吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (3): 903-911.doi: 10.13229/j.cnki.jdxbgxb20180102

运动参数对草地切根刀具与土壤作用关系的影响

梁方1,2( ),尤泳3,4(

),尤泳3,4( ),王德成3,4,王光辉3,4,贺长彬3,李帅3

),王德成3,4,王光辉3,4,贺长彬3,李帅3

- 1. 华中农业大学 工学院,武汉 430070

2. 农业部长江中下游农业装备重点实验室,武汉430070

3. 中国农业大学 工学院,北京 100083

4. 中国农业大学 农业部土壤?机器?植物系统技术重点实验室,北京 100083

Effect of dynamic parameters on relationship between root‑cutting blade and soil in grassland

Fang LIANG1,2( ),Yong YOU3,4(

),Yong YOU3,4( ),De‑cheng WANG3,4,Guang‑hui WANG3,4,Chang‑bin HE3,Shuai LI3

),De‑cheng WANG3,4,Guang‑hui WANG3,4,Chang‑bin HE3,Shuai LI3

- 1. College of Engineering, Huazhong Agricultural University, Wuhan 430070, China

2. Key Laboratory of Agricultural Equipment in Mid?lower YangtzeRiver, Ministry of Agriculture,Wuhan 430070,China

3. College of Engineering, China Agricultural University, Beijing 100083, China

4. Key Laboratory of Soil?machine?plant System of Chinese Agriculture Ministry, China Agricultural University, Beijing 100083, China

摘要:

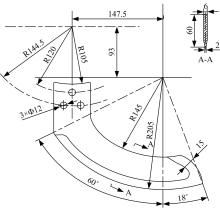

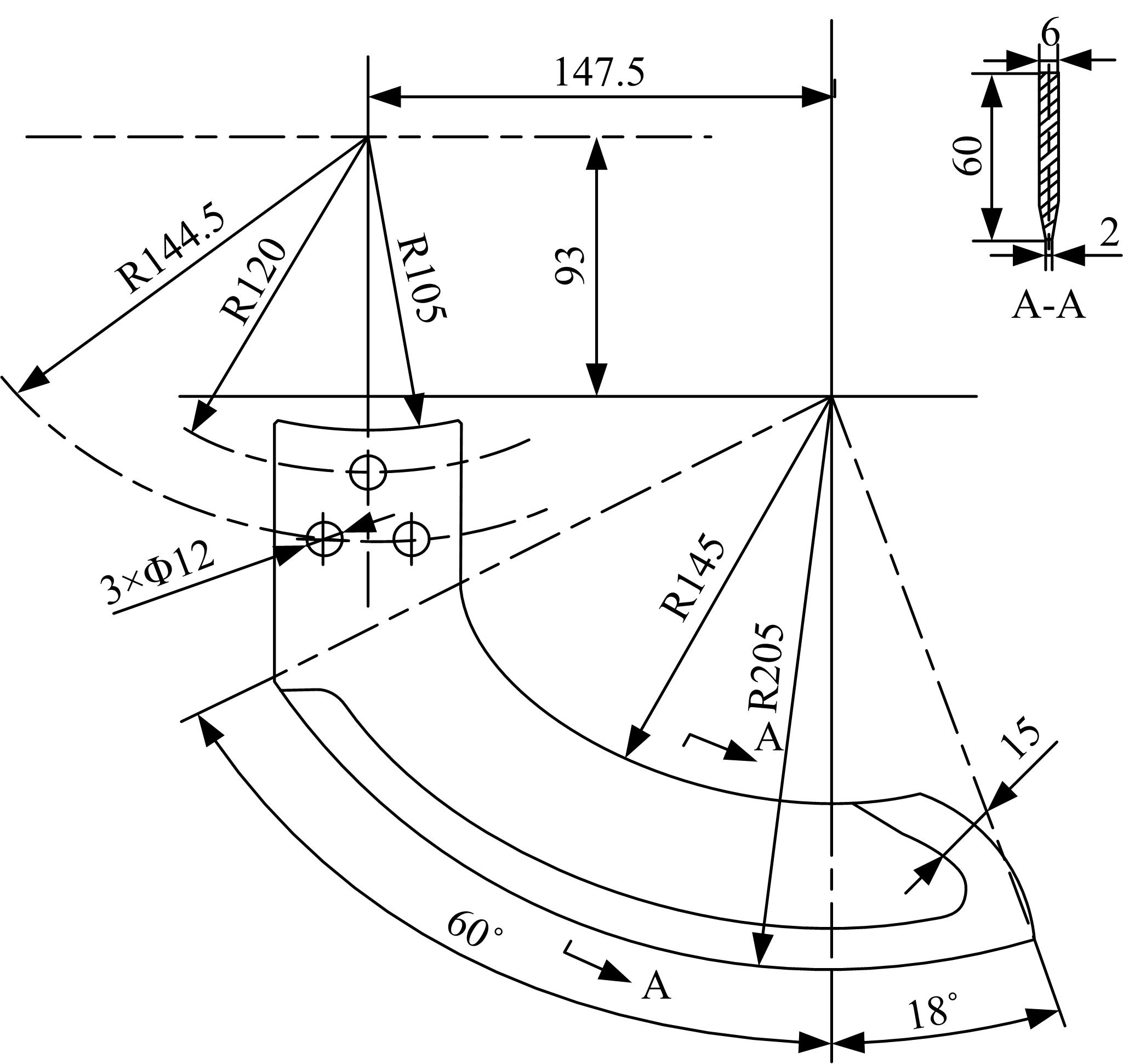

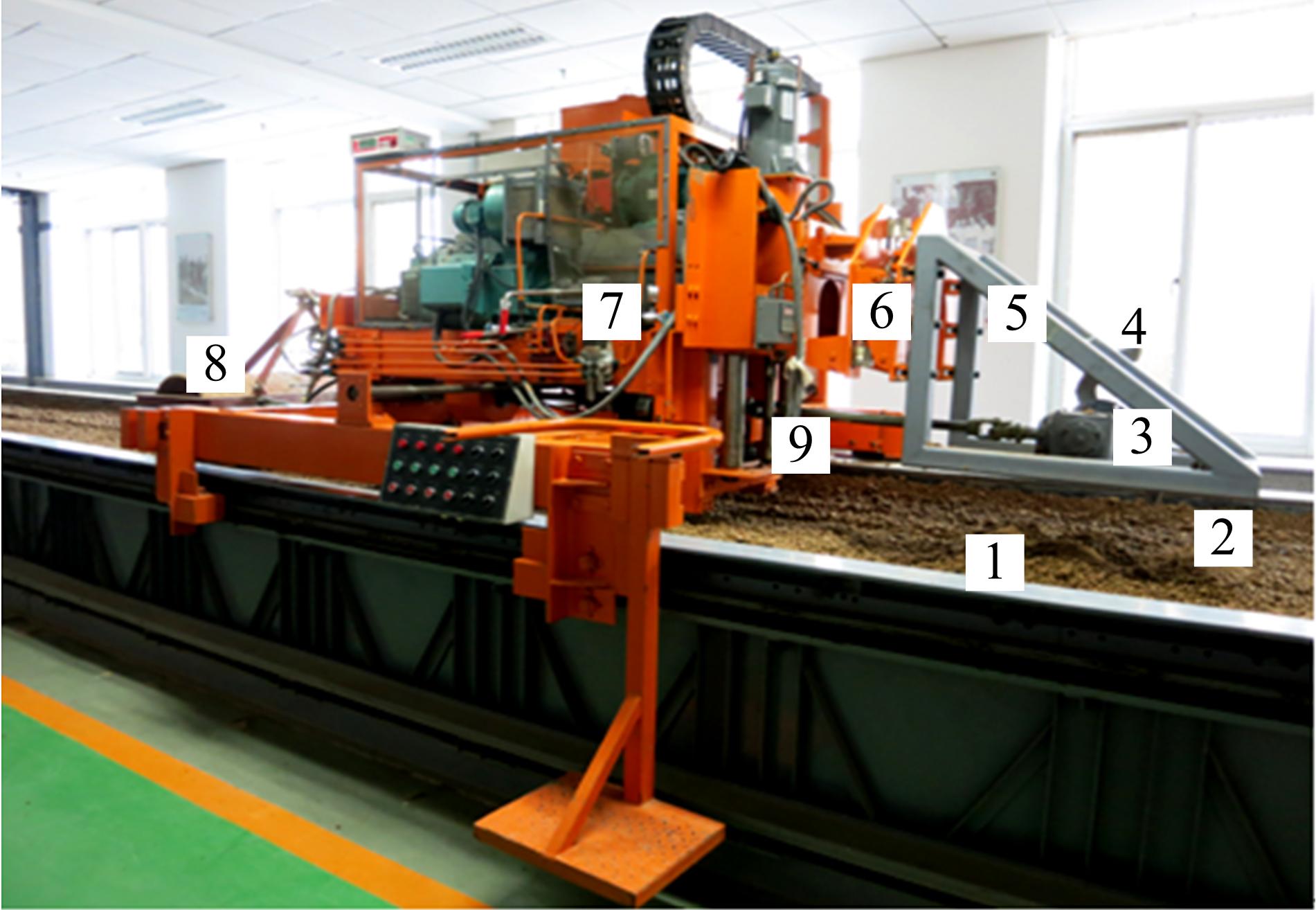

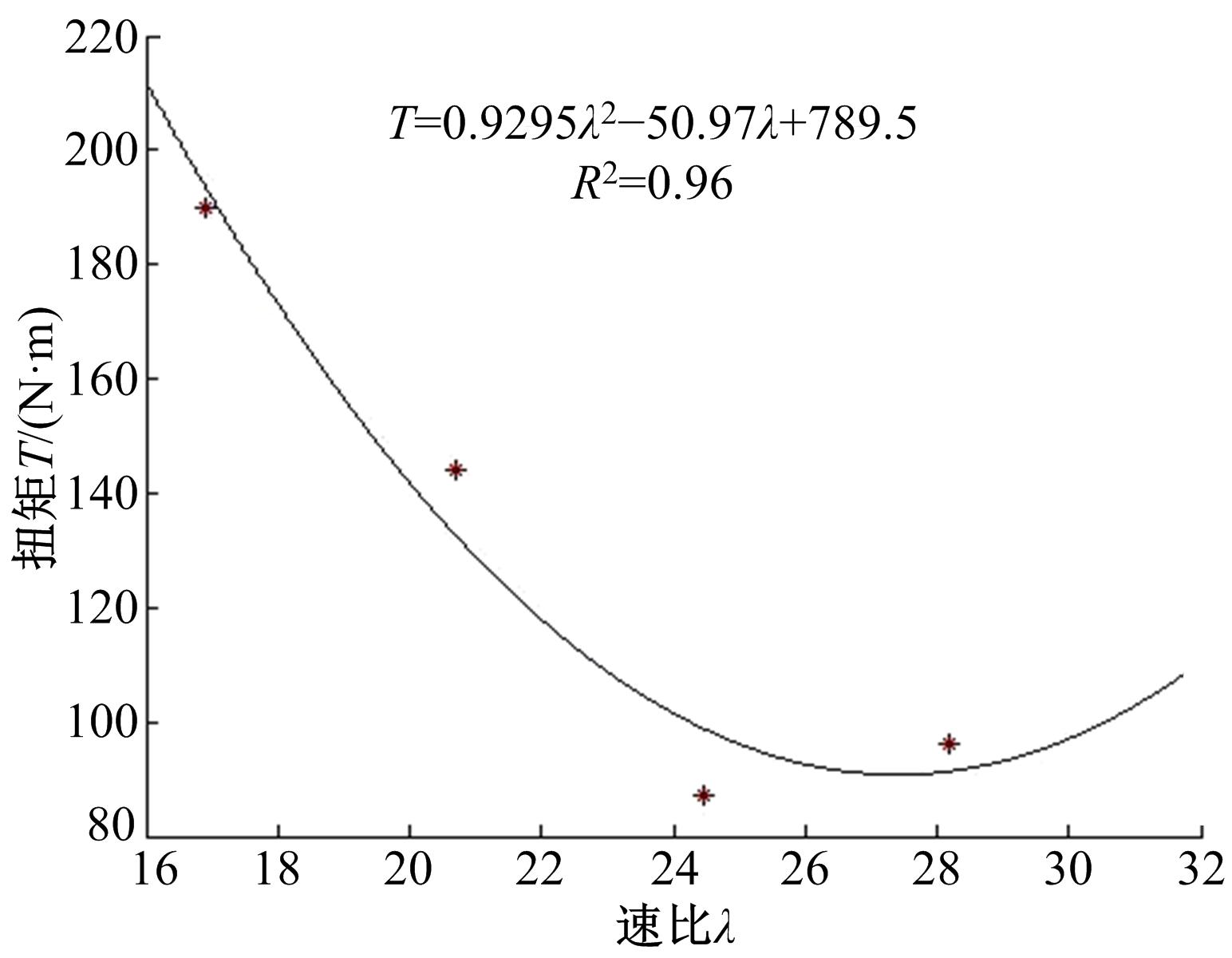

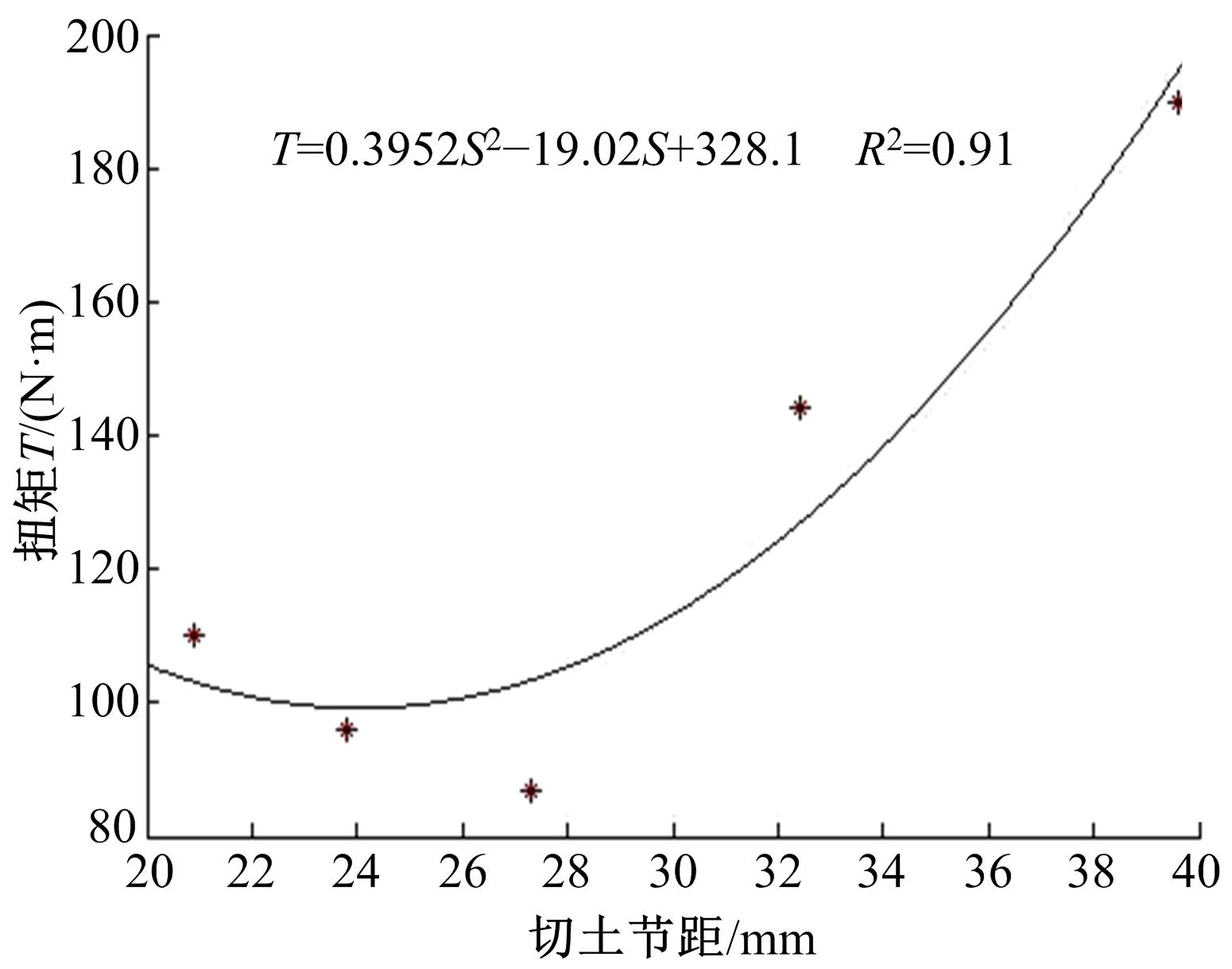

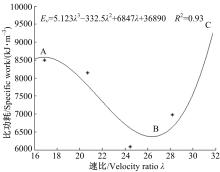

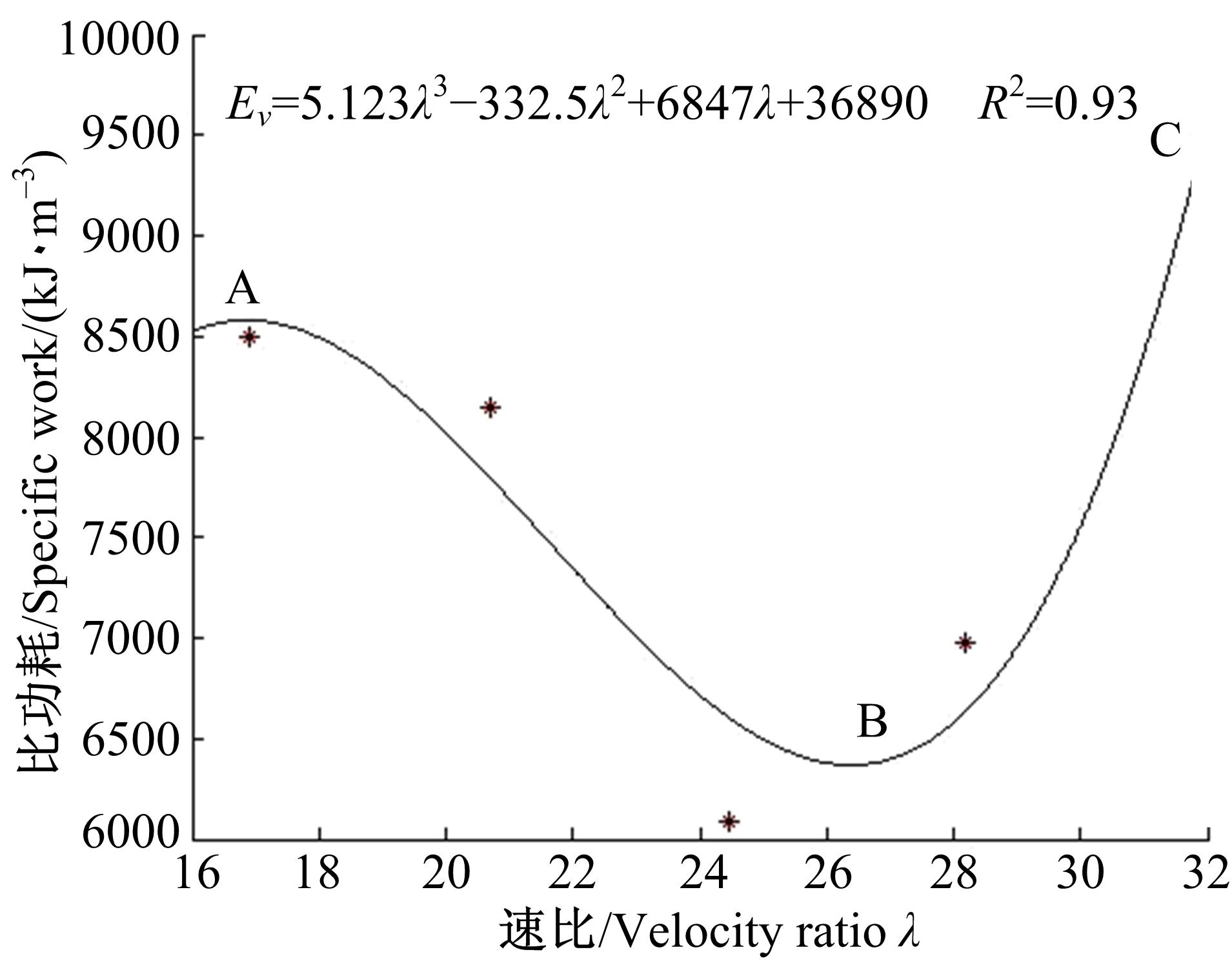

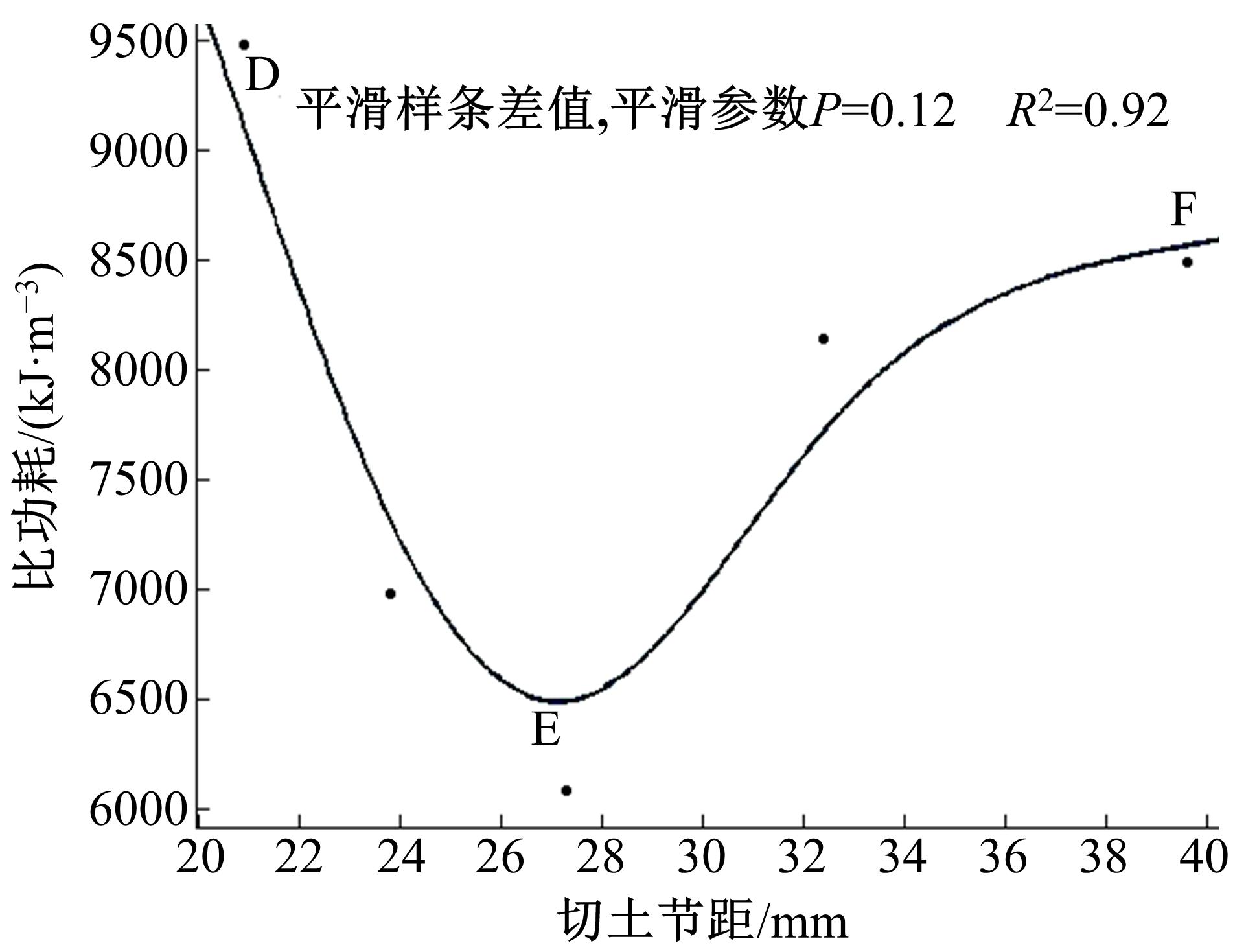

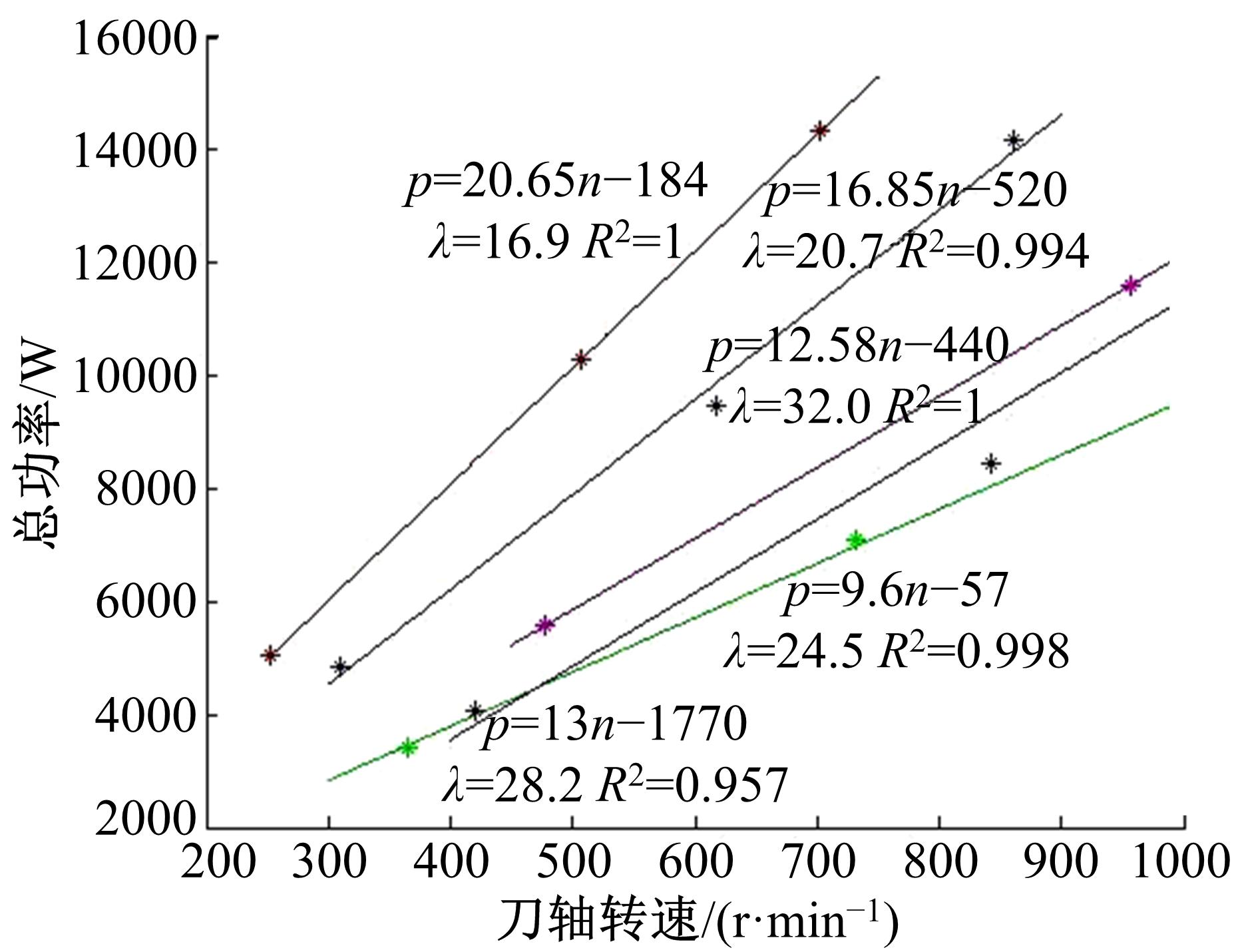

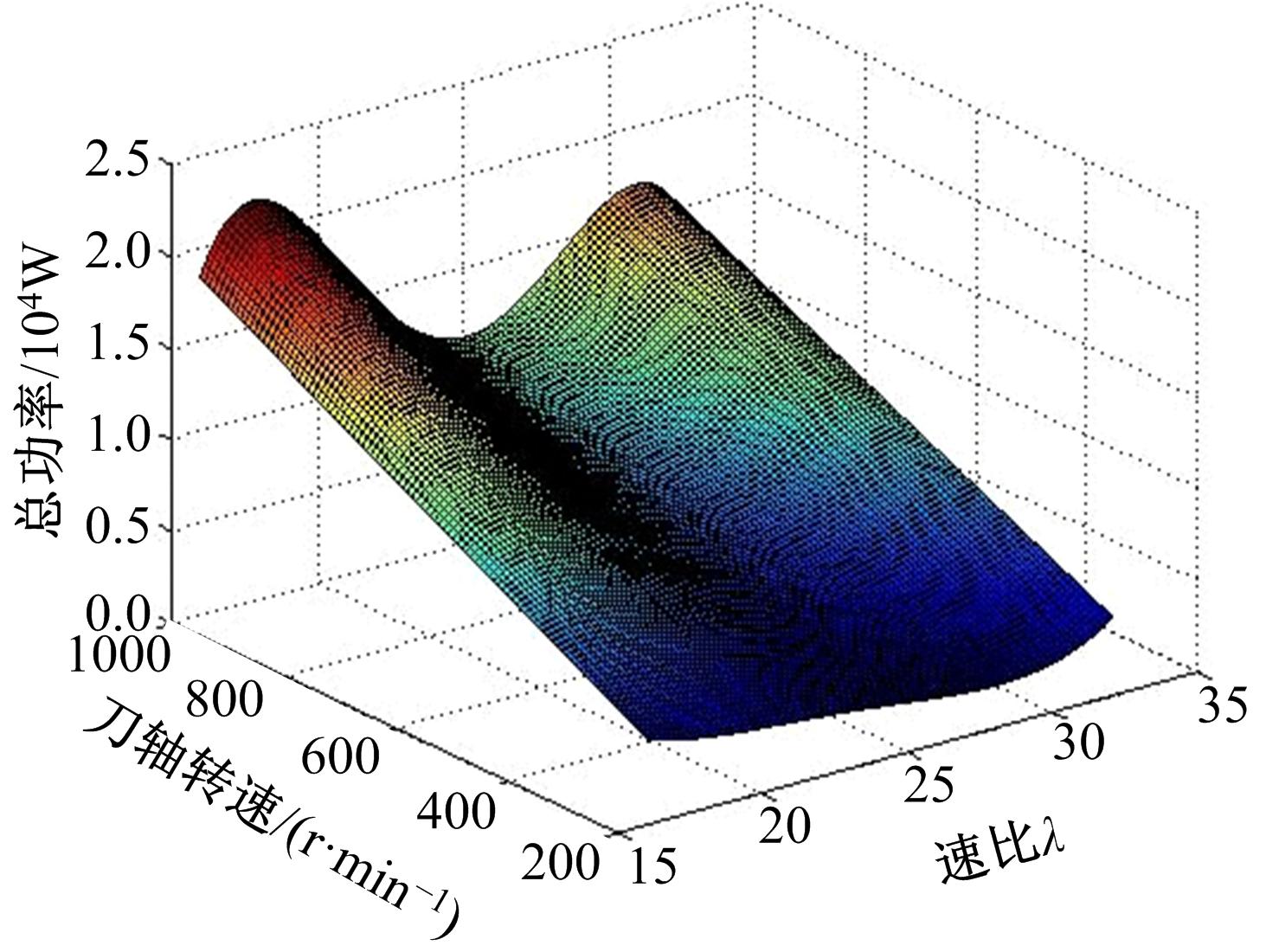

为降低切根刀具与土壤的相互作用力和功耗,优化刀轴转速与前进速度的匹配关系,通过土槽试验,得到速比(刀尖点线速度与机组行进速度的比值)分别为16.9、20.7、24.5、28.2、32.0时,不同前进速度(0.5、 1、 1.4 m/s)与转速(根据速比与前进速度计算得到)组合下的扭矩、比功耗(单位体积功耗)和总功率。分析发现,同一速比下,对应的扭矩变异系数分别为2.4%、5.2%、1.7%、7.5%、3.9%,对应的比功耗变异系数分别为1.0%、3.4%、8.8%、2.7%、2.7%,这表明在速比一定时,扭矩与比功耗同运动参数组合无关,仅由速比决定。因此,建立了速比与扭矩,速比与比功耗,速比、刀轴转速与总功率的数学关系,并通过速比与切土节距的关系,分析了产生上述规律的原因。根据建立的数学关系,在16~32的速比范围内求其极值,得到在速比分别为27.41和26.31时,扭矩和比功耗分别取得最小值90.79 N·m和6369 kJ/m3;在速比为28、转速取最小值200 r·min-1时,总功率取得最小值2362 W。速比为26.31时,即比功耗取得最小值时,扭矩和总功率均接近最小值(与最小值分别相差1.2%和4.2%),是草地切根作业适宜速比。

中图分类号:

- S222.3

| 1 | YouYong, WangDe‑cheng, LiuJu‑de. A device for mechanical remediation of degraded grasslands [J]. Soil & Tillage Research, 2012 ,118:1‑10. |

| 2 | 尤泳,王德成,王光辉. 9QP‑830型草地破土切根机[J]. 农业机械学报,2011,42(10):61‑67. |

| YouYong,WangDe‑cheng,WangGuang‑hui. 9QP‑830 soil‑gashing and root‑cutting machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(10):61‑67. | |

| 3 | 梁方. 草地切根施肥补播复式改良机械的优化设计与试验研究[D]. 北京:中国农业大学工学院,2015. |

| LiangFang. Optimization design and experiment study on root‑cutter with fertilization and reseeding compound remediation machine for grassland[D]. Beijing: College of Engineering,China Agricultural University, 2015. | |

| 4 | SawtschukJ,GalletS, BioretF. Evaluation of the most common engineering methods for maritime cliff‑top vegetation restoration[J]. Ecological Engineering, 2012, 45: 45‑54. |

| 5 | AniO A, UzoejinwaB B, Ezeama AO, et al. Overview of soil‑machine interaction studies in soil bins[J]. Soil and Tillage Research, 2018,175:13‑27. |

| 6 | UcgulM, FielkeJ M, SaundersC S. Three‑dimensional discrete element modelling of tillage: Determination of a suitable contact model and parameters for a cohesionless soil[J]. Biosystems Engineering, 2014,121:105‑117. |

| 7 | 杨艳山,丁启朔,丁为民,等. 田间原位综合耕作试验台设计与应用[J]. 农业机械学报, 2016, 47(1): 68‑74. |

| YangYan‑shan, DingQi‑shuo, DingWei‑min, et al. Design and application of multi‑purpose in‑situ tillage tool testing platform[J]. Transactions of the Chinese Society for Agricultural Machinery,2016,47(1):68‑74. | |

| 8 | 熊平原,杨洲,孙志全,等. 旋耕刀三向工作阻力试验及作业参数优化[J]. 农业工程学报, 2017,33(19): 51‑58. |

| XiongPing‑yuan, YangZhou, SunZhi‑quan, et al. Experiment on three‑axis working resistances of rotary blade and working parameters optimization[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(19): 51‑58. | |

| 9 | 刘孝民,尤玉锴,周晓艳. 旋耕机运动参数优化问题的讨论[J]. 农业机械学报,1996,27(2):137‑140. |

| LiuXiao‑min, YouYu‑kai, ZhouXiao‑yan. The discussion on the optimization of the dynamic parameters of rotary tillage[J]. Transactions of the Chinese Society for Agricultural Machinery, 1996, 27(2):137‑140. | |

| 10 | 李永磊,宋建农,康小军,等. 双辊秸秆还田旋耕机试验[J]. 农业机械学报,2013,44(6):45‑49. |

| LiYong‑lei, SongJian‑nong, KangXiao‑jun, et al. Experiment on twin‑roller cultivator for straw returning[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(6):45‑69. | |

| 11 | 李永磊,宋建农,董向前,等. 基于土槽试验台的旋转耕作部件试验装置设计[J]. 农业工程学报,2012,28(17):38‑43. |

| LiYong‑lei, SongJian‑nong, DongXiang‑qian, et al. Design of test device for rotary tiller components based on soil bin[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(17):38‑43. | |

| 12 | 张秀梅,夏俊芳,张居敏,等. 水旱两用秸秆还田组合刀辊作业性能试验[J]. 农业工程学报,2016,32(9): 9‑15. |

| ZhangXiu‑mei, XiaJun‑fang, ZhangJu‑min, et al. Working performance experiment of combination blade roller for straw returning in paddy field and dry land[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016,32(9):9‑15 . | |

| 13 | MatinM A, FielkeJ M, DesbiollesJ M A. Torque and energy characteristics for strip‑tillage cultivation when cutting furrows using three designs of rotary blade[J]. Biosystems Engineering,2015,129: 329‑340. |

| 14 | AmbassahN O, FukagawaR. Developing an excavation torque model for dense cohesionless soils[J]. Journal of Terramechanics 2005, 42:83‑98. |

| 15 | ImanAhmadi. A torque calculator for rotary tiller using the laws of classical mechanics[J]. Soil and Tillage Research, 2017, 165:137‑143. |

| 16 | ChertkiattipolS, NiyamapaT. Variations of torque and specific tilling energy for different rotary blades[J]. International Agricultural Engineering Journal, 2010,19(3):1‑14. |

| 17 | KarmakarS, AshrafizadehS R, KushwahaR L. Experimental validation of computational fluid dynamics modeling for narrow tillage tool draft[J]. Journal of Terramechanics,2009,46(6): 277‑283. |

| 18 | 方在华,张文春,刘夫云. 拖拉机旋耕机组旋耕速比的确定[J]. 农业机械学报,1997,28(1):24‑28. |

| FangZai‑hua,ZhangWen‑chun,LiuFu‑yun. Determination of the rototilling speed ratio for tractor rototilling unit[J]. Transactions of the Chinese Society for Agricultural Machinery, 1997, 28(1): 24‑28. | |

| 19 | 董向前,宋建农,王继承,等. 作业速度比对草地振动松土机作业性能的影响[J]. 江苏大学学报:自然科学版,2014,35(3):301‑305. |

| DongXiang‑qian, SongJian‑nong, WangJi‑cheng, et al. Effect of velocity ratio on performance of oscillatory tillage[J]. Journal of Jiangsu University (Nature Science Edition), 2014,35(3):301‑305. | |

| 20 | HirasawaK, KataokaT, KuboT. Relationship between required power and PTO speed in rotary tiller[J].IFAC Proceedings Volumes, 2013,46(4): 141‑146. |

| 21 | KheirallaA F, YahyaA, ZohadieM, et al. Modelling of power and energy requirements for tillage implements operating in Serdang sandy clay loam, Malaysia[J]. Soil and Tillage Research, 2004,78(1): 21‑34. |

| 22 | AslJ H, SinghS. Optimization and evaluation of rotary tiller blades: computer solution of mathematical relations[J]. Soil & Tillage Research, 2009, 106(1): 1‑7. |

| 23 | MiszczakM. A torque evaluation for a rotary subsoiler[J]. Soil & Tillage Research , 2005, 84(2): 175‑183. |

| 24 | 曾德超.机械土壤动力学[M].北京:北京科学技术出版社,1995. |

| 25 | 尤泳. 退化羊草草地机械化破土切根改良技术优化研究[D]. 北京:中国农业大学工学院,2011. |

| YouYong. Mechanical remediation technology of degraded grassland (leymus‑chinensis) [D]. Beijing: College of Engineering, China Agricultural University, 2011. | |

| 26 | 李永磊. 双辊秸秆还田旋耕机理论与试验研究[D]. 北京:中国农业大学工学院,2014. |

| LiYong‑lei .Theoretical and experiment study on the twin‑roller cultivator for straw returning[D]. Beijing: College of Engineering, China Agricultural University, 2014. | |

| 27 | 中华人民共和国国家质检总局. NY/T 52—1987,土壤水分测定法[M]. 北京:中国标准出版社,1987. |

| 28 | 王益,刘军,王益权,等.黄土高原南部3种农田土壤剖面坚实度的变化规律[J]. 西北农林科技大学学报:自然科学版,2007,35(9):200‑204. |

| WangYi, LiuJun,WangYi‑quan, et al. Variation of soil compactness in 3 kinds of farmland soil profile in south Loess Plateau[J]. Journal of Northwest A & F University(Naturnal Science Editon), 2007,35(9): 200‑204. | |

| 29 | 张淑娟,裘正军,王凤花,等. 农田土壤含水率和坚实度采集仪设计与试验[J]. 农业机械学报,2010,41(9),41(9):75‑79. |

| ZhangShu‑juan, QiuZheng‑jun, WangFeng‑hua, et al. Design and test on the field soil moisture and compaction acquisition instrument[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(9):75‑79. | |

| 30 | 中国农业机械化科学研究院.农业机械设计手册(上)[M].北京:中国农业科学技术出版社,2007. |

| 31 | 李宝筏. 农业机械学[M]. 北京:中国农业出版社,2003. |

| [1] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [2] | 贾洪雷, 王万鹏, 陈志, 庄健, 王文君, 刘慧力. 基于土壤坚实度的仿形弹性镇压辊镇压力实时测量方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1169-1175. |

| [3] | 陈东辉, 吕建华, 龙刚, 张宇晨, 常志勇. 基于ADAMS的半悬挂式农业机组静侧翻稳定性[J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

| [4] | 秦大同, 林毓培, 胡建军, 郭子涵. 基于无级变速器速比控制的插电式混合动力汽车再生制动控制策略[J]. 吉林大学学报(工学版), 2018, 48(2): 380-386. |

| [5] | 王扬, 吕凤妍, 徐天月, 于建群. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [6] | 贾洪雷, 郑嘉鑫, 袁洪方, 郭明卓, 王文君, 于路路. 大豆播种机双V型筑沟器设计与试验[J]. 吉林大学学报(工学版), 2017, 47(1): 323-331. |

| [7] | 肖志锋, 乐建波, 吴南星, 刘相东. 操作压力对过热蒸汽流化床干燥的影响[J]. 吉林大学学报(工学版), 2015, 45(4): 1375-1380. |

| [8] | 曾义聪,徐海良,李峰,吴波. 鼓形误差对高压辊磨机组合辊承载扭矩的影响[J]. 吉林大学学报(工学版), 2015, 45(2): 466-472. |

| [9] | 张金波,佟金,马云海. 仿生肋条结构表面深松铲刃的磨料磨损特性[J]. 吉林大学学报(工学版), 2015, 45(1): 174-180. |

| [10] | 齐龙, 谭祖庭, 马旭, 陈国锐, 谢俊锋, 邝健霞. 气动振动式匀种装置工作参数的优化及试验[J]. 吉林大学学报(工学版), 2014, 44(6): 1684-1691. |

| [11] | 雷雨龙, 李兴忠, 杨成, 孙少华, 吕二华. TC+AMT中湿式多片离合器带排扭矩及其对换档同步过程的影响[J]. 吉林大学学报(工学版), 2014, 44(01): 22-28. |

| [12] | 齐龙, 廖文强, 马旭, 林建衡, 区志行, 詹志勋. 水田小型除草机器人平台控制系统设计与测试[J]. 吉林大学学报(工学版), 2013, 43(04): 991-996. |

| [13] | 翟治芬, 严昌荣, 张建华, 张燕卿, 刘爽. 基于蚁群算法和支持向量机的节水灌溉技术优选[J]. 吉林大学学报(工学版), 2013, 43(04): 997-1003. |

| [14] | 张强, 张璐, 刘宪军, 于路路, 贾洪雷. 基于有限元法的仿生钩形深松铲耕作阻力[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 117-121. |

| [15] | 王增辉, 黄东岩, 李卓识, 贾洪雷, 万宝成. 工作参数对旋耕碎茬通用刀片功率消耗的影响[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 122-125. |

|

||