吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (7): 1869-1875.doi: 10.13229/j.cnki.jdxbgxb.20230400

• 车辆工程·机械工程 • 上一篇

基于高速摄影技术的行星减速箱故障激光序列脉冲诊断方法

- 长江大学 机械工程学院,湖北 荆州 434023

Laser sequence pulse diagnosis method of planetary reducer fault based on high-speed photography technology

Chang-jian WANG( ),Jiu-ming LIU,Jin-zhou ZHANG,Bin LI

),Jiu-ming LIU,Jin-zhou ZHANG,Bin LI

- School of Mechanical Engineering,Yangtze University,Jingzhou 434023,China

摘要:

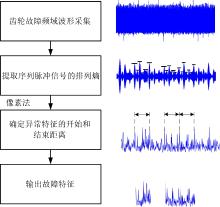

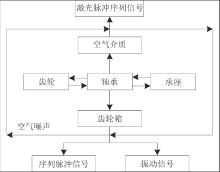

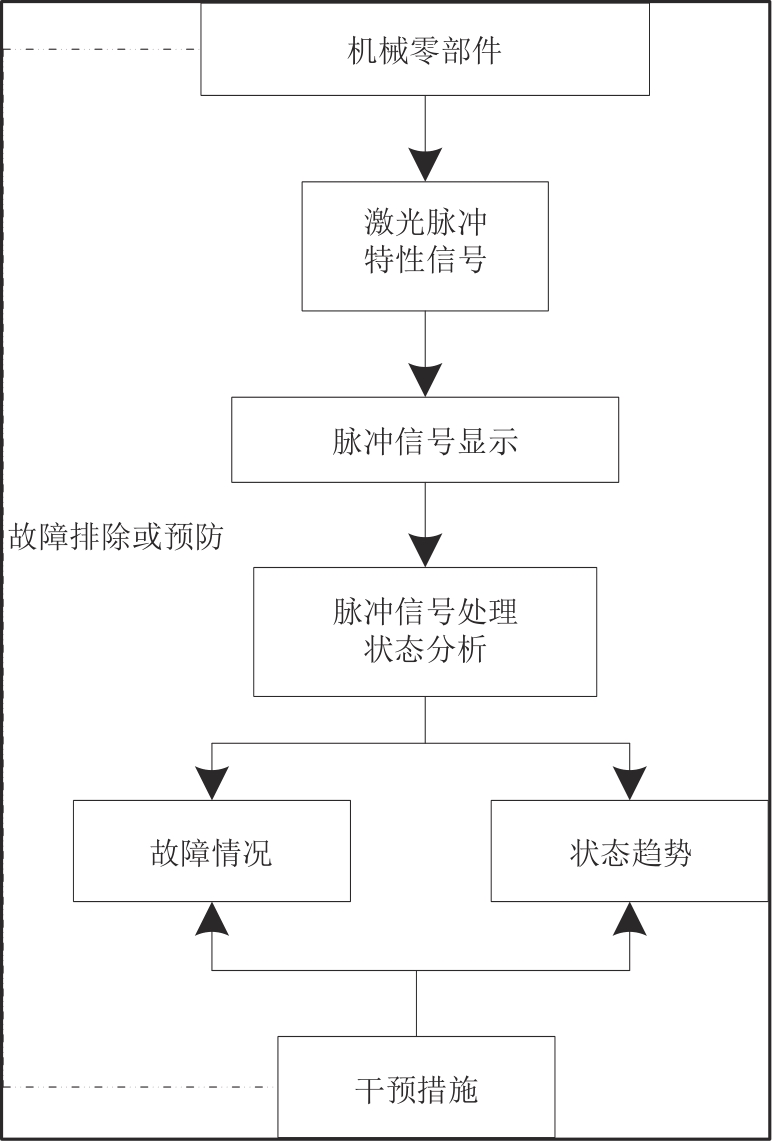

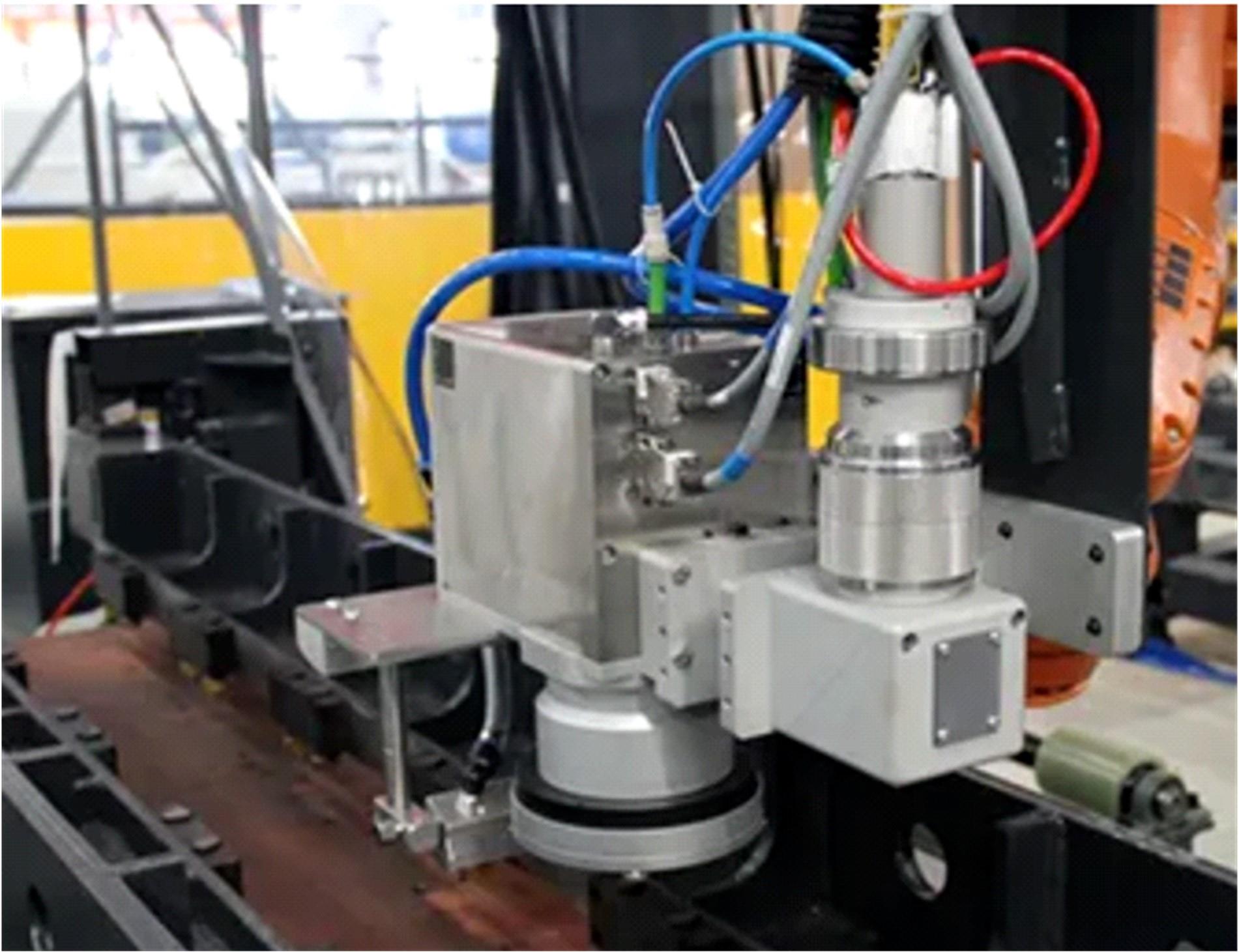

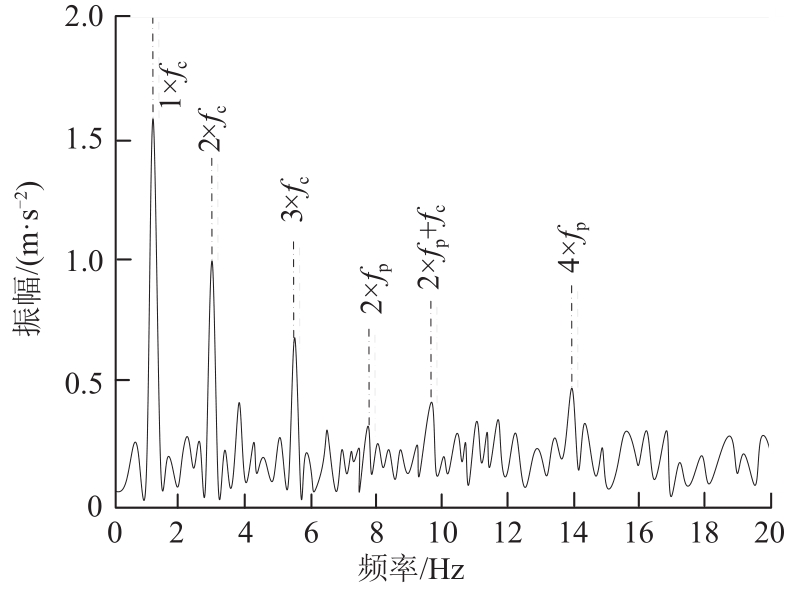

设计了一种基于高速摄影技术的行星减速箱激光序列脉冲诊断方法。将序列脉冲激光器与高速相机配合使用,采集减速箱振动激光序列脉冲信号,利用多传感器收集振动信号,计算信号排列熵。判断激光序列脉冲信号是否存在异常特征,若存在异常,则将序列脉冲信号转换成可非分割线性关系,采用径向基核函数计算出脉冲训练值,凭借训练值高低判断行星减速器齿轮及轴承的故障程度。测试实验证明,研究方法可行有效,检测不同故障信号的序列脉冲信号,概率密度函数特征点分布在[0.23,0.34],能精准分辨出4种不同的故障类型。

中图分类号:

- TJ07

| 1 | 樊家伟,郭瑜,伍星,等.基于LSTM神经网络和故障特征增强的行星齿轮箱故障诊断[J].振动与冲击,2021,40(20):271-277. |

| Fan Jia-wei, Guo Yu, Wu Xing, et al. Fault diagnosis of planetary gearboxes based on LSTM neural network and fault feature enhancement[J]. Journal of Vibration and Shock, 2021,40 (20): 271-277. | |

| 2 | 欧曙东,赵明,周涛,等.基于编码器信号的低转速行星齿轮箱故障诊断技术[J].中国电机工程学报,2021,41(5):1885-1894. |

| Shu-dong Ou, Zhao Ming, Zhou Tao, et al. Fault diagnosis technology for low-speed planetary gearbox based on encoder signals[J]. Proceedings of the CSEE, 2021,41(5): 1885-1894. | |

| 3 | 李涵钊,胡志芳,望昊.基于小波包分解的功率谱方法在人字门启闭机减速器故障诊断中的应用[J].水运工程,2020(2):117-123. |

| Li Han-zhao, Hu Zhi-fang, Wang Hao, et al. Application of power spectrum method based on wavelet packet decomposition in the fault diagnosis of reducer in the hoist of miter gate[J]. Port & Waterway Engineering, 2020(2): 117-123. | |

| 4 | 柳杨,王凌,高雁凤,等.工业机器人谐波减速器的传动误差超限故障诊断[J].机床与液压,2021,49(17):185-190. |

| Liu Yang, Wang Ling, Gao Yan-feng, et al. Transmission error over limit fault diagnosis for harmonic reducer of industrial robot[J]. Machine Tool & Hydraulics, 2021,49 (17): 185-190. | |

| 5 | 刘羊,宗望远,马丽娜,等.采用高速摄影技术测定油葵籽粒三维碰撞恢复系数[J].农业工程学报,2020,36(4):44-53. |

| Liu Yang, Zong Wang-yuan, Ma Li-na, et al. Determination of three-dimensional collision restitution coefficient of oil sunflower grain by high-speed photography[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020,36 (4): 44-53. | |

| 6 | 李宁宁,陈海洋,冯曼,等.多维立体化高速摄影测量系统实时精准控制技术[J].应用光学,2021,42(6):1062-1066. |

| Li Ning-ning, Chen Hai-yang, Feng Man, et al. Real-time precise control technology of multidimensional and stereoscopic high-speed photogrammetry system[J]. Journal of Applied Optics, 2021,42(6): 1062-1066. | |

| 7 | 张猛,苗长云,孟德军. 轴承早期故障特征提取方法研究[J].工矿自动化,2020,46(4):85-90, 116. |

| Zhang Meng, Miao Chang-yun, Meng De-jun. Research on a bearing early fault features extraction method[J]. Industry and Mine Automation, 2020,46(4): 85-90, 116. | |

| 8 | 衷路生,刘东东.多级神经网络的轴承故障诊断研究[J].计算机工程与应用,2020,56(7):193-199. |

| Zhong Lu-sheng, Liu Dong-dong. Research on bearing fault diagnosis of multi-level neural network[J]. Computer Engineering and Applications, 2020,56(7): 193-199. | |

| 9 | 陈仁祥,黄鑫,胡小林,等.多源信息深度融合的行星齿轮箱故障诊断方法[J].振动工程学报,2020,33(5):1094-1102. |

| Chen Ren-xiang, Huang Xin, Hu Xiao-lin, et al. Planetary gearbox fault diagnosis technique based on multi-source information deep fusion[J]. Journal of Vibration Engineering, 2020,33 (5): 1094-1102. | |

| 10 | 溥江,赵鑫,张秀华.基于动力学模型的少齿差行星轮减速器断齿点蚀故障分析[J].组合机床与自动化加工技术,2020(11):28-32. |

| Pu Jiang, Zhao Xin, Zhang Xiu-hua. Analysis of planetary wheel reducer based on dynamic model[J]. Chinese Journal of Scientific and Technical Periodicals, 2020 (11): 28-32. | |

| 11 | Gao C, Yu Z Q, Zhou Q. Application of GA-ACO optimized BP neural network in fault diagnosis of planetary gearbox[J]. Journal of Mechanical Transmission, 2021,45(3): 153-160. |

| 12 | Yao M M, Tang X, Lu A. Research on fault diagnosis of planetary gearbox based on improved convolutional neural network[J]. Manufacturing Technology & Machine Tool, 2021(7): 141-145. |

| 13 | Zhu J, Deng A D, Deng M Q, et al.Fault diagnosis of planetary gearbox based on minimum entropy deconvolution and adaptive variational mode decomposition[J]. Journal of Southeast University(Natural Science Edition), 2020,50(4): 698-704. |

| 14 | Wu Z, Zhang Q, Huang H M.Research on fault diagnosis of compound planetary gear based on dynamic model and multiscale permutation entropy[J] .Machinery Design & Manufacture, 2020(9): 182-186. |

| 15 | 熊俊,薛卫萍,姚志文.高强度铝合金表面激光熔覆温度场仿真[J].计算机仿真,2021,38(4):164-167, 197. |

| Xiong Jun, Xue Wei-ping, Yao Zhi-wen. Simulation of laser cladding temperature field on high strength aluminum alloy surface[J]. Computer Simulation, 2021,38(4): 164-167, 197. |

| [1] | 欧阳丹彤,孙睿,田新亮,高博涵. 基于集合阻塞的不确定系统中传感器选择方法[J]. 吉林大学学报(工学版), 2023, 53(2): 547-554. |

| [2] | 陈永刚,许继业,王海涌,熊文祥. 基于自适应神经模糊网络的转辙机故障诊断方法[J]. 吉林大学学报(工学版), 2023, 53(11): 3274-3280. |

| [3] | 张朝刚,侍中楼,李敏. 基于多状态时间序列预测学习的超精密机床主轴故障诊断仿真[J]. 吉林大学学报(工学版), 2023, 53(11): 3056-3061. |

| [4] | 高文志,王彦军,王欣伟,张攀,李勇,董阳. 基于卷积神经网络的柴油机失火故障实时诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 417-424. |

| [5] | 王进花,胡佳伟,曹洁,黄涛. 基于自适应变分模态分解和集成极限学习机的滚动轴承多故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 318-328. |

| [6] | 董绍江,朱朋,裴雪武,李洋,胡小林. 基于子领域自适应的变工况下滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 288-295. |

| [7] | 罗巍,卢博,陈菲,马腾. 基于PSO-SVM及时序环节的数控刀架故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(2): 392-399. |

| [8] | 曹洁,马佳林,黄黛麟,余萍. 一种基于多通道马尔可夫变迁场的故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(2): 491-496. |

| [9] | 邓飞跃,吕浩洋,顾晓辉,郝如江. 基于轻量化神经网络Shuffle⁃SENet的高速动车组轴箱轴承故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(2): 474-482. |

| [10] | 张龙,徐天鹏,王朝兵,易剑昱,甄灿壮. 基于卷积门控循环网络的齿轮箱故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 368-376. |

| [11] | 陈晓雷,孙永峰,李策,林冬梅. 基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 296-309. |

| [12] | 杜先君,贾亮亮. 基于优化堆叠降噪自编码器的滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(12): 2827-2838. |

| [13] | 陈菲,杨峥,张志成,罗巍. 面向无标签数据的旋转机械故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(11): 2514-2522. |

| [14] | 曹洁,何智栋,余萍,王进花. 数据不平衡分布下轴承故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(11): 2523-2531. |

| [15] | 欧阳丹彤,张必歌,田乃予,张立明. 结合格局检测与局部搜索的故障数据缩减方法[J]. 吉林大学学报(工学版), 2021, 51(6): 2144-2153. |

|

||