吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (8): 2385-2392.doi: 10.13229/j.cnki.jdxbgxb.20231300

脊状结构用于翼型自噪声控制试验

程文1,2( ),张成春2,3,4(

),张成春2,3,4( ),孙潇伟3,沈淳2,3,吴正阳1,2,陈正武1

),孙潇伟3,沈淳2,3,吴正阳1,2,陈正武1

- 1.中国空气动力学研究开发中心空气动力噪声控制重点实验室,四川 绵阳 621000

2.吉林大学 工程仿生教育部重点实验室,长春 130022

3.威海峻铭动力科技有限公司,山东 威海 264200

4.吉林大学 威海仿生研究院,山东 威海 264200

Experimental on self-noise control of airfoil with ridge-like structure

Wen CHENG1,2( ),Cheng-chun ZHANG2,3,4(

),Cheng-chun ZHANG2,3,4( ),Xiao-wei SUN3,Chun SHEN2,3,Zheng-yang WU1,2,Zheng-wu CHEN1

),Xiao-wei SUN3,Chun SHEN2,3,Zheng-yang WU1,2,Zheng-wu CHEN1

- 1.Key Laboratory of Aerodynamic Noise Control,China Aerodynamics Research and Development Center,Mianyang 621000,China

2.Key Laboratory of Bionics Engineering(Ministry of Education),Jilin University,Changchun 130022,China

3.Weihai Junming Power Technology Co. ,Ltd. ,Weihai 264200,China

4.Weihai Institute of Bionics,Jilin University,Weihai 264200,China

摘要:

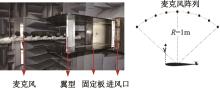

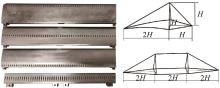

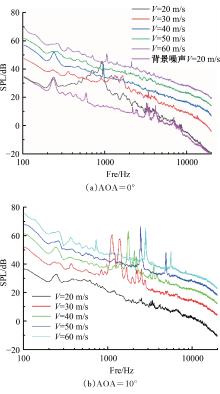

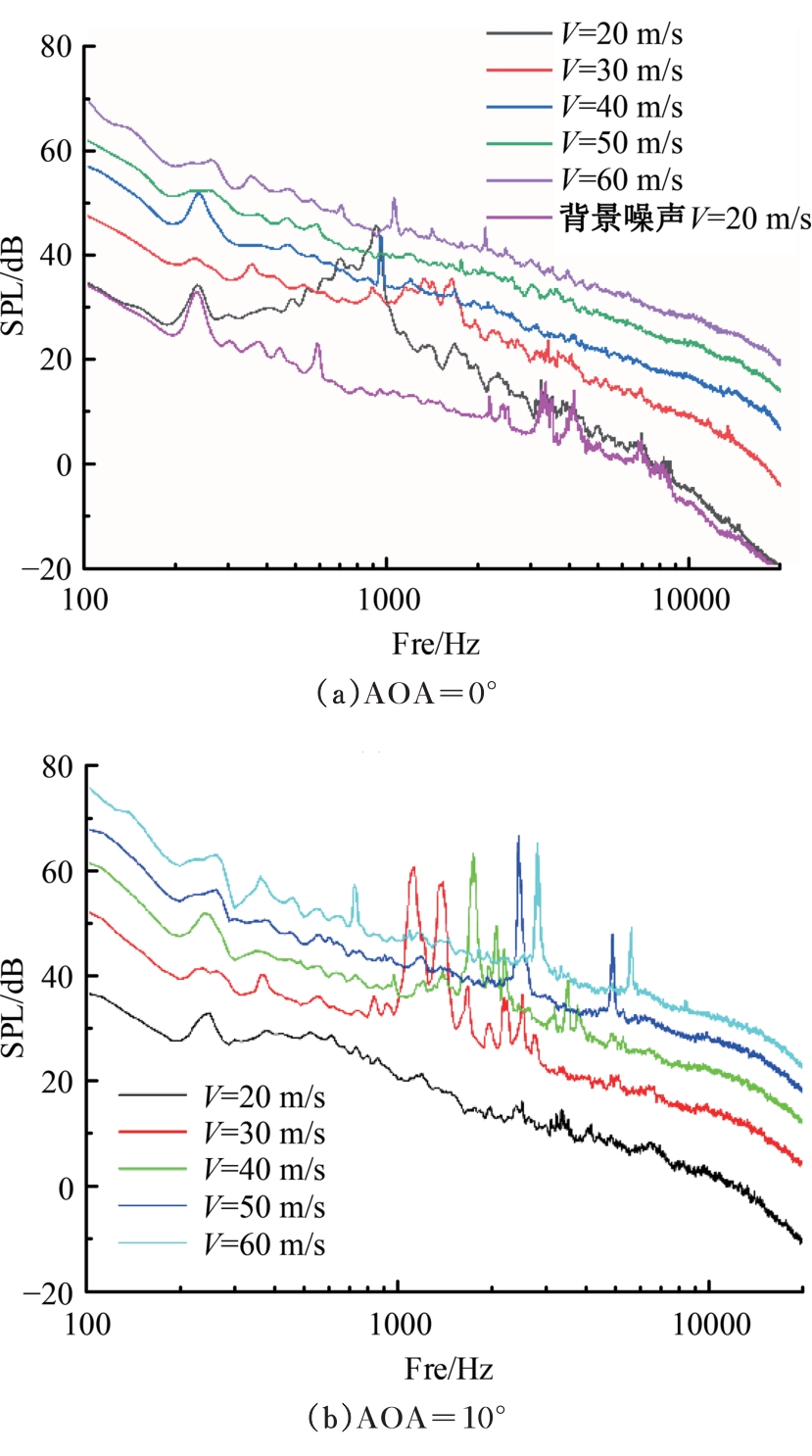

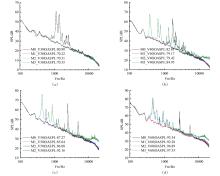

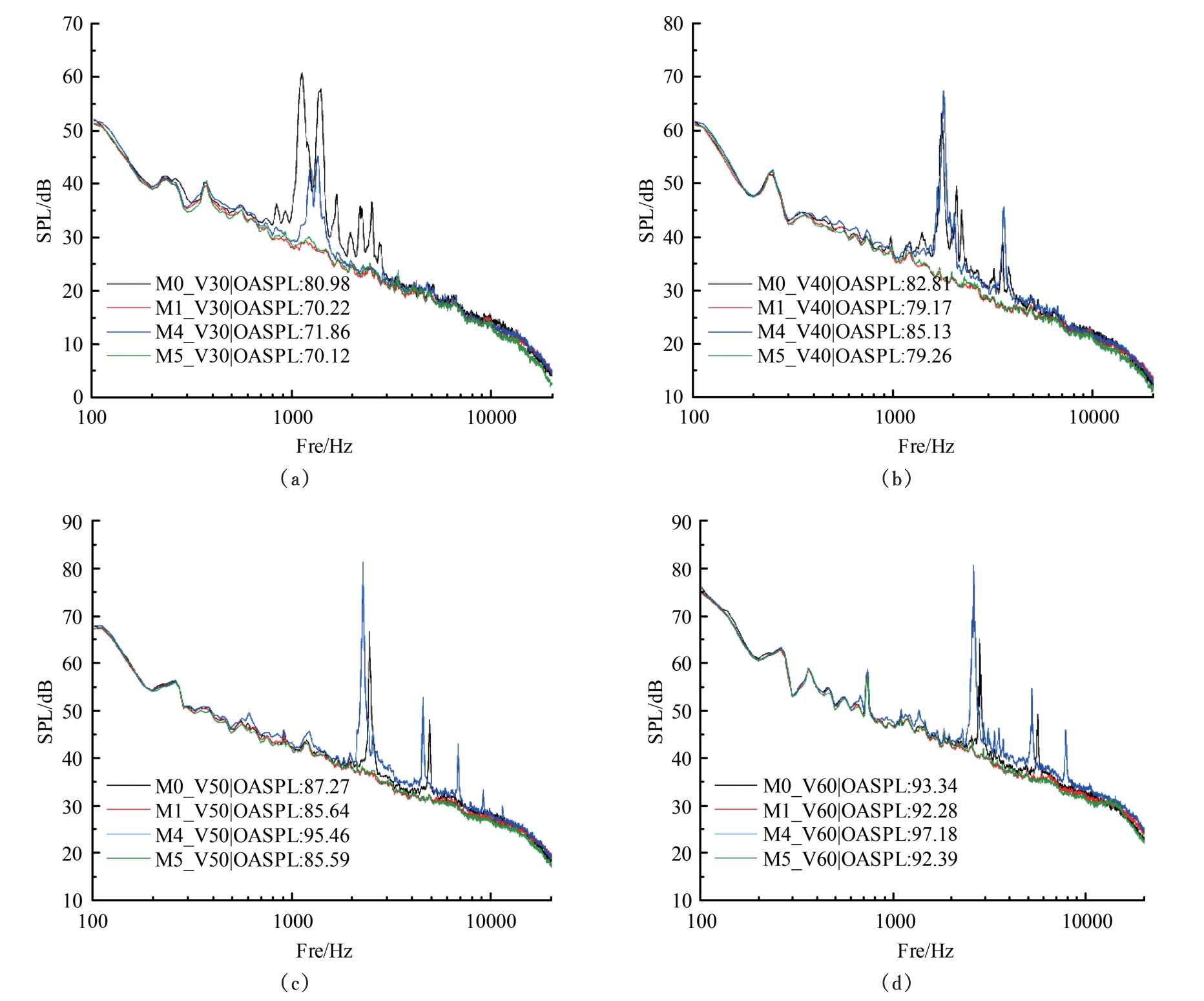

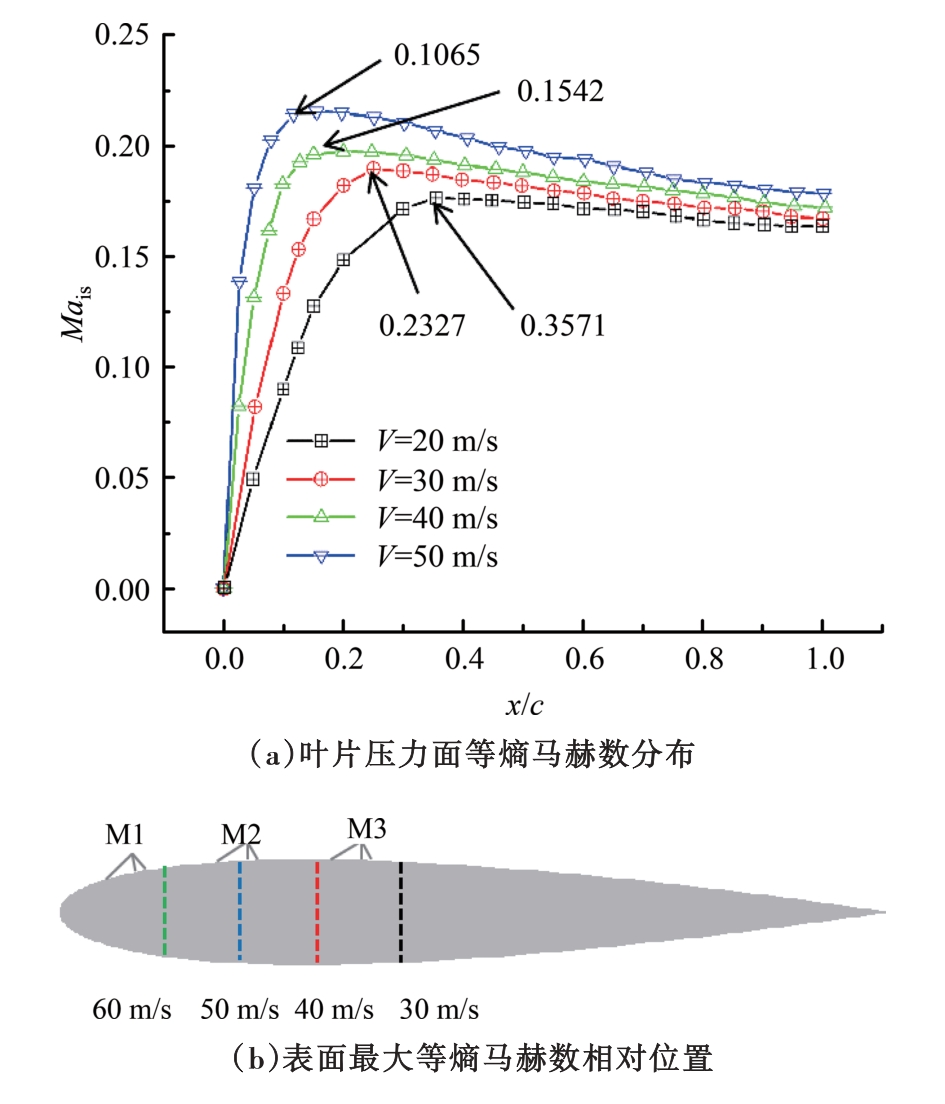

本文研究了NACA0012翼型在0°和10°攻角时不同来流速度下的声学性能,声学风洞试验显示,10°攻角时,翼型在30~60 m/s速度范围内产生明显单音噪声,其频率与Arbey声反馈模型预测结果接近。以有效降低单音噪声为导向,本文提出采用脊状结构打破声反馈回路的设想,并探讨脊状结构位置及排布形式对降噪性能的影响规律。结果表明:脊状结构越靠前,降噪效果越明显;随着速度的增加,靠后位置的脊状结构依次不再具有降噪效果。另外,单音噪声的产生只和压力面的流动状态有关,当压力面的流动状态被脊状结构打破后,便无法形成有效的反馈回路。最后,基于Arbey声学反馈理论,探讨了不同位置的脊状结构的降噪性能差异,发现当脊状结构位于叶片压力面最大速度点之前时,可以有效干预流场从而抑制单音噪声的产生。

中图分类号:

- TB53

| 1 | Amiet R K. Noise due to turbulent flow past a trailing edge[J]. Journal of Sound and Vibration, 1976,47(3): 387-393. |

| 2 | Lowson M, Fiddes S, Nash E. Laminar boundary layer aeroacoustic instabilities[C]∥32th AIAA/CEAS Aeroacoustics Conference,1994: 0358. |

| 3 | Nash E C, McAlpine A, Lowson M V. Boundary-ayer instability noise on aerofoils[J].Journal of Fluid Mechanics, 1999, 382(1): 27-61. |

| 4 | Chen K, Liu Q P, Liao G H,et al. The sound suppression characteristics of wing feather of Owl[J]. Journal of Bionic Engineering, 2012,9(2): 192-199. |

| 5 | 徐成宇,钱志辉,刘庆萍,等. 基于长耳鸮翼前缘的仿生耦合翼型气动性能[J]. 吉林大学学报:工学版, 2010, 40(1): 108-112. |

| Xu Cheng-yu, Qian Zhi-hui, Liu Qing-ping, et al. Aerodynamic performance of bionic coupled foils based on leading edge of long-eared owl wing[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(1): 108-112. | |

| 6 | 葛长江, 叶辉, 胡兴军, 等.鸮翼后缘噪声的预测及控制[J]. 吉林大学学报:工学版, 2016, 46(6): 1981-1986. |

| Ge Chang-jiang, Ye Hui, Hu Xing-jun, et al. Prediction and control of trailing edge noise on owl wings[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(6): 1981-1986. | |

| 7 | Johari H, Henoch C W, Custodio D, et al. Effects of leading-edge protuberances on airfoil performance[J]. AIAA Journal, 2007, 45(11): 2634-2642. |

| 8 | Shorbagy M, El-hadidi B, El-Bayoumi, et al. Experimental study on bio-inspired wings with tubercles[C]∥27th AIAA/CEAS Aeroacoustics Conference, San Diego, USA, 2019: 2643-2672. |

| 9 | 郑覃. 扩压叶栅前缘结状凸起流动机理研究[D].上海:上海交通大学航空航天学院,2019. |

| Zheng Tan. Investigation of flow mechanisms for Leading edge tubercles in compressor cascade[D]. Shanghai: School of Aeronautics and Astronautics, Shanghai Jiaotong University, 2019. | |

| 10 | Alex S H, Lau S H, Kim J W. The effect of wavy leading edges on aerofoil-gust interaction noise[J]. Journal Sound Vib, 2013; 332(24): 6234-6253. |

| 11 | 陈伟杰. 基于仿生学原理的叶片气动噪声控制实验及数值研究[D]. 西安: 西北工业大学动力与能源学院,2018. |

| Chen Wei-jie. Experimental and numerical study on blade aerodynamic noise control by bio-inspired treatments[D].Xi'an: School of Power and Energy, Northwestern Polytechnical University, 2018. | |

| 12 | Paterson R W, Vogt P G, Fink M R. Vortex noise of isolated airfoils[J]. Journal of Aircraft,1973,10(5): 296-302. |

| 13 | Brooks T F, Pope D S, Marcolini, M A. Airfoil Self-noise and Prediction[M]. NSAS Reference Publication, 1989. |

| 14 | Christopher K W T. Discrete tones of isolated airfoils[J]. The Journal of the Acoustical Society of America, 1974,55(6): 1173-1177. |

| 15 | Christopher K W T, Ju H B. Aerofoil tones at moderate Reynolds number[J]. Journal of Fluid Mechanics, 2012,690: 536-570. |

| 16 | Plogmann B, Herrig A, Wurz W. Experimental investigations of a trailing edge noise feedback mechanism on a NACA0012 airfoil[J]. Experiments in Fluids, 2013,54(5): 1-14. |

| 17 | Desquesnes G, Terracol M, Sagaut P. Numerical investigation of the tone noise mechanism over laminar airfoils[J]. Journal of Fluid Mechanics, 2007, 591: 155-182. |

| 18 | Fink M R. Prediction of airfoil tone frequencies[J]. Journal of Aircraft, 1975,12(2): 118-120. |

| 19 | Arbey H, Bataille J. Noise generated by airfoil profiles placed in a uniform laminar flow[J]. Journal of Fluid Mechanics, 1983,134: 33-47. |

| 20 | Prateeka J, Yanna P, Gyuzel Y, et.al. Experimental investigation of aerofoil tonal noise at low Mach number[J]. Journal of Fluid Mechanics, 2022, 932: A37. |

| 21 | Jones L E, Sandberg R D. Numerical analysis of tonal airfoil self-noise and acoustic feedback-loops[J]. Journal of Sound & Vibration, 2011,330(25): 6137- 6152. |

| 22 | Lu W S, Liu P Q, Guo H, et al. Investigation on tones due to self-excited oscillation within leading-edge slat cove at different angles of attack: frequency and intensity[J]. Aerospace Science and Technology, 2019,91: 59-69. |

| 23 | Probsting S, Yang Y N, Zhang H Y, et.al. Effect of Mach number on the aeroacoustic feedback loop generating airfoil tonal noise[J]. Physics of Fluids, 2022,34: 094115. |

| 24 | Jones L E, Richard D. Numerical investigation of tonal airfoil self-noise generated by an acoustic feedback-loop[C]∥16th AIAA/CEAS Aeroacoustics Conference, Stockholm, Sweden, 2010: 3701-3714. |

| 25 | Chong T P, Joseph P. An experimental study of tonal noise mechanism of laminar airfoils[C]∥15th AIAA/CEAS Aeroacoustics Conference, Miami, Florida, 2009: 3345. |

| 26 | Arcondoulis E J G, Doolan C J, Zander A C, et al. An experimental investigation of airfoil tonal noise caused by an acoustic feedback loop[C]∥Annual Conference of the Australian Acoustical Society, Victor Harbor, Australia, 2013: 23-30. |

| [1] | 程亚兵,杨泽宇,李岩,安立持,徐泽辉,曹鹏宇,陈璐翔. 基于混合动力汽车正时齿形链系统的振动噪声特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2465-2473. |

| [2] | 罗乐, 郑旭, 吕义, 郝志勇. 高速列车车轮及轮对的声辐射特性[J]. 吉林大学学报(工学版), 2016, 46(5): 1464-1470. |

| [3] | 孙伟, 李健, 贾师. 硬涂层复合结构非线性刚度及阻尼辨识[J]. 吉林大学学报(工学版), 2016, 46(4): 1156-1162. |

| [4] | 高印寒, 张澧桐, 梁杰, 王智博, 姜文君. 基于客观心理声学参数的重型商用车车内异响噪声分析[J]. 吉林大学学报(工学版), 2016, 46(1): 43-49. |

| [5] | 莫愁, 陈吉清, 兰凤崇. 逆子结构传递路径分析方法[J]. 吉林大学学报(工学版), 2015, 45(6): 1751-1756. |

| [6] | 郝志勇, 丁政印, 孙强. 基于FE-SEA混合法研究高速列车静音地板的隔声性能[J]. 吉林大学学报(工学版), 2015, 45(4): 1069-1075. |

| [7] | 王彬星, 郑四发, 刘海涛, 连小珉. 基于现场测量的多孔材料声学特性参数估计 [J]. , 2012, (03): 545-550. |

| [8] | 邓江华,刘献栋,单颖春. 基于近场声全息的车内噪声贡献量[J]. 吉林大学学报(工学版), 2010, 40(03): 666-0671. |

| [9] | 王中兴, 荣亮亮, 林君. 地面核磁共振找水信号中的奇异干扰抑制[J]. 吉林大学学报(工学版), 2009, 39(05): 1282-1287. |

| [10] | 梁杰, 陆晓军, 孙巍. S493Q柴油机噪声源识别与噪声控制[J]. 吉林大学学报(工学版), 2001, (3): 57-60. |

| [11] | 尚新磊, 林君, 田瑜娟, 王应吉. 继电器平滑切换技术及其在核磁共振感应系统中的应用[J]. 吉林大学学报(工学版), 2011, 41(02): 398-0402. |

| [12] | 常振臣, 王登峰, 周淑辉, 郭骁. 车内噪声控制技术研究现状及展望[J]. 吉林大学学报(工学版), 2002, (4): 86-90. |

| [13] | 梁杰, 孙巍, 陆晓军, 邢四海. CA498型柴油机表面辐射噪声源的识别及其降噪措施[J]. 吉林大学学报(工学版), 2003, (1): 107-109. |

|