吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (10): 3009-3017.doi: 10.13229/j.cnki.jdxbgxb.20221537

• 计算机科学与技术 • 上一篇

基于注意力的多尺度卷积神经网络轴承故障诊断

- 兰州理工大学 计算机与通信学院,兰州 730050

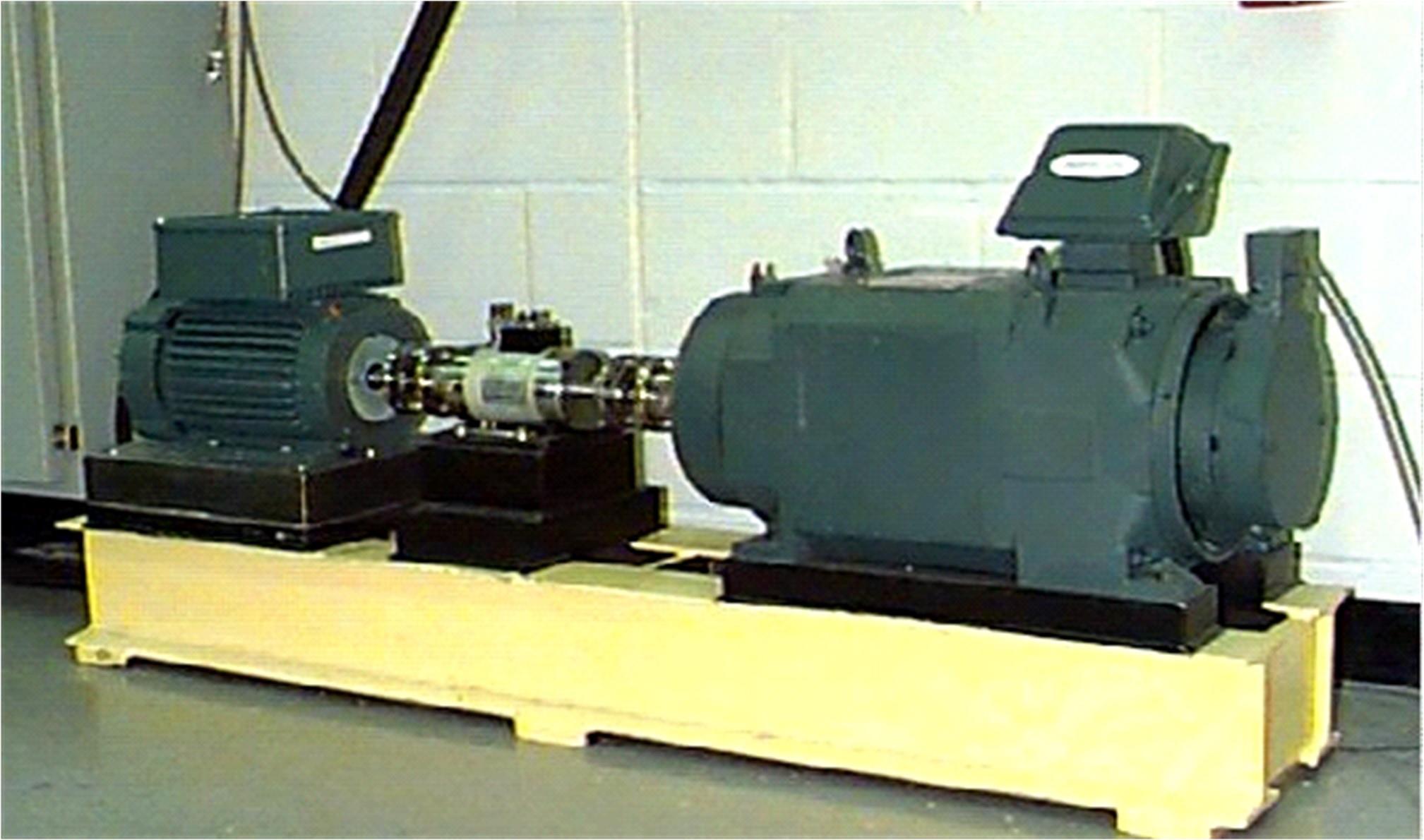

Bearing fault diagnosis based on attention for multi-scale convolutional neural network

Xi-jun ZHANG( ),Ji-yang SHANG,Guang-jie YU,Jun HAO

),Ji-yang SHANG,Guang-jie YU,Jun HAO

- School of Computer and Communication,Lanzhou University of Technology,Lanzhou 730050,China

摘要:

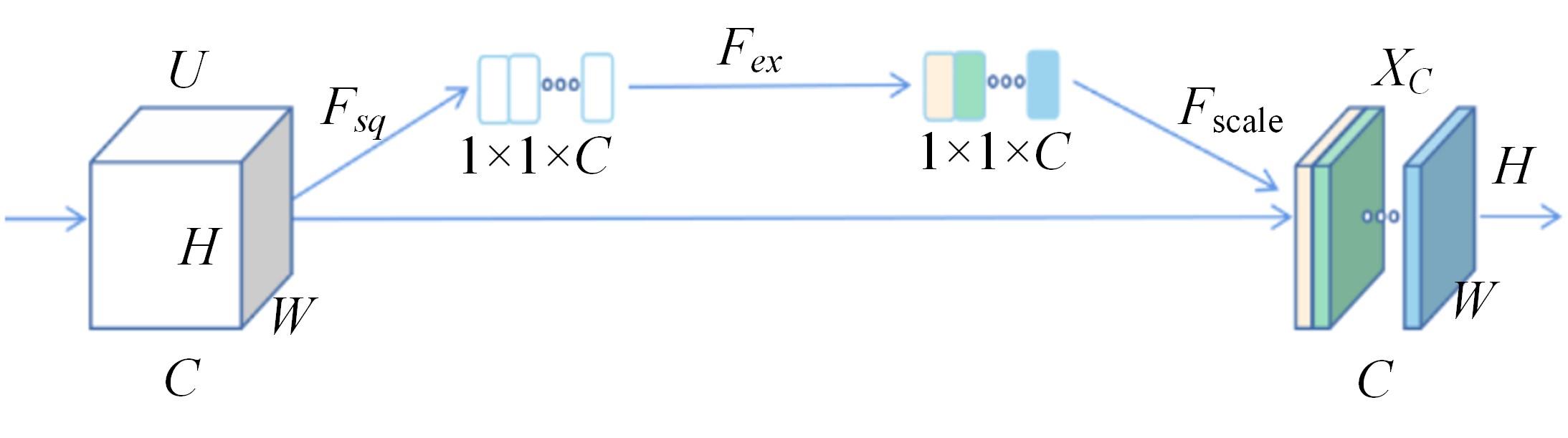

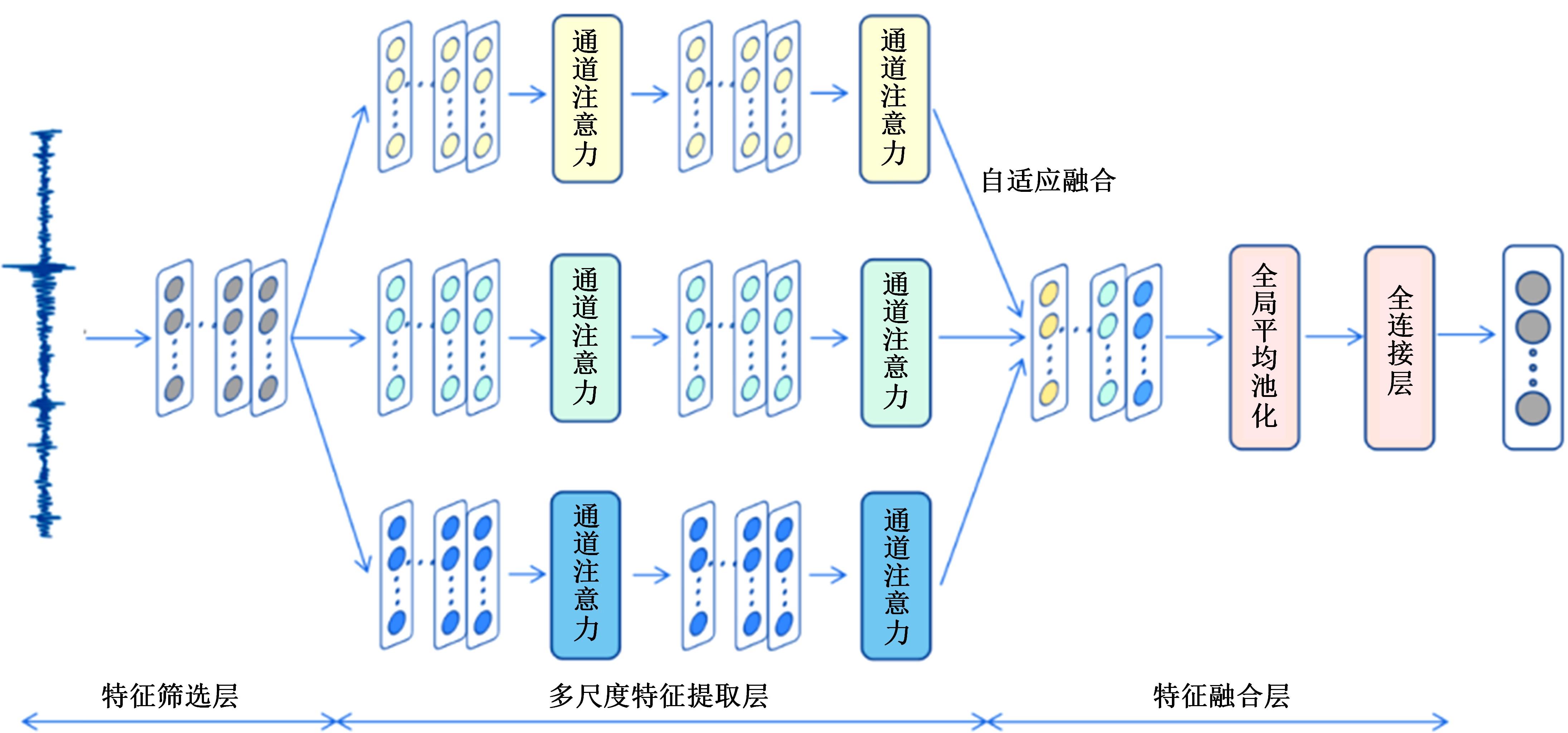

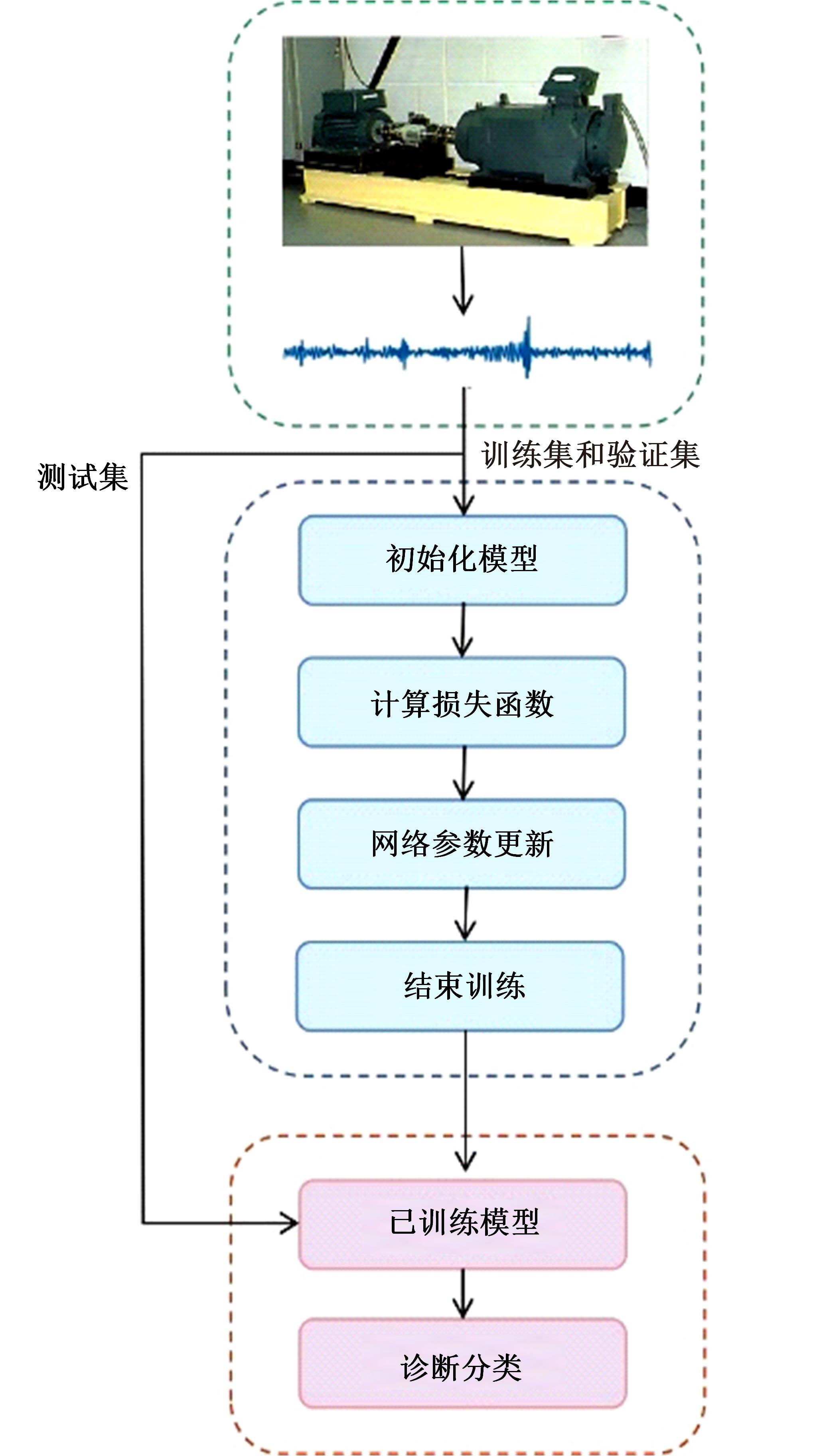

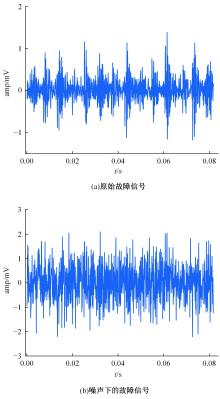

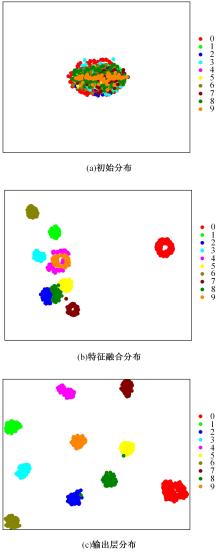

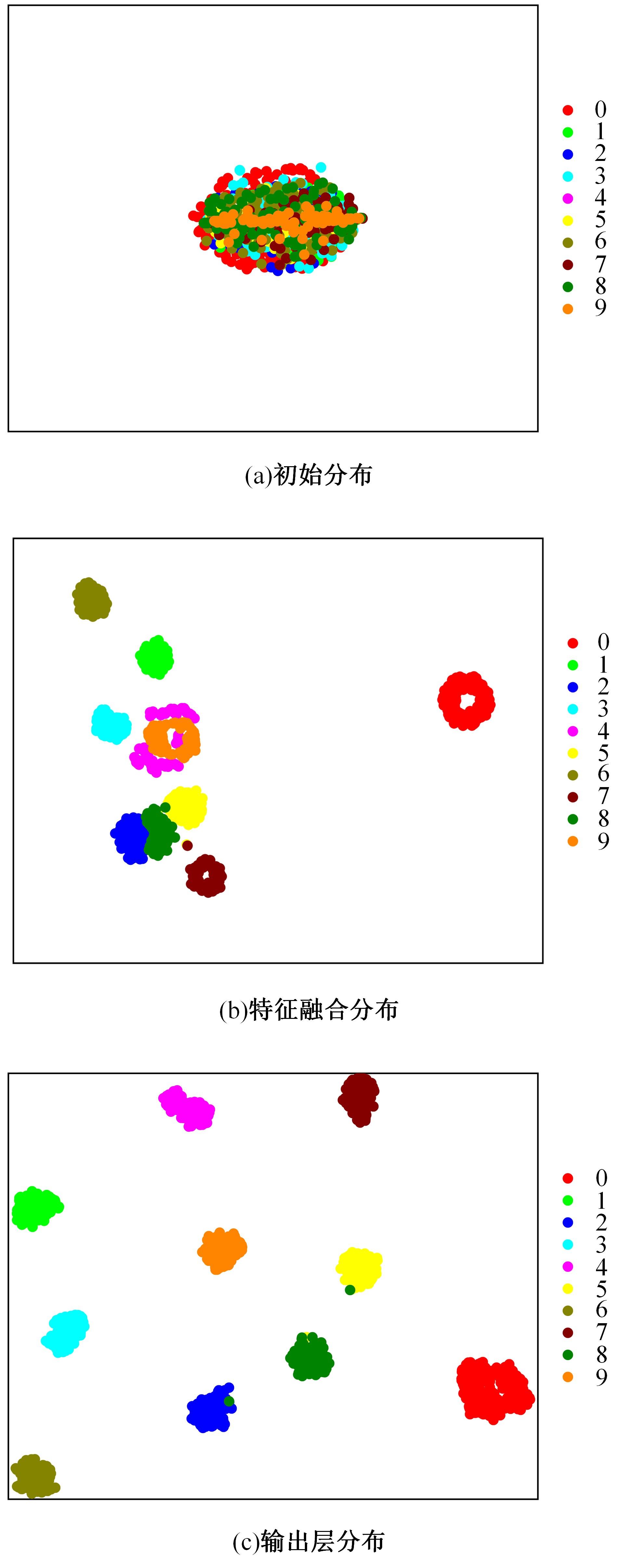

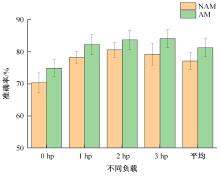

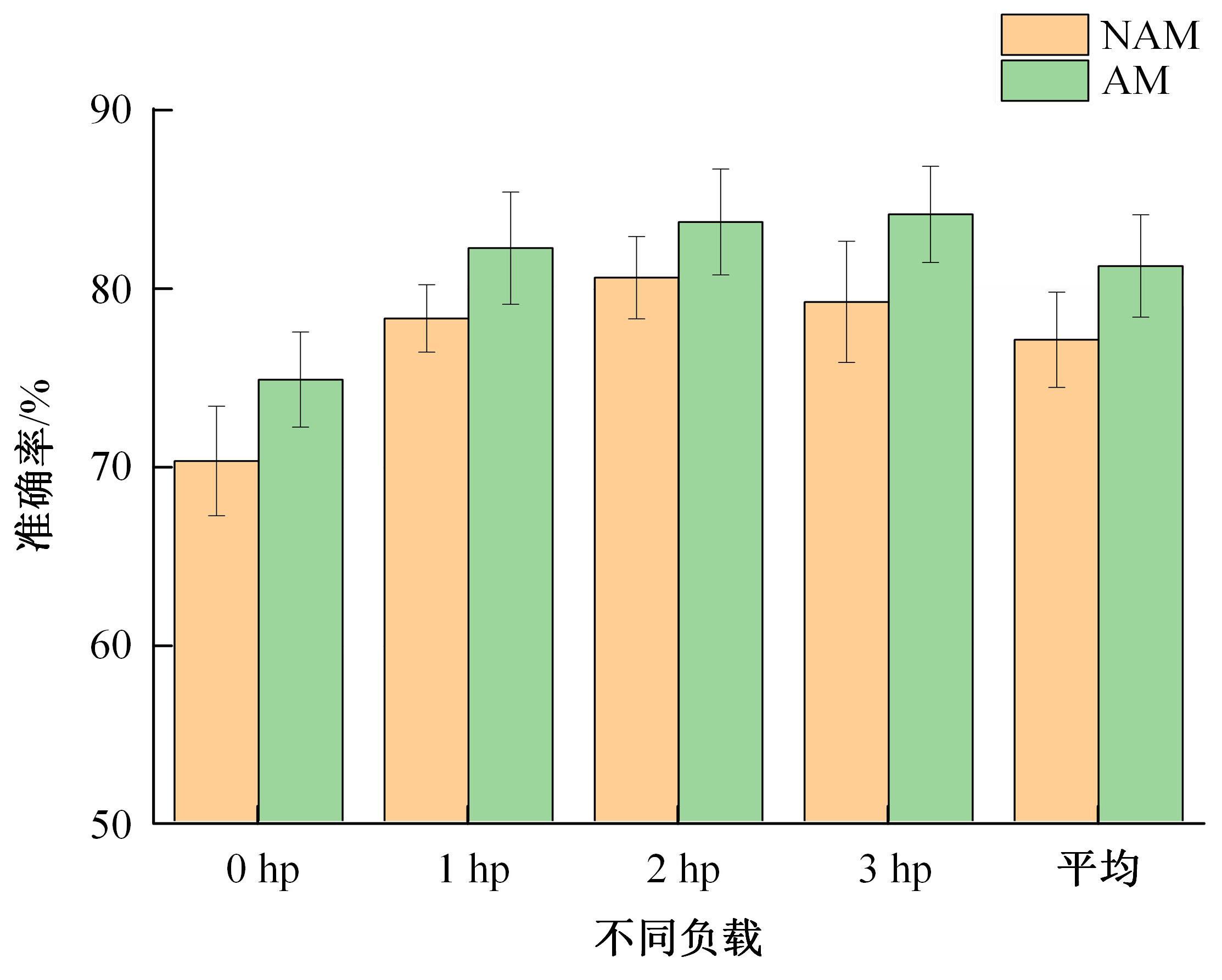

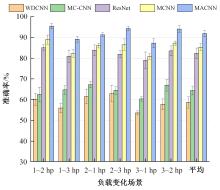

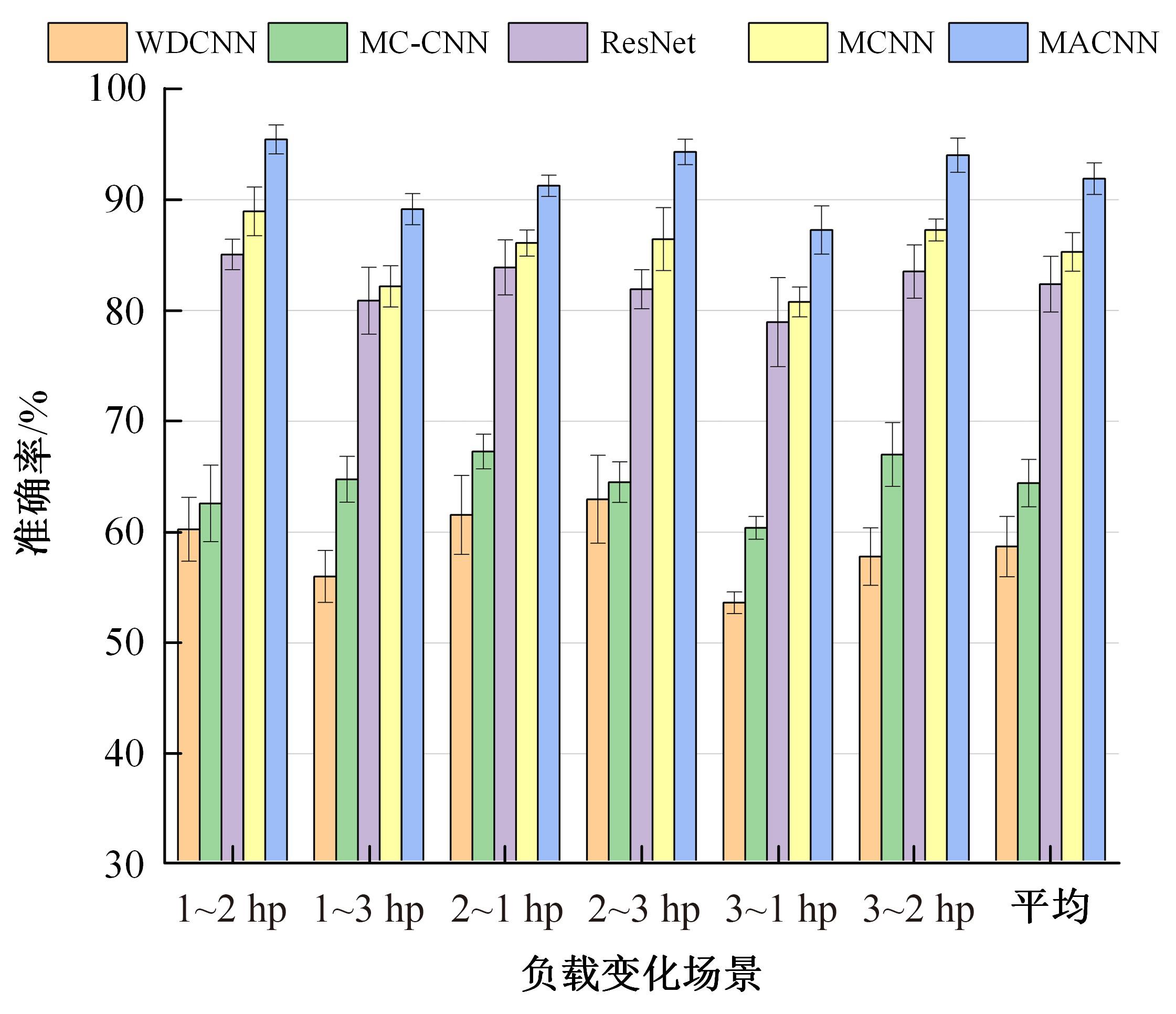

针对卷积神经网络在噪声环境下轴承故障诊断精度较低的问题,提出一种加入通道注意力的多尺度卷积神经网络抗噪模型(MACNN)。该模型首先在提取不同尺度的特征时利用通道注意力自适应地选择包含故障特征的通道提高模型的抗噪能力,抑制噪声的影响;然后利用自适应大小的一维卷积调整不同尺度的特征通道权重,自适应融合不同尺度的特征;最后通过全连接层进行特征分类。两个轴承数据集上的实验结果表明:在不同信噪比的噪声干扰下,相比其他方法,MACNN有更强的轴承故障诊断能力。

中图分类号:

- TP277

| 1 | Zhang S, Zhang S, Zhang S B, et al. Deep learning algorithms for bearing fault diagnostics—a comprehensive review[J]. IEEE Access, 2020, 8: 29857-29881. |

| 2 | Huang Y J, Liao A H, Hu D Y, et al. Multi-scale convolutional network with channel attention mechanism for rolling bearing fault diagnosis[J]. Measurement, 2022, 203: No.111935. |

| 3 | Cai J H, Xiao Y L, Fu L Y. Fault diagnosis of rolling bearing based on fractional fourier instantaneous spectrum[J]. Experimental Techniques, 2022, 46(2): 249-256. |

| 4 | Islam M M M, Kim J M. Automated bearing fault diagnosis scheme using 2D representation of wavelet packet transform and deep convolutional neural network[J]. Computers in Industry, 2019, 106: 142-153. |

| 5 | 胡茑庆, 陈徽鹏, 程哲, 等. 基于经验模态分解和深度卷积神经网络的行星齿轮箱故障诊断方法[J]. 机械工程学报, 2019, 55(7): 9-18. |

| Hu Niao-qing, Chen Hui-peng, Cheng Zhe, et al. Fault di-agnosis for planetary gearbox based on EMD and deep convolutional neural networks[J]. Journal of Mechanical Engineering, 2019, 55(7): 9-18. | |

| 6 | Li J M, Yao X F, Wang X D, et al. Multiscale local features learning based on BP neural network for rolling bearing intelligent fault diagnosis[J]. Measurement, 2020, 153: No.107419. |

| 7 | Malhi A, Gao X R.PCA-based feature selection scheme for machine defect classification[J]. IEEE Transactions on Instrumentation and Measurement, 2004, 53(6): 1517-1525. |

| 8 | Zhang X Y, Li C S, Wang X B, et al. A novel fault diagnosis procedure based on improved symplectic geometry mode decomposition and optimized SVM[J]. Measurement, 2021, 173: No.108644. |

| 9 | Janssens O, Slavkovikj V, Vervisch B, et al. Convolutional neural network based fault detection for rotating machinery[J]. Journal of Sound and Vibration, 2016, 377: 331-345. |

| 10 | Eren L, Ince T, Kiranyaz S. A generic intelligent bearing fault diagnosis system using compact adaptive 1D CNN classifier[J]. Journal of Signal Processing Systems, 2019, 91(2): 179-189. |

| 11 | 孙祺淳, 李媛媛. DE算法优化CNN的滚动轴承故障诊断研究[J]. 噪声与振动控制, 2022, 42(4): 165-171, 176. |

| Sun Qi-chun, Li Yuan-yuan. Research on fault diagnosis of rolling bearings based on DE algorithm optimization of CNN[J]. Noise and Vibration Control, 2022, 42(4): 165-171, 176. | |

| 12 | Zhai X D, Qiao F, Ma Y, et al. A novel fault diagnosis method under dynamic working conditions based on a CNN with an adaptive learning rate[J]. IEEE Transactions on Instrumentation and Measurement, 2022, 71: 1-12. |

| 13 | Zhang W, Peng G L, Li C H, et al. A new deep learning model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals[J]. Sensors, 2017, 17(2): 425. |

| 14 | Liang H P, Cao J, Zhao X Q. Multi-scale dynamic adaptive residual network for fault diagnosis[J]. Measurement,2022, 188: No.110397. |

| 15 | Huang W Y, Cheng J S, Yang Y, et al. An improved deep convolutional neural network with multi-scale information for bearing fault diagnosis[J]. Neurocomputing, 2019, 359: 77-92. |

| 16 | 许子非, 金江涛, 李春. 基于多尺度卷积神经网络的滚动轴承故障诊断方法[J]. 振动与冲击, 2021, 40(18): 212-220. |

| Xu Zi-fei, Jin Jiang-tao, Li Chun. New method for the fault diagnosis of rolling bearings based on a multiscale convolutional neural network[J]. Journal of Vibration and Shock, 2021, 40(18): 212-220. | |

| 17 | 康涛, 段蓉凯, 杨磊,等.融合多注意力机制的卷积神经网络轴承故障诊断方法[J].西安交通大学学报, 2022, 56(12): 68-77. |

| Kang Tao, Duan Rong-kai, Yang Lei, et al. Bearing fault diagnosis method using convolutional neural network fused with multi-attention mechanism[J]. Journal of Xi´an Jiao Tong University, 2022, 56(12): 68-77. | |

| 18 | Hu J, Li S, Samuel A, et al. Squeeze-and-excitation networks[J].IEEE Transactions on Pattern Analysis and Machine Intelligence,2020,42(8):2011-2023. |

| 19 | An Z H, Li S M, Wang J R, et al. Generalization of deep neural network for bearing fault diagnosis under different working conditions using multiple kernel method[J]. Neurocomputing, 2019, 352: 42-53. |

| 20 | Wang Q L, Wu B G, Zhu P F, et al. ECA-Net: efficient channel attention for deep convolutional neural networks[C]//IEEE/CVF Conference on Computer Vision and Pattern Recognition, Piscataway, USA,2020: 11531-11539. |

| 21 | Smith W A, Randall R B. Rolling element bearing diagnostics using the case Western Reserve University data: a benchmark study[J]. Mechanical Systems and Signal Processing, 2015, 64‐65: 100-131. |

| 22 | Wang B, Lei Y G, Li N P, et al. A hybrid prognostics approach for estimating remaining useful life of rolling element bearings[J]. IEEE Transactions on Reliability, 2020, 69(1): 401-412. |

| 23 | Van D M L, Maaten, Hinton G. Visualizing data using t-SNE[J]. Journal of Machine Learning Research, 2008, 9: 2579-2605. |

| 24 | He K M, Zhang X Y, Ren S Q, et al. Deep residual learning for image recognition[C]//IEEE Conference on Computer Vision and Pattern Recognition.Piscataway, USA, 2016: 770-778. |

| [1] | 李路,宋均琦,朱明,谭鹤群,周玉凡,孙超奇,周铖钰. 基于RGHS图像增强和改进YOLOv5网络的黄颡鱼目标提取[J]. 吉林大学学报(工学版), 2024, 54(9): 2638-2645. |

| [2] | 赵宏伟,武鸿,马克,李海. 基于知识蒸馏的图像分类框架[J]. 吉林大学学报(工学版), 2024, 54(8): 2307-2312. |

| [3] | 张锦洲,姬世青,谭创. 融合卷积神经网络和双边滤波的相贯线焊缝提取算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2313-2318. |

| [4] | 余萍,赵康,曹洁. 基于优化A-BiLSTM的滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2024, 54(8): 2156-2166. |

| [5] | 郭昕刚,程超,沈紫琪. 基于卷积网络注意力机制的人脸表情识别[J]. 吉林大学学报(工学版), 2024, 54(8): 2319-2328. |

| [6] | 特木尔朝鲁朝鲁,张亚萍. 基于卷积神经网络的无线传感器网络链路异常检测算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2295-2300. |

| [7] | 朱圣杰,王宣,徐芳,彭佳琦,王远超. 机载广域遥感图像的尺度归一化目标检测方法[J]. 吉林大学学报(工学版), 2024, 54(8): 2329-2337. |

| [8] | 王长建,刘久明,张锦洲,李斌. 基于高速摄影技术的行星减速箱故障激光序列脉冲诊断方法[J]. 吉林大学学报(工学版), 2024, 54(7): 1869-1875. |

| [9] | 魏晓辉,王晨洋,吴旗,郑新阳,于洪梅,岳恒山. 面向脉动阵列神经网络加速器的软错误近似容错设计[J]. 吉林大学学报(工学版), 2024, 54(6): 1746-1755. |

| [10] | 孙铭会,薛浩,金玉波,曲卫东,秦贵和. 联合时空注意力的视频显著性预测[J]. 吉林大学学报(工学版), 2024, 54(6): 1767-1776. |

| [11] | 高云龙,任明,吴川,高文. 基于注意力机制改进的无锚框舰船检测模型[J]. 吉林大学学报(工学版), 2024, 54(5): 1407-1416. |

| [12] | 夏超,王梦佳,朱剑月,杨志刚. 基于分层卷积自编码器的钝体湍流流场降阶分析[J]. 吉林大学学报(工学版), 2024, 54(4): 874-882. |

| [13] | 李晓旭,安文娟,武继杰,李真,张珂,马占宇. 通道注意力双线性度量网络[J]. 吉林大学学报(工学版), 2024, 54(2): 524-532. |

| [14] | 杨国俊,齐亚辉,石秀名. 基于数字图像技术的桥梁裂缝检测综述[J]. 吉林大学学报(工学版), 2024, 54(2): 313-332. |

| [15] | 霍光,林大为,刘元宁,朱晓冬,袁梦,盖迪. 基于多尺度特征和注意力机制的轻量级虹膜分割模型[J]. 吉林大学学报(工学版), 2023, 53(9): 2591-2600. |

|

||