吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (5): 1237-1245.doi: 10.13229/j.cnki.jdxbgxb.20220756

• 材料科学与工程 • 上一篇

基于BP神经网络和Arrhenius本构模型的石墨烯/7075复合材料热变形行为

- 山东科技大学 智能装备学院,山东 泰安 271019

Thermal deformation behavior of graphene nanosheets reinforced 7075Al based on BP neural network and Arrhenius constitutive equation

Shu-mei LOU( ),Yi-ming LI,Xin LI,Peng CHEN,Xue-feng BAI,Bao-jia CHENG

),Yi-ming LI,Xin LI,Peng CHEN,Xue-feng BAI,Bao-jia CHENG

- College of Intelligent Equipment,Shandong University of Science and Technology,Taian 271019,China

摘要:

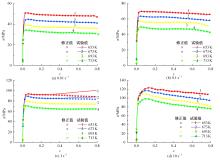

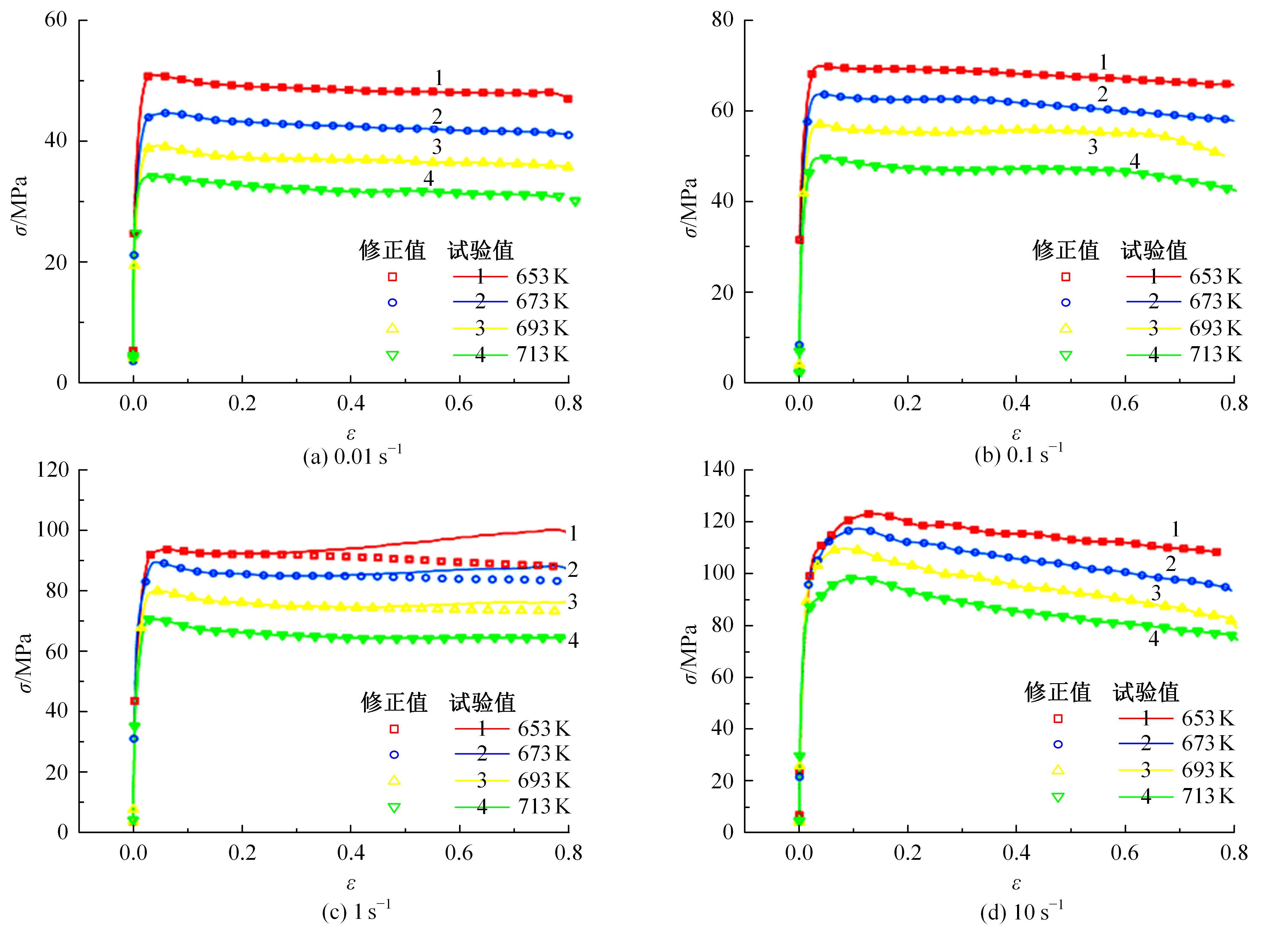

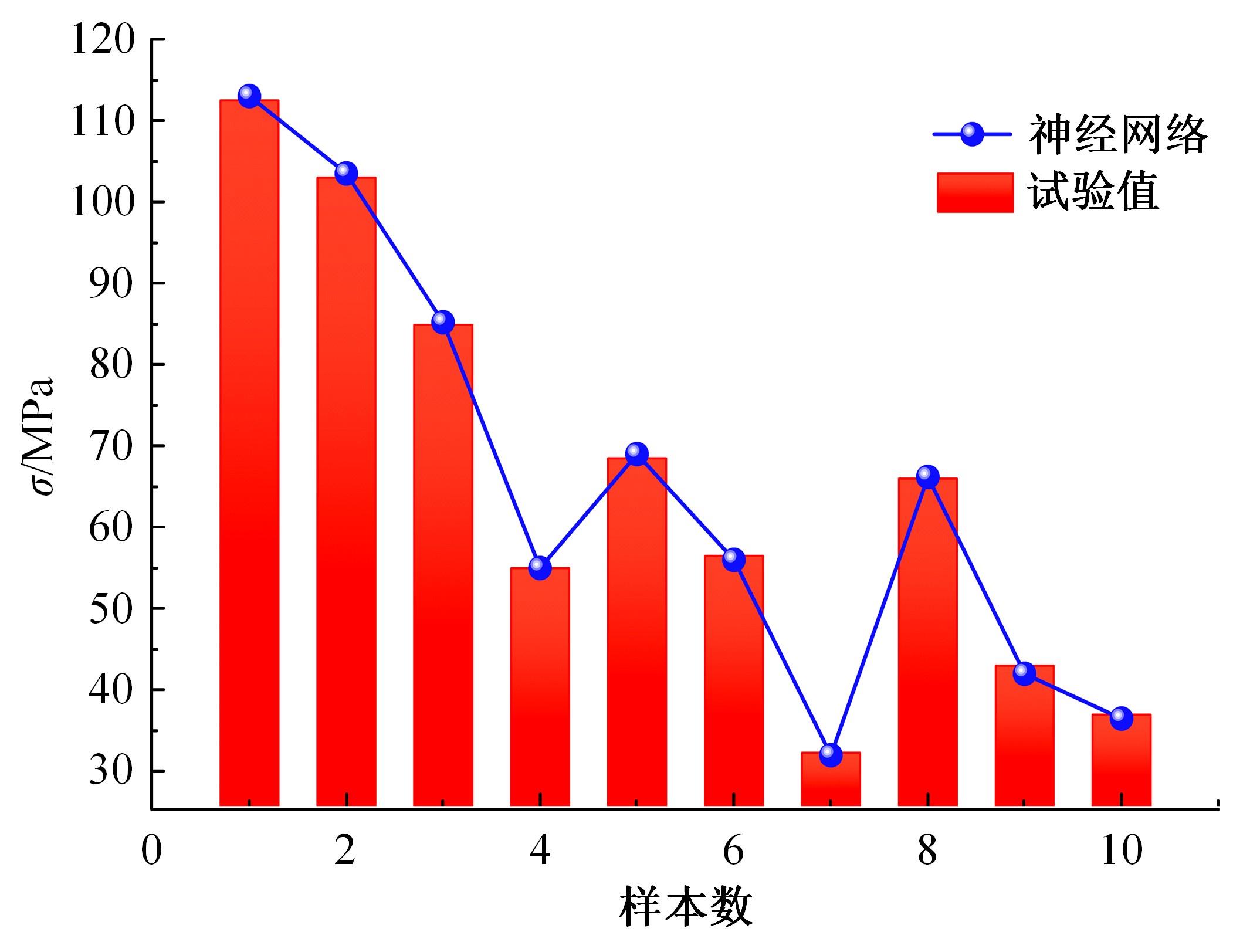

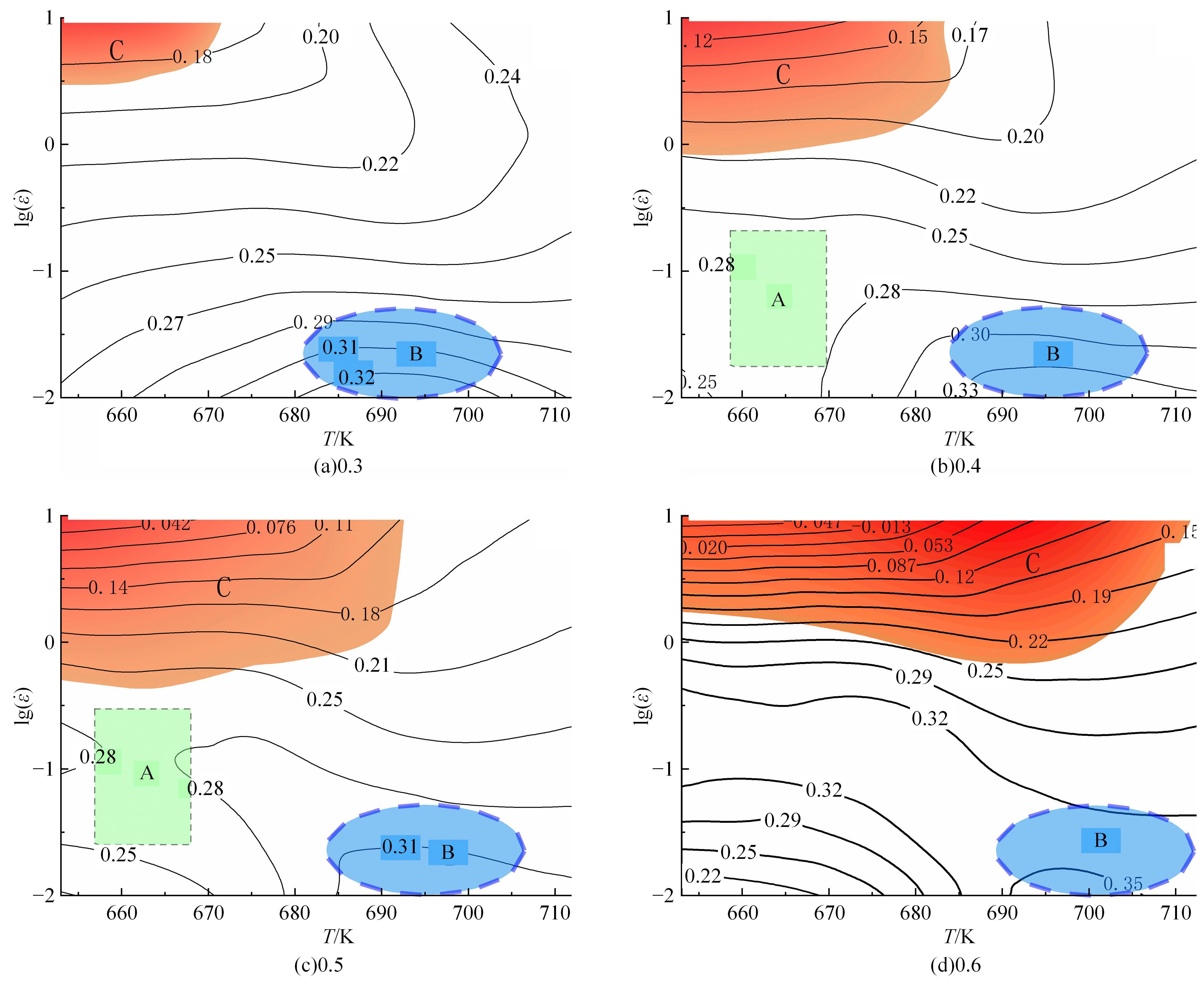

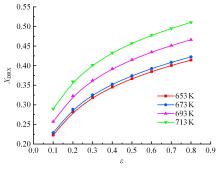

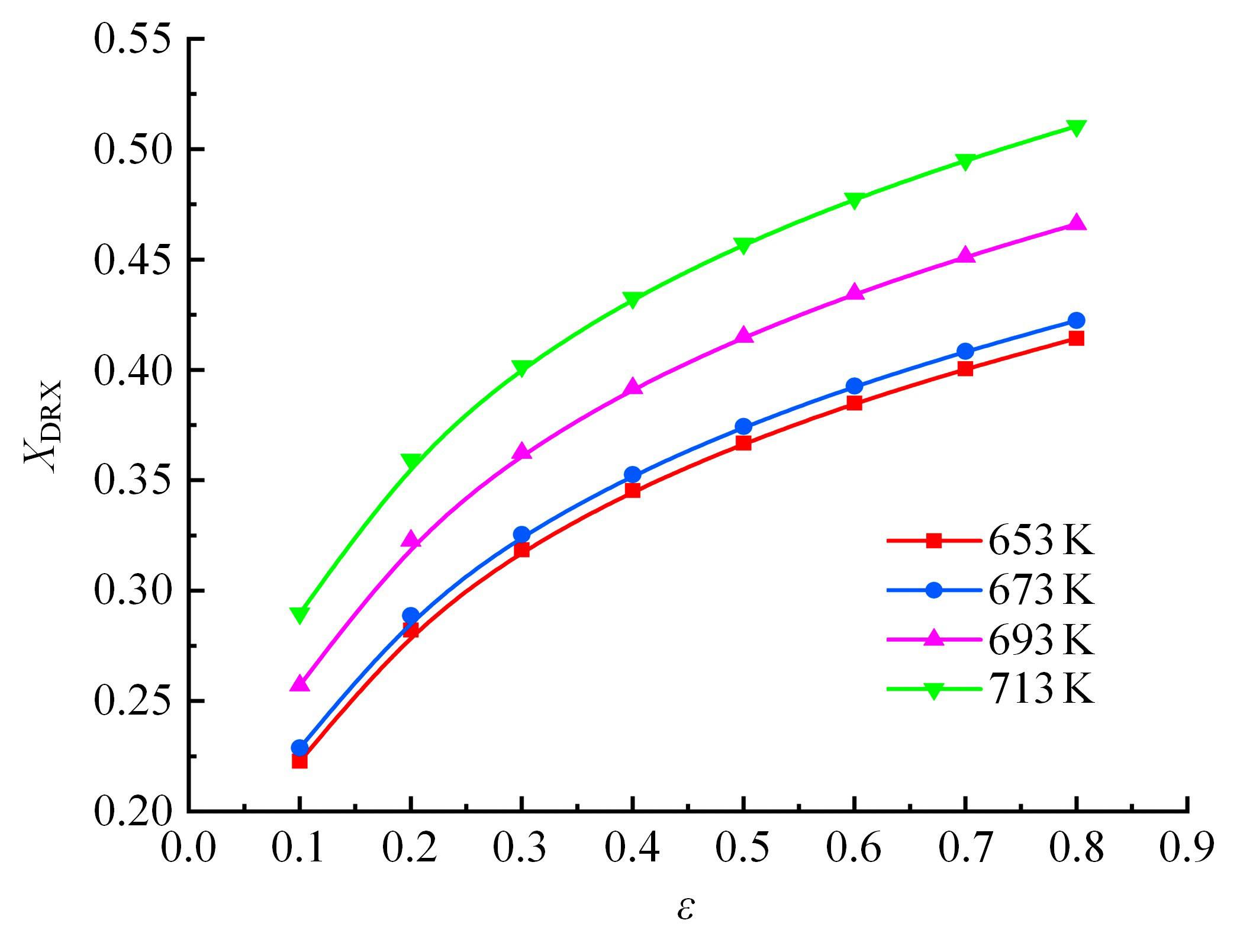

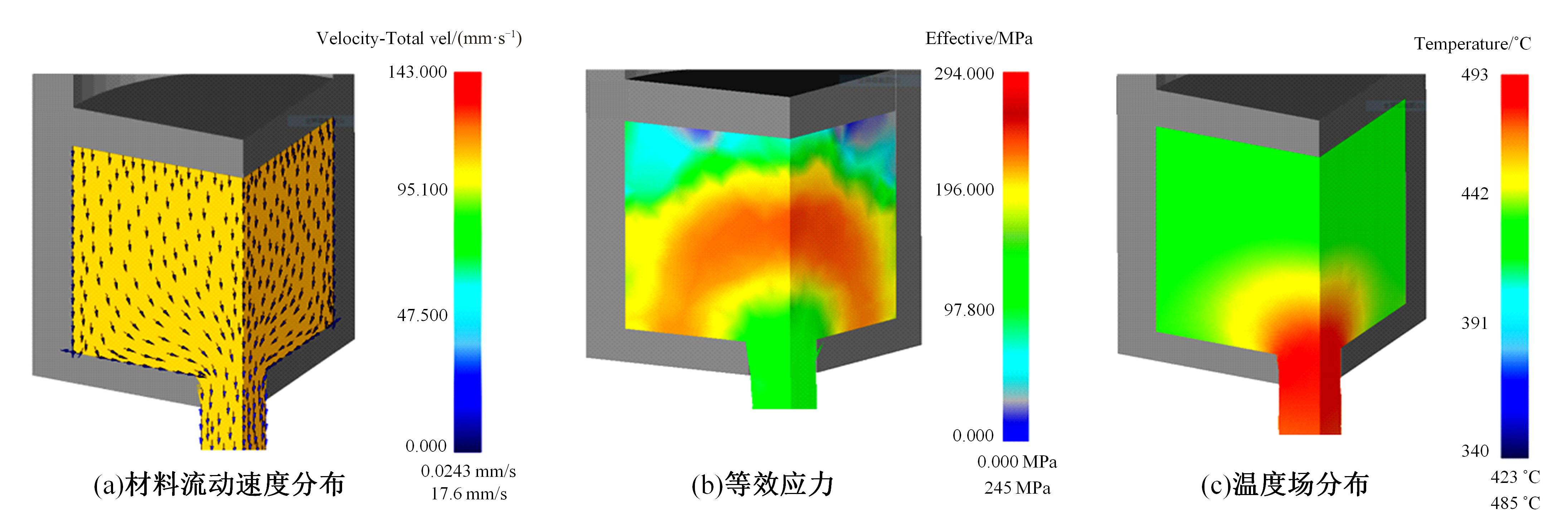

在653~713 K温度范围和0.01~10 s-1应变速率下,进行了w(GNP/7075Al)=0.5% 增强7075铝基复合材料的热压缩试验,建立了BP神经网络和应变补偿Arrhenius模型,同时建立了复合材料的热加工图和动态再结晶体积分数预测模型,研究了复合材料的热变形行为,并确定了复合材料的热加工工艺参数。结果表明:BP神经网络模型得到的流变应力预测值与试验结果吻合较好,其相关系数最高为99.9983%,平均相对误差绝对值最小为0.5%,表明神经网络对w(GNP/7075Al)=0.5% 复合材料的热变形行为具有较高的预测精度。w(GNP/7075Al)=0.5%复合材料最佳变形温度和应变速率分别为685~705 K和0.01~0.1 s-1。动态再结晶(DRX)倾向于在低应变速率和高变形温度下发生。数值模拟和热挤压试验表明,在挤压温度693 K、挤压速度1 mm/min的工艺参数下可以挤出表面质量良好的型材。

中图分类号:

- TG376.2

| 1 | Pérez-Bustamante R, Bolaños-Morales D, Bonilla-Martínez J, et al. Microstructural and hardness behavior of graphene-nanoplatelets/aluminum composites synthesized by mechanical alloying[J]. Journal of Alloys and Compounds, 2014, 615(Sup.1): 5578-5582. |

| 2 | Li De-jun, Feng Yao-rong, Yin Zhi-fu, et al. Hot deformation behavior of an austenitic Fe-20Mn-3Si-3Al transformation induced plasticity steel[J]. Materials and Design, 2011, 34: 713-718. |

| 3 | He Hai-lin, Yi You-pin, Cui Jin-dong, et al. Hot deformation characteristics and processing parameter optimization of 2219 Al alloy using constitutive equation and processing map[J]. Vacuum,2019,160:293-302. |

| 4 | Dong Yuan-yuan, Zhang Cun-sheng, Zhao Guo-qun, et al. Constitutive equation and processing maps of an Al-Mg-Si aluminum alloy: determination and application in simulating extrusion process of complex profiles[J]. Materials Design,2016, 92: 983-997. |

| 5 | Ramanathan S, Karthikeyan R, Gupta M. Development of processing maps for Al/SiCp composite using fuzzy logic[J]. Journal of Materials Processing Technology, 2007, 183(1): 104-110. |

| 6 | Senthilkumar V, Balaji A, Narayanasamy R. Analysis of hot deformation behavior of Al 5083-TiC nanocomposite using constitutive and dynamic material models[J]. Materials & Design, 2012, 37: 102-110. |

| 7 | 臧雪柏,管秀君,赵宏伟,等.基于遗传算法的神经网络振动钻削参数优化[J].吉林大学学报:工学版,2002, 32(1): 37-41. |

| Zang Xue-bai, Guan Xiu-jun, Zhao Hong-wei, et al. Optimization of neural network vibration drilling parameter based on genetic algorithm[J]. Journal of Jilin University (Engineering and Technology Edition),2002, 32(1): 37-41. | |

| 8 | 闫楚良,郝云霄,刘克格.基于遗传算法优化的BP神经网络的材料疲劳寿命预测[J].吉林大学学报:工学版,2014,44(6):1710-1715. |

| Yan Chu-liang, Hao Yun-xiao, Liu Ke-ge,et al. Fatigue life prediction of materials based on BP neural networksoptimized by genetic algorithm[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(6): 1710-1715. | |

| 9 | 娄淑梅,张苹苹,冉令伟,等. 石墨烯增强铝基复合材料制备工艺对比与分析[J]. 热加工工艺, 2021, 50(8): 51-54, 58. |

| Lou Shu-mei, Zhang Ping-ping, Ran Ling-wei, et al. Comparison and analysis of preparation technology of graphene reinforced aluminum matrix composites [J]. Hot Working Technology, 2021, 50(8): 51-54, 58. | |

| 10 | Ebrahimi R, Najafizadeh A.A new method for evaluation of friction in bulk metal forming[J]. Journal of Materials Processing Tech, 2004, 152(2): 136-143. |

| 11 | Zeng Jian, Wang Feng-hua, Dong Shuai, et al. A new dynamic recrystallization kinetics model of cast-homogenized magnesium alloys[J]. Metallurgical and Materials Transactions A, 2020,52(1):1-16. |

| 12 | Chen Xiao-min, Wen Dong-xu, Zhan Jin-long,et al. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation-scienceDirect[J]. Materials & Design, 2014, 57(5): 568-577. |

| [1] | 赵秋,陈鹏,赵煜炜,余澳. 台后设置拱形结构的无缝桥梁整体受力性能[J]. 吉林大学学报(工学版), 2024, 54(4): 1016-1027. |

| [2] | 卫星,高亚杰,康志锐,刘宇辰,赵骏铭,肖林. 低温环境下栓钉环焊缝焊接残余应力场数值模拟[J]. 吉林大学学报(工学版), 2024, 54(1): 198-208. |

| [3] | 郑植,袁佩,金轩慧,魏思斯,耿波. 桥墩复合材料柔性防撞护舷试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2581-2590. |

| [4] | 王峰,刘双瑞,王佳盈,宋佳玲,王俊,张久鹏,黄晓明. 尺寸和形状效应对多孔结构风阻系数的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1677-1685. |

| [5] | 顾正伟,张攀,吕东冶,吴春利,杨忠,谭国金,黄晓明. 基于数值仿真的简支梁桥震致残余位移分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1711-1718. |

| [6] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [7] | 金敬福,董新桔,贾志成,王康,贺连彬,邹猛,齐迎春. 板簧式弹性金属车轮胎面弹片结构优化[J]. 吉林大学学报(工学版), 2023, 53(4): 964-972. |

| [8] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [9] | 解方喜,赵士杰,王梓森,刘爽,李小平,张程. 多孔喷油器闪急沸腾喷雾坍塌影响因素的仿真分析[J]. 吉林大学学报(工学版), 2023, 53(12): 3314-3325. |

| [10] | 梁策,黄富雷,梁继才,李义. 日字形防护梁绕弯成形形变数值模拟[J]. 吉林大学学报(工学版), 2023, 53(12): 3397-3403. |

| [11] | 戴理朝,周亮,杨晓文,王磊. 基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟[J]. 吉林大学学报(工学版), 2023, 53(10): 2886-2896. |

| [12] | 卢晓红,乔金辉,周宇,马冲,隋国川,孙卓. 搅拌摩擦焊温度场研究进展[J]. 吉林大学学报(工学版), 2023, 53(1): 1-17. |

| [13] | 郑植,耿波,王福敏,董俊宏,魏思斯. 既有低等级混凝土护栏防护能力提升[J]. 吉林大学学报(工学版), 2022, 52(6): 1362-1374. |

| [14] | 梁言,王强,宋雨来,刘耀辉. 新型5Cr5MoV模具钢修复性能[J]. 吉林大学学报(工学版), 2022, 52(6): 1301-1307. |

| [15] | 华琛,牛润新,余彪. 地面车辆机动性评估方法与应用[J]. 吉林大学学报(工学版), 2022, 52(6): 1229-1244. |

|

||