吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (2): 494-502.doi: 10.13229/j.cnki.jdxbgxb.20230530

• 车辆工程·机械工程 • 上一篇

基于小波包对数能量图的滚动轴承故障诊断方法

- 1.天津工业大学 控制科学与工程学院,天津 300387

2.天津市电气装备智能控制重点实验室,天津 300387

Rolling bearing fault diagnosis method via wavelet packet logarithmic-energy map

Na WANG1,2( ),Yue-lei CUI1,Yang LI1,Zi-cong WANG1

),Yue-lei CUI1,Yang LI1,Zi-cong WANG1

- 1.School of Control Science and Engineering,Tiangong University,Tianjin 300387,China

2.Key Laboratory of Intelligent Control of Electrical Equipment,Tianjin 300387,China

摘要:

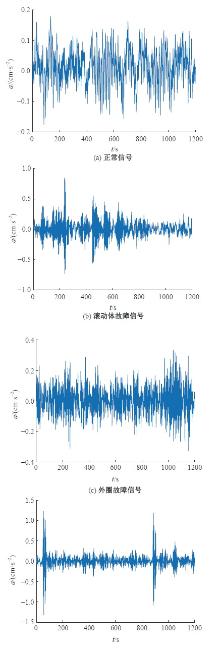

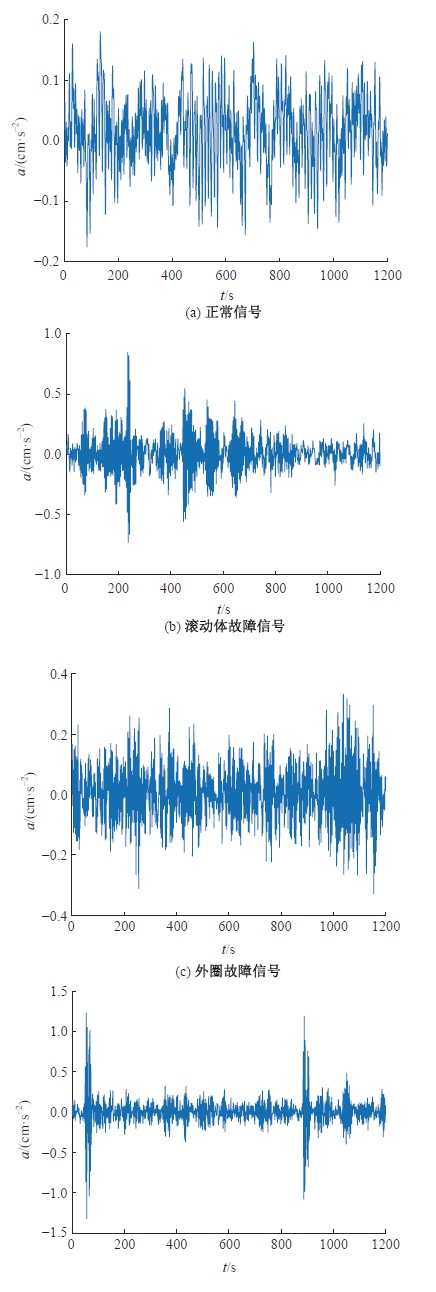

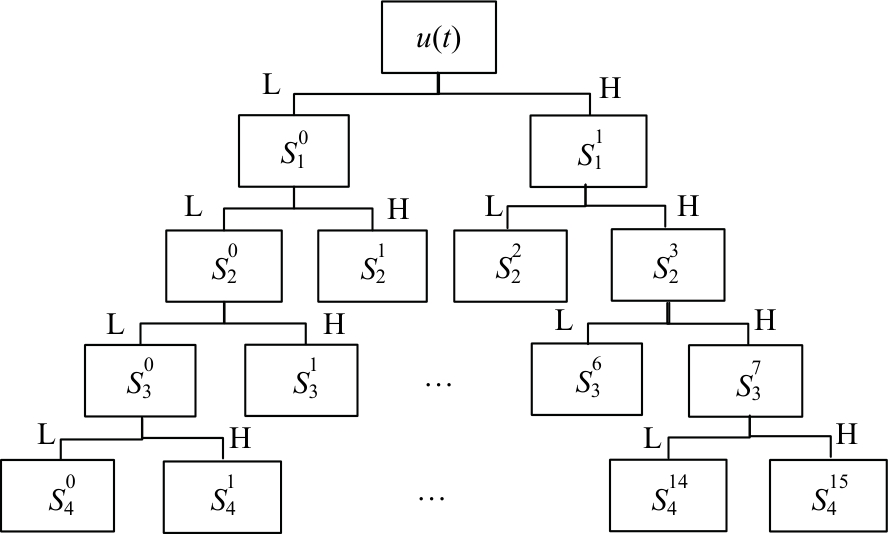

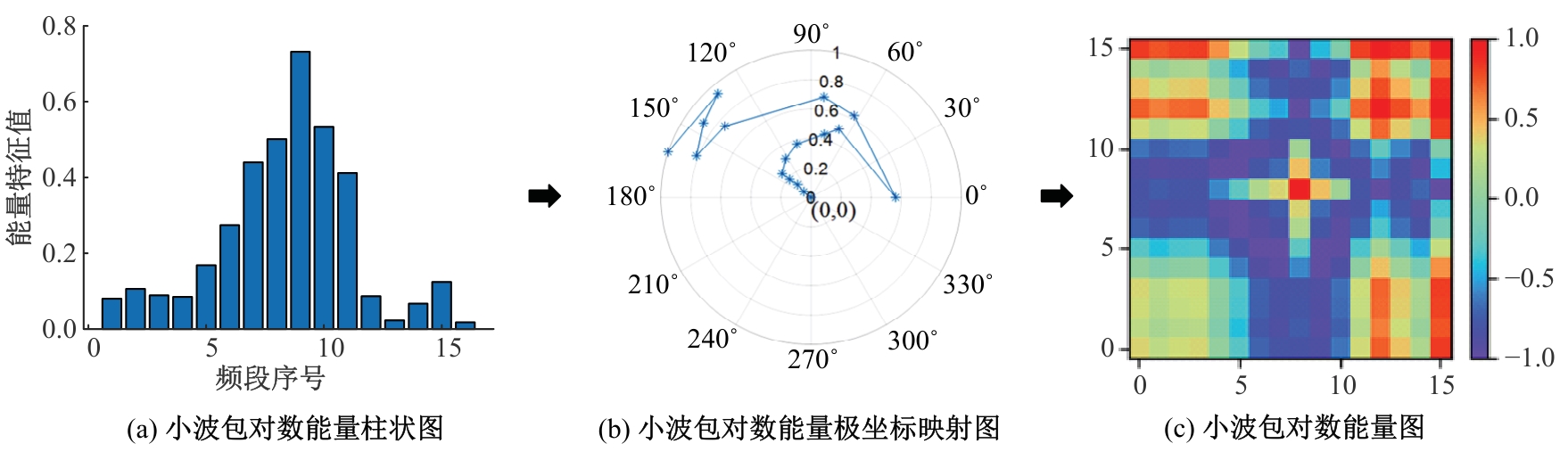

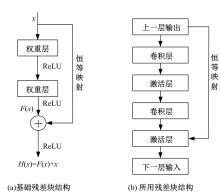

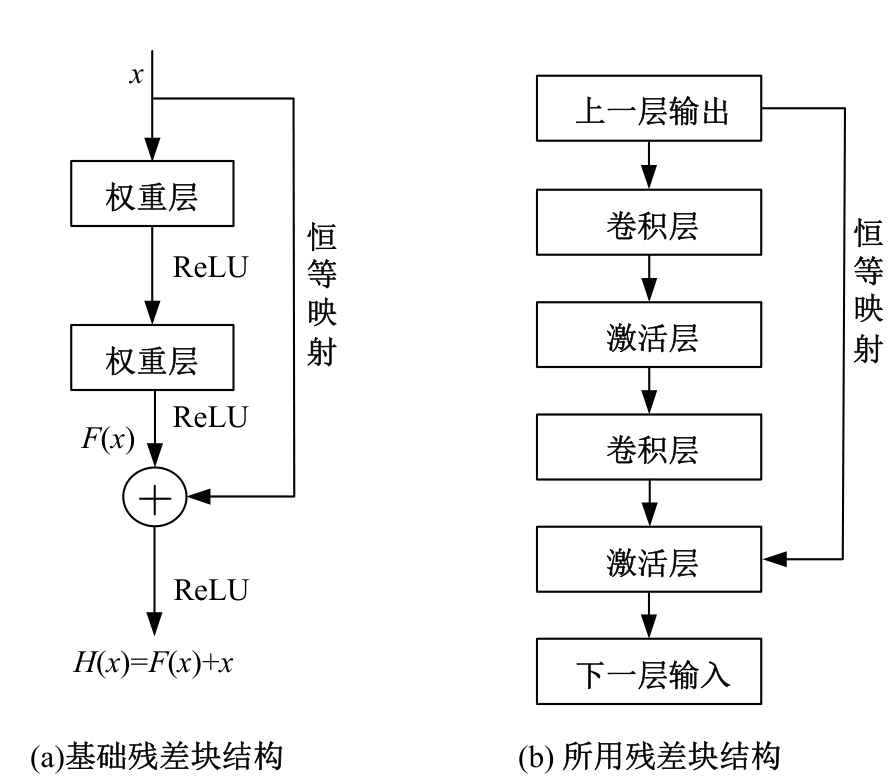

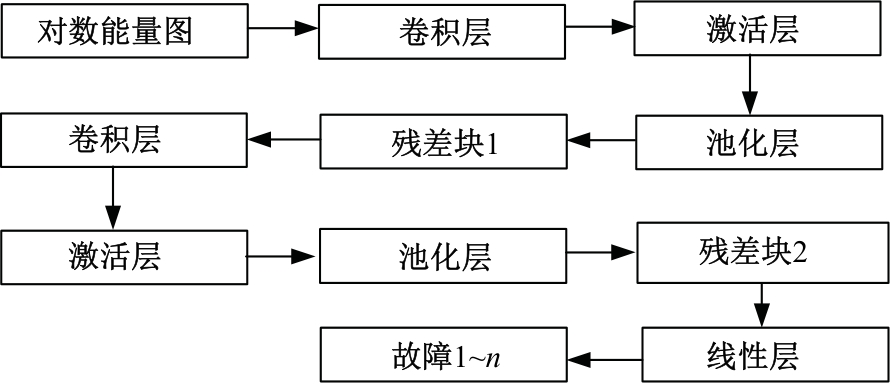

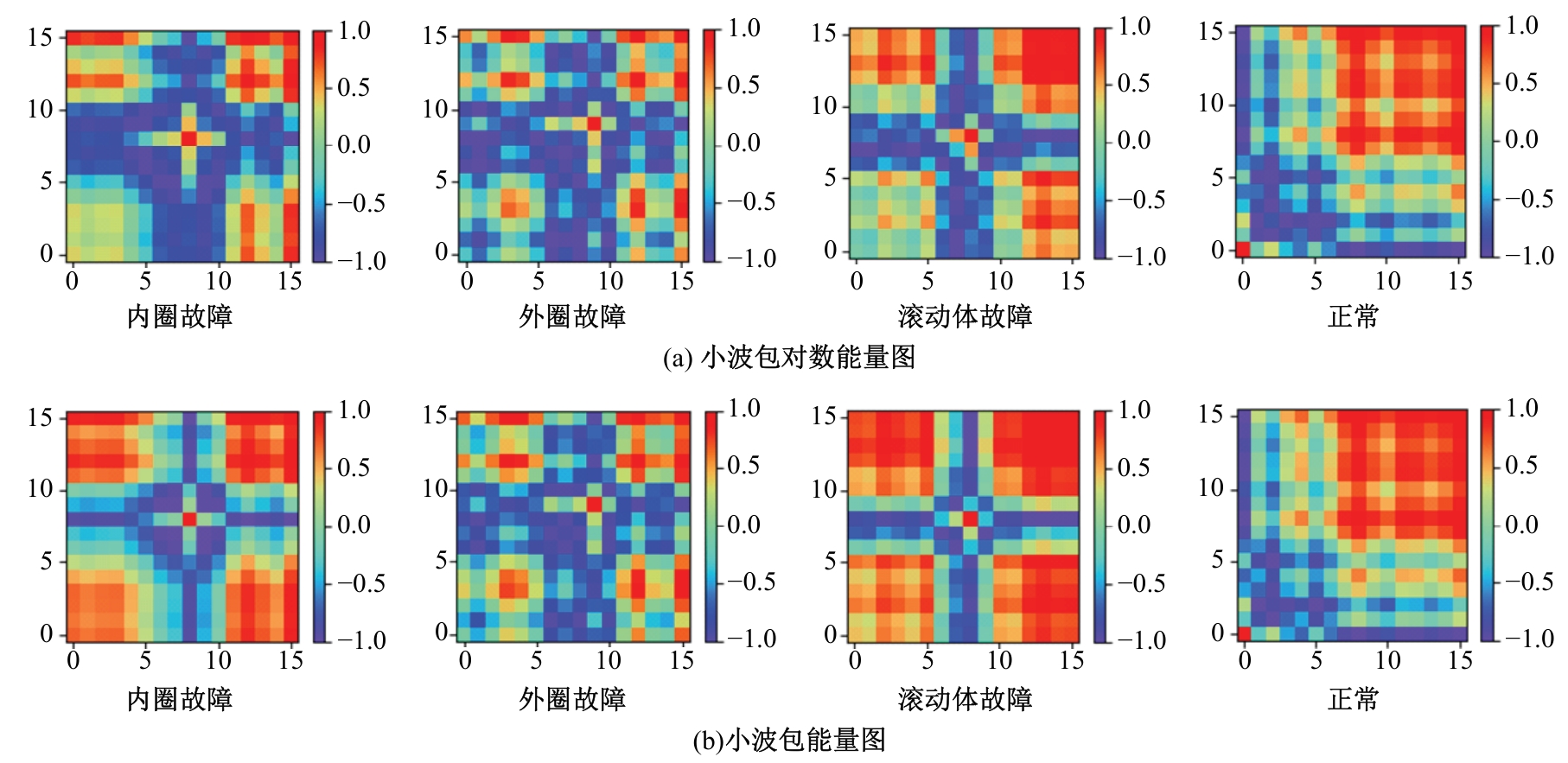

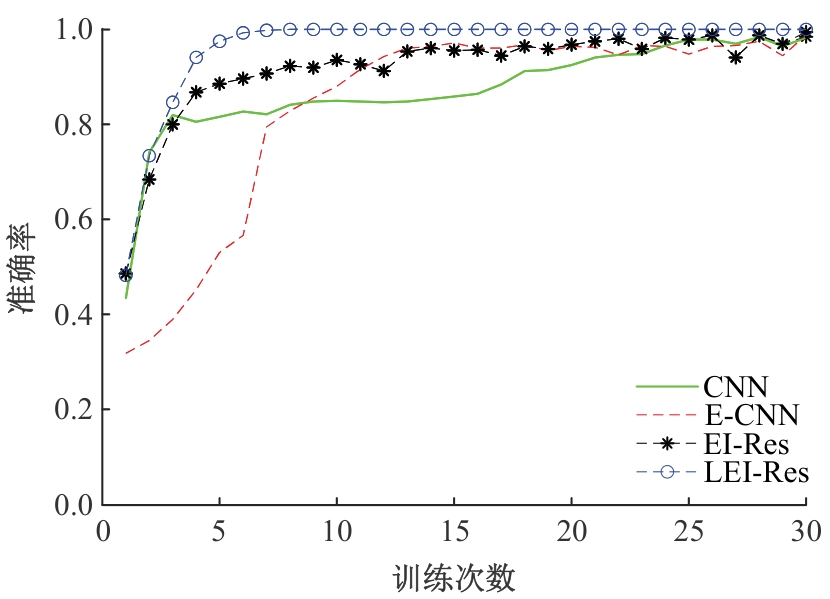

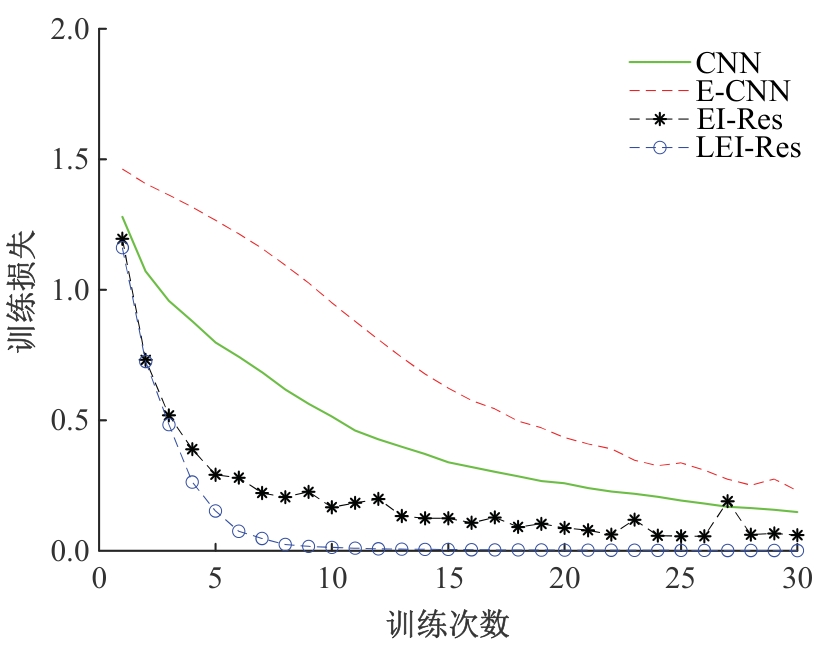

针对滚动轴承的故障诊断问题,提出一种基于小波包对数能量图的诊断方法。首先,改进并提出新的小波包节点对数能量公式,以克服传统小波包能量公式中参数确定烦琐且主观性强的缺点,提高对高频故障的辨识度和对低频故障类别的区分度,以实现对初始时频域特征的充分提取;其次,利用格拉姆角和场思想实现由一维特征到二维图像特征的转换,以此构造出基于小波包的对数能量图特征,其进一步考虑相邻特征之间的空间信息,从而实现对初始时频域特征的优化,提高了所得特征的显著性。在此基础上,通过残差网络改善故障诊断分类结果的精度;最后,通过凯斯西储大学的标准滚动轴承数据集仿真验证可知,本文方法构建的故障诊断模型具有较高的诊断精度,并且泛化能力较强。

中图分类号:

- TH113.1

| 1 | 陈晓雷, 孙永峰, 李策, 等. 基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断[J]. 吉林大学学报: 工学版, 2022, 52(2): 296-309. |

| Chen Xiao-lei, Sun Yong-feng, Li Ce, et al. Stable anti-noise fault diagnosis of rolling bearing based on CNN-BiLSTM[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(2): 296-309. | |

| 2 | 江星星, 彭德民, 沈长青, 等. 快速固有成分滤波特征融合的轴承故障诊断方法[J]. 机械工程学报, 2022, 58(22): 129-139. |

| Jiang Xing-xing, Peng De-min, Shen Chang-qing, et al. Feature fusion of fast intrinsic component filtering for bearing fault diagnosis[J]. Journal of Mechanical Engineering, 2022, 58(22): 129-139. | |

| 3 | 刘新厂. 含齿根裂纹的机车齿轮传动系统振动特性与故障诊断方法研究[D]. 成都: 西南交通大学机械工程学院, 2022. |

| Liu Xin-chang. Study on vibration characteristics and fault diagnosis method of locomotive gear transmission system with root crack[D]. Chengdu: School of Mechanical Engineering, Southwest Jiaotong University, 2022. | |

| 4 | 吴彬云. 考虑变转速工况的转子动平衡故障诊断方法研究及应用[D]. 厦门: 厦门大学机械工程学院, 2022. |

| Wu Bin-yun. Research and application of rotor dynamic balance fault diagnosis method considering variable speed condition[D]. Xiamen: School of Mechanical Engineering, Xiamen University, 2022. | |

| 5 | 王泽坤, 贾彦, 许瑾, 等. 风电机组叶片桨距角安装偏差故障诊断[J]. 动力工程学报, 2022, 42(2): 138-143. |

| Wang Ze-kun, Jia Yan, Xu Jin, et al. Fault diagnosis of blade pitch angle installation deviation of wind turbine[J]. Journal of Chinese Society of Power Engineering, 2022, 42(2): 138-143. | |

| 6 | 张宗振, 王金瑞, 韩宝坤, 等. 非线性稀疏盲解卷积的轴承早期故障诊断方法[J]. 机械工程学报, 2023, 59(16): 157-166. |

| Zhang Zong-zhen, Wang Jin-rui, Han Bao-kun, et al. Early stage fault diagnosis method of bearings based on nonlinear sparse blind deconvolution[J]. Journal of Mechanical Engineering, 2023,59(16): 157-166. | |

| 7 | Zhou H, Yan P, Yuan Y F, et al. Denoising the hob vibration signal using improved complete ensemble empirical mode decomposition with adaptive noise and noise quantization strategies[J]. ISA Transactions, 2022, 131: 715-735. |

| 8 | 时培明, 范雅斐, 伊思颖, 等. HVD小波包降噪编码深度学习的风电机组智能诊断研究[J]. 振动与冲击, 2022, 41(12): 196-201. |

| Shi Pei-ming, Fan Ya-fei, Yi Si-ying, et al. A study on wind turbine intelligent diagnosis based on HVD wavelet packet de noising coding deep learning[J]. Journal of Vibration and Shock, 2022, 41(12): 196-201. | |

| 9 | 皮骏, 刘鹏, 马圣, 等. 基于MGA-BP网络的航空轴承故障诊断[J]. 振动、测试与诊断, 2020, 40(2): 381-388. |

| Pi Jun, Liu Peng, Ma Sheng, et al. Aero-engine bearing fault diagnosis based on MGA-BP neural network[J]. Journal of Vibration, Measurement & Diagnosis, 2020, 40(2): 381-388. | |

| 10 | Zhou Q C, Shen H H, Zhao J, et al. Bearing fault diagnosis based on improved stacked recurrent neural network[J]. Journal of Tongji University, 2019, 47(10): 1500-1507. |

| 11 | 王兴, 张晗, 朱家正, 等. 多头注意力驱动的航空高速轴承故障诊断方法[J]. 振动与冲击, 2023, 42(4): 295-305. |

| Wang Xing, Zhang Han, Zhu Jia-zheng, et al. A fault diagnosis method for aviation high-speed bearings driven by multi-head attention[J]. Journal of Vibration and Shock, 2023, 42(4): 295-305. | |

| 12 | 刘颖, 陶建峰, 黄武涛, 等. 小波包能量与CNN相结合的滚动轴承故障诊断方法[J]. 机械设计与制造, 2021(11): 127-131. |

| Liu Ying, Tao Jian-feng, Huang Wu-tao, et al. Rolling bearing fault diagnosis method based on the combination of wavelet packet energy and CNN[J]. Machinery Design & Manufacture, 2021(11): 127-131. | |

| 13 | 古莹奎, 吴宽, 李成, 等. 基于格拉姆角场和迁移深度残差神经网络的滚动轴承故障诊断[J]. 振动与冲击, 2022, 41(21): 228-237. |

| Gu Ying-kui, Wu Kuan, Li Cheng, et al. Rolling bearing fault diagnosis based on Gram angle field and transfer deep residual neural network[J]. Journal of Vibration and Shock, 2022, 41(21): 228-237. | |

| 14 | Liu J Y, Wang X S, Wu S J, et al. Wind turbine fault detection based on deep residual networks[J]. Expert Systems with Applications, 2023, 213: 1-13. |

| 15 | Han T, Liu C, Yang W G, et al. Deep transfer network with joint distribution adaptation: a new intelligent fault diagnosis framework for industry application[J]. ISA Transactions, 2020, 97: 269-281. |

| 16 | Zhao M H, Fu X Y, Zhang Y J, et al. Highly imbalanced fault diagnosis of mechanical systems based onwavelet packet distortion and convolutional neural networks[J]. Advanced Engineering Informatics, 2022, 51: 1-10. |

| 17 | Yu X, Liang Z T, Wang Y J, et al. A wavelet packet transform-based deep feature transfer learning method for bearing fault diagnosis under different working conditions[J]. Measurement, 2022, 201: 1-14. |

| [1] | 余萍,赵康,曹洁. 基于优化A-BiLSTM的滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2024, 54(8): 2156-2166. |

| [2] | 赖丹晖,罗伟峰,袁旭东,邱子良. 复杂环境下多模态手势关键点特征提取算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2288-2294. |

| [3] | 张云佐,郑宇鑫,武存宇,张天. 基于双特征提取网络的复杂环境车道线精准检测[J]. 吉林大学学报(工学版), 2024, 54(7): 1894-1902. |

| [4] | 王长建,刘久明,张锦洲,李斌. 基于高速摄影技术的行星减速箱故障激光序列脉冲诊断方法[J]. 吉林大学学报(工学版), 2024, 54(7): 1869-1875. |

| [5] | 张玺君,尚继洋,余光杰,郝俊. 基于注意力的多尺度卷积神经网络轴承故障诊断[J]. 吉林大学学报(工学版), 2024, 54(10): 3009-3017. |

| [6] | 陈文杰,苏振兴,孙先涛,刘远远,胡祥涛,智亚丽. 噪声环境下外骨骼设备语音信号的特征提取[J]. 吉林大学学报(工学版), 2024, 54(10): 3050-3057. |

| [7] | 杨志飞,张佳,李泽阳. 基于增量式学习的复杂网络节点攻击检测算法[J]. 吉林大学学报(工学版), 2024, 54(10): 2963-2968. |

| [8] | 宋世军,樊敏. 基于随机森林算法的大数据异常检测模型设计[J]. 吉林大学学报(工学版), 2023, 53(9): 2659-2665. |

| [9] | 龙恩深,班光泽. 基于小波包信包提取的空调制冷压缩机怠速噪声诊断算法[J]. 吉林大学学报(工学版), 2023, 53(7): 1929-1934. |

| [10] | 白琳,刘林军,李轩昂,吴沙,刘汝庆. 基于自监督学习的单目图像深度估计算法[J]. 吉林大学学报(工学版), 2023, 53(4): 1139-1145. |

| [11] | 欧阳丹彤,孙睿,田新亮,高博涵. 基于集合阻塞的不确定系统中传感器选择方法[J]. 吉林大学学报(工学版), 2023, 53(2): 547-554. |

| [12] | 吕晓琪,李浩,谷宇. 基于深度学习算法的人脸图像活体特征变换尺度提取[J]. 吉林大学学报(工学版), 2023, 53(11): 3201-3206. |

| [13] | 陈永刚,许继业,王海涌,熊文祥. 基于自适应神经模糊网络的转辙机故障诊断方法[J]. 吉林大学学报(工学版), 2023, 53(11): 3274-3280. |

| [14] | 张朝刚,侍中楼,李敏. 基于多状态时间序列预测学习的超精密机床主轴故障诊断仿真[J]. 吉林大学学报(工学版), 2023, 53(11): 3056-3061. |

| [15] | 周怡娜,董宏丽,张勇,路敬祎. 基于VMD去噪和散布熵的管道信号特征提取方法[J]. 吉林大学学报(工学版), 2022, 52(4): 959-969. |

|

||