吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (9): 1982-1995.doi: 10.13229/j.cnki.jdxbgxb20220344

• • 上一篇

质子交换膜燃料电池氢气供应系统的建模及匹配设计

陈凤祥1( ),张俊宇1,裴冯来2,侯明涛1,李其朋3,李培庆3,王洋洋4,张卫东5

),张俊宇1,裴冯来2,侯明涛1,李其朋3,李培庆3,王洋洋4,张卫东5

- 1.同济大学 汽车学院,上海 201804

2.上海机动车检测认证技术研究中心,上海 201805

3.浙江科技学院 机械与能源工程学院,杭州 310023

4.绍兴学森能源科技有限公司,浙江 绍兴 312000

5.海南大学 信息与通讯工程学院,海口 570228

Modeling and selection scheme of proton exchange membrane fuel cell hydrogen supply system

Feng-xiang CHEN1( ),Jun-yu ZHANG1,Feng-lai PEI2,Ming-tao HOU1,Qi-peng LI3,Pei-qing LI3,Yang-yang WANG4,Wei-dong ZHANG5

),Jun-yu ZHANG1,Feng-lai PEI2,Ming-tao HOU1,Qi-peng LI3,Pei-qing LI3,Yang-yang WANG4,Wei-dong ZHANG5

- 1.School of Automotive Studies,Tongji University,Shanghai 201804,China

2.Shanghai Motor Vehicle Inspection Certification and Technology Innovation Center,Shanghai 201805,China

3.School of Mechanical and Energy Engineering,Zhejiang University of Science and Technology,Hangzhou 310023,China

4.Shaoxing Xuesheng Energy Technology Co. ,Ltd. ,Shaoxing 312000,China

5.School of Information and Communication Engineering,Hainan University,Haikou 570228,China

摘要:

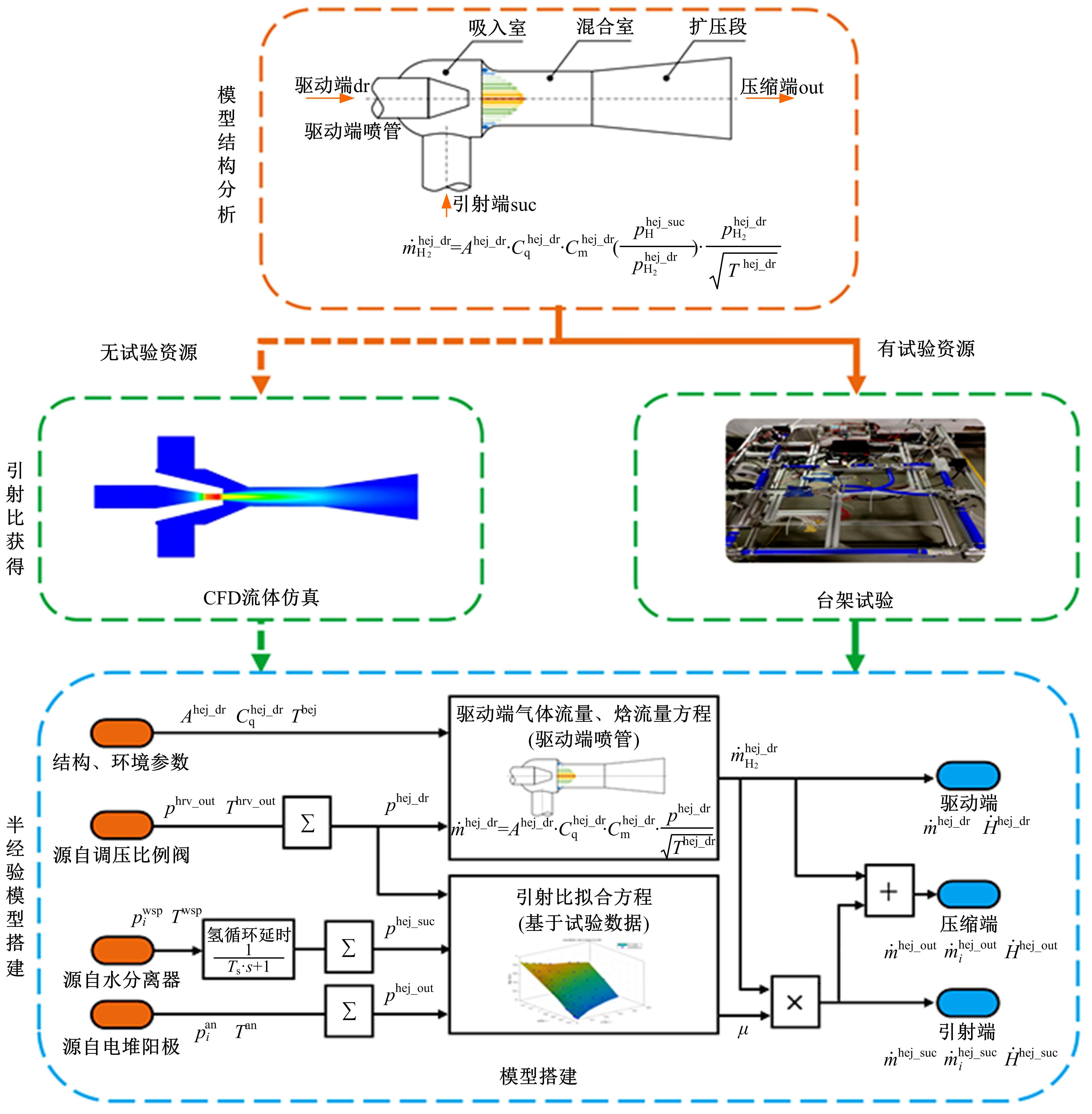

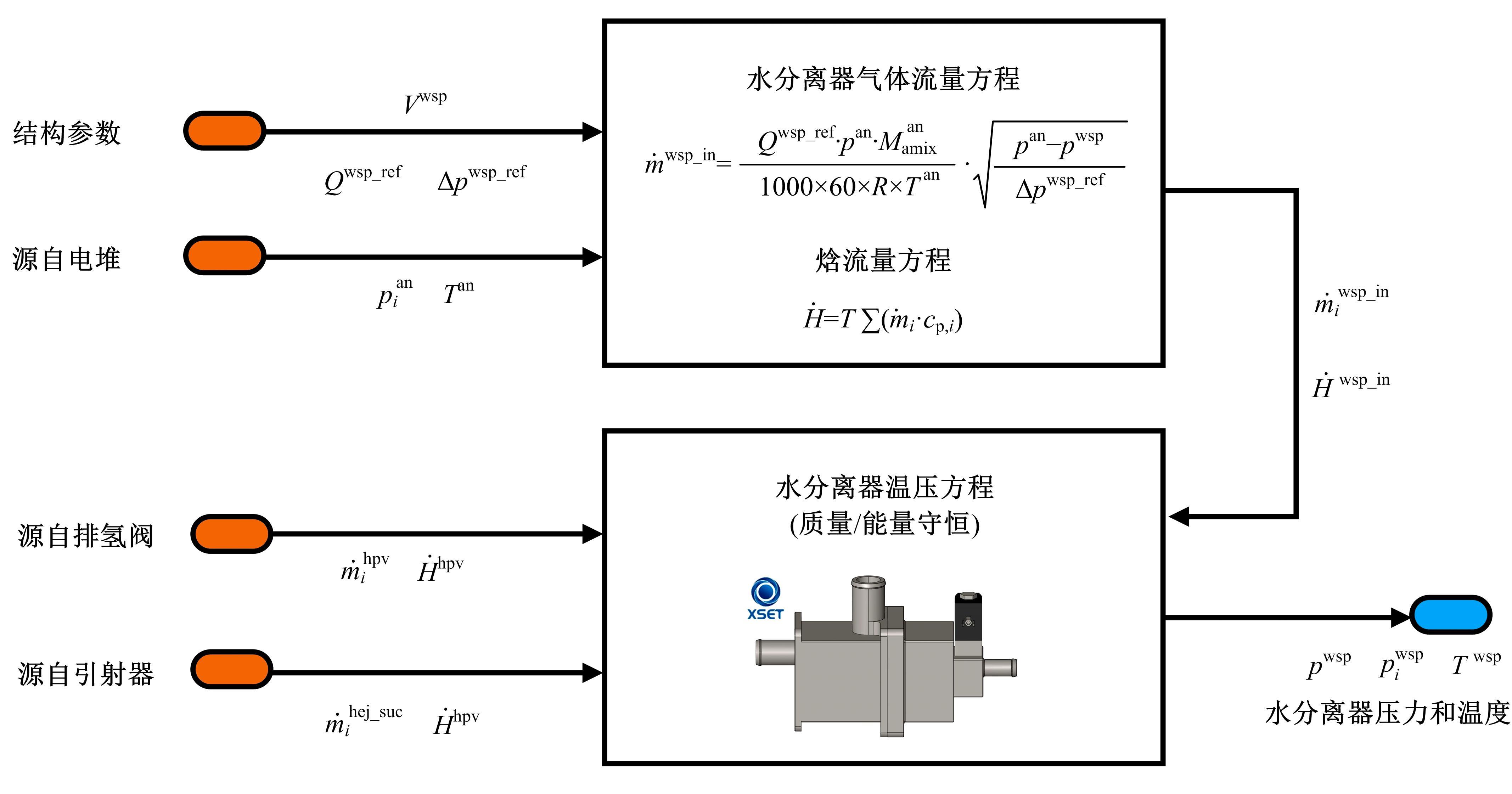

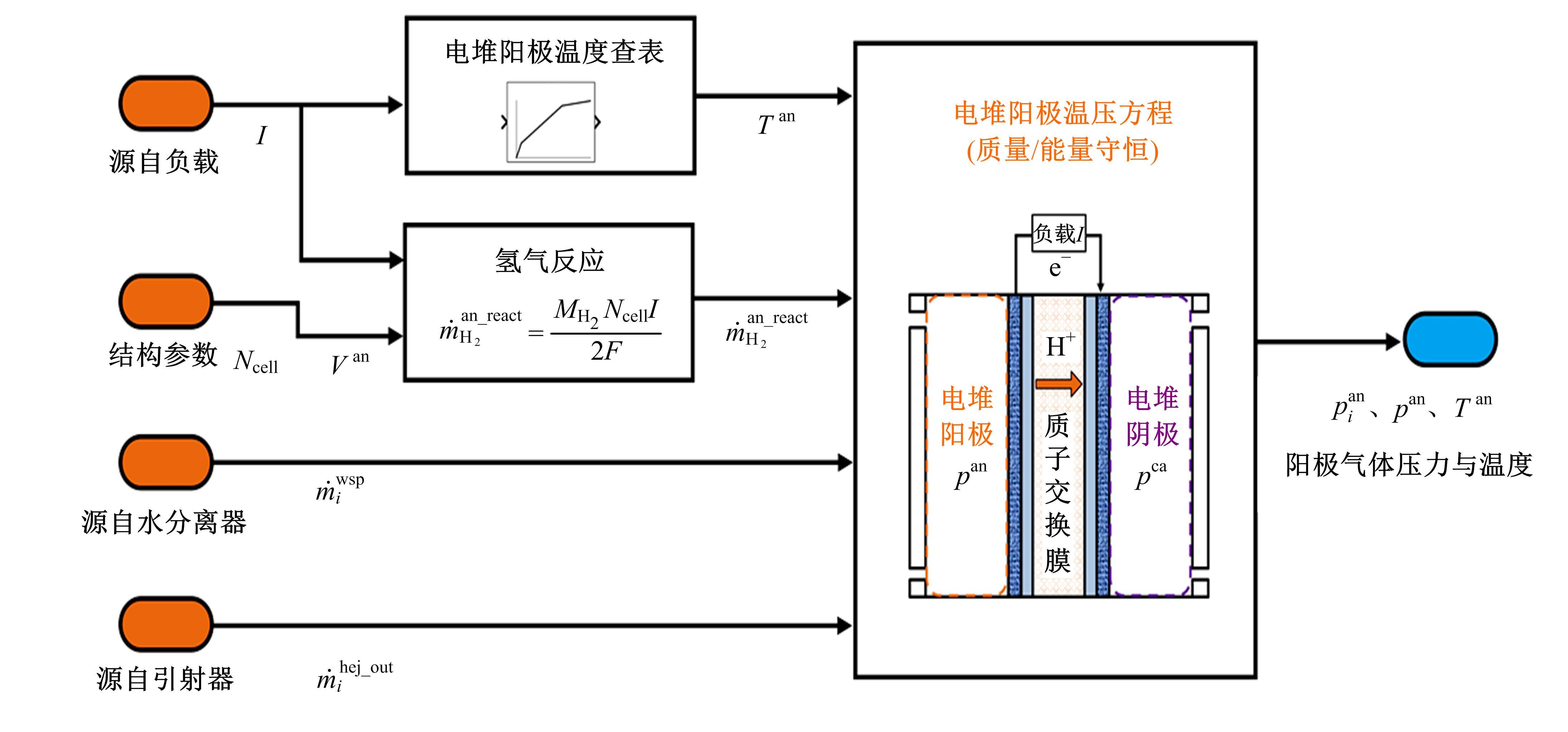

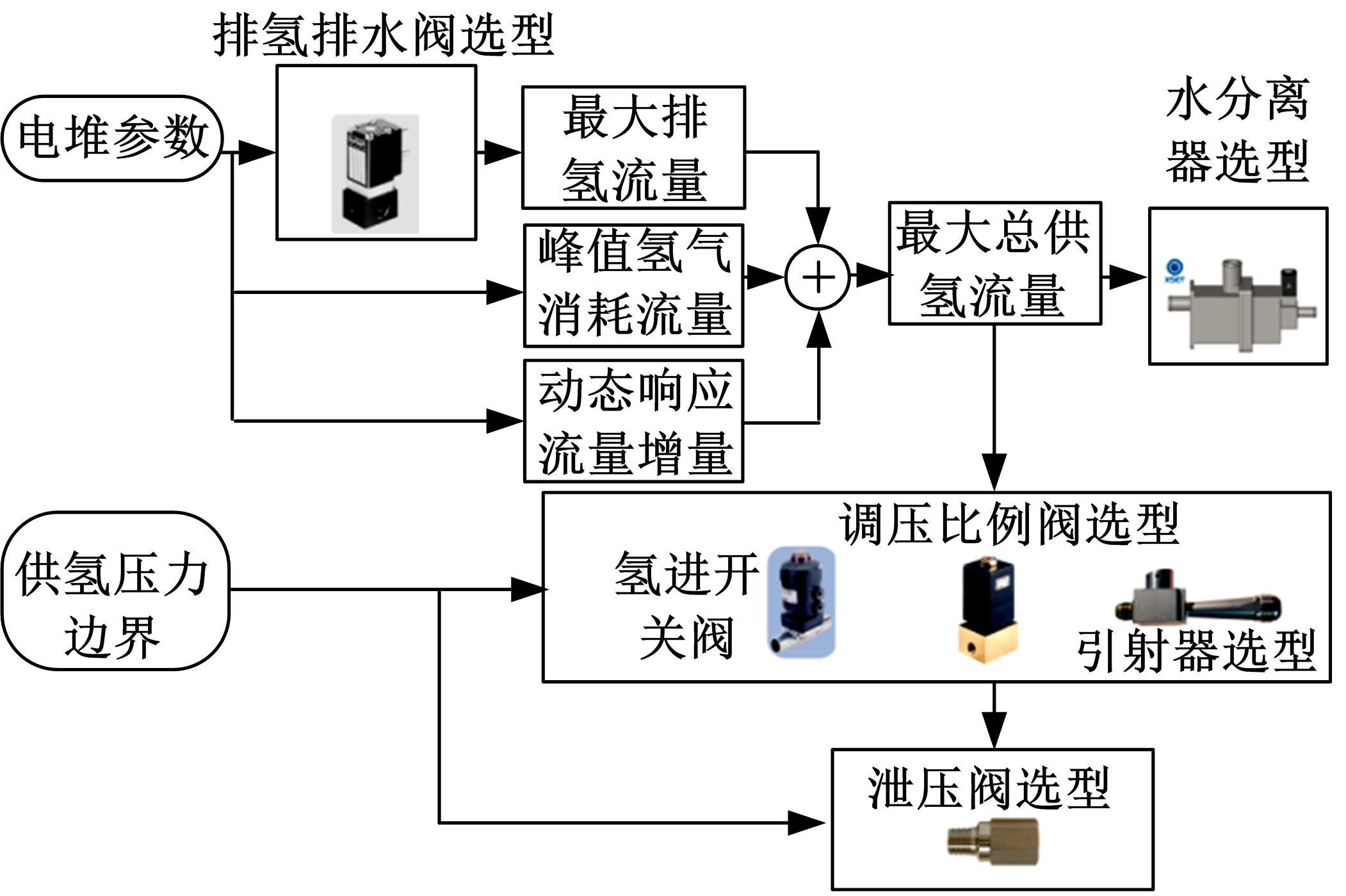

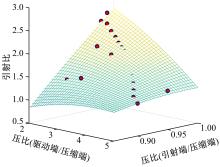

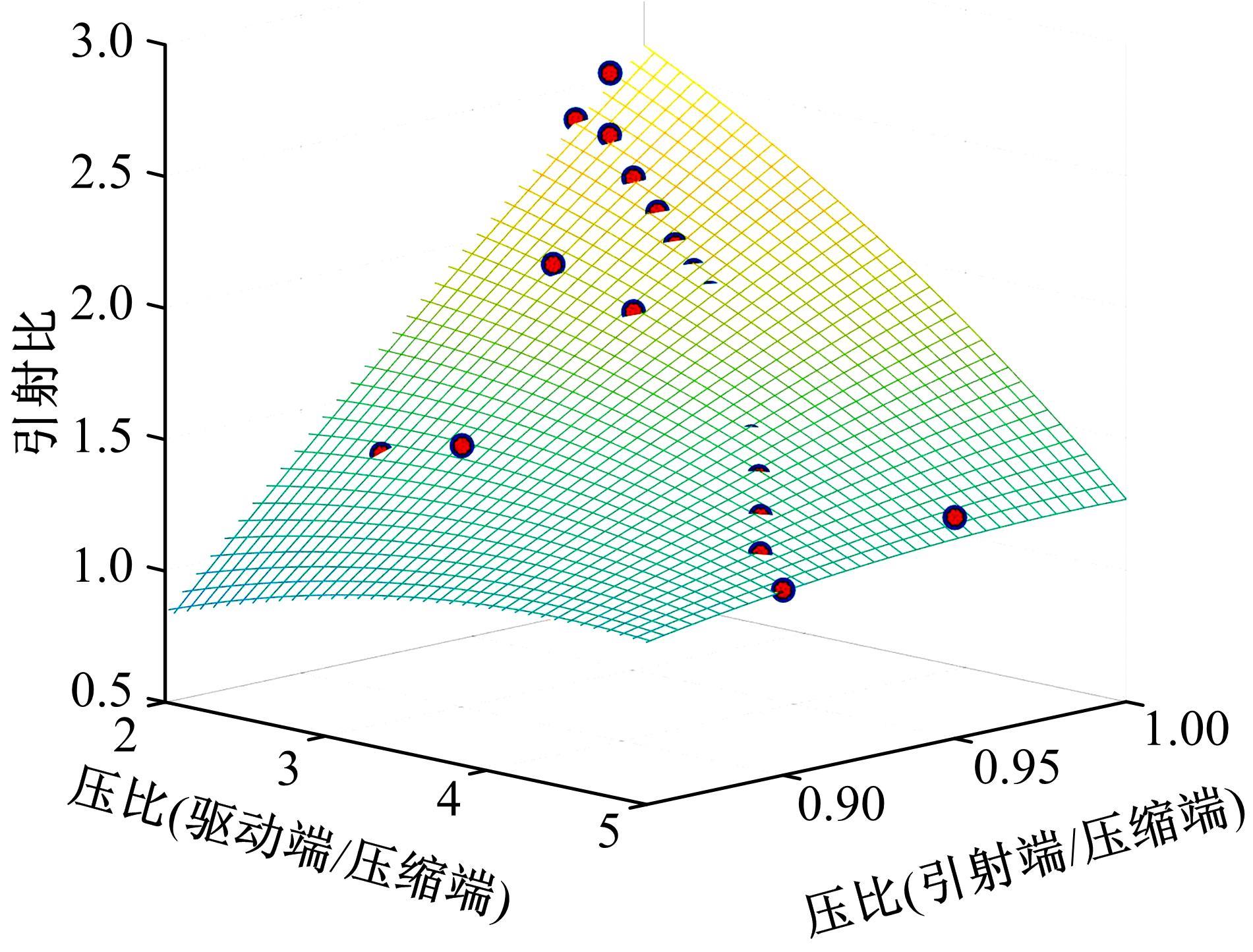

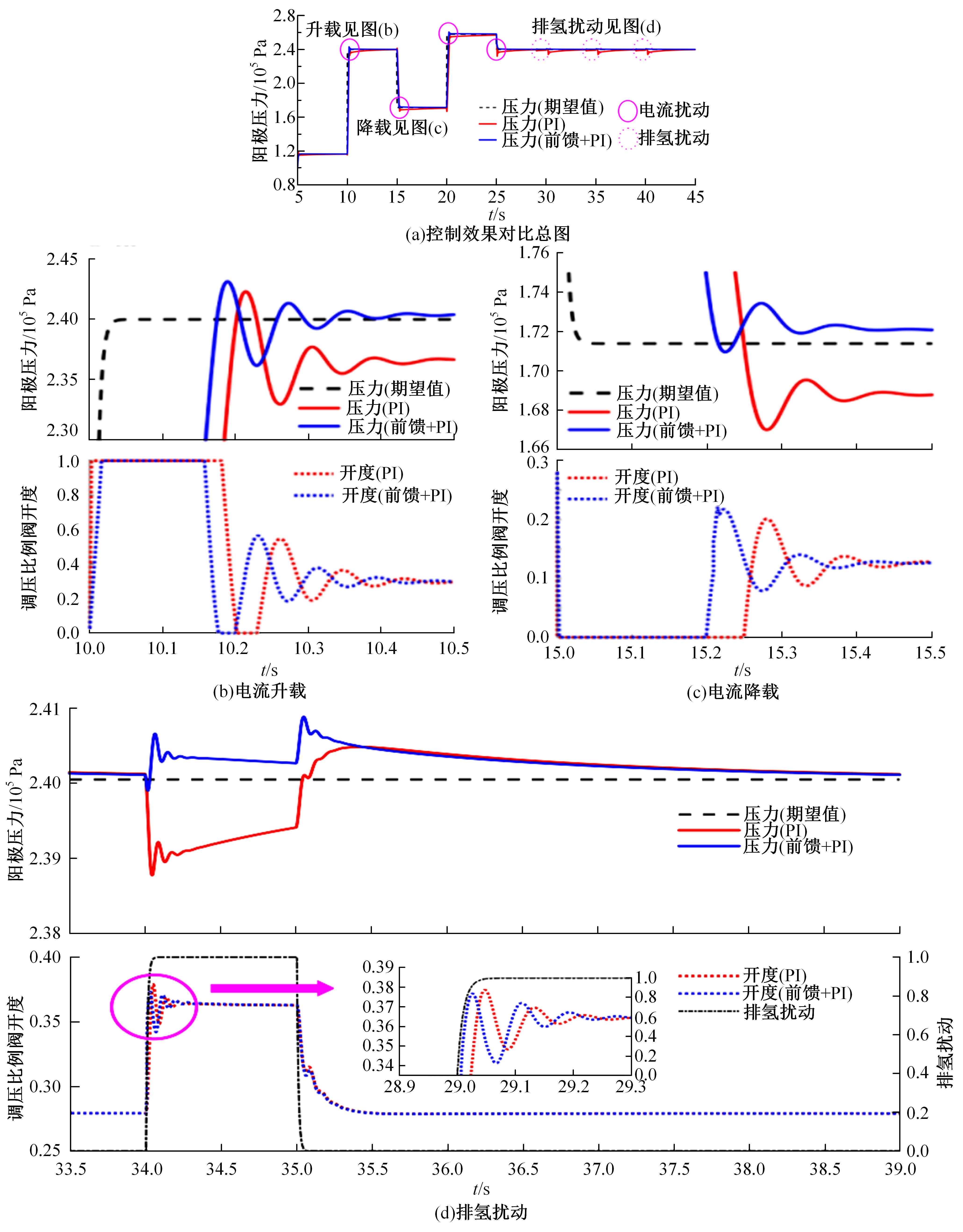

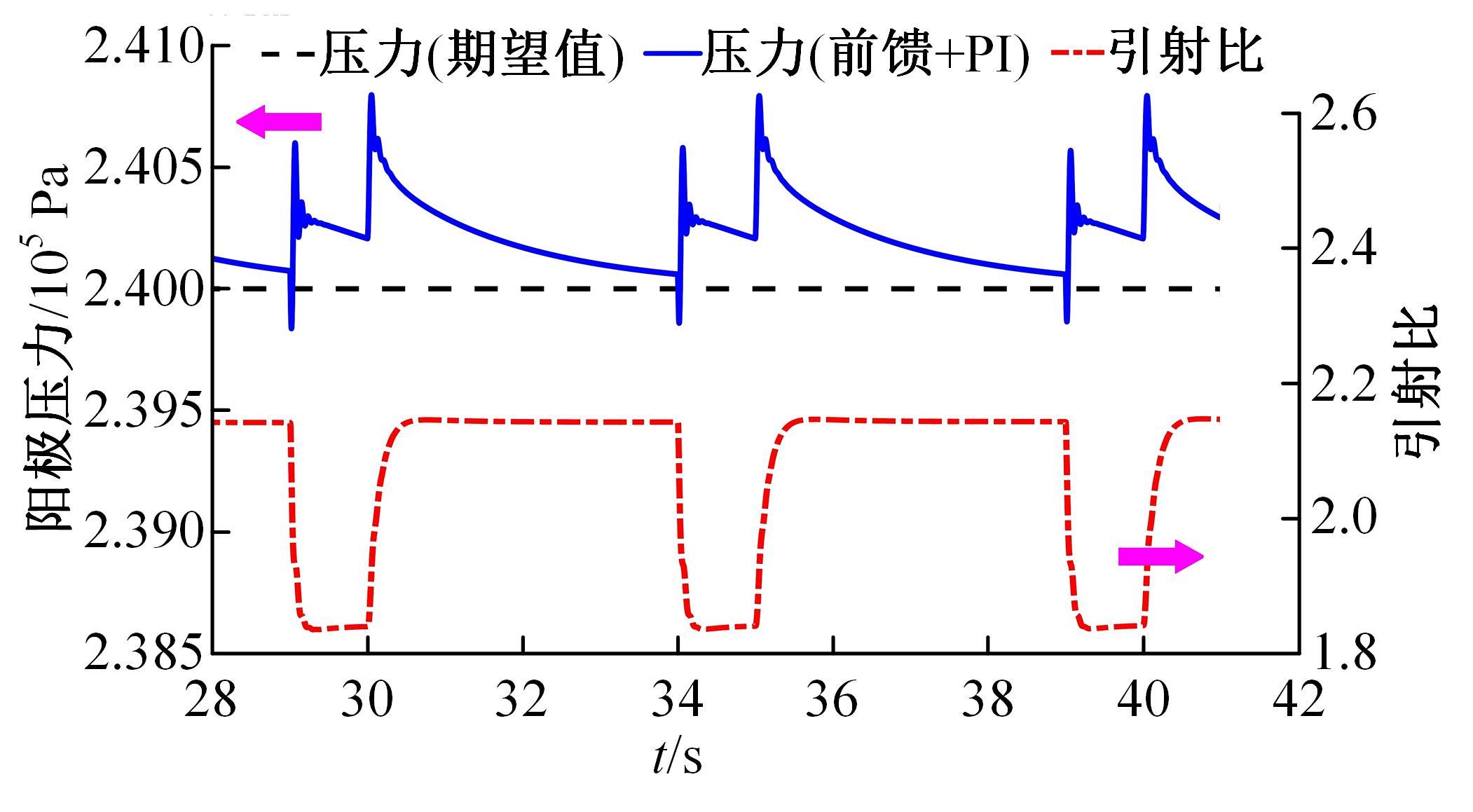

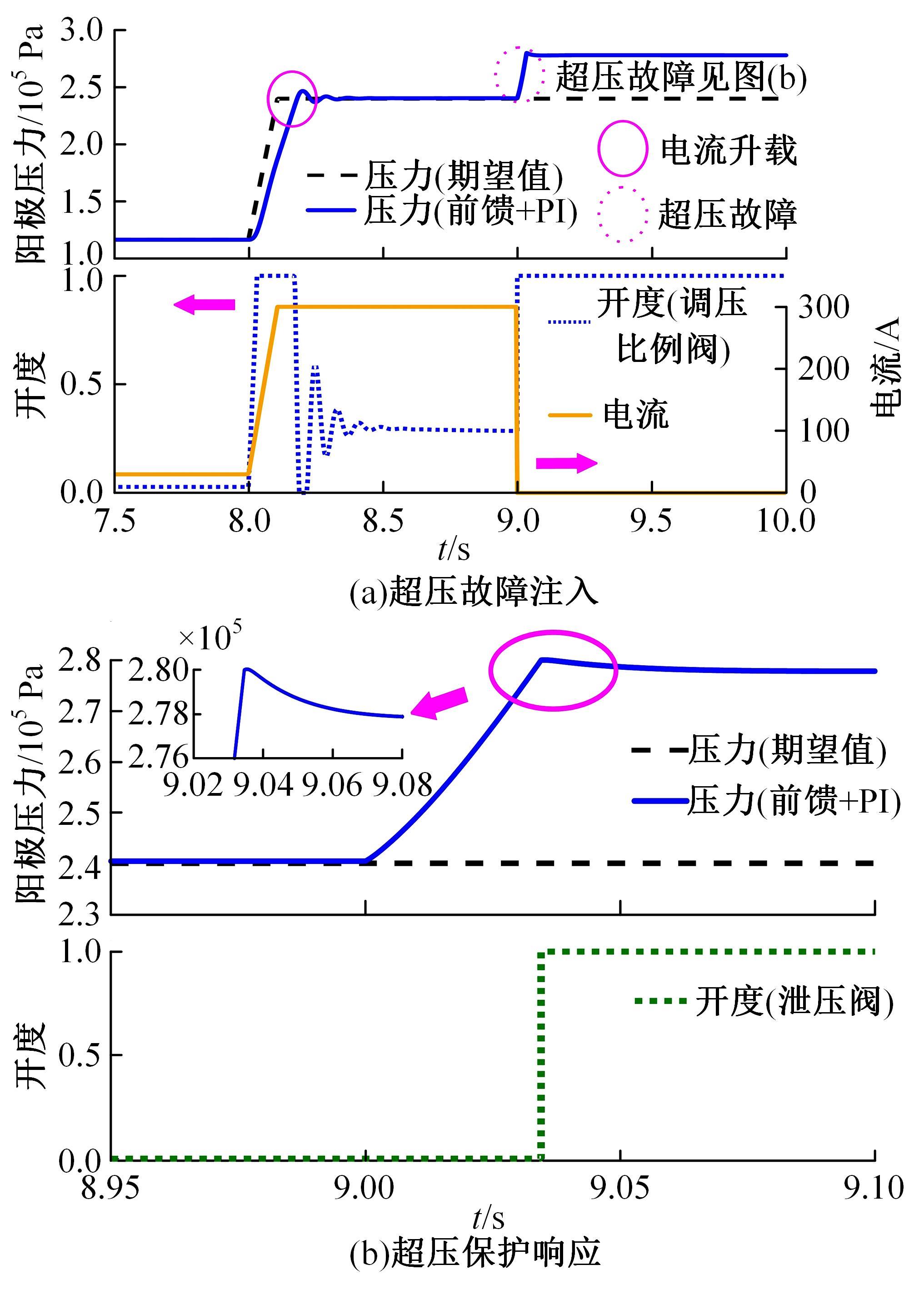

针对质子交换膜燃料电池(PEMFC)供氢系统供气充分且氢压响应迅速的要求,提出了供氢系统零部件匹配设计方法。首先,采用机理和半经验建模相结合的方法建立了燃料电池氢气供应系统集总参数模型,并结合该模型提出了氢气供应系统的匹配设计方法。为验证匹配设计方法的合理性,针对一80 kW电堆进行了仿真分析。结果表明:在前馈+PI控制策略作用下,从怠速阶跃至额定工况的阳极压力上升时间为0.5 s、超调量为3 kPa;排氢扰动作用下压力波动小于0.8 kPa;额定工况引射器的引射比为2.14;泄压阀流量足以保证电堆安全运行。该匹配方法满足了供氢系统动态响应、氢气循环、安全特性的需求,为质子交换膜燃料电池氢气供应系统的选型匹配提供了理论基础。

中图分类号:

- U469.72

| 1 | Ryan O'Hayre Whitney Colella. 燃料电池基础[M].北京:电子工业出版社, 2007. |

| 2 | 衣宝廉. 燃料电池原理、技术、应用[M].北京:化学工业出版社, 2003. |

| 3 | Pukrushpan J T. Modeling and control of fuel cell systems and fuel processors[D]. Michigan: Department of Mechanical Engineering the University of Michigan, 2003. |

| 4 | Hu M, Cao G. Research on the long-term stability of a PEMFC stack: analysis of pinhole evolution[J]. International Journal of Hydrogen Energy, 2014, 39(15): 7940-7954. |

| 5 | Bao C, Ouyang M, Yi B. Modeling and control of air stream and hydrogen flow with recirculation in a PEM fuel cell system—I. Control-oriented modeling[J]. International Journal of Hydrogen Energy, 2006, 31(13): 1879-1896. |

| 6 | 董凯瑞, 刘广彬, 高志成. 燃料电池氢气循环系统综述[J]. 电源技术, 2021, 45(4): 545-551. |

| Dong Kai-rui, Liu Guang-bin, Gao Zhi-cheng. Review of fuel cell hydrogen circulation system[J]. Chinese Journal of Power Sources, 2021, 45(4): 545-551. | |

| 7 | 南泽群, 许思传, 章道彪, 等. 车用PEMFC系统氢气供应系统发展现状及展望[J]. 电源技术, 2016, 40(8): 1726-1730. |

| Ze-qun Nan, Xu Si-chuan, Zhang Dao-biao, et al. Development and prospect of hydrogen supply system in vehicle PEMFC[J]. Chinese Journal of Power Sources, 2016, 40(8): 1726-1730. | |

| 8 | 索科洛夫, 津格尔.喷射器[M].黄秋云译.北京:科学出版社, 1977. |

| 9 | Chen F X, Yu Y, Liu Y, et al. Control system design for proton exchange membrane fuel cell based on a common rail (I): Control strategy and performance analysis[J]. International Journal of Hydrogen Energy, 2017, 42(7): 4285-4293. |

| 10 | Chen F X, Yu Y, Liu Y. Control system design for proton exchange membrane fuel cell based on a common rail (II): optimization and schedule scheme for the common rail[J]. International Journal of Hydrogen Energy, 2017, 42(7): 4294-4301. |

| 11 | 张家明, 马天才, 丛铭, 等. 大功率燃料电池氢气系统建模与控制[J]. 汽车技术, 2021, 51(2): 23-27. |

| Zhang Jia-ming, Ma Tian-cai, Cong Ming, et al. Hydrogen system modelling & control for high-power fuel cell system[J]. Automobile Technology, 2021, 51(2): 23-27. | |

| 12 | Brunner D A, Marcks S, Bajpai M, et al. Design and characterization of an electronically controlled variable flow rate ejector for fuel cell applications[J]. International Journal of Hydrogen Energy, 2012, 37(5): 4457-4466. |

| 13 | Zhang Q Q, Feng J M, Zhang Q Q, et al. Performance prediction and evaluation of the scroll-type hydrogen pump for FCVs based on CFD–Taguchi method[J]. International Journal of Hydrogen Energy, 2019, 44(29): 15333-15343. |

| 14 | Macedo-Valencia J, Sierra J M, Figueroa-Ramírez S J, et al. 3D CFD modeling of a PEM fuel cell stack[J]. International Journal of Hydrogen Energy, 2016, 41(48): 23425-23433. |

| 15 | Nanadegani F S, Lay E N, Iranzo A, et al. On neural network modeling to maximize the power output of PEMFCs[J]. Electrochimica Acta, 2020, 348: NO. 136345. |

| 16 | Zheng L, Hou Y, Zhang T, et al. Performance prediction of fuel cells using long short‐term memory recurrent neural network[J]. International Journal of Energy Research, 2021, 45(6): 9141-9161. |

| 17 | Ma T C, Zhang Z L, Lin W K, et al. Impedance prediction model based on convolutional neural networks methodology for proton exchange membrane fuel cell[J]. International Journal of Hydrogen Energy, 2021, 46(35): 18534-18545. |

| 18 | 郭爱, 陈维荣, 李奇, 等. 车用燃料电池氢气供应系统的预测控制[J]. 太阳能学报, 2013, 34(8): 1484-1491. |

| Guo Ai, Chen Wei-rong, Li Qi, et al. Predictive control of hydrogen supplying system for fuel cells for vehicle[J]. Acta Energiae Solaris Sinica, 2013, 34(8): 1484-1491. | |

| 19 | 裴冯来, 侯明涛, 贺继龙, 等. 质子交换膜燃料电池空压机建模[J]. 储能科学与技术, 2019, 8(6): 1247-1252. |

| Pei Feng-lai, Hou Ming-tao, He Ji-long, et al. Modeling of air compressors for proton exchange membrane fuel cell [J]. Energy Storage Science and Technology, 2019, 8(6):1247-1252. | |

| 20 | Amphlett J C, Baumert R M, Mann R F, et al. Performance modeling of the Ballard Mark IV solid polymer electrolyte fuel cell II. Empirical model development[J]. Journal of The Electrochemical Society, 1995, 142(1): 9-15. |

| 21 | Mann R F, Amphlett J C, Hooper M, et al. Development and application of a generalized steady-state electrochemical model for a PEM fuel cell[J]. Journal of Power Sources, 2000, 86(1-2): 173-180. |

| 22 | 卢兰光, 欧阳明高. 车用低压质子交换膜燃料电池电堆的半经验模型[J]. 机械工程学报, 2007, 43(2): 110-114. |

| Lu Lan-guang, Ouyang Ming-gao. Performance modeling for low pressure vehicle proton exchange membrane fuel cell stack[J]. Chinese Journal of Mechanical Engineering, 2007, 43(2): 110-114. | |

| 23 | Chen F X, Hou M T, Li J H, et al. Proton exchange membrane fuel cell ejector test platform design and ejector test analysis[J]. World Electric Vehicle Journal, 2021, 12(3): No.103. |

| 24 | Yuan H, Dai H F, Wu W, et al. A fuzzy logic PI control with feedforward compensation for hydrogen pressure in vehicular fuel cell system[J]. International Journal of Hydrogen Energy, 2021, 46(7): 5714-5728. |

| 25 | 张浩琛. 质子交换膜燃料电池供气系统控制策略研究[D]. 兰州: 兰州理工大学电气工程与信息工程学院, 2013. |

| Zhang Hao-chen. The research on control strategy of air supply system in proton exchange membrane fuel cell[D]. Lanzhou: College of Electrical and Information Engineering, Lanzhou University of Technology,2013. | |

| 26 | Quan S W, Wang Y X, Xiao X L, et al. Feedback linearization-based MIMO model predictive control with defined pseudo-reference for hydrogen regulation of automotive fuel cells[J]. Applied Energy, 2021, 293: No. 116919. |

| 27 | 唐紫英. 控制阀流量系数Kv设计计算中的修正[J]. 抚顺石油学院学报, 1997, 16(3): 59-65. |

| Tang Zi-ying. The correction for design calculation of flow coefficient Kv on the control valve[J]. Journal of Fushun Petroleum Institute, 1997, 16(3): 59-65. | |

| 28 | Zhu Y H, Li Y Z. New theoretical model for convergent nozzle ejector in the proton exchange membrane fuel cell system[J]. Journal of Power Sources, 2009, 191(2): 510-519. |

| [1] | 杨子荣,李岩,冀雪峰,刘芳,郝冬. 质子交换膜燃料电池运行工况参数敏感性分析[J]. 吉林大学学报(工学版), 2022, 52(9): 1971-1981. |

| [2] | 池训逞,侯中军,魏伟,夏增刚,庄琳琳,郭荣. 基于模型的质子交换膜燃料电池系统阳极气体浓度估计技术综述[J]. 吉林大学学报(工学版), 2022, 52(9): 1957-1970. |

| [3] | 何仁,杨柳,胡东海. 冷藏运输车太阳能辅助供电制冷系统设计及分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1645-1652. |

| [4] | 甘心, 殷琨, 何将福, 殷其雷. 救援井用大直径贯通式潜孔锤及钻头的研制[J]. 吉林大学学报(工学版), 2015, 45(6): 1844-1851. |

| [5] | 郭洪艳, 陈虹, 高振海, 于海洋, 吉岩. 基于随机算法的级联车速观测器设计[J]. 吉林大学学报(工学版), 2014, 44(2): 296-304. |

|

||