吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (4): 1287-1295.doi: 10.13229/j.cnki.jdxbgxb20200209

• 交通运输工程·土木工程 • 上一篇

基于不同孔径范围的碳化作用下纤维混凝土的气体渗透性能和细观结构

- 东北大学 资源与土木工程学院,沈阳 110819

Gas permeability and meso-structure of fiber reinforced concrete under carbonation based on different pore sizes

- School of Resources and Civil Engineering,Northeastern University,Shenyang 110819,China

摘要:

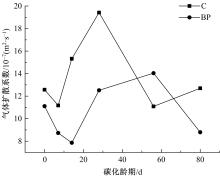

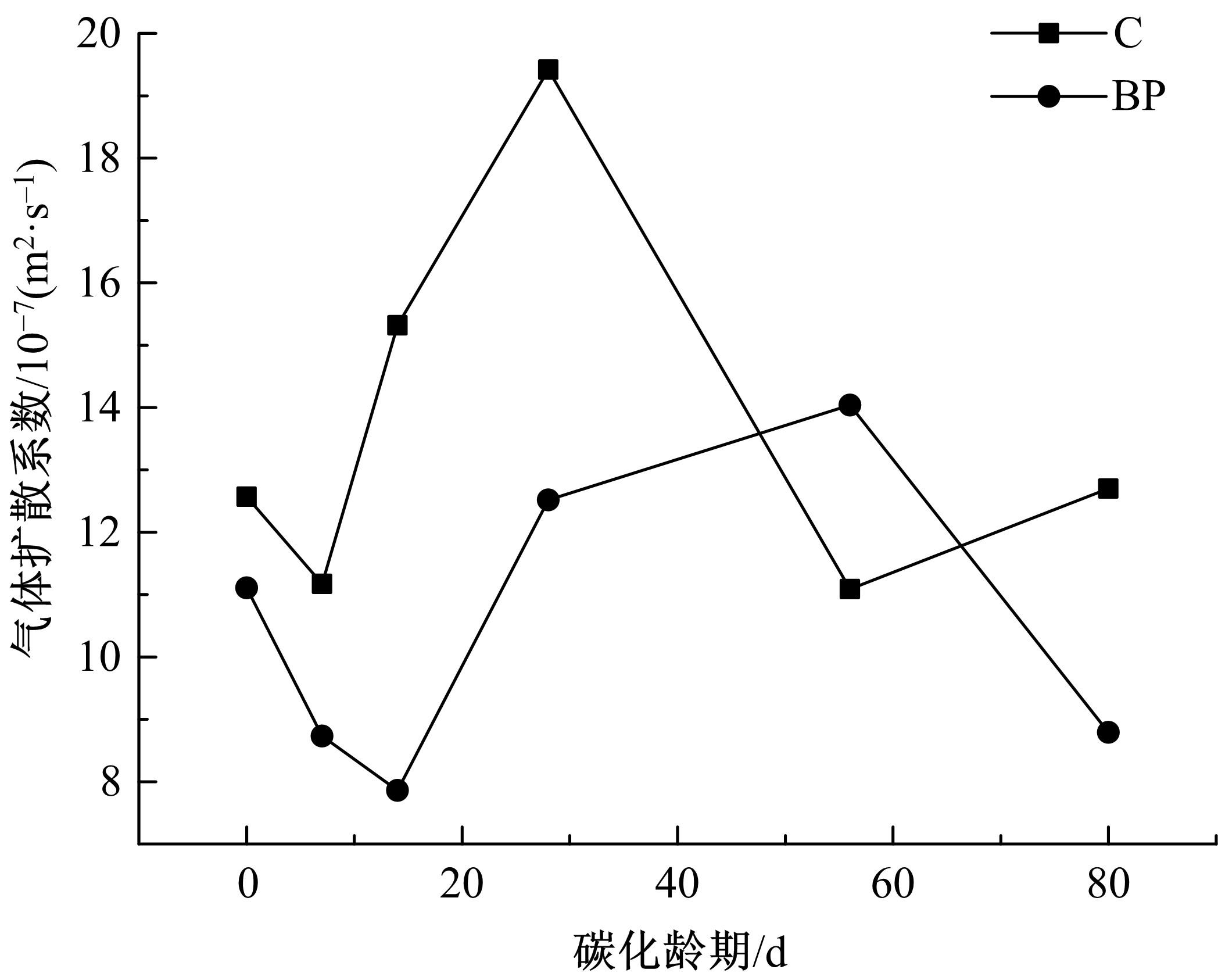

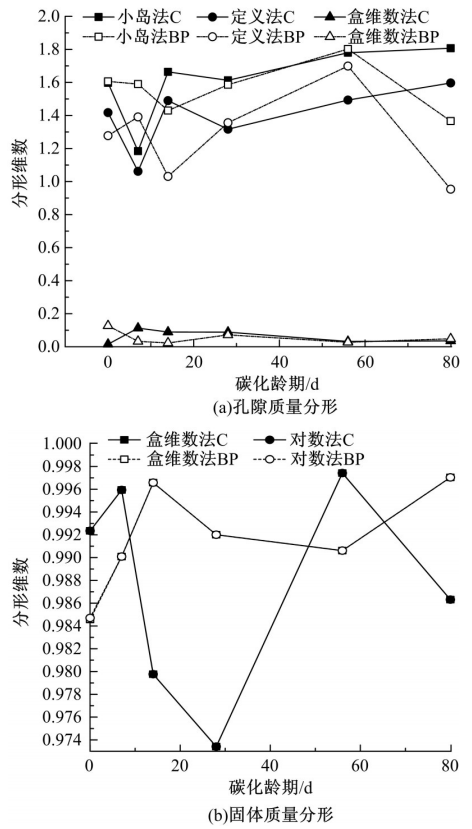

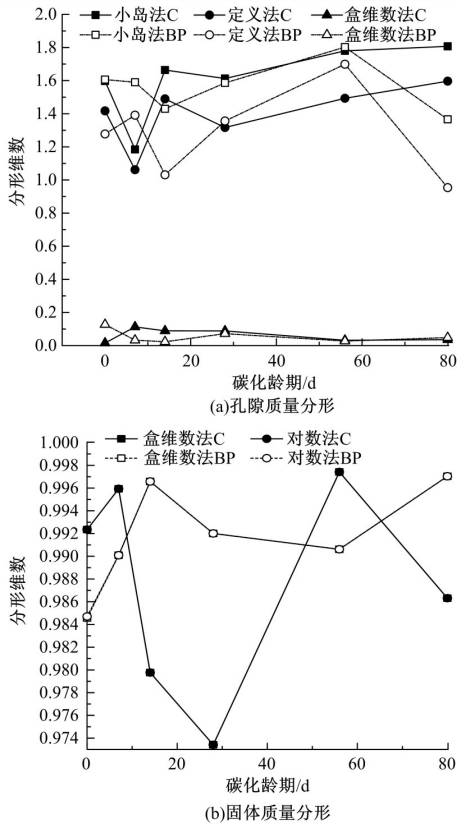

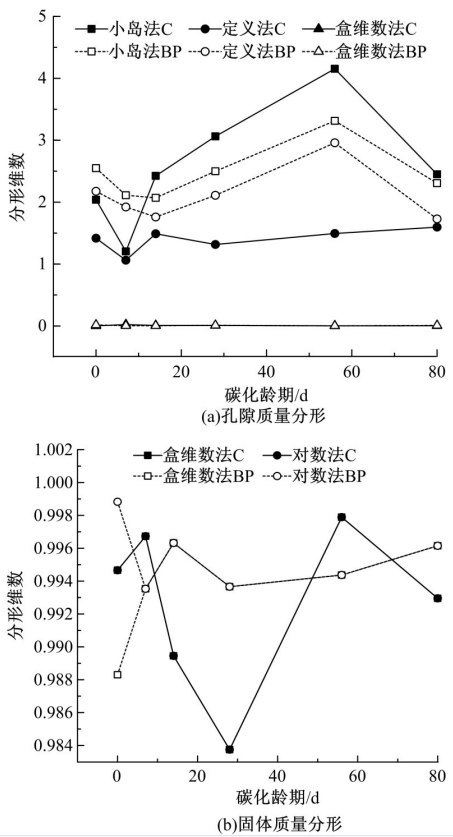

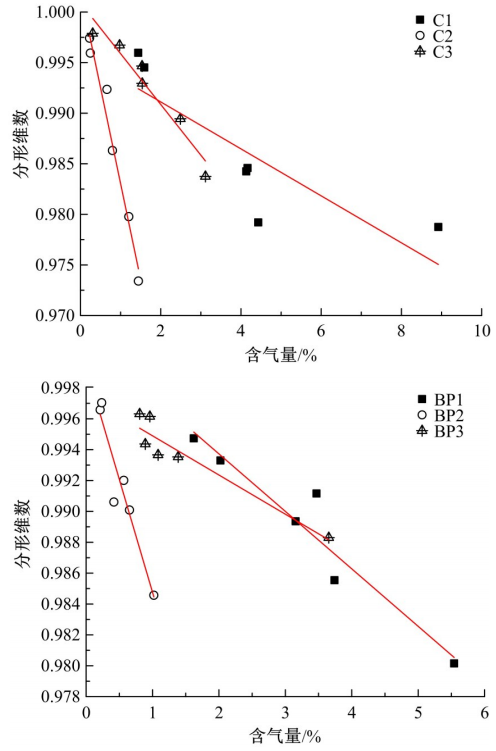

为研究碳化后混凝土的气体渗透性能和细观结构的关系,针对普通混凝土(C)和聚丙烯-玄武岩纤维混凝土(BP)进行碳化龄期分别为0、7、14、28、56、80天碳化试验和气体渗透性试验,采用丹麦Rapidair457混凝土气孔结构分析仪获取混凝土细观结构特征参数,基于不同孔径范围、计算方法对混凝土含气量、分形维数的影响水平不同,将混凝土孔径划分为0~160、160~300、300~4000 μm三个范围,分别计算含气量和分形维数,分析碳化龄期和材料对于宏、细观性能的影响,研究混凝土气渗性能、分形维数和细观结构的内在联系,给出敏感孔径范围。结果表明:BP气体扩散系数和含气量总体上小于C,说明纤维混掺可从不同层次上改善纤维三维分布的均衡性,提高混凝土抗碳化性能。随碳化龄期增加,对于C,小孔径范围下孔隙质量分形维数的变化趋势与气体扩散系数相反程度较高;对于BP,中孔径范围下固体质量分形维数的变化趋势与气体扩散系数相反程度较高。固体质量分形维数能更好地反映混凝土内部结构的复杂程度。综合混凝土气渗性能、分形维数和细观结构分析,均可得到:小孔径范围是C的敏感孔径范围,中孔径范围是BP的敏感孔径范围。

中图分类号:

- TU528

| 1 | Dong L F, Zhang S P. Effect of steel fiber on comprehensive performance of concrete materials[J]. Applied Mechanics and Materials, 2015, 723:440-444. |

| 2 | Liu J, Yao S, Ba M, et al. Effects of carbonation on micro structures of hardened cement paste[J]. Journal of Wuhan University of Technology (Mater Sci Ed), 2016, 31(1):146-150. |

| 3 | Lu Bao, Shi Cai-jun, Cao Zhi-jie, et al. Effect of carbonated coarse recycled concrete aggregate on the properties and microstructure of recycled concrete[J]. Journal of Cleaner Production,2019,233:421-428. |

| 4 | 郭子麟. 单面冻融条件下玄武岩纤维混凝土孔结构及力学性能研究[D]. 包头:内蒙古工业大学土木工程学院, 2018. |

| Guo Zi-lin. Study on pore structure and mechanical properties of basalt fiber reinforced concrete under single-sided freeze-thaw condition[D]. Baotou: School of Civil Engineering,Inner Mongolia University of Technology, 2018. | |

| 5 | Jin S, Zhang J, Han S. Fractal analysis of relation between strength and pore structure of hardened mortar[J]. Construction and Building Materials, 2017, 135:1-7. |

| 6 | 张俊芝, 吕萌, 方赵峰, 等. 基于核磁共振的粉煤灰混凝土水和气体渗透性与孔结构的研究[J]. 南昌工程学院学报, 2018,37(6):63-70. |

| Zhang Jun-zhi, Lü Meng, Fang Zhao-feng, et al. Study on water and gas permeability and pore structure of fly ash concrete based on NMR[J]. Journal of Nanchang Institute of Technology, 2018, 37(6): 63-70. | |

| 7 | Bu J, Tian Z. Relationship between pore structure and compressive strength of concrete: experiments and statistical modeling[J]. Sādhanā, 2016, 41(3):1-8. |

| 8 | 郭明磊, 肖佳, 左胜浩. 水泥-石灰石粉胶凝材料孔结构多重分形特征以及与渗透性的关系[J]. 硅酸盐学报,2019,47(5):1-8. |

| Guo Ming-lei, Xiao Jia, Zuo Sheng-hao. Multifractal characteristics of pore structure of cement limestone cementitious materials and its relationship with permeability [J]. Journal of the Chinese Ceramic Society, 2019,47(5): 1-8. | |

| 9 | 宋凯强. 混杂纤维混凝土碳化性能与孔结构研究[D]. 沈阳:东北大学资源与土木工程学院,2017. |

| Song Kai-qiang. Study on carbonation performance and pore structure of hybrid fiber concrete[D]. Shenyang: School of Resources and Civil Engineering of Northeast University, 2017. | |

| 10 | Perrier E M A, Bird N R A. Modelling soil fragmentation: the pore solid fractal approach[J]. Soil & Tillage Research,2002,64(1):91-99. |

| 11 | Vahab Naderi Zarnaghi, Fouroghi-Asl Ali, Nourani Vahid, et al. On the pore structures of lightweight self-compacting concrete containing silica fume[J]. Construction and Building Materials,2018,193:557-564. |

| 12 | Gao Yun, Wu Kai, Jiang Jin-yang. Examination and modeling of fractality for pore-solid structure in cement paste: starting from the mercury intrusion porosimetry test[J]. Construction and Building Materials,2016,124:237-243. |

| 13 | 侯超群, 席瑶, 孙志彬, 等. 基于IPP图像处理的膨胀土微观结构定量研究[J].水文地质工程地质,2019,46(2):156-161. |

| Hou Chao-qun, Xi Yao, Sun Zhi-bin, et al. Quantitative study on microstructure of expansive soil based on IPP image processing[J]. Hydrogeology & Engineering Geology, 2019,46(2): 156-161. | |

| 14 | 张文生, 张建波, 李建勇, 等.混凝土孔隙面分形特征与测试方法研究[J]. 建筑材料学报,2012,15(3):312-316. |

| Zhang Wen-sheng, Zhang Jian-bo, Li Jian-yong, et al. Study on fractal characteristics and test methods of concrete pore surface[J]. Journal of Building Materials, 2012,15(3): 312-316. | |

| 15 | 丁一宁,马跃,郝晓卫.基于分形理论分析裂缝形态对纤维/混凝土渗透性的影响[J].复合材料学报:2020,37(11): 2908-2916. |

| Ding Yi-ning, Ma Yue, Hao Xiao-wei. Analysis of the influence of crack shape on the permeability of fiber / concrete based on fractal theory[J]. Acta Materiae Compositae Sinica, 2020, 37(11): 2908-2916. | |

| 16 | Cui Shen-gai, Liu Pin, Cui En-qi, et al. Experimental study on mechanical property and pore structure of concrete for shotcrete use in a hot-dry environment of high geothermal tunnels[J]. Construction and Building Materials, 2018, 173:124-135. |

| 17 | Almeida A E F S, Tonoli G H D, Santos S F, et al. Improved durability of vegetable fiber reinforced cement composite subject to accelerated carbonation at early age[J]. Cement and Concrete Composites, 2013, 42:49-58. |

| 18 | Li Yang, Fu Teng-huan, Wang Rui-jun, et al. An assessment of microcracks in the interfacial transition zone of recycled concrete aggregates cured by CO2[J]. Construction and Building Materials, 2020, 236: 214-221. |

| 19 | Flores Medina N, Barluenga G, Hernández-Olivares F. Enhancement of durability of concrete composites containing natural pozzolans blended cement through the use of Polypropylene fibers[J]. Composites Part B, 2014,61:214-221. |

| 20 | 赵燕茹, 郭子麟, 范晓奇, 等.玄武岩纤维混凝土应力应变关系及孔结构分析[J].硅酸盐通报,2017,36(12):4142-4150. |

| Zhao Yan-ru, Guo Zi-lin, Fan Xiao-qi, et al. Stress strain relationship and pore structure analysis of basalt fiber reinforced concrete[J]. Bulletin of the Chinese Ceramic Society, 2017, 36 (12): 4142-4150. | |

| 21 | Qing Lü, Qiu Qing-li, Zheng Jun, et al. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability[J]. Construction and Building Materials,2019,No.228. |

| 22 | 刘俊亮, 田长安, 曾燕伟, 等. 分形多孔介质孔隙微结构参数与渗透率的分维关系[J].水科学进展,2006(6):812-817. |

| Liu Jun-liang, Tian Chang-an, Zeng Yan-wei, et al. Fractal dimension relationship between pore microstructure parameters and permeability of fractal porous media [J]. Advance in Water Science, 2006(6): 812-817. |

| [1] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [2] | 李晓珍,柳俊哲,戴燕华,贺智敏,巴明芳,李玉顺. 碳化作用下水泥浆内亚硝酸根离子的含量分布[J]. 吉林大学学报(工学版), 2019, 49(4): 1162-1168. |

| [3] | 祝宏, 张海, 唐高弟, 李中云, 刘以农. 基于信息维数的欺骗干扰存在性检测[J]. 吉林大学学报(工学版), 2016, 46(2): 616-620. |

| [4] | 柳俊哲, 袁伟静, 贺智敏, 巴明芳, 陈剑斌. 碳化对混凝土碱骨料反应的影响[J]. 吉林大学学报(工学版), 2015, 45(3): 783-787. |

| [5] | 富爽,李一兵,叶方,高振国. 利用频域Sevcik分形维数进行快速盲频谱感知[J]. 吉林大学学报(工学版), 2014, 44(3): 854-860. |

| [6] | 吴晓璇, 倪志伟, 倪丽萍. 基于分形维数的聚类融合算法[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 364-367. |

| [7] | 杨冬风, 马秀莲. 基于分形纹理分析的蛋壳裂纹识别[J]. 吉林大学学报(工学版), 2011, 41(增刊1): 348-352. |

| [8] | 孟松鹤, 高慧婷, 孙莉安, 史洪军. 硅灰-矿渣对聚丙烯纤维混凝土性能的影响[J]. 吉林大学学报(工学版), 2010, 40(增刊): 214-0217. |

| [9] | 何凯, 晏磊. 利用随机中点替代法改进遥感影像分维算法[J]. 吉林大学学报(工学版), 2005, 35(06): 617-0620. |

| [10] | 高论, 连相明, 刘向阳, 王立江. 无磨料低温抛光件表面分形特性[J]. 吉林大学学报(工学版), 2004, (1): 7-11. |

| [11] | 崔向红, 王树奇, 吴宏, 姜启川. 变质莱氏体钢中共晶碳化物的热处理粒化[J]. 吉林大学学报(工学版), 2002, (1): 42-46. |

| [12] | 崔向红, 孙国恩, 吕晓霞, 姜启川, 何镇明. 具有粒状碳化物的新型莱氏体铸造模具钢的组织与性能[J]. 吉林大学学报(工学版), 2000, (2): 33-37. |

|

||