吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (1): 211-220.doi: 10.13229/j.cnki.jdxbgxb.20230306

• 交通运输工程·土木工程 • 上一篇

玄武岩纤维网格水泥基复合材料加固RC梁抗剪性能试验

- 1.吉林建筑大学 土木工程学院,长春 130011

2.中建八局华中建设有限公司 安徽分公司,安徽 阜阳 236000

Experiment on shear performance of RC beams strengthened with basalt fiber grid cement-based composites

Hao JIANG1( ),Zheng-wen ZHAO1,2

),Zheng-wen ZHAO1,2

- 1.College of Civil Engineering,Jilin Jianzhu University,Changchun 130011,China

2.China Construction Eight Bureau Central China Construction Co. ,Ltd. ,Anhui Branch,Fuyang 236000,China

摘要:

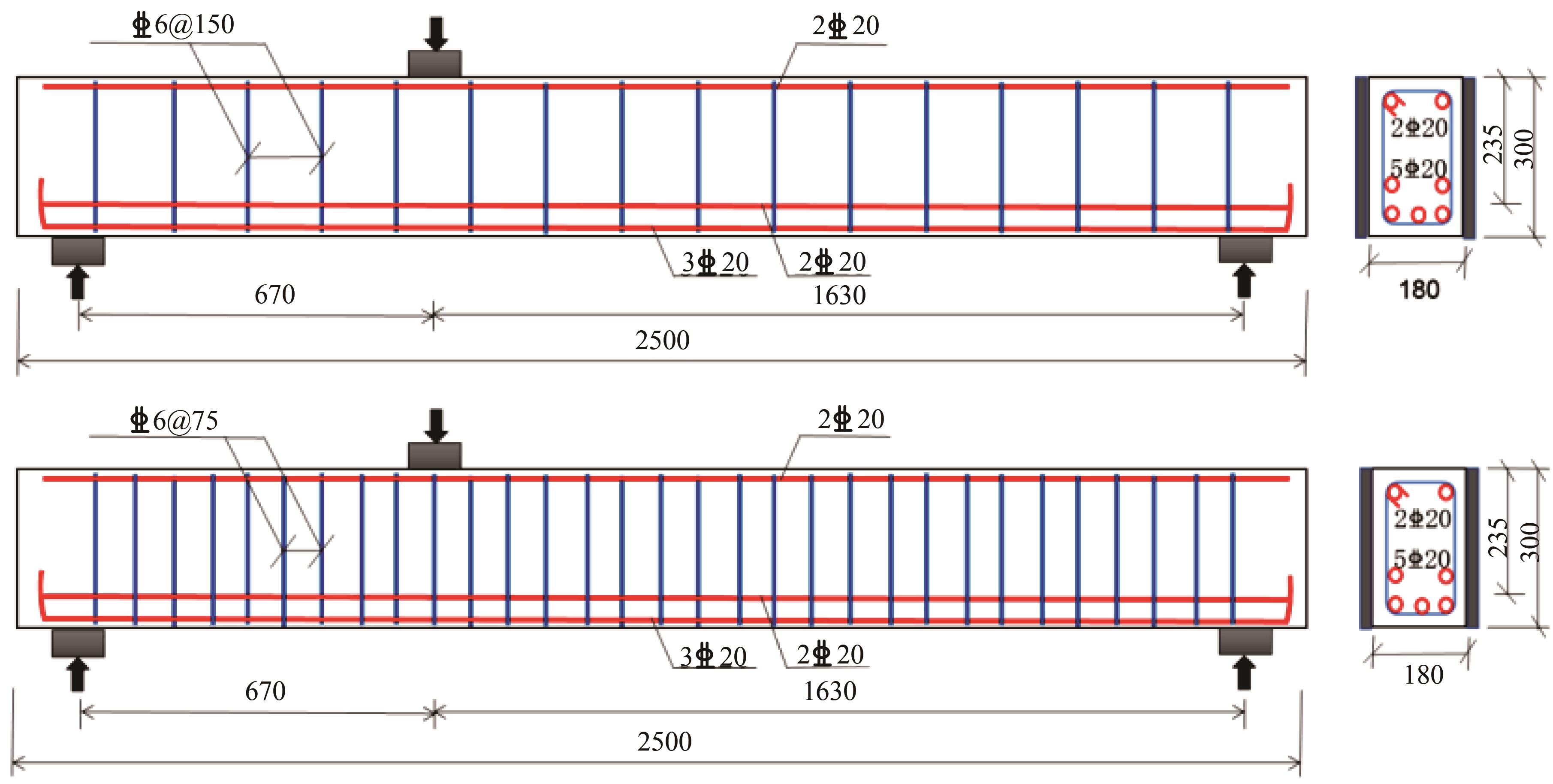

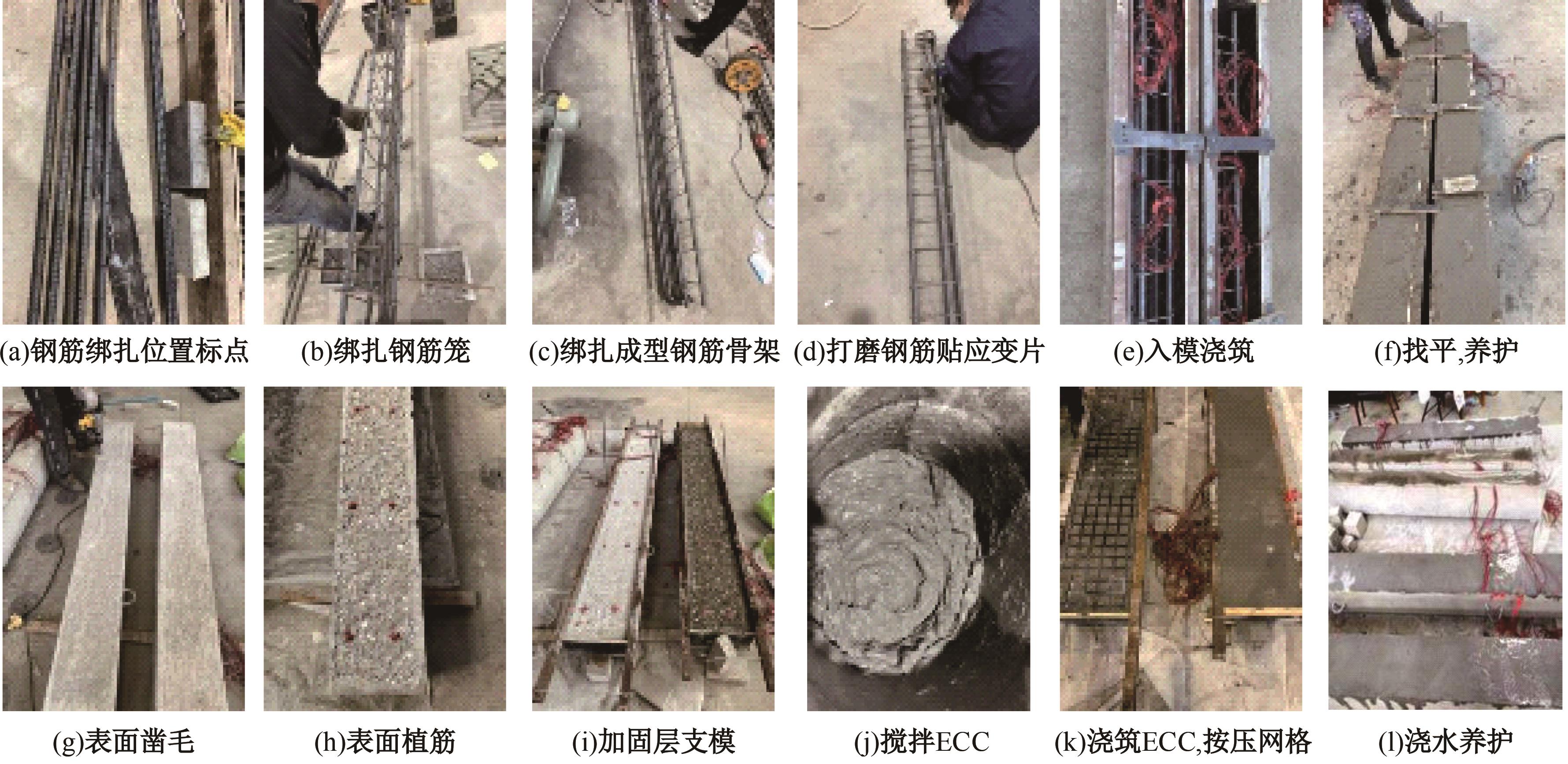

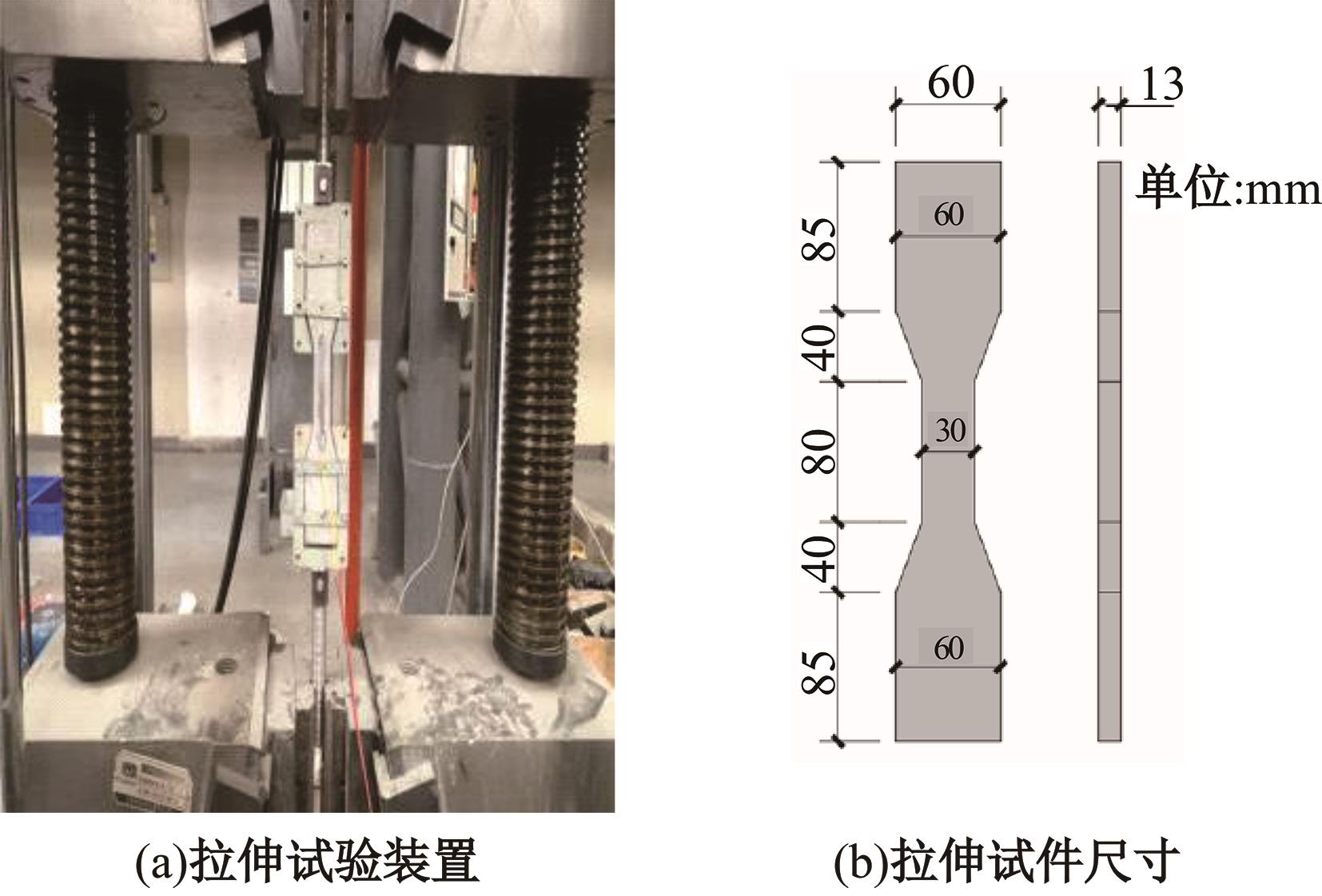

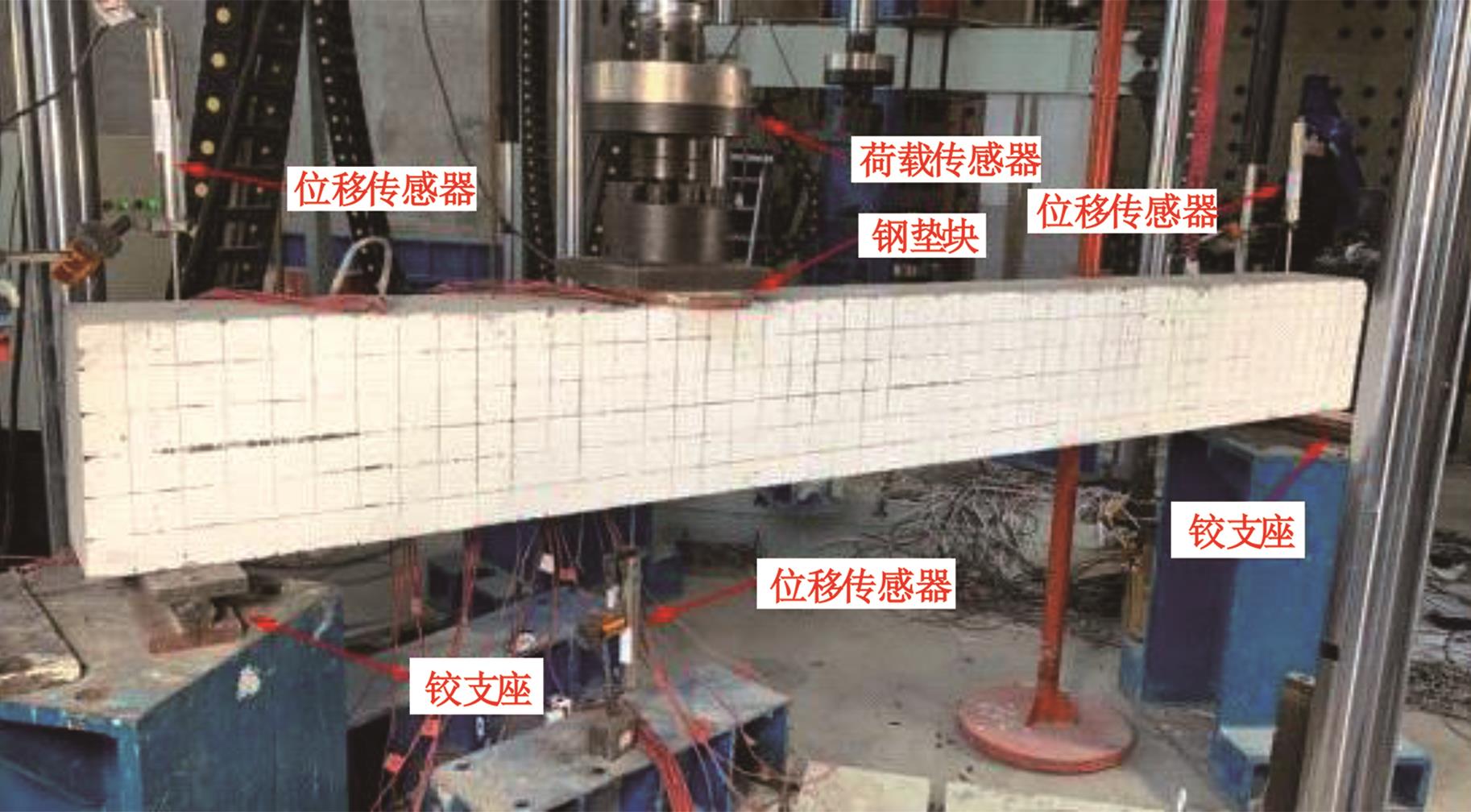

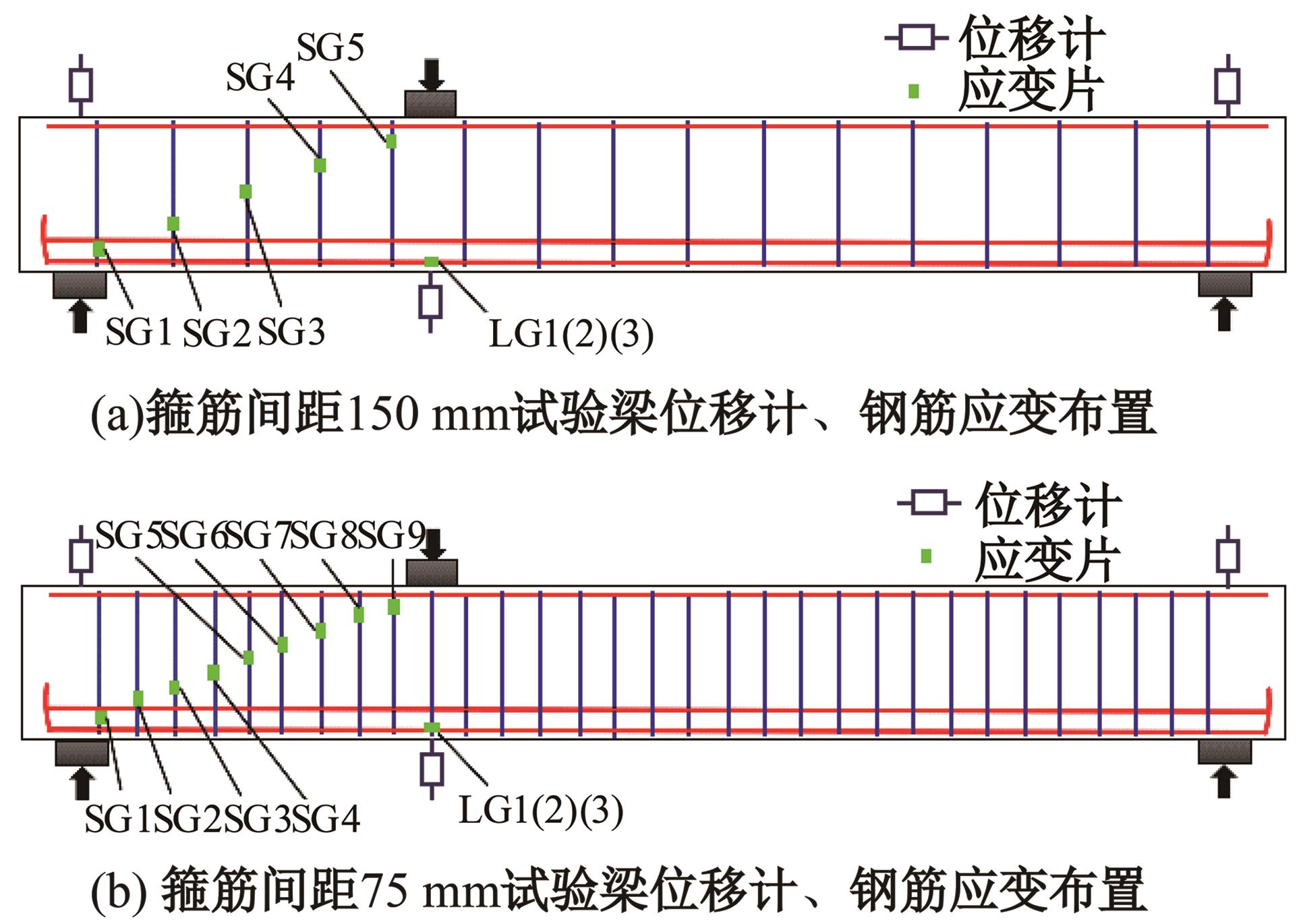

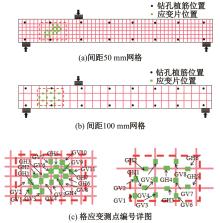

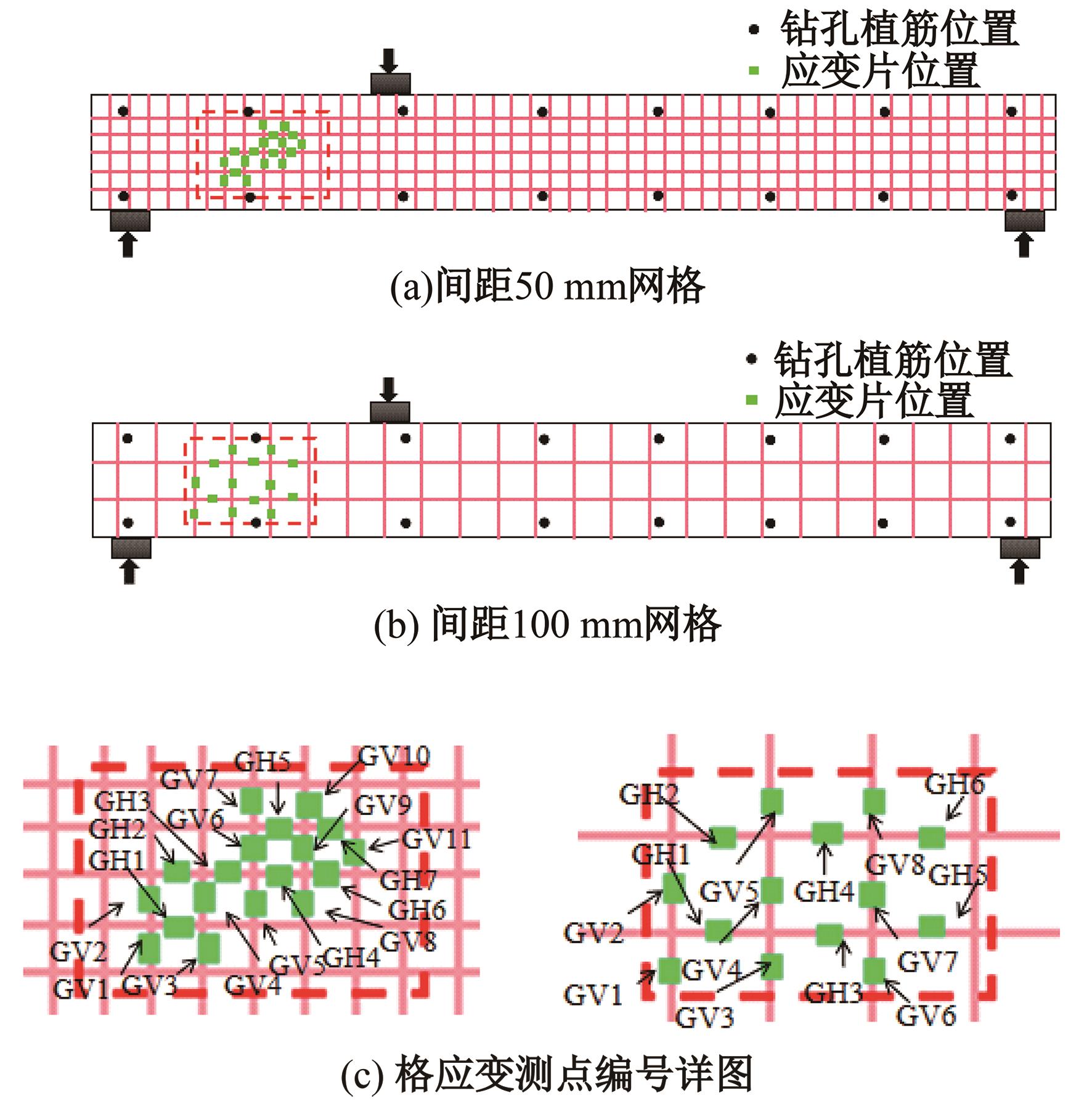

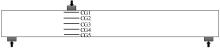

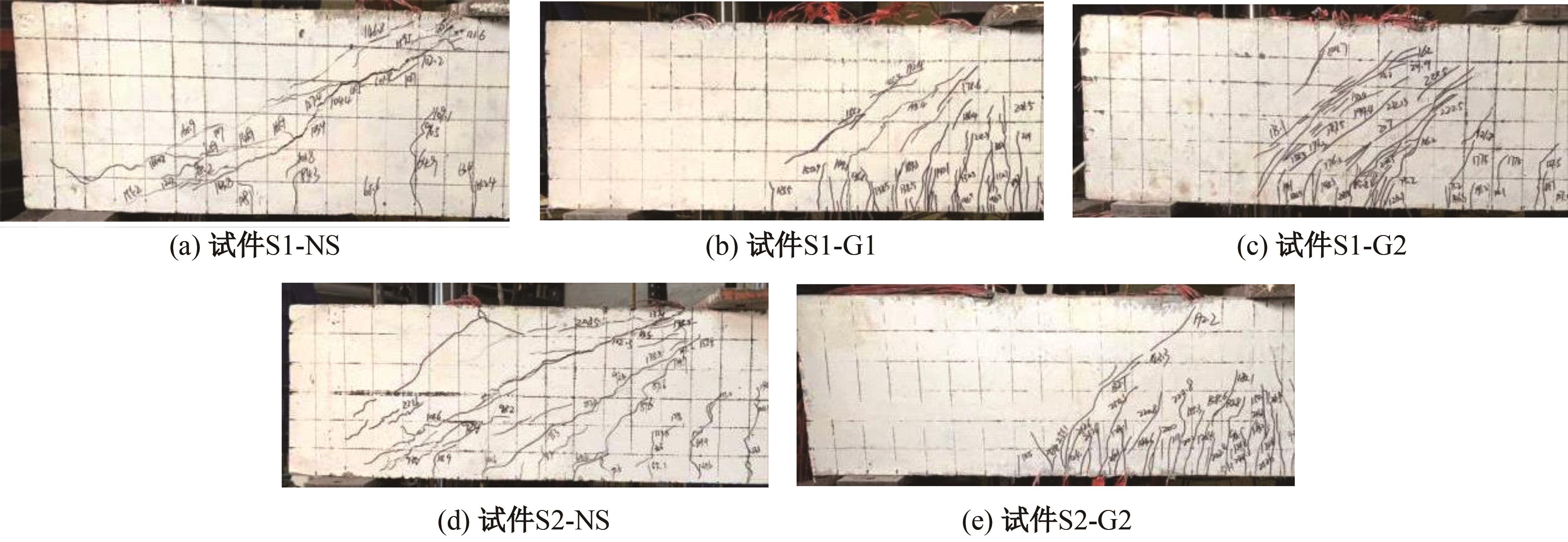

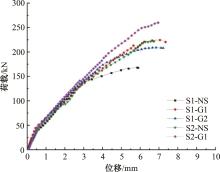

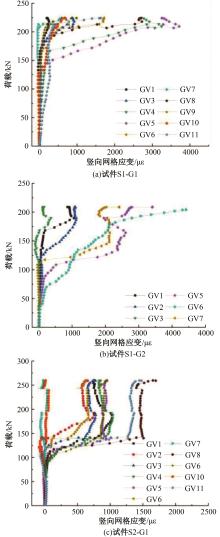

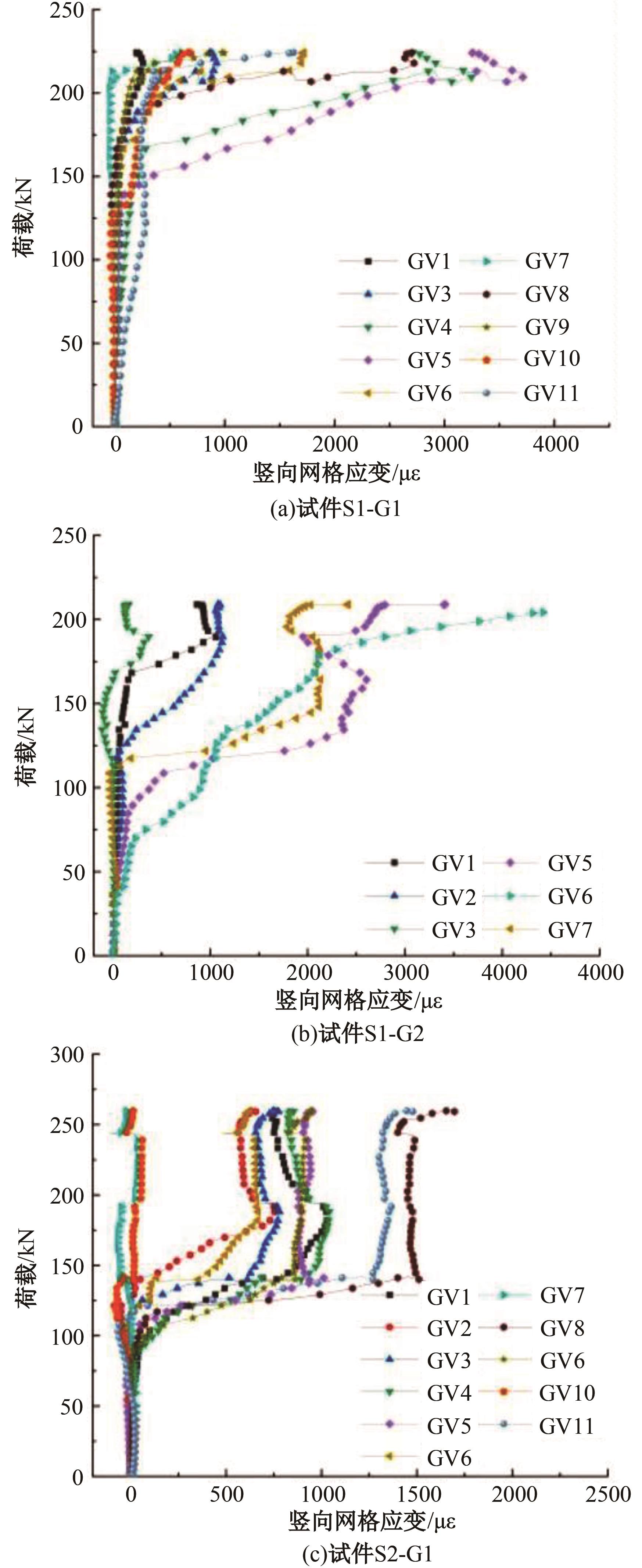

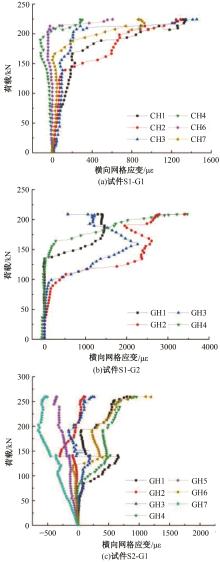

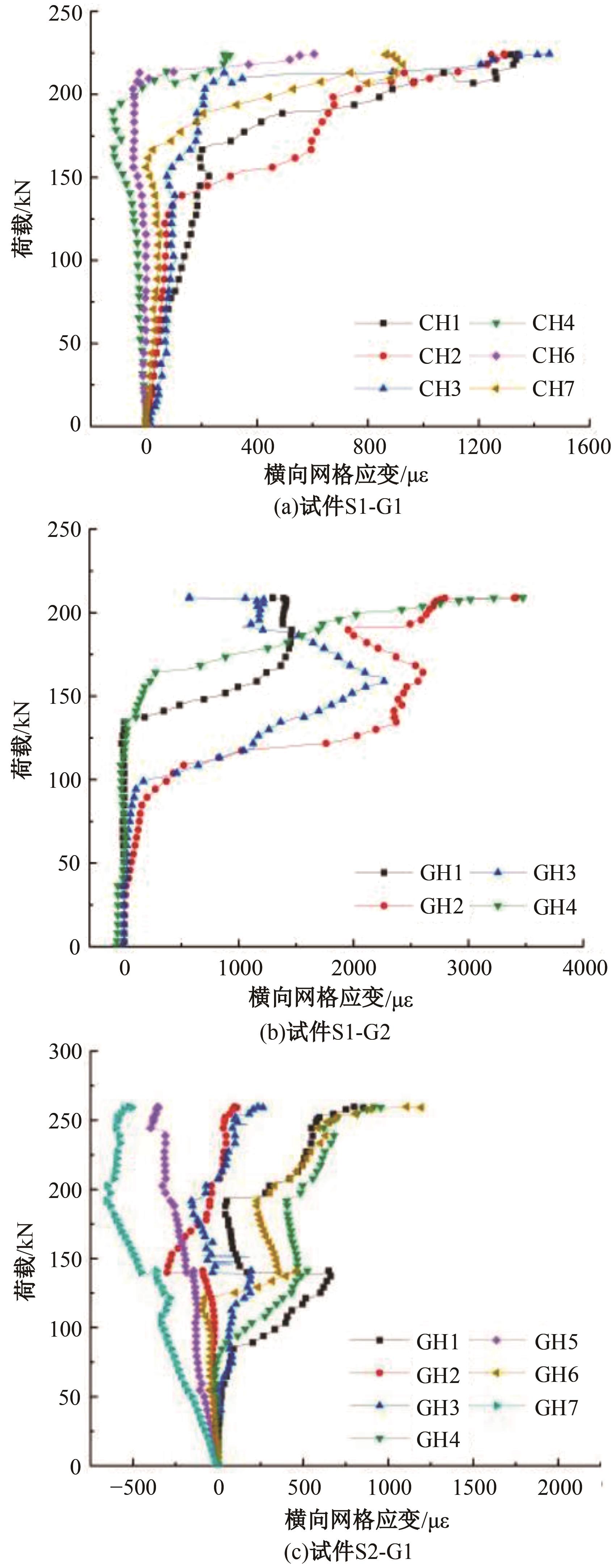

通过5根试验梁进行三点弯曲静力加载试验,研究了玄武岩纤维网格水泥基复合材料(Basalt fabric-reinforced cementitious matrix,B-FRCM)对钢筋混凝土梁的抗剪加固效果的影响,分析了试验梁的破坏形态以及玄武岩纤维增强复合材料(Basalt fiber reinforced polymer, BFRP)网格在受力过程中的抗剪贡献,并将试验结果与收集的计算模型进行对比。结果表明:采用B-FRCM加固后的RC梁抗剪承载力有较为明显的提升,提升幅值在24%~33%;B-FRCM加固可有效抑制斜裂缝发展,延缓极限状态的出现;在已有4种计算模型中,都高估了BFRP网格的抗剪贡献。

中图分类号:

- TU375.1

| 1 | 邢丽丽, 孔祥清. 外贴FRP加固钢筋混凝土梁结构性能研究进展[J]. 混凝土, 2018(9): 40-44. |

| Xing Li-li, Kong Xiang-qing. Research progress on structural performance of reinforced concrete beams strengthened with FRP[J]. Concrete, 2018(9): 40-44. | |

| 2 | Li W W, Huang Z Q, Huang Z F, et al. Shear behavior of RC beams with corroded stirrups strengthened using FRP laminates: effect of the shear span-to-depth ratio[J]. Journal of Composites for Construction, 2020, 24(4): No.4020033. |

| 3 | 张海霞, 孙闯, 李程翔. 内嵌FRP筋加固混凝土梁的抗剪性能研究[J]. 沈阳建筑大学学报:自然科学版,2018, 34(3): 419-429. |

| Zhang Hai-xia, Sun Chuang, Li Cheng-xiang. Study on shear behavior of concrete beams strengthened with embedded FRP bars[J]. Journal of Shenyang Architecture University(Natural Science Edition), 2018,34(3): 419-429. | |

| 4 | 叶华文, 唐诗晴, 段智超, 等. 预应力纤维增强复合材料(FRP)桥梁结构加固应用2020年度研究进展[J]. 土木与环境工程学报: 中英文, 2021, 43():185-189. |

| Ye Hua-wen, Tang Shi-qing, Duan zhi-chao, et al. Research progress of prestressed fiber reinforced polymer (FRP) bridge structure reinforcement in 2020[J]. Journal of Civil and Environmental Engineering (Chinese and English), 2021,43(Sup.1): 185-189. | |

| 5 | D'Antino T, Focacci F, Sneed L H,et al. Relationship between the effective strain of PBO FRCM-strengthened RC beams and the debonding strain of direct shear tests[J]. Engineering Structures,2020,216(C): No.110631. |

| 6 | Feng R, Liu Y X, Zhu J H, et al. Flexural behaviour of C-FRCM strengthened corroded RC continuous beams[J]. Composite Structures,2020,245:No. 112200. |

| 7 | Hadad H A, Erickson B, Nanni A. Flexural analysis and design of FRCM-strengthened RC beams[J]. Construction and Building Materials,2020,244(C):No.118371. |

| 8 | Younis A, Ebead U, Shrestha K C. Different FRCM systems for shear-strengthening of reinforced concrete beams[J]. Construction and Building Materials,2017,153: 514-526. |

| 9 | 王姝燏. B-FRCM加固钢筋混凝土梁抗弯性能有限元分析[D]. 长春:吉林建筑大学土木工程学院, 2019. |

| Wang Shu-yu. Finite element analysis of flexural behavior of reinforced concrete beams strengthened with B-FRCM[D]. Changchun: College of Civil Engineering, Jilin Jianzhu University,2019. | |

| 10 | 王娟. 玄武岩纤维的生产及其应用[J]. 国际纺织导报,2022, 50(2): 3-6. |

| Wang Juan. Production and application of basalt fiber [J]. International Textile Herald, 2022,50(2): 3-6. | |

| 11 | .混凝土结构试验方法标准 [S]. |

| 12 | 罗利波. 高性能复合砂浆钢筋网抗剪加固混凝土梁试验研究[J]. 建筑科学, 2013, 29(5): 52-55. |

| Luo Li-bo.Experimental study on shear strengthened concrete beams with high performance composite mortar mesh[J].Building Science, 2013, 29(5): 52-55. | |

| 13 | 陈文永, 陈小兵, 丁一, 等. 纤维网格及ECC材料抗剪加固性能研究[J]. 工业建筑, 2009, 39(12):118-122. |

| Chen Wen-yong, Chen Xiao-bing, Ding Yi, et al. Research on shear reinforcement performance of fiber grid and ECC materials[J]. Industrial Building, 2009, 39(12): 118-122. | |

| 14 | Blanksvärd T, Täljsten B, Carolin A. Shear strengthening of concrete structures with the use of mineral-based composites[J]. Journal of Composites for Construction, 2009, 13(1): 25-34. |

| 15 | Guo R, Pan Y, Cai L H, et al. Study on design formula of shear capacity of RC beams reinforced by CFRP grid with PCM shotcrete method[J]. Engineering Structures, 2018, 166(5): 427-440. |

| [1] | 赵金全,周龙,丁永刚,朱熔基. 螺旋箍筋-波纹管浆锚连接锚固性能试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2484-2494. |

| [2] | 杨伟松,张安,许卫晓,李海生,杜轲. 刚度增强型金属连梁阻尼器的抗震性能[J]. 吉林大学学报(工学版), 2024, 54(9): 2469-2483. |

| [3] | 阎奇武,邹忠亮. 减震结构阻尼器优化布置混合算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2267-2274. |

| [4] | 姜封国,周玉明,白丽丽,梁爽. 改进磷虾群算法及其在结构优化中的应用[J]. 吉林大学学报(工学版), 2024, 54(8): 2256-2266. |

| [5] | 张广泰,周乘孝,刘诗拓. 盐渍土环境下纤维锂渣混凝土柱恢复力模型[J]. 吉林大学学报(工学版), 2024, 54(7): 1944-1957. |

| [6] | 刁延松,任义建,杨元强,赵凌云,刘秀丽,刘芸. 带有摩擦耗能组件的可更换钢梁柱拼接节点抗震性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1643-1656. |

| [7] | 樊学平,刘月飞. 基于改进高斯混合粒子滤波新算法的桥梁极值应力动态预测[J]. 吉林大学学报(工学版), 2024, 54(4): 1038-1044. |

| [8] | 刘一凡,缪志伟,申晨,耿祥东. 基于蒙特卡罗法的不均匀锈蚀钢筋力学性能评估[J]. 吉林大学学报(工学版), 2024, 54(4): 1007-1015. |

| [9] | 樊学平,周衡,刘月飞. 基于Gaussian Copula-贝叶斯动态模型的桥梁构件时变可靠性分析[J]. 吉林大学学报(工学版), 2024, 54(2): 485-493. |

| [10] | 杨海旭,郭悦,王海飙,胡宜. 冷弯薄壁型钢-胶合木组合梁受弯性能[J]. 吉林大学学报(工学版), 2024, 54(12): 3513-3525. |

| [11] | 范亮,徐英铭,谭阳. 集束群钉式装配组合梁界面滑移计算[J]. 吉林大学学报(工学版), 2023, 53(9): 2533-2541. |

| [12] | 樊学平,周衡,刘月飞. 桥梁时变可靠性的多过程贝叶斯动态混合预测[J]. 吉林大学学报(工学版), 2023, 53(8): 2332-2338. |

| [13] | 熊二刚,巩忠文,罗佳明,范团结. 基于数字图像相关技术的钢筋混凝土梁裂缝试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1094-1104. |

| [14] | 王晓东,李宁静,李强. 高压脉冲放电破碎混凝土梁试验[J]. 吉林大学学报(工学版), 2023, 53(2): 496-504. |

| [15] | 匡亚川,陈立斌,李超举,贺宇豪. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报(工学版), 2023, 53(2): 538-546. |

|

||