吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (5): 1385-1391.doi: 10.13229/j.cnki.jdxbgxb20180797

• •

采用聚乳酸复合材料的汽车零件多材料优化设计

马芳武1,2( ),韩露1,2,周阳3,王世英4,蒲永锋1,2(

),韩露1,2,周阳3,王世英4,蒲永锋1,2( )

)

- 1. 吉林大学 汽车仿真与控制国家重点实验室, 长春 130022

2. 吉林大学 青岛汽车研究院, 山东 青岛 266000

3. 中国一汽轿车整车开发部, 长春 130031

4. 中国第一汽车集团有限公司 研发总院试验所, 长春 130031

Multi material optimal design of vehicle product using polylactic acid composites

Fang-wu MA1,2( ),Lu HAN1,2,Yang ZHOU3,Shi-ying WANG4,Yong-feng PU1,2(

),Lu HAN1,2,Yang ZHOU3,Shi-ying WANG4,Yong-feng PU1,2( )

)

- 1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2. Qingdao Automotive Research Institute, Jilin University, Qingdao 266000, China

3. FAW Vehicle Development Department, Changchun 130031, China

4. China FAW Group CO. , LTD. Product Development and Research Center Vehicle Test Department, Changchun 130031, China

摘要:

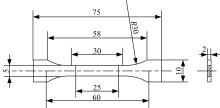

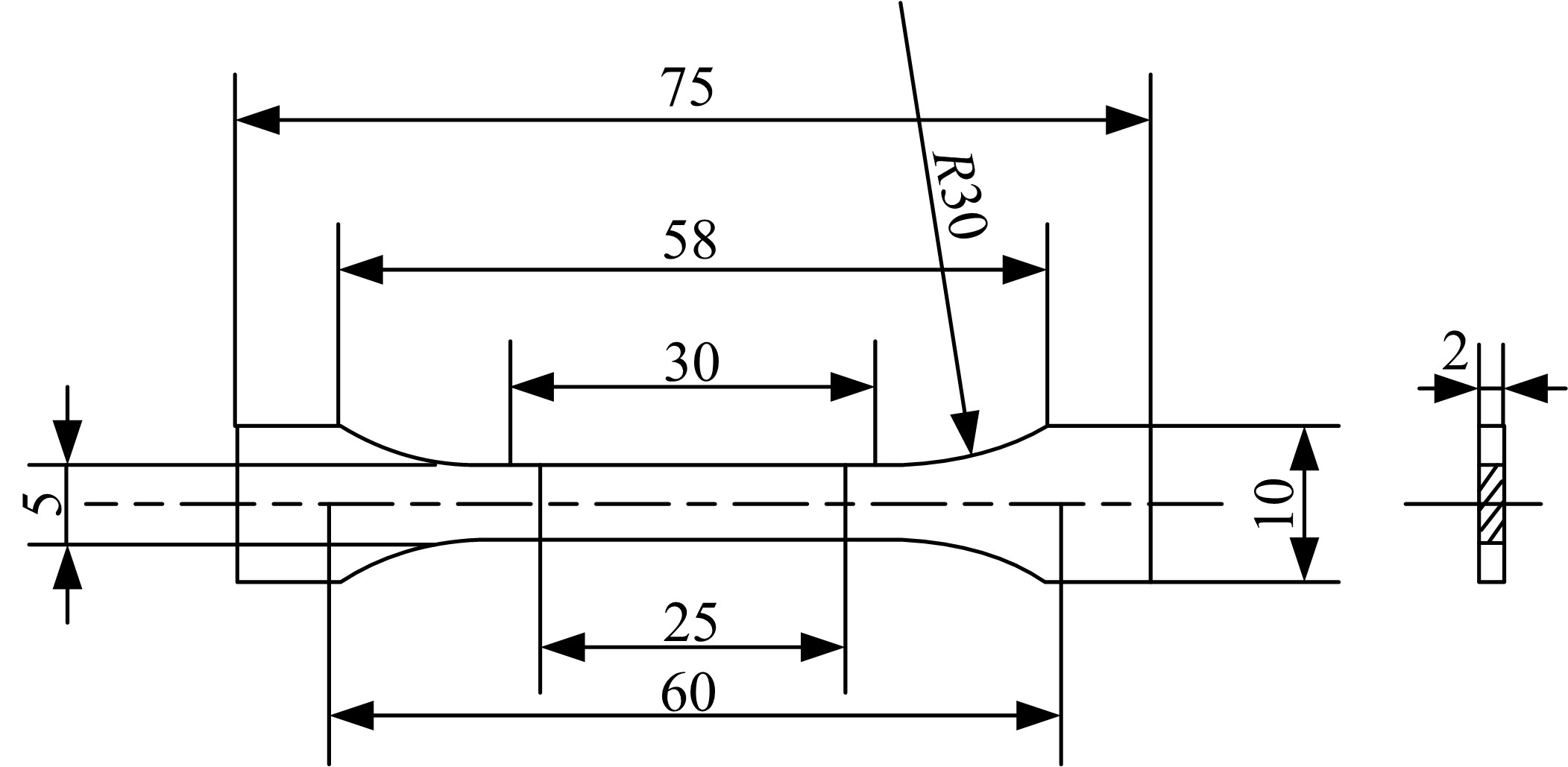

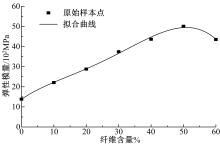

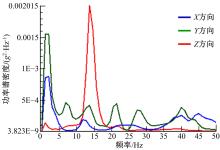

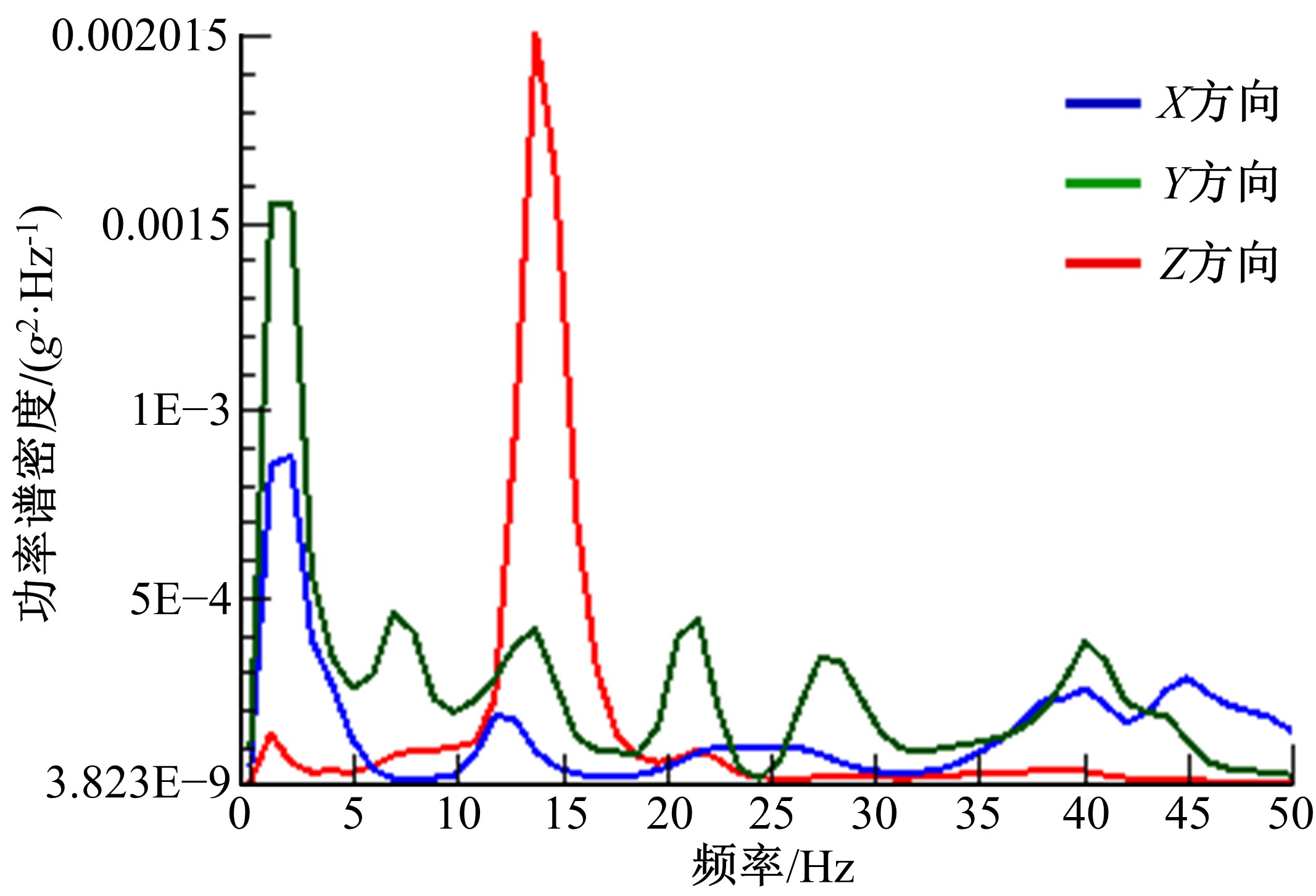

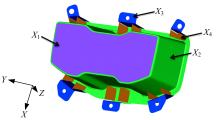

以玄武岩纤维为增强材料,增强聚乳酸拉伸力学性能使其满足汽车非金属产品的力学性能要求,同时利用多材料方法设计产品,实现轻量化。首先研究了玄武岩纤维含量与其复合材料的关系,通过多材料设计方法并以零件的实际工况为设计条件对产品进行再设计。利用多岛遗传算法(MIGA)与遗传算法-响应面(GA?RSM)模型结合的优化方法寻求最优材料参数组合。结果表明:玄武岩纤维可提高聚乳酸的力学性能,GA?RSM模型在预测值时有较高的精确性,通过以上设计方法,使零件质量降低了9%。以上结果证明了聚乳酸复合材料可作为石油基材料的替代品应用到汽车产品研发中;多材料设计结合MIGA的方法可实现汽车产品轻量化。

中图分类号:

- U41

| 1 | 刘永涛, 赵俊玮, 乔洁, 等. 我国汽车产品再制造的问题剖析与对策建议[J]. 汽车工程学报, 2018, 8(3): 168-175. |

| LiuYong-tao, ZhaoJun-wei, QiaoJie, et al. Analysis and countermeasures of automotive parts remanufacturing in china[J]. Chinese Journal of Automotive Engineering, 2018, 8(3): 168-175. | |

| 2 | 刘国伟. 欧盟要求汽车材料回收率达85%各国报废汽车怎样涅槃重生[J]. 环境与生活, 2018(4): 16-21. |

| LiuGuo-wei. The EU calls for the recovery rate of automobile materials up to 85%[J]. Green Living, 2018(4): 16-21. | |

| 3 | 陈元华, 杨沿平, 胡纾寒, 等. 我国报废汽车回收利用现状分析与对策建议[J]. 中国工程科学, 2018, 20(1): 113-119. |

| ChenYuan-hua, YangYan-ping, HuXu-han, et al. Analysis and countermeasures for the status quo of the recycling and utilization of end-of-life vehicles in China[J]. Engineering Sciences, 2018, 20(1): 113-119. | |

| 4 | 孔茗. 新环保要求下报废车用塑料回收利用现状分析与展望[J]. 塑料科技, 2018, 46(6): 127-130. |

| KongMing. Analysis and prospect of recycling of discarded vehicle plastics under new environmental protection requirements[J]. Plastics Science and Technology, 2018, 46(6): 127-130. | |

| 5 | TianGuang-dong, ZhangHong-hao. Green decoration materials selection under interior environment characteristics: a grey-correlation based hybrid MCDM method[J]. Renewable & Sustainable Energy Reviews, 2018, 81: 682-692. |

| 6 | TianGuang-dong, ZhangHong-hao. Operation patterns analysis of automotive components remanufacturing industry development in China[J]. Journal of Cleaner Production, 2017, 164: 1363-1375. |

| 7 | 张迪, 齐锦刚, 张伟, 等. 碳纤维表面处理对脉冲电磁场作用下碳纤维增强聚乳酸基复合材料降解行为的影响[J]. 复合材料学报, 2018, 35(3): 521-527. |

| ZhangDi, QiJin-gang, ZhangWei, et al. Effect of carbon fiber surface treatment on the degradation of carbon fiber reinforced polylactic acid composites under pulsed electromagnetic[J]. Acta Materiae Compositae Sinica, 2018, 35(3): 521-527. | |

| 8 | 马艾丽, 肖翔云, 黄丹敏, 等. 木质素/PLA复合材料力学性能研究[J]. 广东化工, 2018(3): 32-33. |

| MaAi-li, XiaoXiang-yun, HuangDan-min, et al. Study on mechanical property of lignin/PLA composites[J]. Guangdong Chemical Industry, 2018(3): 32-33. | |

| 9 | LobanovD S, SlovikovS V. Mechanical properties of a unidirectional basalt-fiber-reinforced plastic under a loading simulating operation conditions[J]. Mechanics of Composite Materials, 2017, 52(6): 767-772. |

| 10 | 董丽茜, 陈进富. 玄武岩纤维在环保领域的应用研究现状及展望[J]. 当代化工, 2018, 47(2): 387-391, 420. |

| DongLi-qian, ChenJin-fu. Application status and prospect of basalt fiber in environmental protection[J]. Contemporary Chemical Industry, 2018, 47(2): 387-391, 420. | |

| 11 | 王明超, 张佐光, 孙志杰, 等. 连续玄武岩纤维及其复合材料耐腐蚀特性[J]. 北京航空航天大学学报, 2006, 32(10): 1255-1258. |

| WangMing-chao, ZhangZuo-guang, SunZhi-jie, et al. Corrosion resistance characteristic of continuous basalt fiber and its reinforcing composites[J]. Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(10): 1255-1258. | |

| 12 | Sakhaei, AmirH, Kaijima, et al. Design and investigation of a multi-material compliant ratchet-like mechanism[J]. Mechanism and Machine Theory, 2018, 121: 184-197. |

| 13 | 陈进, 李松林, 孙振业, 等. 风力机专用翼型气动结构一体化设计[J]. 吉林大学学报: 工学版, 2016, 46(6): 1940-1945. |

| ChenJin, LiSong-lin, SunZhen-ye, et al. Integrated design of aerodynamic and structural performance for wind turbine dedicated airfoil[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(6): 1940-1945. | |

| 14 | 王登峰, 卢放. 基于多学科优化设计方法的白车身轻量化[J]. 吉林大学学报: 工学版, 2015, 45(1): 29-37. |

| WangDeng-feng, LuFang. Body-in-white lightweight based on multidisciplinary design optimization[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(1): 29-37. | |

| 15 | LiuJian, YuGao-yuan, LiYao, et al. Multidisciplinary design optimization of crankshaft structure based on cooptimization and multi-island genetic algorithm[J]. Mathematical Problems in Engineering, 2016(539): 1-11. |

| 16 | HuXing-zhi, ChenXiao-qian. Optimization design of satellite separation systems based on Multi-Island Genetic Algorithm[J] Advances in Space Research, 2014, 53(5): 870-876. |

| 17 | 孙宝寿, 吴真繁, 陈哲. 响应面法与遗传算法相结合的注塑工艺优化[J]. 中国机械工程, 2010, 21(9): 1115-1118. |

| SunBao-shou, WuZhen-fan, ChenZhe. Process parameter optimization of injection molding by combining RSM/GA method[J]. China Mechanical Engineering, 2010, 21(9): 1115-1118. | |

| 18 | 王穗辉, 潘国荣. 遗传算法在非线性回归模型建立中的应用[J]. 大地测量与地球动力学, 2008, 28(1): 59-64. |

| WangHui-hui, PanGuo-rong. Application of genetic algorithm in nonlinear regression model generating[J]. Journal of Geodesy and Geodynamics, 2008, 28(1): 59-64. |

| [1] | 李静,石求军,刘鹏,户亚威. 基于纵向车速估算的商用车ABS神经网络滑模控制[J]. 吉林大学学报(工学版), 2019, 49(4): 1017-1025. |

| [2] | 杨顺,蒋渊德,吴坚,刘海贞. 基于多类型传感数据的自动驾驶深度强化学习方法[J]. 吉林大学学报(工学版), 2019, 49(4): 1026-1033. |

| [3] | 陈鑫,李铭,阮新建,王宁,王佳宁. 基于浸入单元法和延迟分离涡模型的Ahmed车模尾流涡旋结构[J]. 吉林大学学报(工学版), 2019, 49(4): 1034-1042. |

| [4] | 周华,杨志刚,朱晖. 基于整车风洞试验的MIRA车型数值计算[J]. 吉林大学学报(工学版), 2019, 49(4): 1043-1053. |

| [5] | 陈吉清,刘蒙蒙,兰凤崇. 三元动力电池及其成组后的过充安全性试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1072-1080. |

| [6] | 柳润东,毛军,郗艳红,张宏宇,彭飞. 横风下高速列车会车压力波对风障的气动冲击[J]. 吉林大学学报(工学版), 2019, 49(4): 1054-1062. |

| [7] | 秦国锋,那景新,慕文龙,谭伟,栾建泽,申浩. 高温老化对CFRP/铝合金粘接接头失效的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1063-1071. |

| [8] | 张立斌,吴岛,单洪颖,邓祥敬. 基于制动试验台架的多轴车轴荷自调系统设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1081-1091. |

| [9] | 李寿涛,李秋媛,刘辉,丁辉,田彦涛,于丁力. 可实现车辆稳定性控制的滑模变结构策略[J]. 吉林大学学报(工学版), 2019, 49(4): 1288-1292. |

| [10] | 常成,宋传学,张雅歌,邵玉龙,周放. 双馈电机驱动电动汽车变频器容量最小化[J]. 吉林大学学报(工学版), 2018, 48(6): 1629-1635. |

| [11] | 席利贺,张欣,孙传扬,王泽兴,姜涛. 增程式电动汽车自适应能量管理策略[J]. 吉林大学学报(工学版), 2018, 48(6): 1636-1644. |

| [12] | 何仁,杨柳,胡东海. 冷藏运输车太阳能辅助供电制冷系统设计及分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1645-1652. |

| [13] | 那景新,慕文龙,范以撒,谭伟,杨佳宙. 车身钢-铝粘接接头湿热老化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1653-1660. |

| [14] | 刘玉梅,刘丽,曹晓宁,熊明烨,庄娇娇. 转向架动态模拟试验台避撞模型的构建[J]. 吉林大学学报(工学版), 2018, 48(6): 1661-1668. |

| [15] | 赵伟强, 高恪, 王文彬. 基于电液耦合转向系统的商用车防失稳控制[J]. 吉林大学学报(工学版), 2018, 48(5): 1305-1312. |

|

||