Hong-liang. Finite element study of void behavior under low stress triaxiality[J]. Journal of Mechanical Strength, 2017, 39(1): 85-91. | |

| 10 | Zhao K, Wang L, Chang Y, et al. Identification of post-necking stress-strain curve for sheet metals by inverse method[J]. Mechanics of Materials, 2016, 92(1): 107-118. |

| 11 | Abdullah K, Wild P M, Jeswiet J J, et al. Tensile testing for weld deformation properties in similar gage tailor welded blanks using the rule of mixtures[J]. Journal of Materials Processing Tech, 2001, 112(1): 91-97. |

| 12 | Song Y L, Lin H, Chu D, et al. Characterization of the in-homogeneous constitutive properties of laser welding beams by the micro-vickers hardness test and the rule of mixture[J]. Materials and Design, 2012, 37(5): 19-27. |

| 13 | Mohr D, Marcadet S J. Micromechanically-motivated phenomenological Hosford-Coulomb model for predicting ductile fracture initiation at low stress triaxialities[J]. International Journal of Solids and Structures, 2015, 67(16): 40-55. |

| 14 | Nahshon K, Xue Z. A modified Gurson model and its application to punchout experiments[J]. Engineering Fracture Mechanics, 2009, 76(8): 997-1009. |

| 15 | Wang J L, Li C Z, Wan Y, et al. Size effect on the shear damage under low stress triaxiality in micro-scaled plastic deformation of metallic materials[J]. Materials & Design, 2020, 196(12): 109-125. |

| 16 | Li X, Chen Z H, Dong C F. Size effect on the damage evolution of a modified GTN model under high/low stress triaxiality in meso-scaled plastic deformation[J]. Materials Today Communications, 2021, 26(1):No. 101782. |

| 17 | Tvergaard V. Influence of voids on shear band instabilities under plane strain conditions[J]. International Journal of Fracture,1981, 17(4): 389-407. |

| 18 | Springmann M, Kuna M. Identification of material parameters of the Gurson-Tvergaard-Needleman model by combined experimental and numerical techniques[J]. Computational Materials Science, 2005, 32(3/4): 544-552. |

| 19 | 张永波, 朱英韬. 基于主成分分析和GA-BP神经网络的带钢焊接质量预测[J]. 热加工工艺, 2020, 49(17): 128-132. |

| Zhang Yong-bo, Zhu Ying-tao. Prediction of welding quality of strip steel based on principal component analysis and GA-BP neural network[J]. Hot Working Technology, 2020, 49(17): 128-132. | |

| 20 | 洪永昌, 计遥遥, 张武,等. DP500高强钢脉冲激光焊接接头的组织和性能[J]. 电焊机, 2014, 44(5): 79-84. |

| Hong Yong-chang, Ji Yao-yao, Zhang Wu. Research on microstructure and properties of DP500 high strength steel joints by pulsed laser welding[J]. Electric Welding Machine, 2014, 44(5): 79-84. |

| [1] | 娄淑梅,李一明,李鑫,陈鹏,白雪峰,程宝嘉. 基于BP神经网络和Arrhenius本构模型的石墨烯/7075复合材料热变形行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1237-1245. |

| [2] | 郭玉荣,潘建中. 基于改进Bouc-Wen模型的RC柱数值模拟方法[J]. 吉林大学学报(工学版), 2024, 54(4): 1028-1037. |

| [3] | 宋雨来,李伟光,张林阳,宋庆军,张华,李军,刘庆. Gd对挤压镁合金AZ91组织和氢脆的影响[J]. 吉林大学学报(工学版), 2024, 54(10): 2792-2798. |

| [4] | 李新宇,凌贤长,曲娜. 考虑温度效应的冻结膨胀土统计损伤模型[J]. 吉林大学学报(工学版), 2023, 53(8): 2339-2349. |

| [5] | 张云龙,张家源,钱雪松,张攀,杨润超. 环境激励下桥梁模态参数识别的频谱方法综述[J]. 吉林大学学报(工学版), 2023, 53(6): 1580-1591. |

| [6] | 梁策,黄富雷,梁继才,李义. 日字形防护梁绕弯成形形变数值模拟[J]. 吉林大学学报(工学版), 2023, 53(12): 3397-3403. |

| [7] | 梁言,王强,宋雨来,刘耀辉. 新型5Cr5MoV模具钢修复性能[J]. 吉林大学学报(工学版), 2022, 52(6): 1301-1307. |

| [8] | 姜屏,周琳,毛天豪,袁俊平,王伟,李娜. 水泥改性废弃泥浆损伤模型及时间效应[J]. 吉林大学学报(工学版), 2022, 52(12): 2874-2882. |

| [9] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

| [10] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [11] | 刘文权,盈亮,荣海,胡平. 基于损伤修正M⁃K模型的高强度钢成形极限预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1266-1271. |

| [12] | 宋军, 石雪飞, 阮欣. 大体积混凝土热学参数识别的优化[J]. 吉林大学学报(工学版), 2018, 48(5): 1418-1425. |

| [13] | 杨越东, 陈吉清, 兰凤崇, 周云郊. 基于焊点参数识别的白车身动态特性[J]. 吉林大学学报(工学版), 2017, 47(5): 1379-1386. |

| [14] | 王文权, 商延赓, 李秀娟, 王春生, 张桂兰. 激光焊接650 MPa相变诱发塑性钢的组织与性能[J]. , 2012, 42(05): 1203-1207. |

| [15] | 程永春, 郭庆林, 谭国金. 沥青混合料黏弹性参数的改进识别 [J]. , 2012, (03): 629-633. |

|