吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (7): 1944-1957.doi: 10.13229/j.cnki.jdxbgxb.20221118

• 交通运输工程·土木工程 • 上一篇

盐渍土环境下纤维锂渣混凝土柱恢复力模型

- 1.新疆大学 建筑工程学院,乌鲁木齐 830017

2.新疆大学 新疆建筑结构与抗震重点实验室,乌鲁木齐 830017

3.重庆市万州区市政设施维护管理中心,重庆 404100

Restoring force model of fiber lithium slag concrete column in saline soil environment

Guang-tai ZHANG1,2( ),Cheng-xiao ZHOU1,Shi-tuo LIU3

),Cheng-xiao ZHOU1,Shi-tuo LIU3

- 1.School of Engineering,Xinjiang University,Urumqi 830017,China

2.Key Laboratory of Building Structure and Earthquake Resistance,Xinjiang University,Urumqi 830017,China

3.Chongqing Wanzhou District Municipal Facilities Maintenance Management Center,Chongqing 404100,China

摘要:

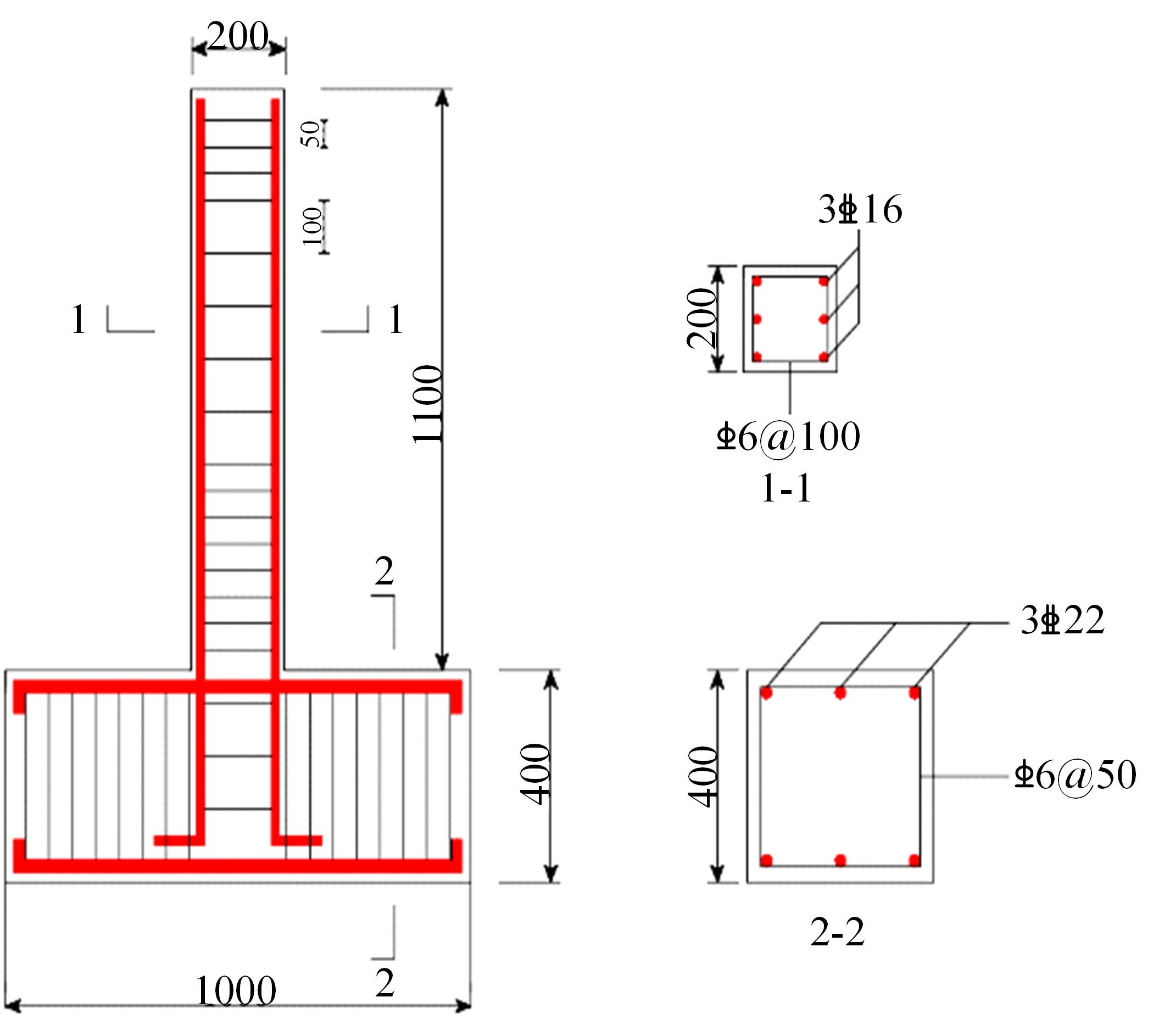

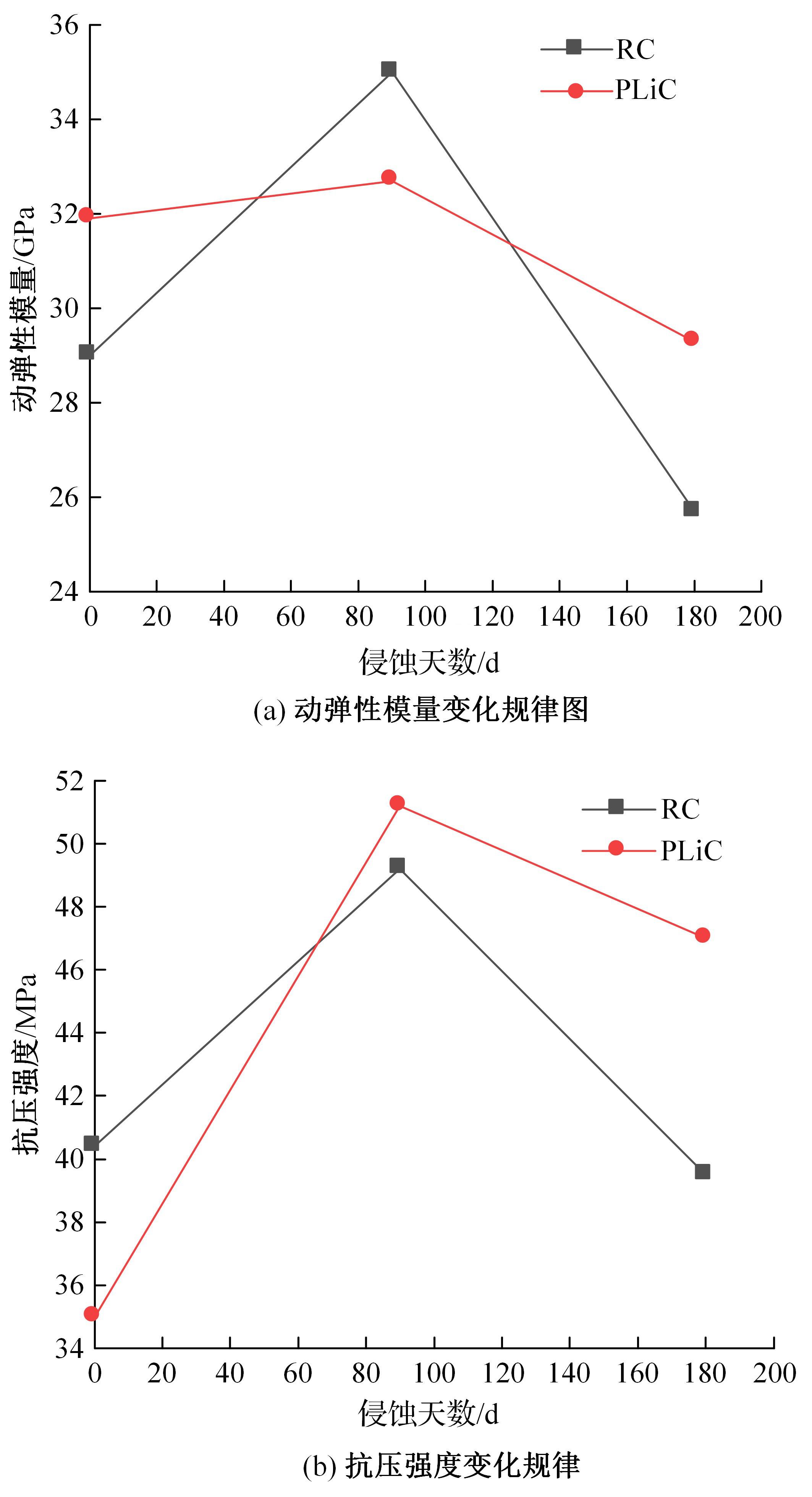

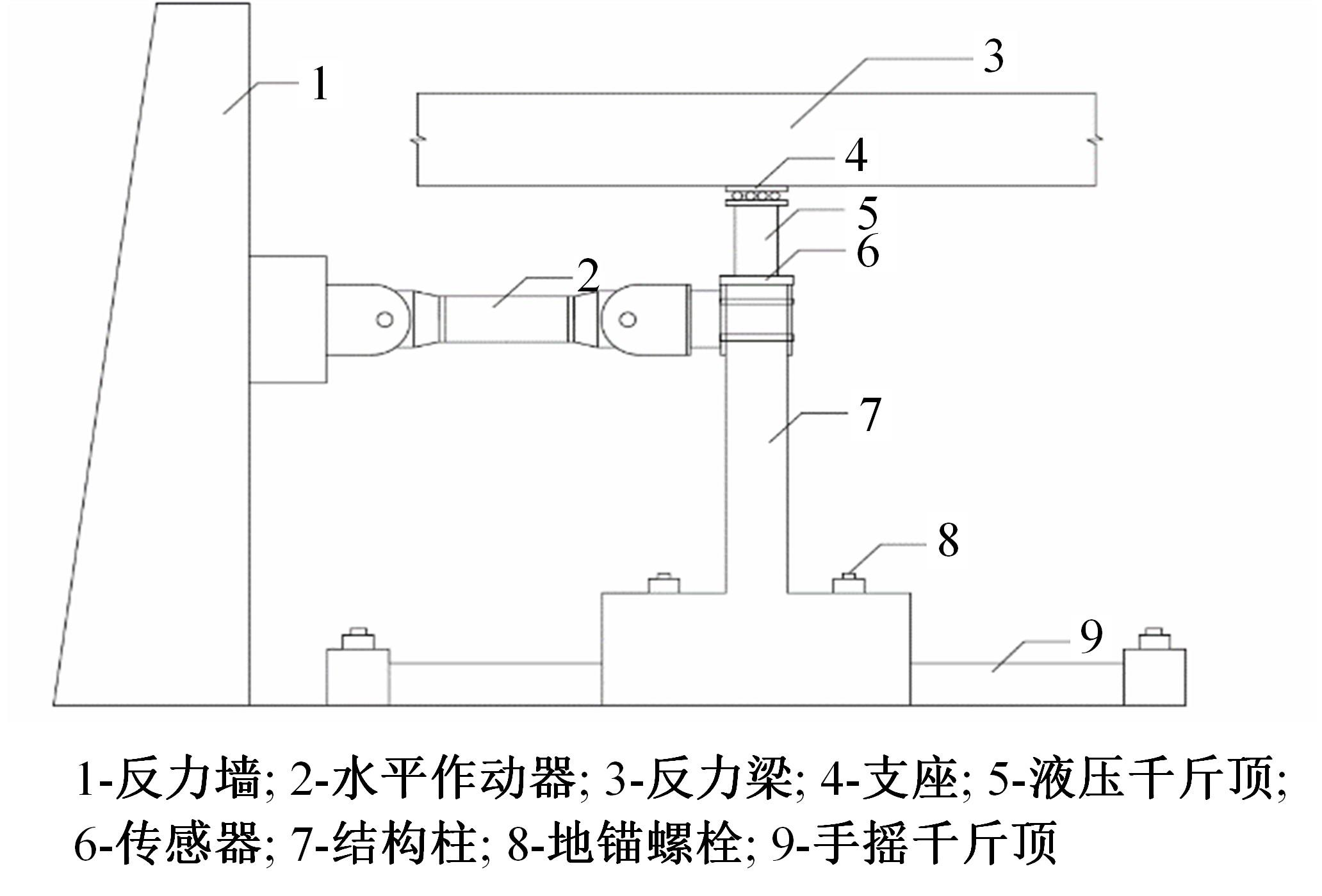

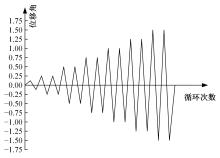

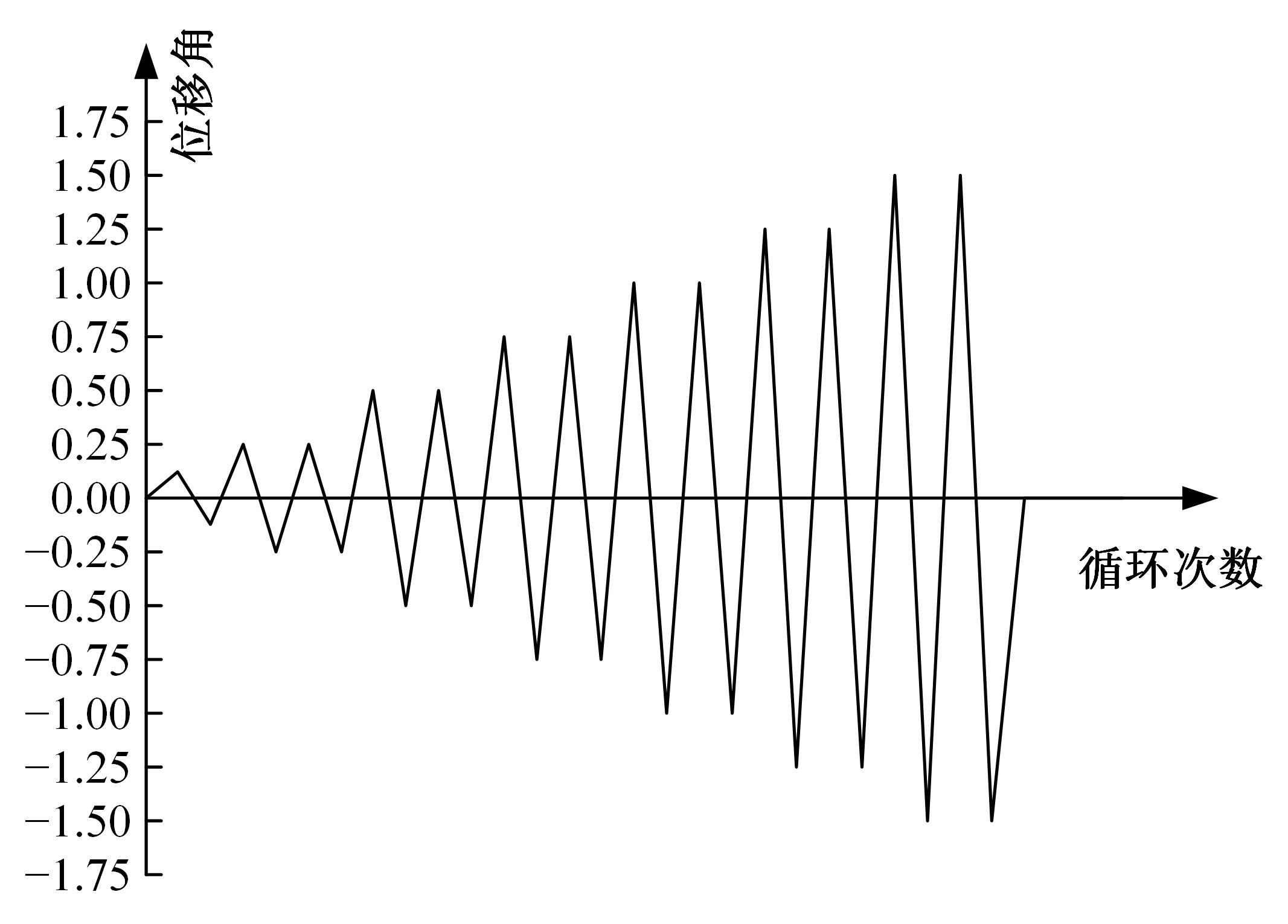

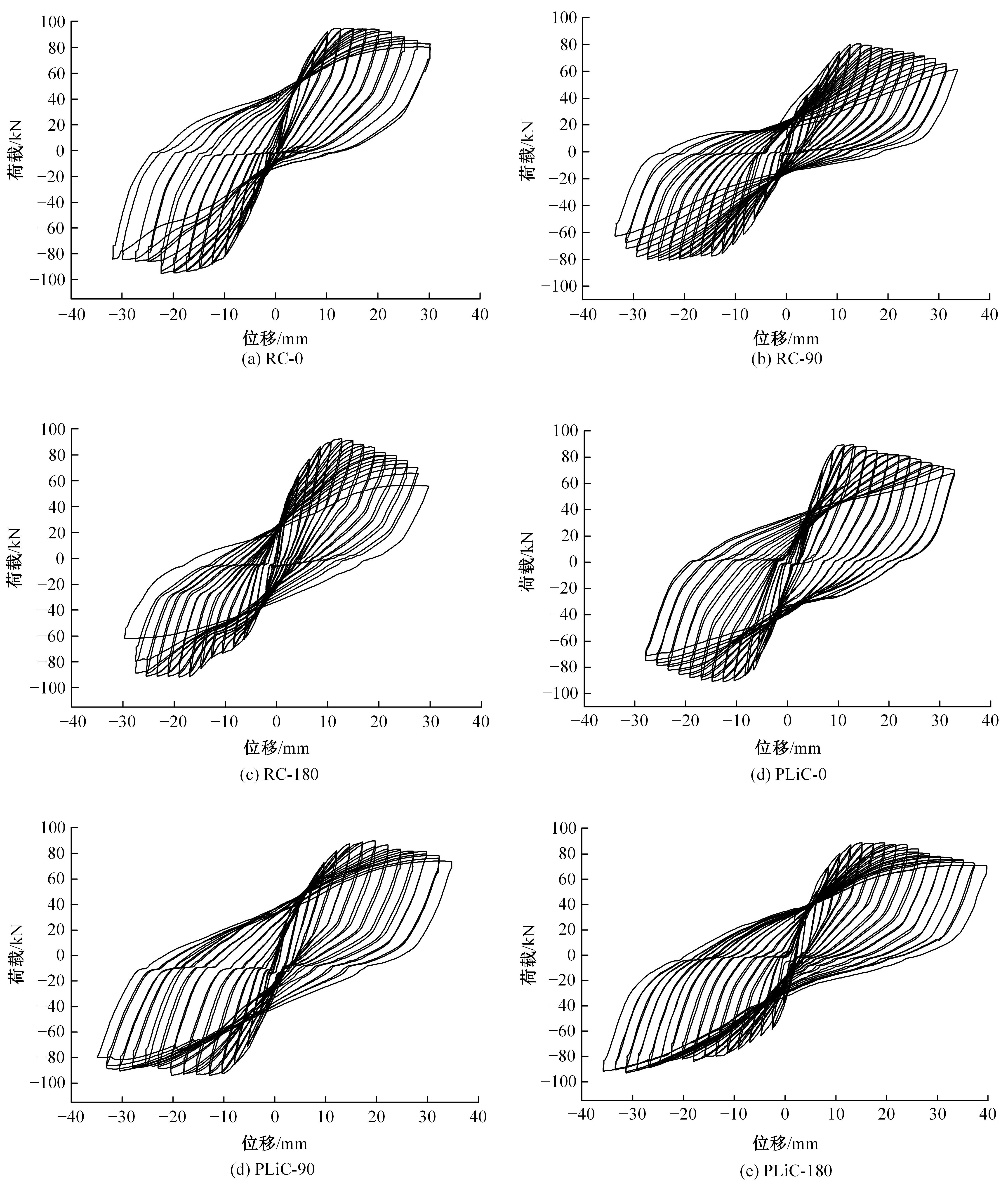

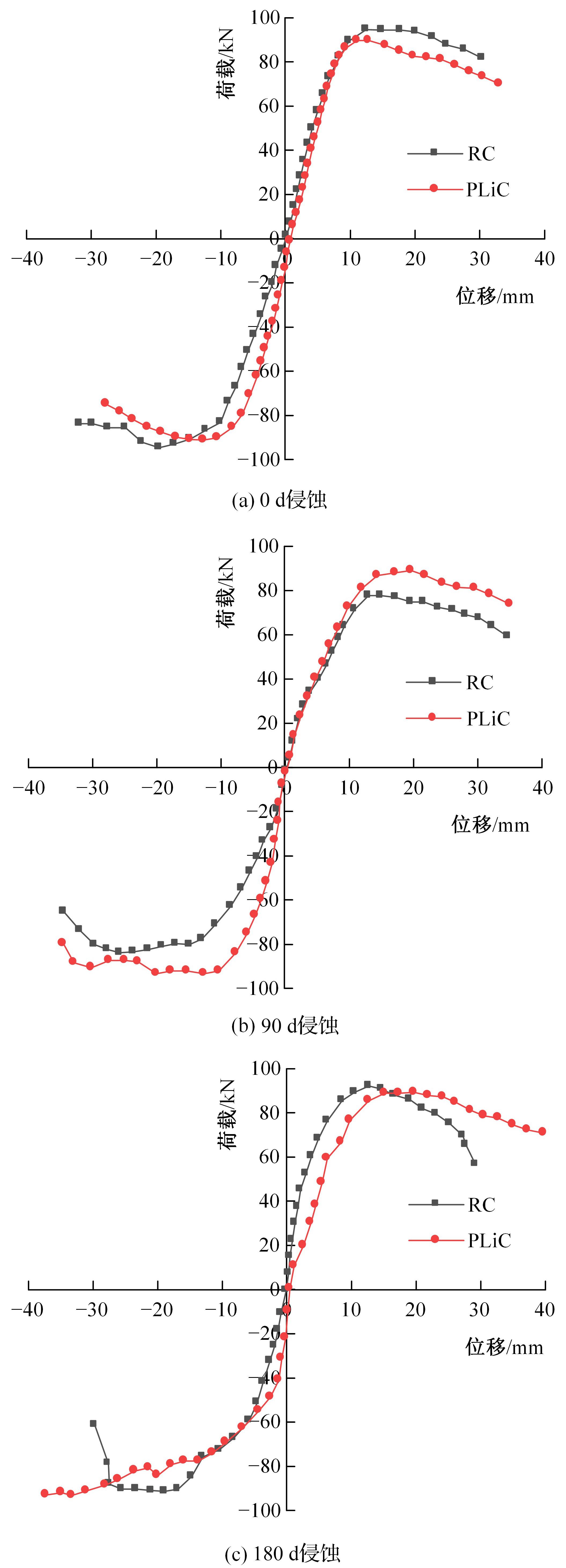

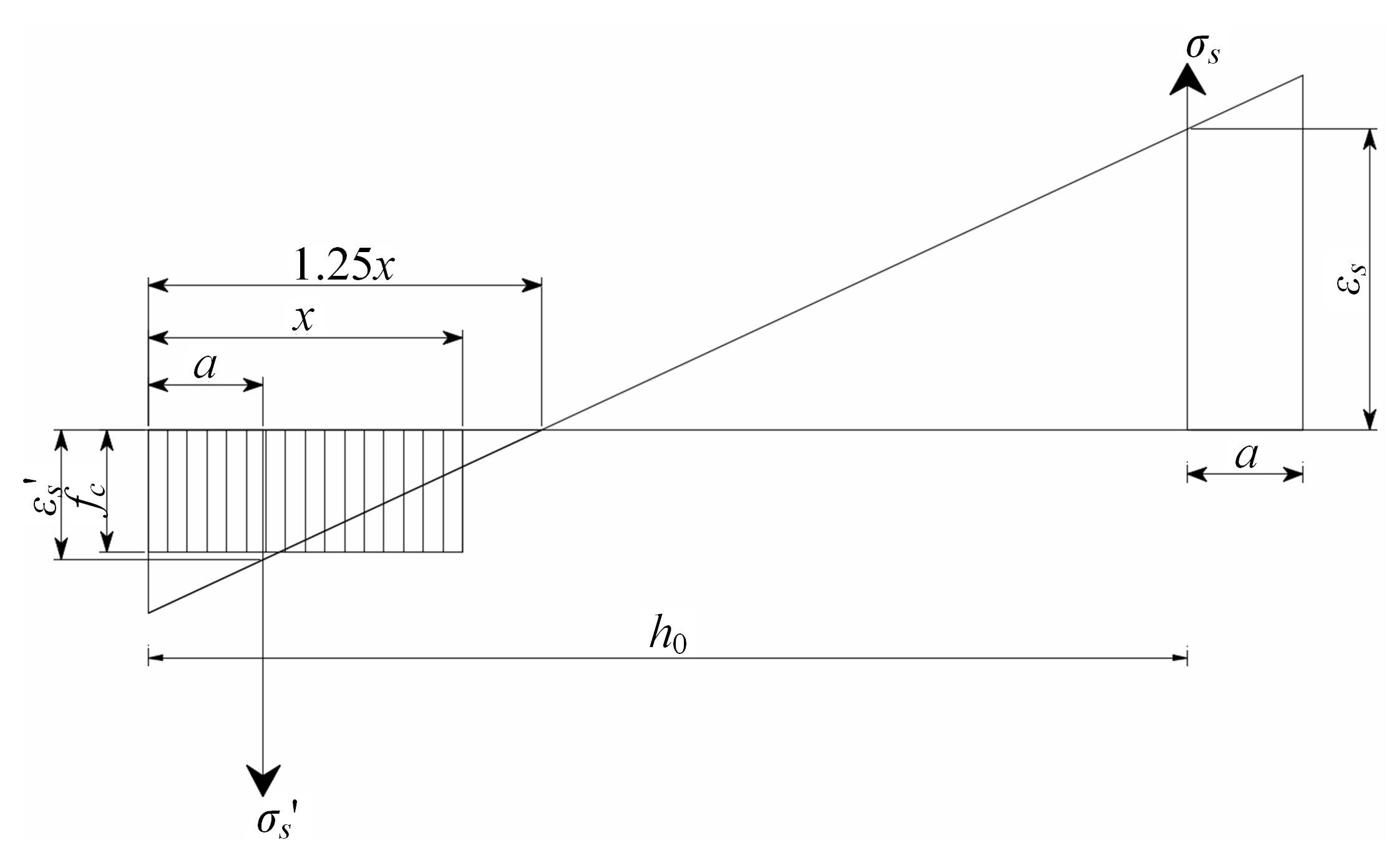

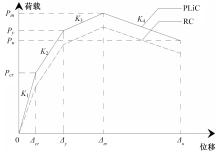

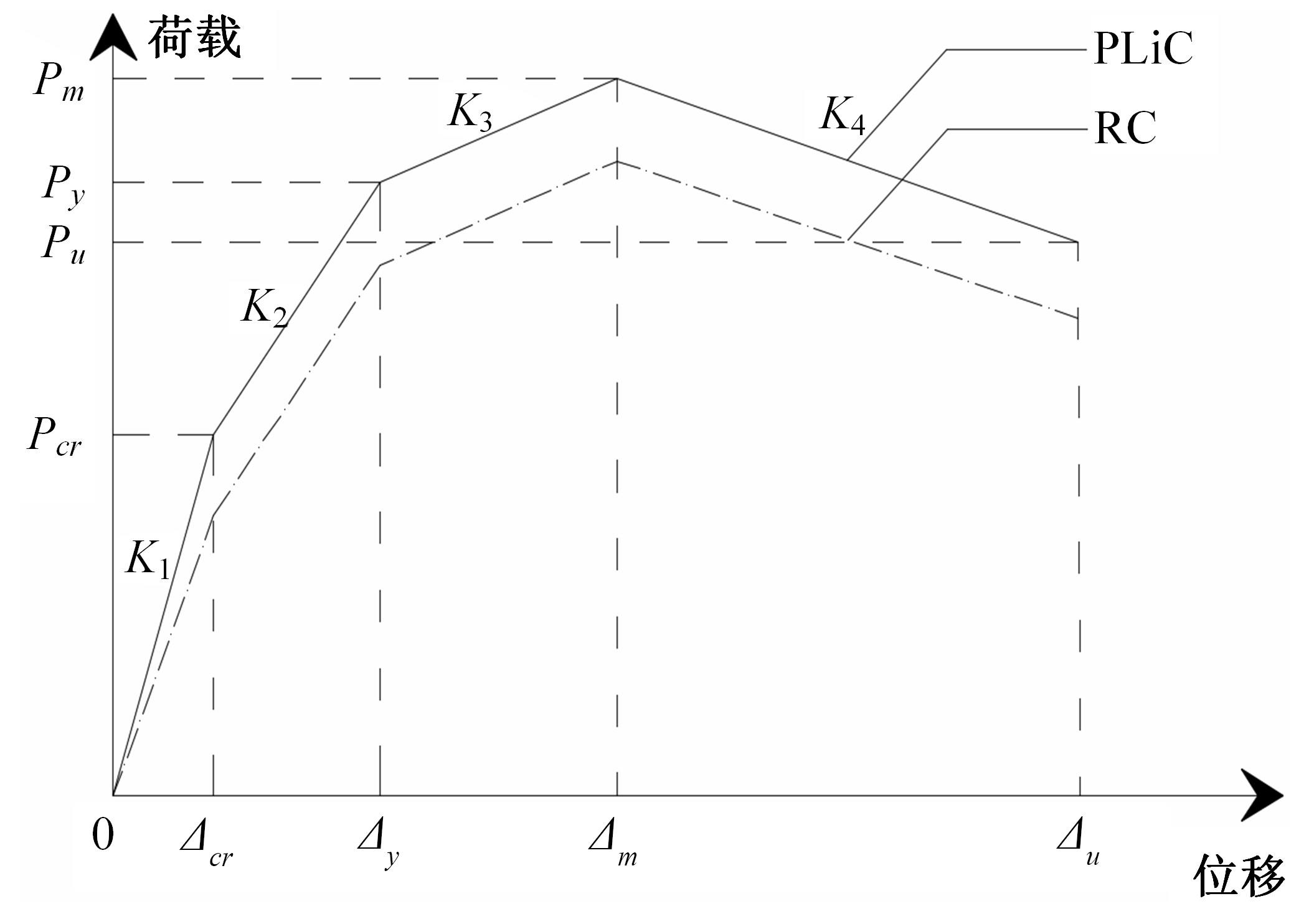

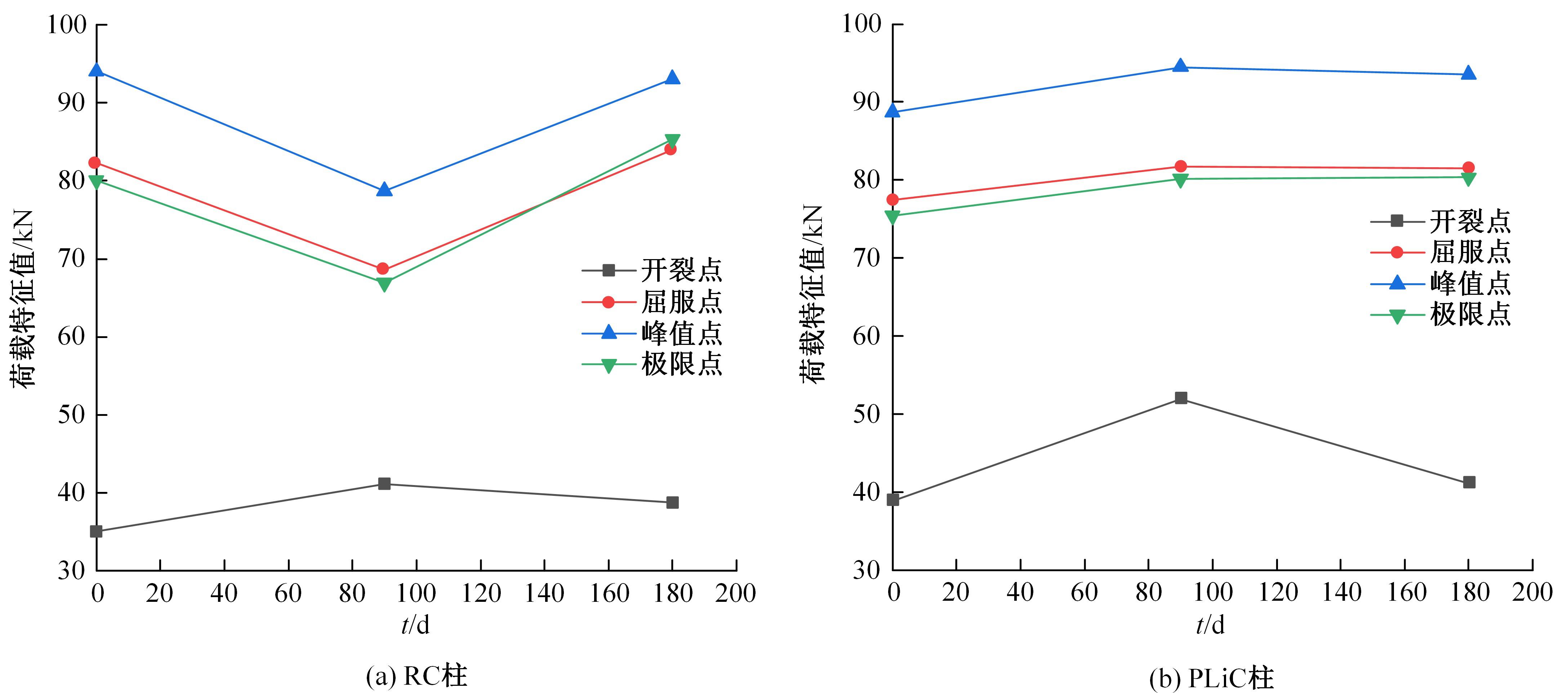

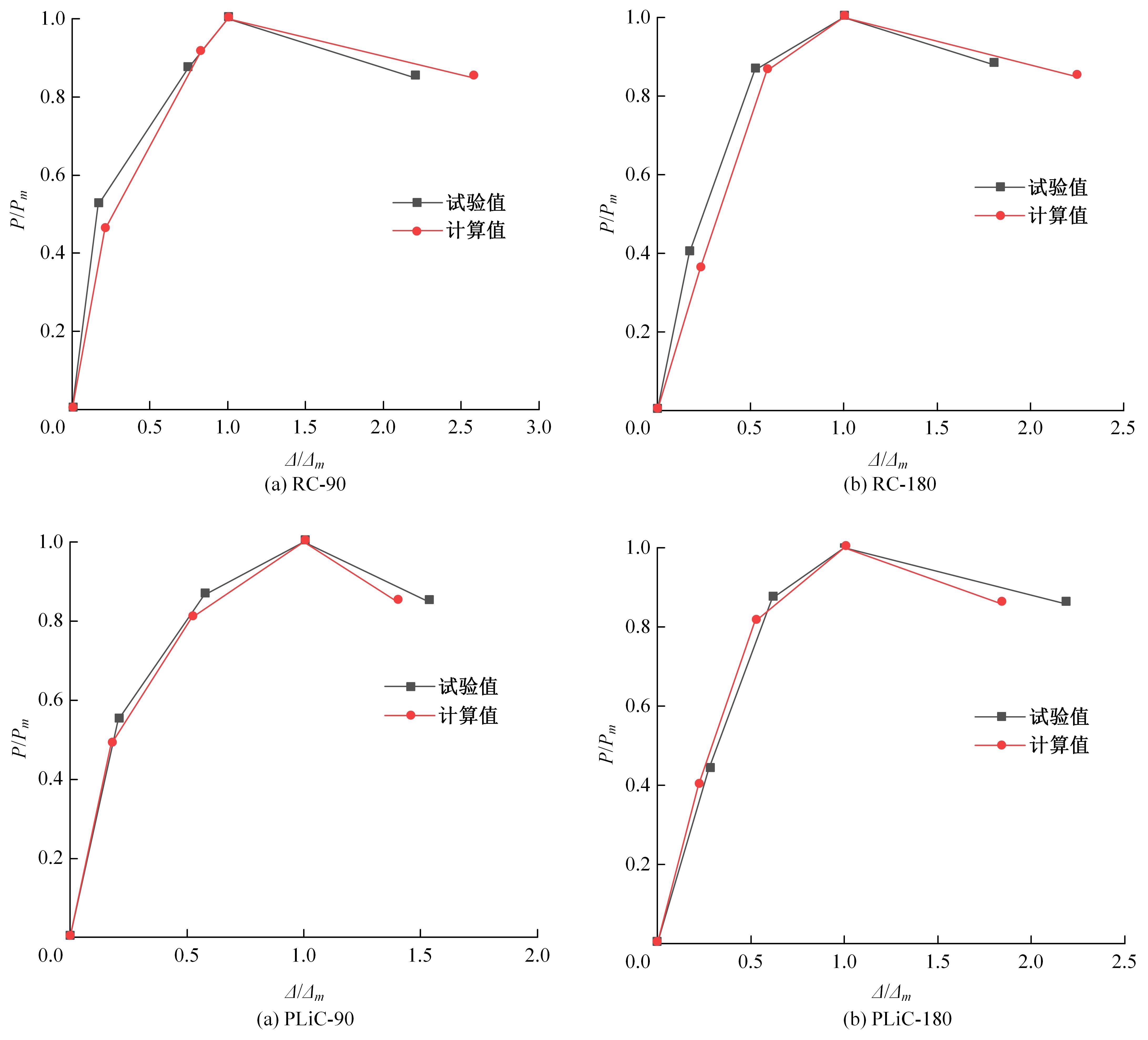

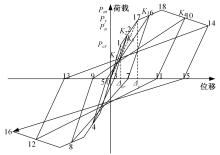

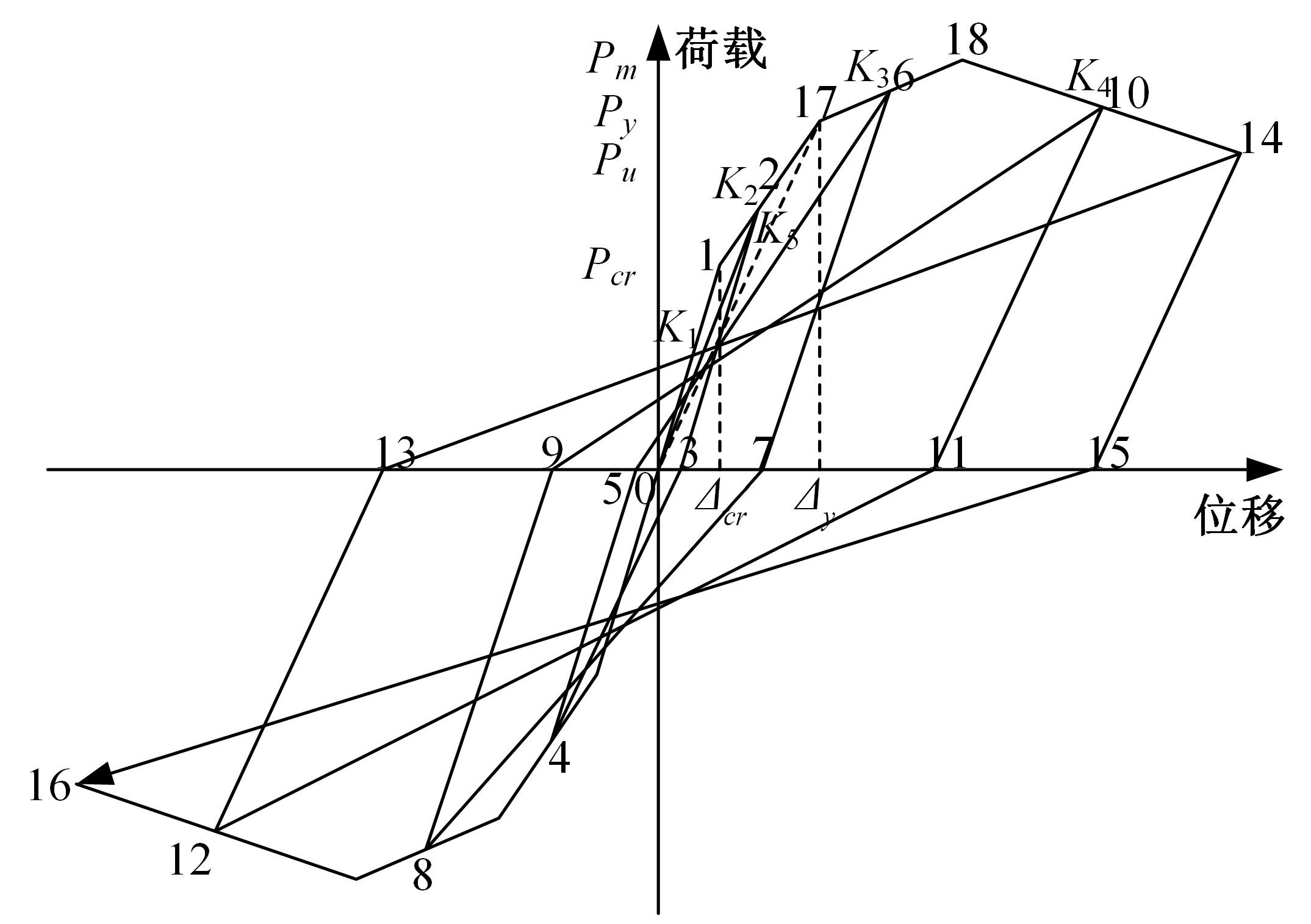

为研究聚丙烯纤维锂渣混凝土(PLiC)柱在盐渍土环境下的抗震性能,对6根试验柱进行低周反复荷载试验。基于试验结果,得到四折线骨架曲线,并在众学者的研究基础上考虑纤维和锂渣的作用,通过回归分析得到各特征点修正系数计算公式。结合侵蚀时间的影响,引入刚度退化指数μ和损伤因子D,采用适用于PLiC柱承载力衰减、刚度退化的滞回规则,建立了盐渍土环境作用下的PLiC柱力-位移恢复力模型。结果表明,加入聚丙烯纤维和锂渣可一定程度上提高混凝土柱的极限承载力、延性等力学性能及耐久性。由本文恢复力模型得到的骨架曲线、滞回曲线与试验结果吻合度良好,可为盐渍土环境下聚丙烯纤维锂渣混凝土柱抗震性能非线性分析提供参考。

中图分类号:

- TU375.3

| 1 | 孙志诚, 郭迅.钢筋混凝土匹配度对框架柱破坏模式影响试验研究[J].土木工程学报,2020,53():80-86. |

| Sun Zhi-cheng, Guo Xun. Experimental study on influence of reinforced concrete matching degree on failure mode of frame columns[J]. China Civil Engineering Journal,2020,53(Sup.2):80-86. | |

| 2 | 邵旭东,樊伟,黄政宇.超高性能混凝土在结构中的应用[J].土木工程学报,2021,54(1):1-13. |

| Shao Xu-dong, Fan Wei, Huang Zheng-yu. Application of ultra-high-performance concrete in engineering structures[J]. China Civil Engineering Journal,2021,54(1):1-13. | |

| 3 | Jamshaid H, Mishra R, Militký J, et al. Interfacial performance and durability of textile reinforced concrete[J]. The Journal of The Textile Institute, 2018, 109(7): 879-890. |

| 4 | Jamshaid H, Mishra R, Militky J, et al. Mechanical, thermal and interfacial properties of green composites from basalt and hybrid woven fabrics[J]. Fibers and Polymers, 2016, 17(10): 1675-1686. |

| 5 | Liu Y Z, Wang L, Cao K, et al. Review on the durability of polypropylene fibre-reinforced concrete[J]. Advances in Civil Engineering, 2021, 13:No.6652077. |

| 6 | Lothenbach B, Scrivener K, Hooton R D. Supplementary cementitious materials[J]. Cement and Concrete Research, 2011, 41(12): 1244-1256. |

| 7 | He Z, Li L, Du S. Mechanical properties, drying shrinkage, and creep of concrete containing lithium slag[J]. Construction and Building Materials, 2017, 147: 296-304. |

| 8 | 过镇海, 时旭东. 钢筋混凝土原理和分析[M].北京: 清华大学出版社, 2003. |

| 9 | 韦翠梅,徐礼华,黄乐,等.钢-聚丙烯混杂纤维混凝土柱恢复力模型试验研究[J].土木工程学报,2014,47():227-234. |

| Wei Cui-mei, Xu Li-hua, Huang Le, et al. Experimental study on restoring force models for steel-polypropylene hybrid fiber reinforced concrete columns[J]. China Civil Engineering Journal,2014,47(Sup.2):227-234. | |

| 10 | 张建伟,李晨,李翔宇,等.HRB600级钢筋高强混凝土柱抗震性能试验研究[J].土木工程学报,2019,52(8):6-17. |

| Zhang Jian-wei, Li Chen, Li Xiang-yu, et al. Experimental study on seismic behavior of high-strength concrete columns with HRB600 steel bars[J]. China Civil Engineering Journal,2019,52(8):6-17. | |

| 11 | Sheng P, Zhou X, Xiang G Z. A restoring force model for CFRP seismic-damaged RACFST columns: theoretical, experimental, and simulation analysis[J]. Structures, 2022, 40:273-283. |

| 12 | Yang T, Wang S, Liu W. Restoring-force model of modified RAC columns with silica fume and hybrid fiber[J]. Journal of Central South University, 2017, 24(11): 2674-2684. |

| 13 | 李一,张广泰,田虎学,等.锂渣聚丙烯纤维混凝土基本力学性能试验[J].河南科技大学学报:自然科学版,2016,37(4):60-65. |

| Li Yi, Zhang Guang-tai, Tian Hu-xue, et al. Test on basic mechanical properties of lithium slag polypropylene fiber concrete[J]. Journal of Henan University of Science and Technology(Natural Science), 2016,37(4):60-65. | |

| 14 | 张广泰,李瑞祥,令芳,等.聚丙烯纤维锂渣混凝土与HRB500钢筋的黏结特性[J].混凝土,2022(4):1-7. |

| Zhang Guang-tai, Li Rui-xiang, Ling Fang,et al. Bonding characteristics between polypropylene fiber lithium slag concrete and HRB500 reinforcement[J]. Concrete,2022(4):1-7. | |

| 15 | . 岩土工程勘察规范 [S]. |

| 16 | Kang T H. Dynamic tests and modeling of RC and PT slab-column connections[C]∥The 100 th Anniversary Earthquake Conference, San Francisco, USA 2006: 5360-5369. |

| 17 | 郑山锁,郑跃,董立国,等.酸雨环境下锈蚀RC剪力墙恢复力模型研究[J].工程力学,2019,36(10):75-85. |

| Zheng San-suo, Zheng Yue, Dong Li-guo, et al. A restoring force model of RC shear walls in a simulated acid environment[J]. Engineering Mechanics,2019,36(10):75-85. | |

| 18 | 邹银生,王选民,刘英魁. 薄壁杆件截面剪应力分布不均匀系数的计算方法[C]∥ 第二届全国结构工程学术会议论文集(上),中国,长沙,1993:222-227. |

| Zou Yin-sheng, Wang Xuan-min, Liu Ying-kui. Calculation method of uneven coefficient of shear stress distribution in section of thin-walled member[C]∥ Proceedings of the Second National Conference on Structural Engineering (Part I),Changsha,China,1993:222-227. | |

| 19 | Zhang J, Zhao Y, Li X, et al. Experimental study on seismic performance of recycled aggregate concrete shear wall with high-strength steel bars[J].Structure, 2021, 33: 1457-1472. |

| 20 | Liu K, Yan J, Alam M S, et al. Seismic fragility analysis of deteriorating recycled aggregate concrete bridge columns subjected to freeze-thaw cycles[J]. Engineering Structures, 2019, 187:1-15. |

| 21 | . 混凝土结构设计规范 [S]. |

| 22 | 吴小勇.钢筋钢丝网砂浆加固混凝土柱的轴压、偏压及抗震滞回性能试验研究[D].汕头:汕头大学工学院, 2011. |

| Wu Xiao-yong. Experimental study on behavior of concrete columns strengthened by ferrocement including steel bars under axial compression, rccentric and seismic load[D]. Santou:College of Engineering, Santou University, 2011. | |

| 23 | Youssf O, Elgawady M A, Mills J E. Displacement and plastic hinge length of FRP-confined circular reinforced concrete columns[J]. Engineering Structures, 2015, 101:465-476. |

| 24 | Priestley M J N, Kowalsky M J. Aspects of drift and ductility capacity of rectangular cantilever structural walls[J]. Bulletin of the New Zealand Society for Earthquake Engineering, 1998, 31(2): 73-85. |

| 25 | 王铁成.混凝土结构设计原理[M].北京:中国建筑工业出版社,2012. |

| 26 | Park R, Paulay T. Reinforced Concrete Structures[M]. Hoboken:John Wiley & Sons, 1991. |

| 27 | 宋文. FRP增强和修复加固大尺寸RC方柱抗震性能研究[D].北京: 清华大学土木水利学院,2019. |

| Saravath Suong. Seismic performance of strengthened and repaired large scale square section RC columu using FRP[D]. Beijing: School of Civil Engineering,Tsinghua University,2019. | |

| 28 | Ozcan O, Binici B, Ozcebe G. Seismic strengthening of rectangular reinforced concrete columns using fiber reinforced polymers[J]. Engineering Structures, 2010, 32(4): 964-973. |

| 29 | Ozcan O, Binici B, Canbay E, et al. Repair and strengthening of reinforced concrete columns with CFRPs[J]. Journal of Reinforced Plastics and Composites, 2010, 29(22): 3411-3424. |

| 30 | Li B, Harries K A. Seismic performance assessment of flexure-dominate FRP-confined RC columns using plastic rotation angle[J]. Engineering Structures, 2018, 172:453-471. |

| 31 | Yuan F, Wu Y F, Li C Q. Modelling plastic hinge of FRP-confined RC columns[J]. Engineering Structures, 2017, 131:651-668. |

| 32 | Paulay T, Priestley M J N. Seismic design of reinforced concrete and masonry buildings[M]. Hoboken:Wiley, 1992. |

| 33 | 李冬,金浏,杜修力,等.混凝土Ⅰ-型细观断裂模型及其在材料层次尺寸效应中的应用[J].土木工程学报,2020,53(2):48-61. |

| Li Dong, Jin Liu, Du Xiu-li, et al. Concrete mode-I mesoscale fracture model and its application in analysis of size effect at material level[J]. China Civil Engineering Journal,2020,53(2):48-61. | |

| 34 | 姚谦峰, 常鹏. 工程结构抗震分析[M]. 北京:北京交通大学出版社,2012. |

| 35 | 水中和,魏小胜,王栋民.现代混凝土科学技术[M].北京:科学出版社,2014. |

| 36 | 史才军.水泥基材料中氯离子的传输及相互作用[M].北京:化学工业出版社,2021. |

| 37 | 逄锦伟.冻融循环作用下锂渣混凝土抗硫酸盐侵蚀研究[J].硅酸盐通报,2019,38(1):304-309. |

| Pang Jin-wei. Study on the sulfate corrosion resistance of concrete with lithium slag under the freezing and thawing cycles[J]. Bulletin of the Chinese Ceramic Society,2019,38(1):304-309. | |

| 38 | 张广泰, 董海蛟, 温勇. 冻融循环下锂渣粉对混凝土渗透性的影响[J]. 混凝土与水泥制品, 2015(3):83-86. |

| Zhang Guang-tai, Dong Hai-jiao, Wen Yong. Effects of lithium slag powder on permeability of concrete under freeze-thaw cycles[J]. China Concrete and Cement Products, 2015(3):83-86. | |

| 39 | 张喜娥.锂渣对混凝土徐变的影响[J]. 硅酸盐通报,2018,37(3):856-860, 867. |

| Zhang Xi-e. Effect of lithium slag on creep of concrete[J]. Bulletin of the Chinese Ceramic Society,2018,37(3):856-860, 867. |

| [1] | 刁延松,任义建,杨元强,赵凌云,刘秀丽,刘芸. 带有摩擦耗能组件的可更换钢梁柱拼接节点抗震性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1643-1656. |

| [2] | 樊学平,刘月飞. 基于改进高斯混合粒子滤波新算法的桥梁极值应力动态预测[J]. 吉林大学学报(工学版), 2024, 54(4): 1038-1044. |

| [3] | 刘一凡,缪志伟,申晨,耿祥东. 基于蒙特卡罗法的不均匀锈蚀钢筋力学性能评估[J]. 吉林大学学报(工学版), 2024, 54(4): 1007-1015. |

| [4] | 樊学平,周衡,刘月飞. 基于Gaussian Copula-贝叶斯动态模型的桥梁构件时变可靠性分析[J]. 吉林大学学报(工学版), 2024, 54(2): 485-493. |

| [5] | 范亮,徐英铭,谭阳. 集束群钉式装配组合梁界面滑移计算[J]. 吉林大学学报(工学版), 2023, 53(9): 2533-2541. |

| [6] | 樊学平,周衡,刘月飞. 桥梁时变可靠性的多过程贝叶斯动态混合预测[J]. 吉林大学学报(工学版), 2023, 53(8): 2332-2338. |

| [7] | 熊二刚,巩忠文,罗佳明,范团结. 基于数字图像相关技术的钢筋混凝土梁裂缝试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1094-1104. |

| [8] | 王晓东,李宁静,李强. 高压脉冲放电破碎混凝土梁试验[J]. 吉林大学学报(工学版), 2023, 53(2): 496-504. |

| [9] | 匡亚川,陈立斌,李超举,贺宇豪. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报(工学版), 2023, 53(2): 538-546. |

| [10] | 戴理朝,周亮,杨晓文,王磊. 基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟[J]. 吉林大学学报(工学版), 2023, 53(10): 2886-2896. |

| [11] | 褚云朋,孙鑫晖,李明,姚勇,黄汉杰. 下击暴流作用下圆形马鞍面屋盖风压特性[J]. 吉林大学学报(工学版), 2022, 52(8): 1826-1833. |

| [12] | 姚勇,苏留锋,李明,褚云朋,黄汉杰. 下击暴流作用下双面球壳型屋面风载特性[J]. 吉林大学学报(工学版), 2022, 52(3): 615-625. |

| [13] | 匡亚川,宋哲轩,刘胤虎,莫小飞,伏亮明,罗时权. 新型装配式双舱综合管廊力学性能试验[J]. 吉林大学学报(工学版), 2022, 52(3): 596-603. |

| [14] | 王毅红,田桥罗,兰官奇,姚圣法,张建雄,刘喜. 630 MPa高强钢筋混凝土大偏压柱受力性能试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2626-2635. |

| [15] | 龚永智,况锦华,柯福隆,周泉,罗小勇. UHPC连接的装配式剪力墙节点抗震性能试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2367-2375. |

|

||