吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 409-416.doi: 10.13229/j.cnki.jdxbgxb20211148

• 车辆工程·机械工程 • 上一篇

考虑参数权重的数控机床电主轴加速试验优化设计

赵泓荀1,2( ),杨兆军1,2,陈传海1,2,3(

),杨兆军1,2,陈传海1,2,3( ),田海龙1,2,王立平4

),田海龙1,2,王立平4

- 1.吉林大学 数控设备可靠性教育部重点实验室,长春 130022

2.吉林大学 机械与航空航天工程学院,长春 130022

3.吉林大学 重庆研究院,重庆 400037

4.清华大学 机械工程系,北京 100084

Optimal design of acceleration test of motorized spindle of numerical control Machine Tool considering parameter weight

Hong-xun ZHAO1,2( ),Zhao-jun YANG1,2,Chuan-hai CHEN1,2,3(

),Zhao-jun YANG1,2,Chuan-hai CHEN1,2,3( ),Hai-long TIAN1,2,Li-ping WANG4

),Hai-long TIAN1,2,Li-ping WANG4

- 1.Key Laboratory of Numerical Control Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

3.Chongqing Research Institute,Jilin University,Chongqing 400037,China

4.Department of Mechanical Engineering,Tsinghua University,Beijing 100084,China

摘要:

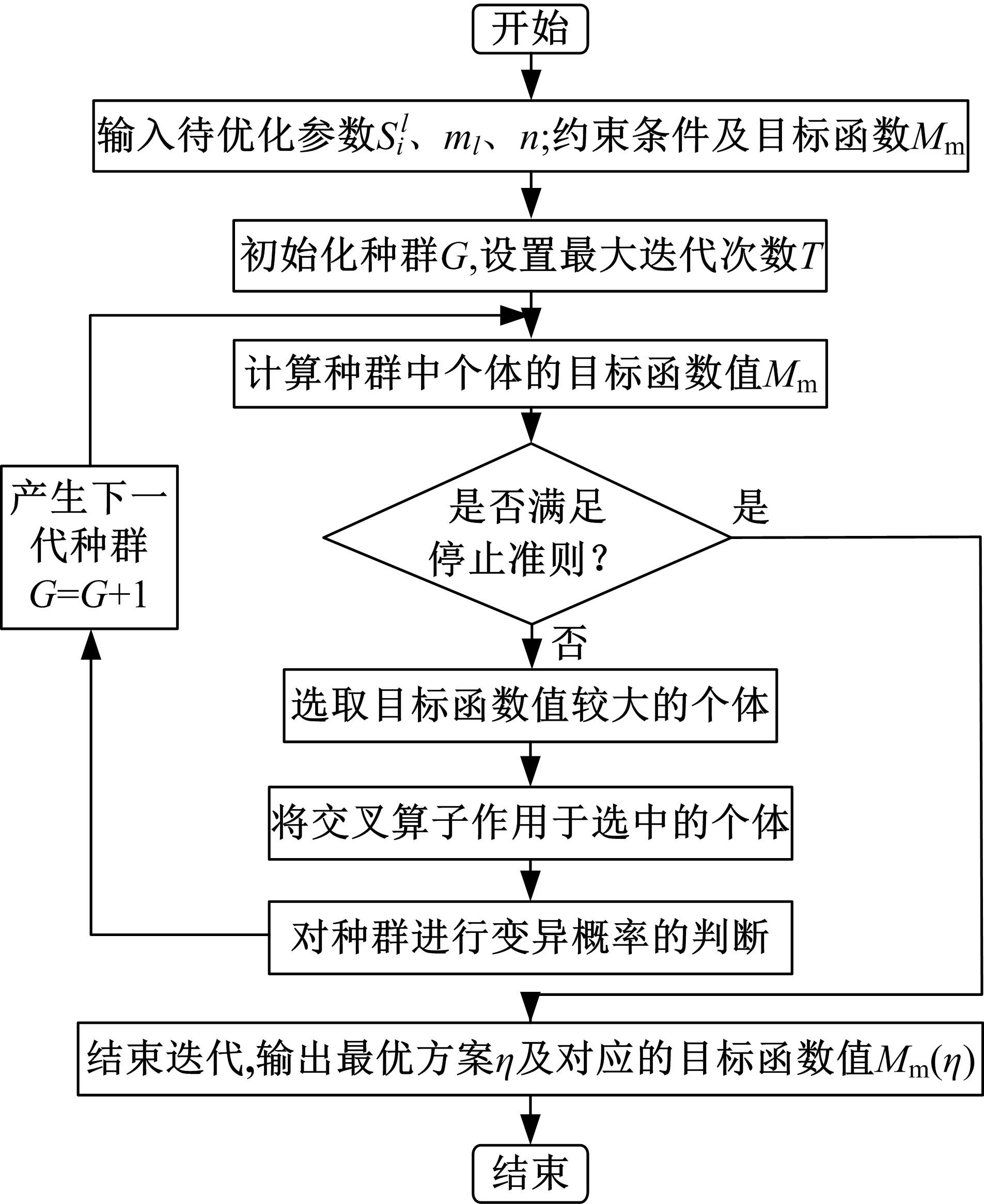

为解决电主轴步进多应力加速退化试验针对模型参数优化设计时部分模型参数估计精度低的问题,提出了一种新的步进多应力加速退化试验方案优化设计方法。利用敏感性分析方法、应力综合重要度确定加速退化试验中加速模型的各参数权重,基于Ds准则与各参数权重提出了一种新的优化设计准则,结合遗传算法给出了优化流程。最后,以国产电主轴为例,对其加速退化试验方案进行了优化设计,将结果与现有准则进行对比,验证方法的有效性。

中图分类号:

- TH17

| 1 | 杨兆军, 陈传海, 陈菲, 等. 数控机床可靠性技术的研究进展[J].机械工程学报, 2013, 49(20): 130-139. |

| Yang Zhao-jun, Chen Chuan-hai, Chen Fei, et al. Progress in the research of reliability technology of machine tools[J]. Journal of Mechanical Engineering, 2013, 49(20): 130-139. | |

| 2 | 杨佐卫, 殷国富, 尚欣, 等. 高速电主轴热态特性与动力学特性耦合分析模型[J]. 吉林大学学报: 工学版, 2011, 41(1): 100-105. |

| Yang Zuo-wei, Yin Guo-fu, Shang Xin, et al. Coupling analysis model of thermal and dynamic characteristics of high-speed motorized spindle[J]. Journal of Jilin University(Engineering and Technology Edition), 2011, 41(1): 100-105. | |

| 3 | 郑玉彬, 杨斌, 王晓峰, 等. 基于威布尔分布的电主轴加速寿命试验时间设计[J]. 吉林大学学报: 工学版, 2018, 48(3): 767-772. |

| Zheng Yu-bin, Yang Bin, Wang Xiao-feng, et al. Design of accelerated life test time of motorized spindle based on weibull distribution[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(3): 767-772. | |

| 4 | Nelson W. Analysis of performance degradation data from accelerated tests[J]. IEEE Transactions on Reliability, 1981, 30(2): 149-155. |

| 5 | Nelson W. Accelerated Testing: Statistical Methods, Test Plans, and Data Analysis[M]. New York: John Wiley Press, 1990. |

| 6 | 葛蒸蒸, 姜同敏, 韩少华, 等. 基于D优化的多应力加速退化试验设计[J]. 系统工程与电子技术, 2012, 34(4): 846-853. |

| Ge Zheng-zheng, Jiang Tong-min, Han Shao-hua,et al. Design of accelerated degradation testing with multiple stresses based on D optimality[J]. Systems Engineering and Electronic Technology, 2012, 34(4): 846-853. | |

| 7 | 韩少华, 葛蒸蒸, 姜同敏, 等. 基于D优化方法的CSADT设计[J]. 装备环境工程, 2012, 9(4): 82-87. |

| Han Shao-hua, Ge Zheng-zheng, Jiang Tong-min, et al. CSADT design based on D optimization method [J]. Equipment Environmental Engineering, 2012, 9(4): 82-87. | |

| 8 | Zhang C F, Shi Y. Optimum simple accelerated life tests based on progressively Type-I hybrid censoring[J]. International Journal of System Assurance Engineering and Management, 2017, 8(2): 849-856. |

| 9 | Huang T, Jiang T. Optimum design of equivalent accelerated life testing plans based on proportional hazards-proportional odds model[J]. Journal of Systems Engineering and Electronics, 2011, 22: 871-878. |

| 10 | Toyoda M, Shen T. A receding horizon D-optimization approach for model identification-oriented input design and application in combustion engines[J]. Applied Mathematical Modelling, 2017, 42: 175-187. |

| 11 | Zhang C, Wang S, Wang Z, et al. An accelerated life test model for harmonic drives under a segmental stress history and its parameter optimization[J]. Chinese Journal of Aeronautics, 2015, 28(6):1758-1765. |

| 12 | 李晓旭. 加工中心主轴系统可靠性综合应力加速模型研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2019. |

| Li Xiao-xu. Study on reliability comprehensive stress acceleration model of spindle system of machining center[D]. Changchun: College of Mechanical and Aerospace Engineering, Jilin University, 2019. | |

| 13 | 程云鹏. 矩阵论[M]. 西安: 西北工业大学出版社,2006. |

| 14 | Holland J. Adaptation in Natural and Artificial Systems[M]. Cambridge, MA: MIT Press, 1992. |

| 15 | 鲍俊. 基于步进双应力加速退化试验的电主轴可靠性建模研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2018. |

| Bao Jun. Research on reliability modeling of motorized spindle based on stepping double stress accelerated degradation test[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2018. | |

| 16 | 蔡忠义, 陈云翔, 张诤敏, 等. 非线性步进加速退化数据的可靠性评估方法[J]. 北京航空航天大学学报, 2016, 42(3): 576-582. |

| Cai Zhong-yi, Chen Yun-xiang, Zhang Zheng-min, et al. Reliability assessment method of nonlinear step-stress accelerated degradation data[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(3): 576-582. |

| [1] | 于立娟,刘昂,杨兆军,田海龙,陈传海,高景文. 基于网络层次和数据包络的数控机床可靠性分析[J]. 吉林大学学报(工学版), 2022, 52(2): 400-408. |

| [2] | 陈传海,王成功,杨兆军,刘志峰,田海龙. 数控机床可靠性建模研究现状及发展动态分析[J]. 吉林大学学报(工学版), 2022, 52(2): 253-266. |

| [3] | 张立杰,阿喜塔,田笑,李稳. 基于Gamma过程的加速退化试验多目标优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 361-367. |

| [4] | 王立平,朱斌,吴军,陶子寒. 基于贝叶斯网络的盘式刀库故障分析[J]. 吉林大学学报(工学版), 2022, 52(2): 280-287. |

| [5] | 章子玲,胡雄,亓寅,王微,陶志强,刘志峰. 基于向量投影响应面的数控机床几何误差分配方法[J]. 吉林大学学报(工学版), 2022, 52(2): 384-391. |

| [6] | 樊学平,杨光红,尚志鹏,赵小雄,肖青凯,刘月飞. 考虑适用性的大跨桥梁主梁动态可靠性融合预测[J]. 吉林大学学报(工学版), 2022, 52(1): 144-153. |

| [7] | 李国发,陈泽权,何佳龙. 新型结构可靠性分析自适应加点策略[J]. 吉林大学学报(工学版), 2021, 51(6): 1975-1981. |

| [8] | 杜尊令,张义民. 基于随机流量下柱塞泵的可靠性分析[J]. 吉林大学学报(工学版), 2021, 51(6): 1967-1974. |

| [9] | 樊学平,杨光红,肖青凯,刘月飞. 大跨桥梁主梁失效概率分析的最优R-Vine Copula[J]. 吉林大学学报(工学版), 2021, 51(4): 1296-1305. |

| [10] | 李卫,张怀亮,瞿维. 随机振动环境下液压直管道设计方法[J]. 吉林大学学报(工学版), 2021, 51(4): 1222-1229. |

| [11] | 李国龙,陶小会,徐凯,李喆裕. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报(工学版), 2021, 51(2): 458-467. |

| [12] | 吴昊天,郭锐锋,彭阿珍,王品. 一种考虑可靠性的常带宽服务器低功耗调度算法[J]. 吉林大学学报(工学版), 2020, 50(5): 1802-1808. |

| [13] | 叶辉,刘畅,闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2): 417-425. |

| [14] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [15] | 郭昊添,徐涛,梁逍,于征磊,刘欢,马龙. 仿鲨鳃扰流结构的过渡段换热表面优化设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1793-1798. |

|

||