吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (11): 3151-3159.doi: 10.13229/j.cnki.jdxbgxb.20220004

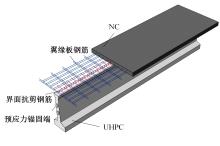

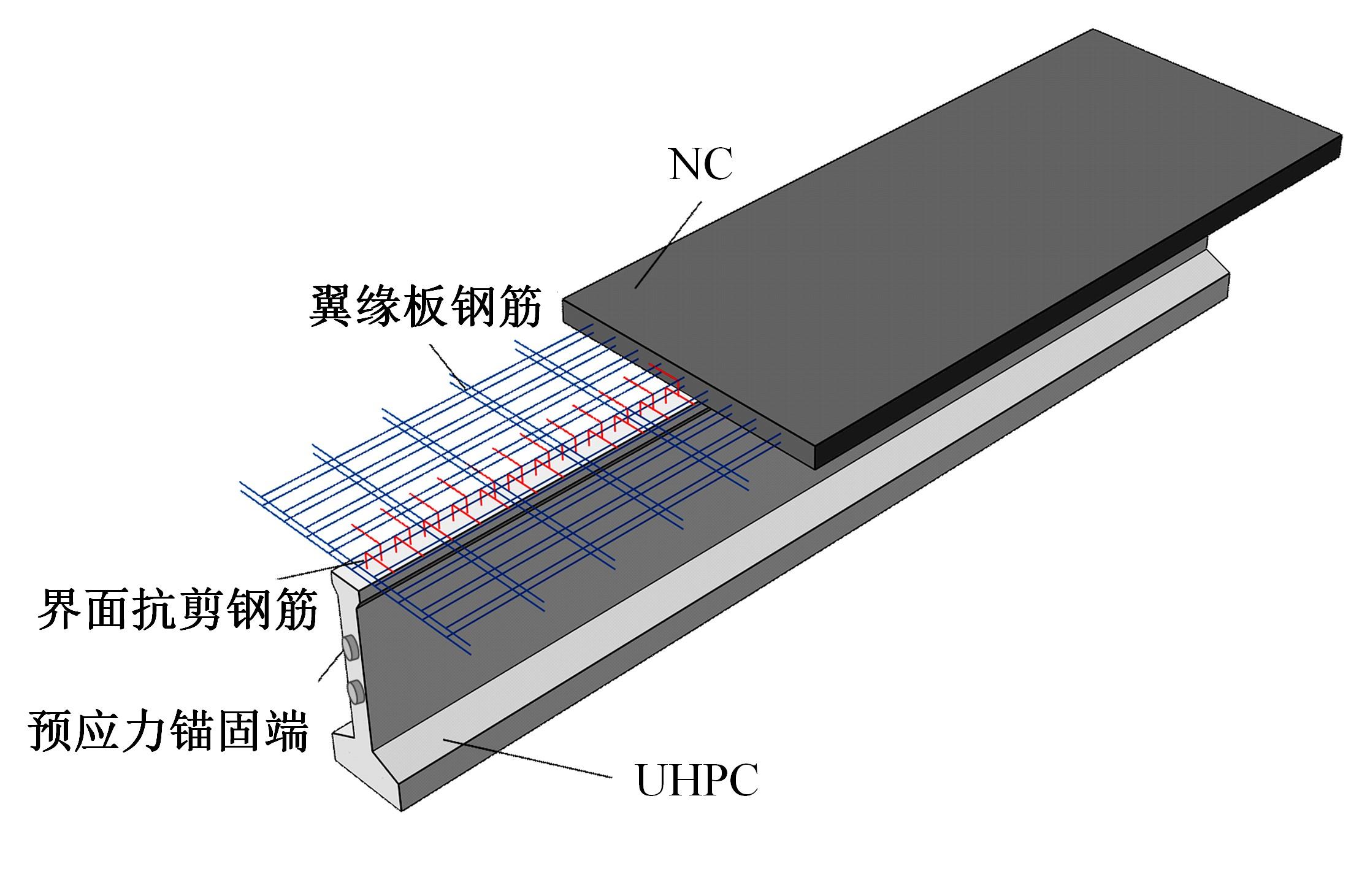

预应力UHPC-NC组合梁截面优化设计

- 1.天津大学 建筑工程学院,天津 300072

2.天津大学,滨海土木工程与安全教育部重点实验室,天津 300072

Section optimization design of prestressed UHPC-NC composite beams

Jin-song ZHU1,2( ),Ya-ting QIN1,Zhou-qiang LIU1

),Ya-ting QIN1,Zhou-qiang LIU1

- 1.School of Civil Engineering,Tianjin University,Tianjin 300072,China

2.Key Laboratory of Coast Civil Structure Safety,Ministry of Education,Tianjin University,Tianjin 300072,China

摘要:

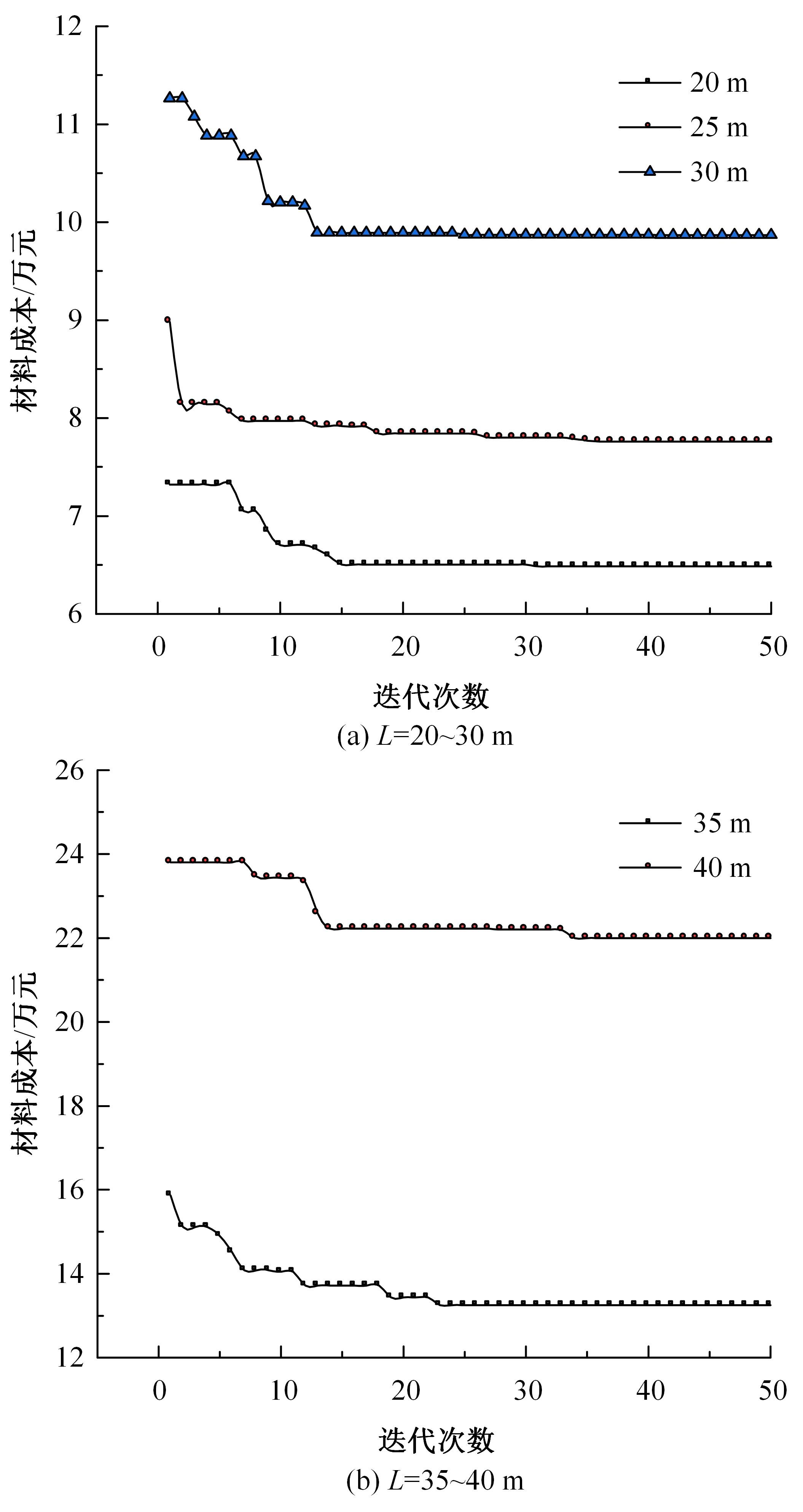

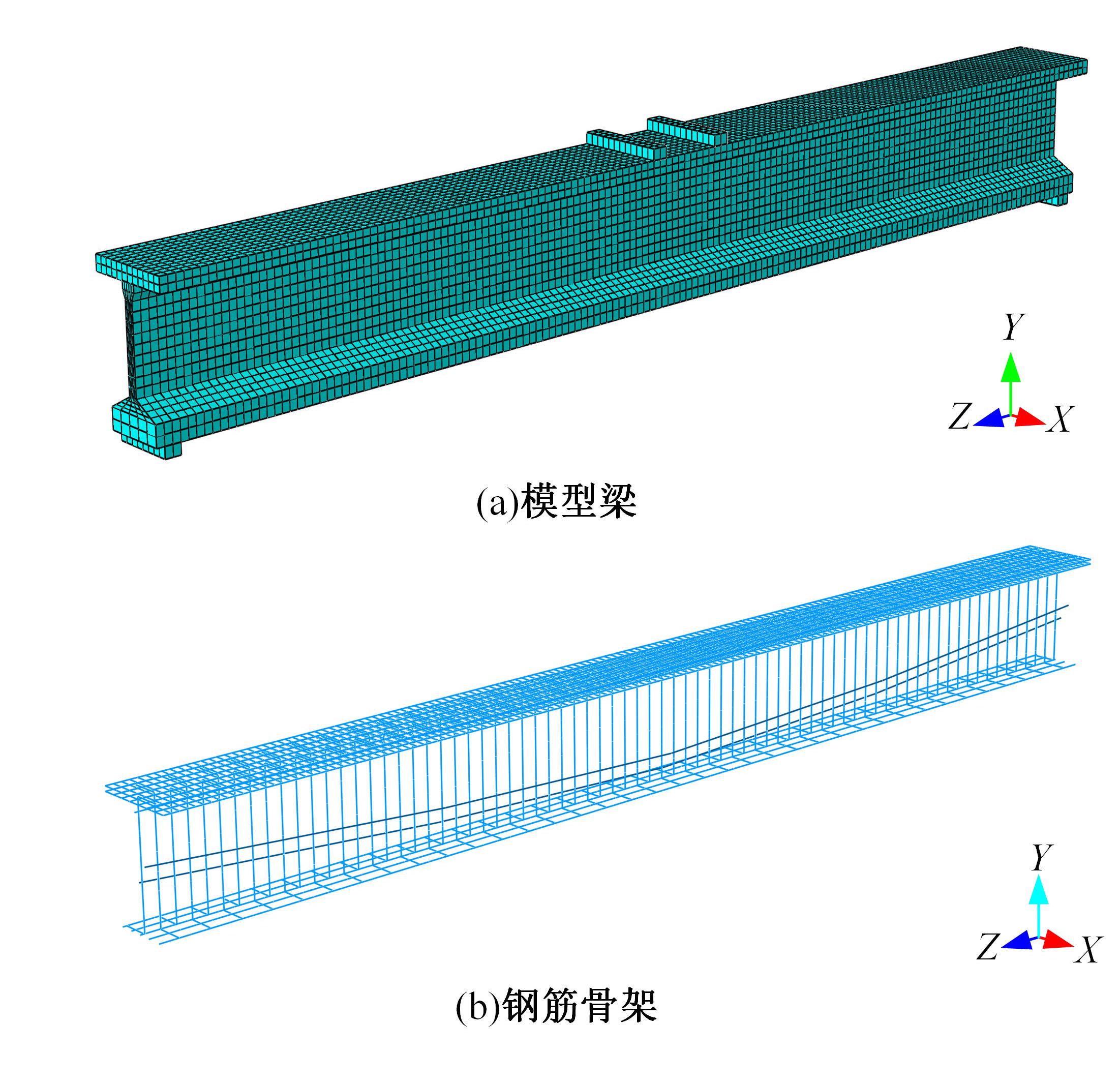

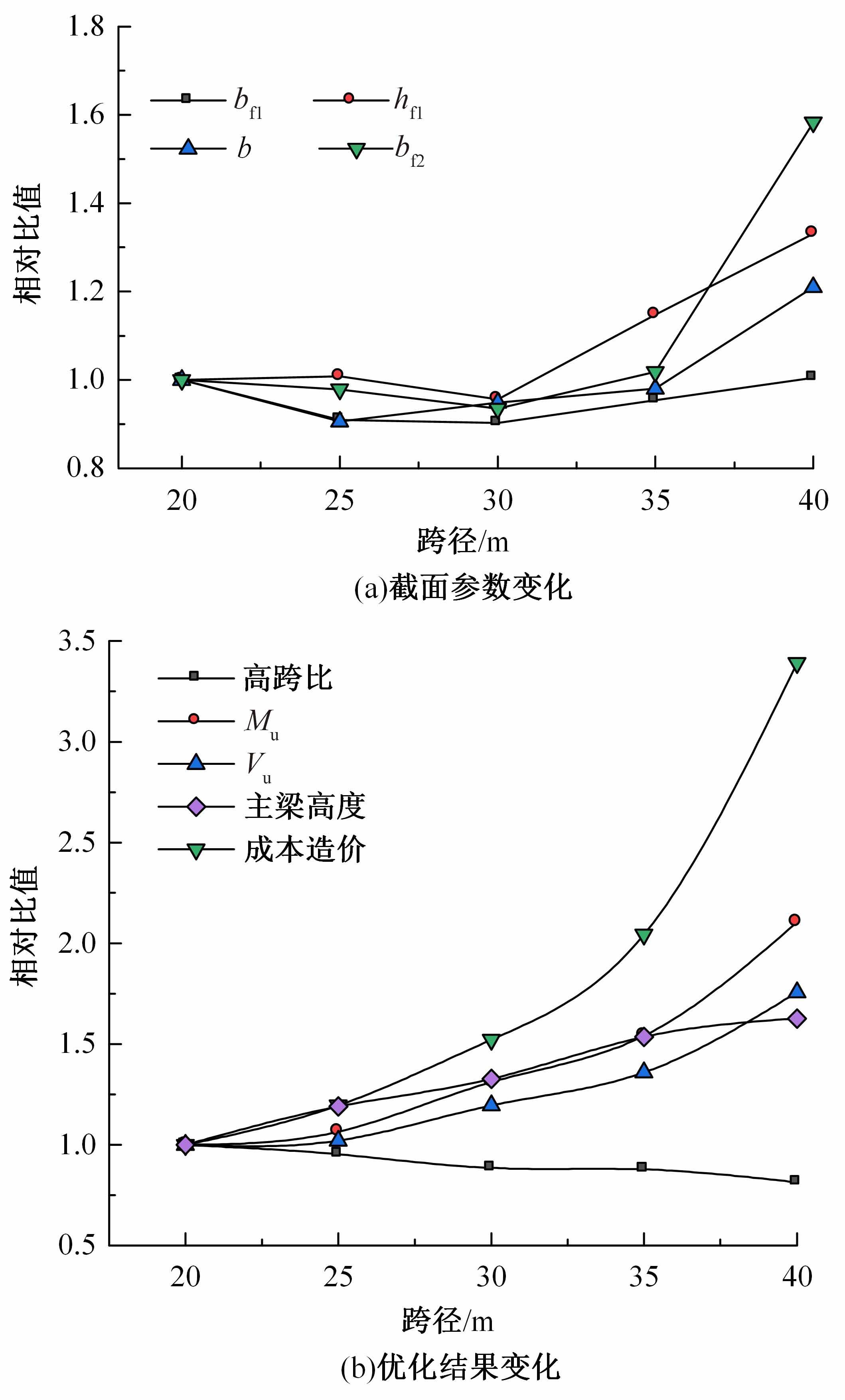

针对预应力超高性能混凝土-普通混凝土(UHPC-NC)组合梁结构的优化设计,提出了基于改进的自适应遗传算法的结构优化设计方法。优化设计以材料成本最小化为优化目标,以组合梁截面参数作为优化设计变量,并结合承载力及变形等约束条件,建立预应力UHPC-NC组合梁的数学模型。通过优化算例表明,改进的自适应遗传算法具有较好的极值寻优能力和收敛性能。利用自适应遗传算法搜索求解预应力UHPC-NC组合梁最优设计参数,优化结果表明:优化后得到的组合梁截面参数取值合理,满足约束条件要求。

中图分类号:

- TU318.1

| 1 | Al-Osta M A, Isa M N, Baluch M H, et al. Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete[J]. Construction and Building Materials, 2017, 134: 279-296. |

| 2 | Valikhani A, Jahromi A J, Mantawy I M, et al. Experimental evaluation of concrete-to-UHPC bond strength with correlation to surface roughness for repair application[J]. Construction and Building Materials, 2020, 238: 117753. |

| 3 | Shirai K, Yin H, Teo W. Flexural capacity prediction of composite RC members strengthened with UHPC based on existing design models[J]. Structures, 2020, 23: 44-55. |

| 4 | Shafieifar M, Farzad M, Azizinamini A. Experimental and numerical study on mechanical properties of ultra high performance concrete (UHPC)[J]. Construction and Building Materials, 2017, 156: 402-411. |

| 5 | 张哲,邵旭东,李文光,等. 超高性能混凝土轴拉性能试验[J]. 中国公路学报, 2015, 28(8): 50-58. |

| Zhang Zhe, Shao Xu-dong, Li Wen-guang, et al. Experimental study on axial tension performance of ultra-high performance concrete[J]. China Journal of Highway and Transport, 2015, 28(8): 50-58. | |

| 6 | Tayeh B A, Abu Bakar B H, Megat Johari M A, et al. Mechanical and permeability properties of the interface between normal concrete substrate and ultra high performance fiber concrete overlay[J]. Construction and Building Materials, 2012, 36: 538-548. |

| 7 | 李昭,赵华,朱平,等. UHPC-NC组合结构抗弯性能试验及有限元分析[J]. 公路工程, 2019,44(2): 194-200. |

| Li Zhao, Zhao Hua, Zhu Ping, et al. Test and finite element analysis of flexural performance of UHPC-NC composite structure[J]. Highway Engineering, 2019, 44(2): 194-200. | |

| 8 | 曾蔚,秦阳. 钢筋混凝土梁遗传算法优化设计[J]. 公路交通科技, 2006(8): 81-83. |

| Zeng Wei, Qin Yang. Optimization design of reinforced concrete beam based on genetic algorithm[J]. Journal of Highway and Traffic Science, 2006(8): 81-83. | |

| 9 | Senouci A B, Al-Ansari M S. Cost optimization of composite beams using genetic algorithms[J]. Advances in Engineering Software, 2009, 40(11): 1112-1118. |

| 10 | Pedro R L, Demarche J, Miguel L F F, et al. An efficient approach for the optimization of simply supported steel-concrete composite I-girder bridges[J]. Advances in Engineering Software, 2017, 112: 31-45. |

| 11 | Sudira I G N, Hadi B K, Moelyadi M A, et al. Application of genetic algorithm for the design optimization of geodesic beam structure[J]. Applied Mechanics and Materials, 2016, 842: 266-272. |

| 12 | 邬沛, 李玉顺, 许达, 等. 基于遗传算法的钢-竹组合工字形梁截面优化设计[J]. 建筑结构学报, 2020,41(1): 149-155. |

| Wu Pei, Li Yu-shun, Xu Da, et al. Optimization of section of steel-bamboo composite i-beam based on genetic algorithm[J]. Journal of Building Structures, 2020, 41(1): 149-155. | |

| 13 | de Munck M, de Sutter S, Verbruggen S, et al. Multi-objective weight and cost optimization of hybrid composite-concrete beams[J]. Composite Structures, 2015, 134: 369-377. |

| 14 | Umeonyiagu I E, Nwobi-Okoye C C. Modelling and multi objective optimization of bamboo reinforced concrete beams using ANN and genetic algorithms[J]. European Journal of Wood and Wood Products, 2019, 77(5): 931-947. |

| 15 | 黄冀卓,王湛. 基于遗传算法的抗震钢框架多目标优化设计[J]. 力学学报, 2007(3): 389-397. |

| Huang Ji-zhuo, Wang Zhan. Multi-objective optimization design of seismic steel frame based on genetic algorithm[J]. Chinese Journal of Theoretical and Applied Mechanics, 2007(3): 389-397. | |

| 16 | 王佩艳,赵晨,耿小亮,等. 基于改进自适应遗传算法的层合板铺层顺序优化方法[J]. 科学技术与工程, 2018, 18(6): 336-340. |

| Wang Pei-yan, Zhao Chen, Geng Xiao-liang, et al. Optimization method of laminate layering sequence based on improved adaptive genetic algorithm[J]. Science Technology and Engineering, 2018, 18(6): 336-340. | |

| 17 | Whitworth A H, Tsavdaridis K D. Embodied energy optimization of steel-concrete composite beams using a genetic algorithm[J]. Procedia Manufacturing, 2020, 44: 417-424. |

| 18 | 万世成, 黄侨, 关健, 等. 预应力碳纤维板加固钢-混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报: 工学版, 2019, 49(4): 1114-1123. |

| Wan Shi-cheng, Huang Qiao, Guan Jian, et al. Negative moment zone test of prestressed carbon fiber plate reinforced steel-concrete composite continuous beam[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1114-1123. | |

| 19 | 孙琪凯, 张楠, 刘潇, 等. 基于Timoshenko梁理论的钢-混组合梁动力折减系数[J]. 吉林大学学报: 工学版, 2023, 53(2): 488-495. |

| Sun Qi-kai, Zhang Nan, Liu Xiao, et al. Dynamic reduction coefficient of steel-composite beams based on Timoshenko beam theory[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(2): 488-495. | |

| 20 | 朱劲松, 秦亚婷, 史腾. 预应力UHPC-NC组合梁抗弯承载力计算方法[J]. 中南大学学报, 2022, 53(10): 3989-4000. |

| Zhu Jin-song, Qin Ya-ting, Shi Teng. Calculation method for flexural capacity of prestressed UHPC-NC composite beams[J]. Journal of Central South University(Science and Technology Edition), 2022, 53(10): 3989-4000. | |

| 21 | 刘大同. 中小跨径桥梁截面优化设计研究[D]. 武汉: 武汉理工大学交通学院, 2005. |

| Liu Da-tong. Study on section optimization design of medium and small span bridges[D]. Wuhan: College of Transportation, Wuhan University of Technology, 2005. |

| [1] | 郑长江,胡欢,杜牧青. 考虑枢纽失效的多式联运快递网络结构设计[J]. 吉林大学学报(工学版), 2023, 53(8): 2304-2311. |

| [2] | 田国红,代鹏杰. 基于单亲遗传算法的无人驾驶汽车主动避撞方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2404-2409. |

| [3] | 惠迎新,陈嘉伟. 基于改进遗传算法的挤扩支盘群桩优化方法[J]. 吉林大学学报(工学版), 2023, 53(7): 2089-2098. |

| [4] | 卜建清,郭至博,张吉仁,荀敬川,黄晓明. 多损伤钢-混组合梁桥力学性能有限元分析方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1621-1637. |

| [5] | 毛亚娜,刘世忠,杏剑,杨华,焦峪波. 超高性能玻璃砂混凝土-高强钢筋粘结滑移特性及其声发射参数表征[J]. 吉林大学学报(工学版), 2023, 53(6): 1686-1694. |

| [6] | 李艳波,柳柏松,姚博彬,陈俊硕,渠开发,武奇生,曹洁宁. 考虑路网随机特性的高速公路换电站选址[J]. 吉林大学学报(工学版), 2023, 53(5): 1364-1371. |

| [7] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于NSGA⁃II的斜齿轮宏观参数多目标优化[J]. 吉林大学学报(工学版), 2023, 53(4): 1007-1018. |

| [8] | 马敏,胡大伟,舒兰,马壮林. 城市轨道交通网络韧性评估及恢复策略[J]. 吉林大学学报(工学版), 2023, 53(2): 396-404. |

| [9] | 韩智强,谢刚,周勇军,刘世忠,晋民杰. 曲线桥梁车桥耦合振动数值分析方法[J]. 吉林大学学报(工学版), 2023, 53(2): 515-522. |

| [10] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于某二级减速齿轮系统的齿面修形优化[J]. 吉林大学学报(工学版), 2022, 52(7): 1541-1551. |

| [11] | 杨国俊,田骐玮,吕明航,杜永峰,唐光武,韩宗健,伏一多. 大跨度悬索桥隧道式锚碇力学特性研究综述[J]. 吉林大学学报(工学版), 2022, 52(6): 1245-1263. |

| [12] | 张英朝,李昀航,郭子瑜,王国华,张喆,苏畅. 长头重型卡车气动减阻优化[J]. 吉林大学学报(工学版), 2022, 52(4): 745-753. |

| [13] | 姜斌祥,姜彤彤,王永雷. 基于文化遗传算法的毒品检验区块链共识算法优化[J]. 吉林大学学报(工学版), 2022, 52(3): 684-692. |

| [14] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [15] | 张立杰,阿喜塔,田笑,李稳. 基于Gamma过程的加速退化试验多目标优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 361-367. |

|