吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3367-3378.doi: 10.13229/j.cnki.jdxbgxb.20220075

• 车辆工程·机械工程 • 上一篇

阀套交叉孔磨粒流精密加工质量分析

郭静1( ),桂林1,侯威1,李俊烨2(

),桂林1,侯威1,李俊烨2( ),朱志宝2,孙立伟2

),朱志宝2,孙立伟2

- 1.中国北方车辆研究所 车辆传动重点实验室,北京 100072

2.长春理工大学 跨尺度微纳制造教育部重点实验室,长春 130022

Quality analysis of abrasive flow precision machining of cross hole of valve sleeve

Jing GUO1( ),Lin GUI1,Wei HOU1,Jun-ye LI2(

),Lin GUI1,Wei HOU1,Jun-ye LI2( ),Zhi-bao ZHU2,Li-wei SUN2

),Zhi-bao ZHU2,Li-wei SUN2

- 1.Key Laboratory of Vehicle Transmission,China North Vehicle Research Institute,Beijing 100072,China

2.Ministry of Education Key Laboratory for Cross-Scale Micro and Nano Manufacturing,Changchun University of Science and Technology,Changchun 130022,China

摘要:

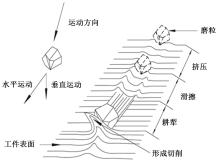

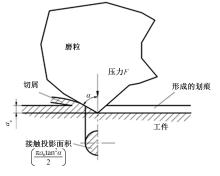

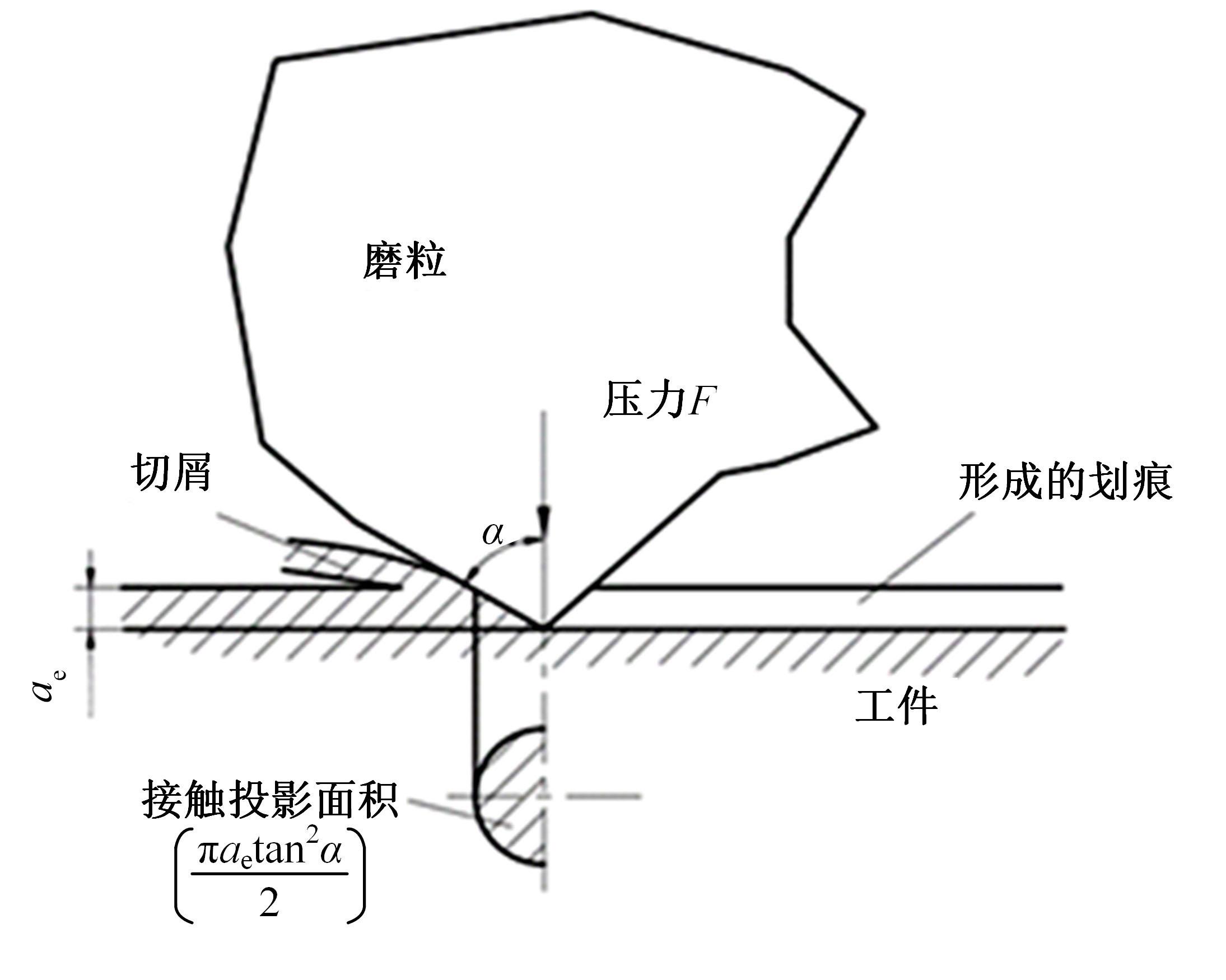

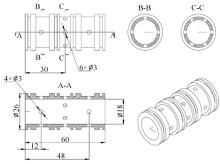

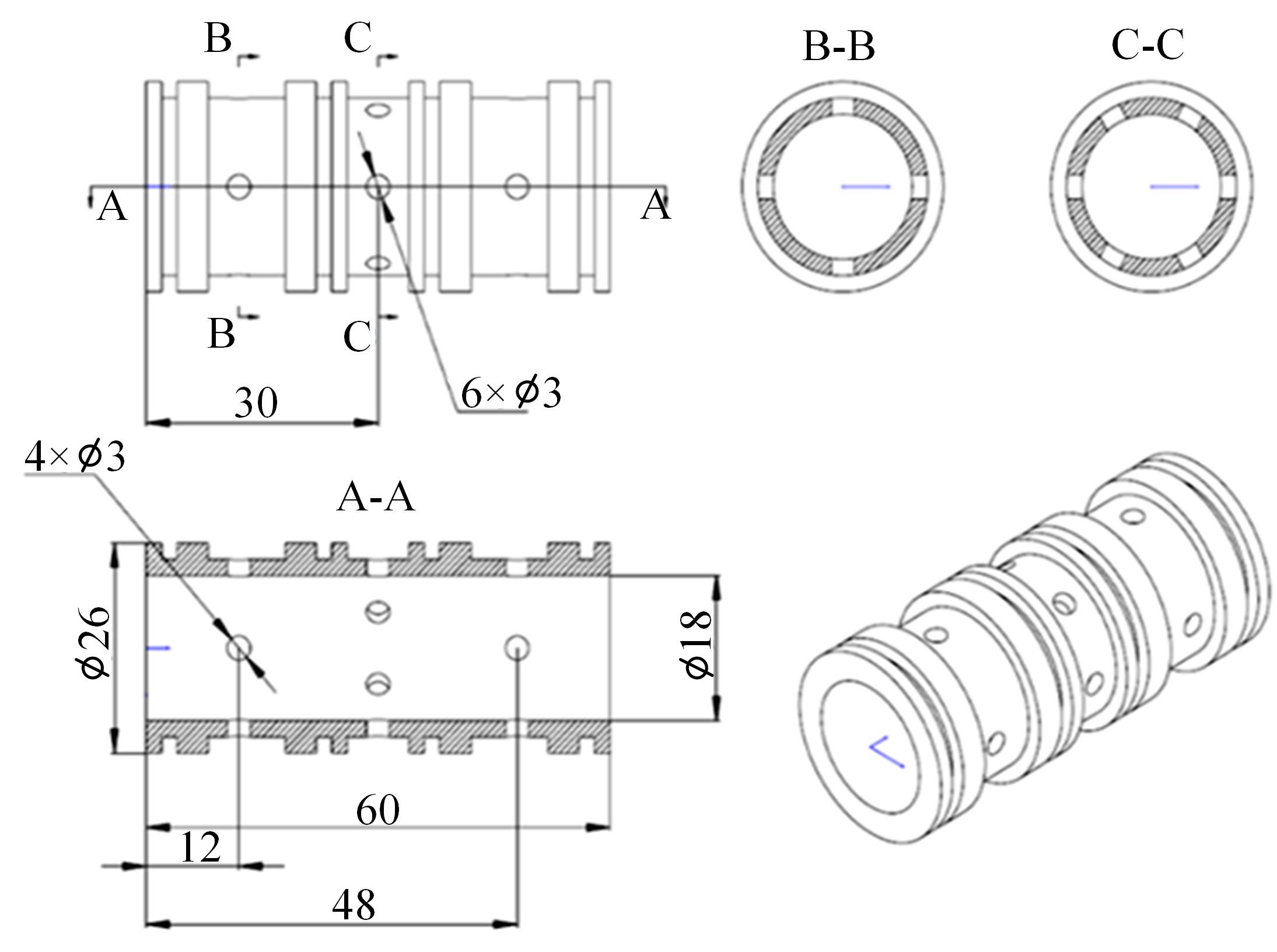

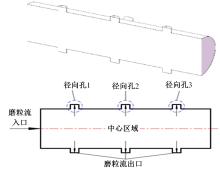

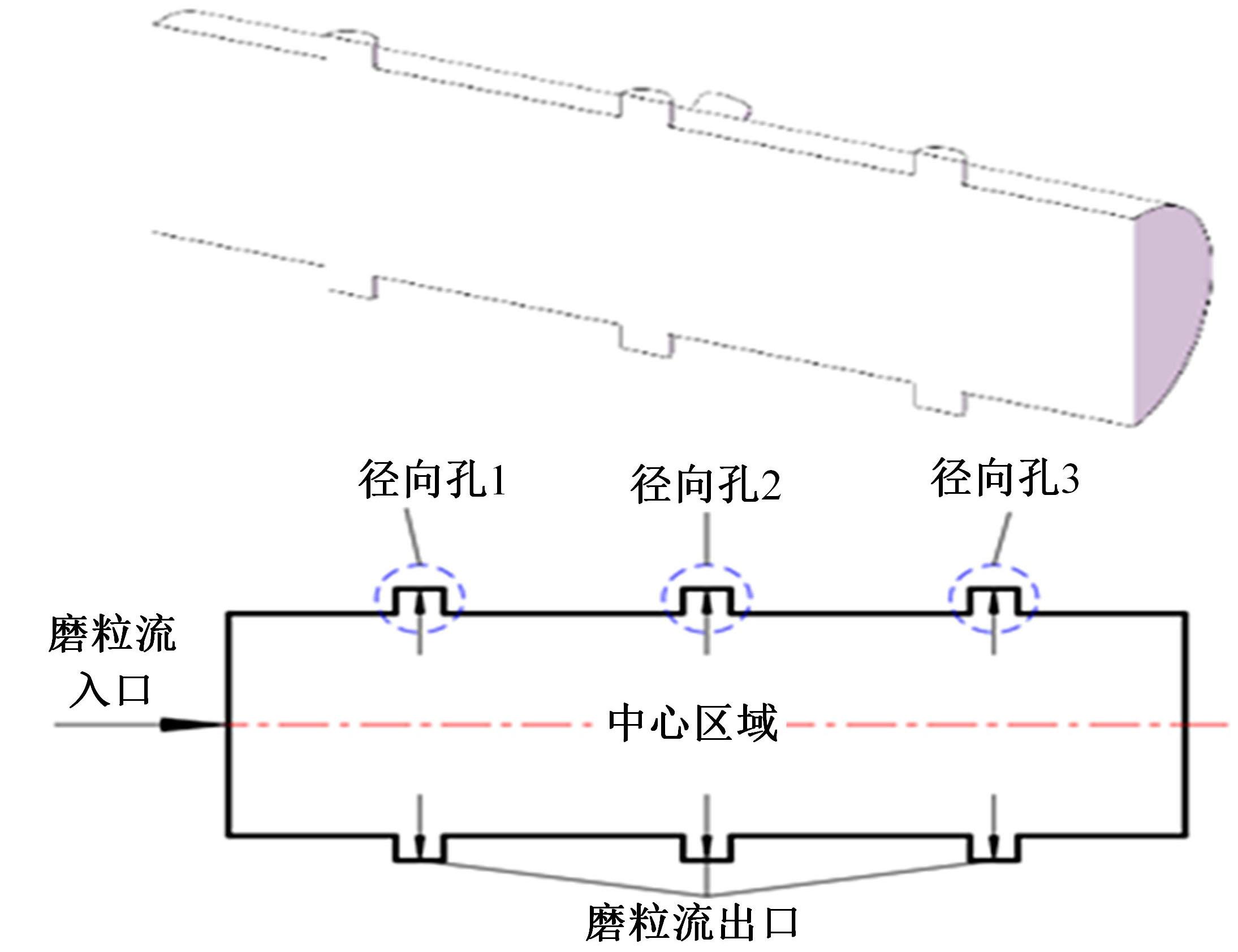

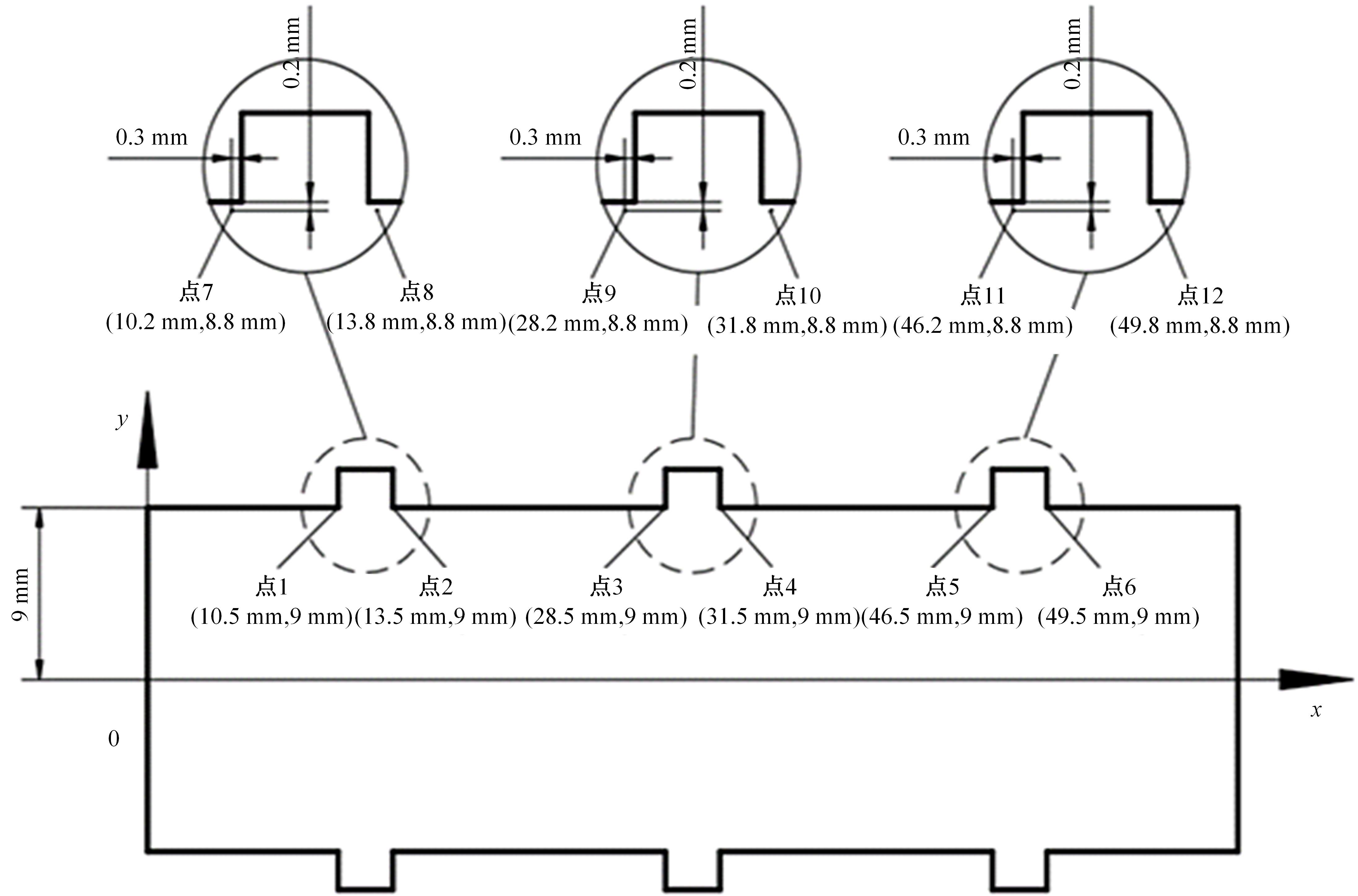

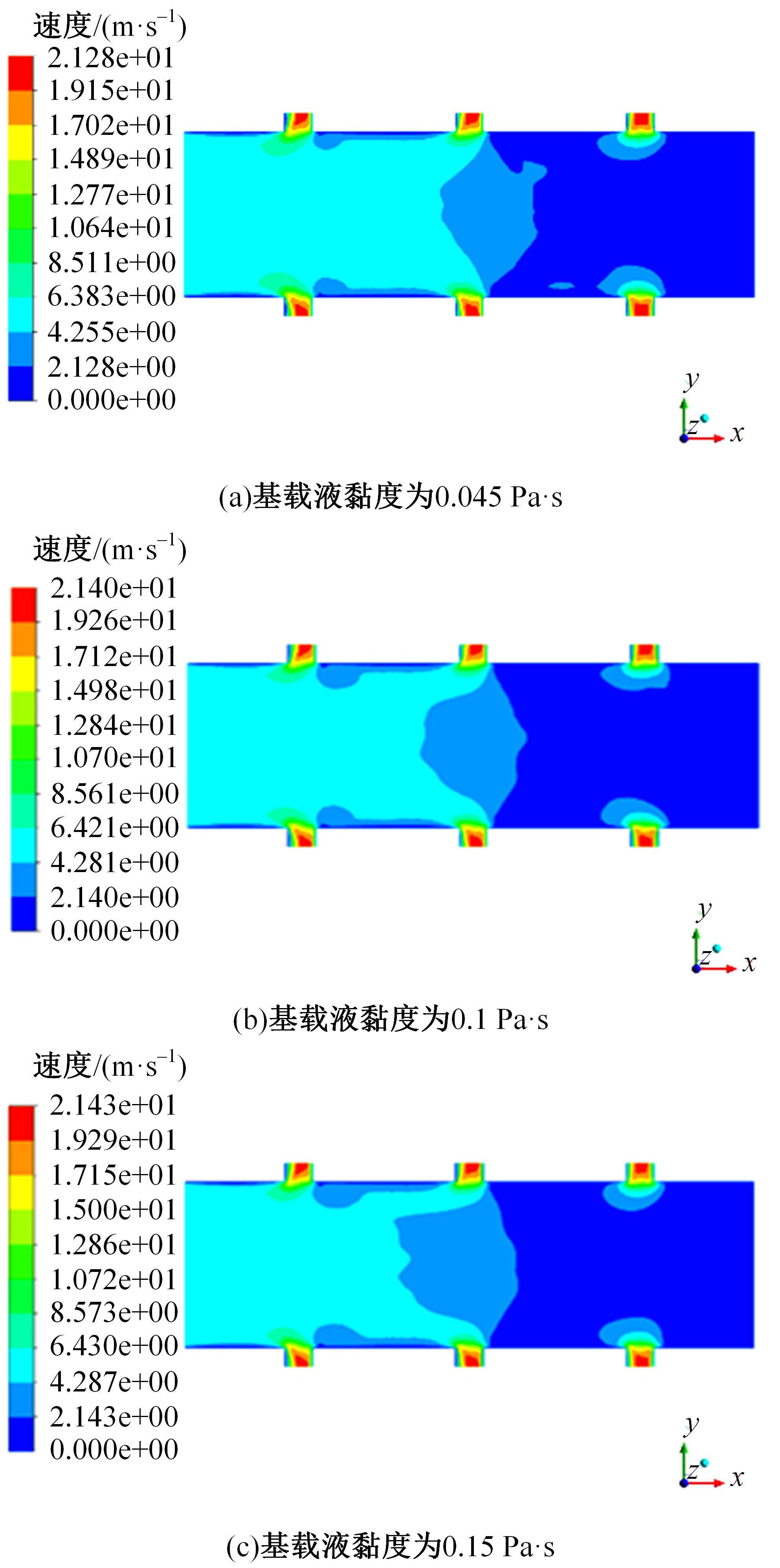

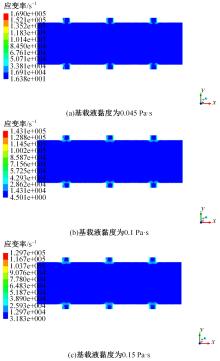

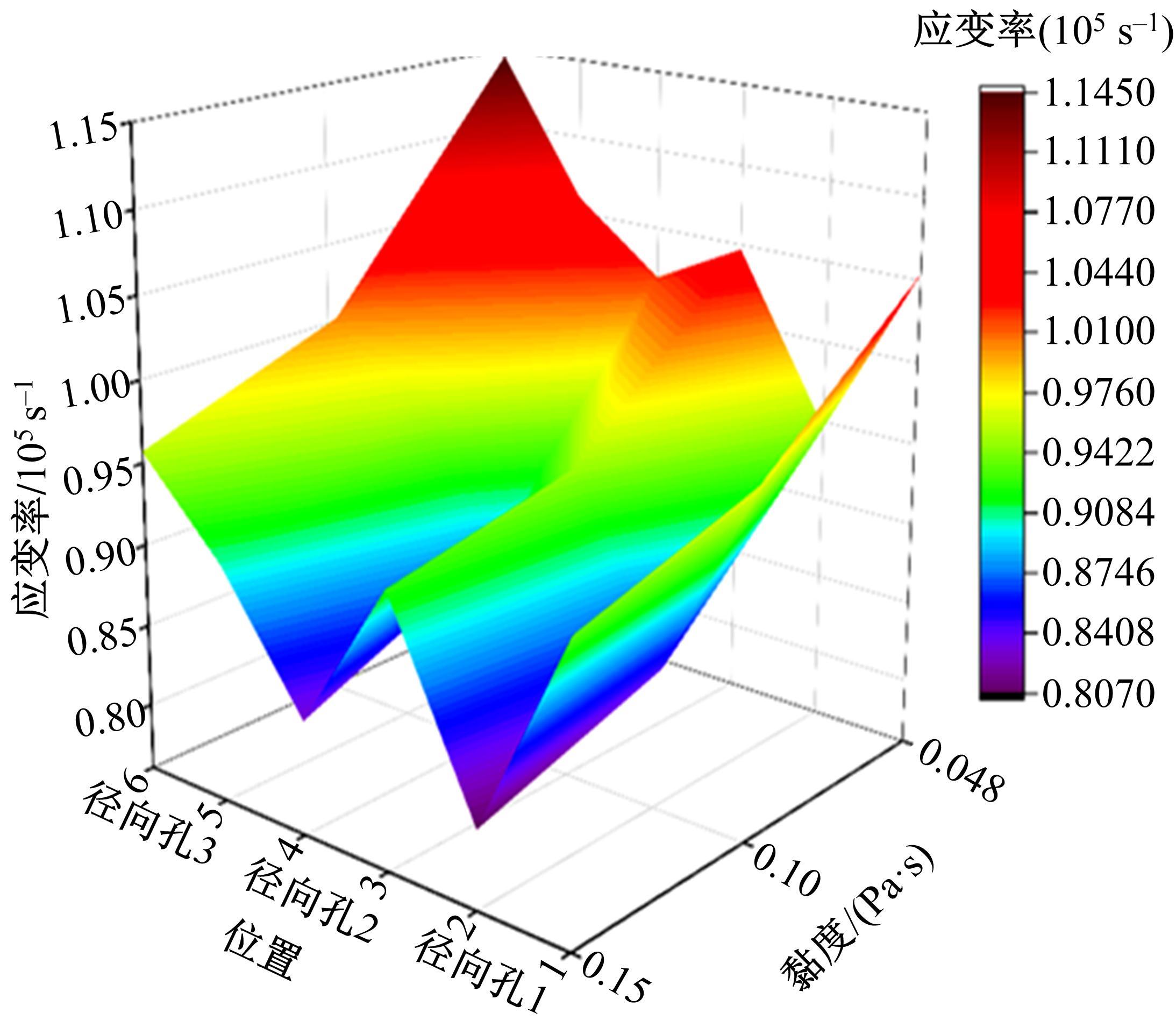

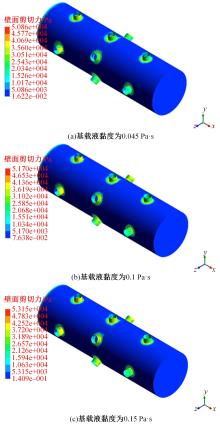

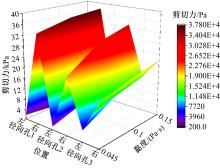

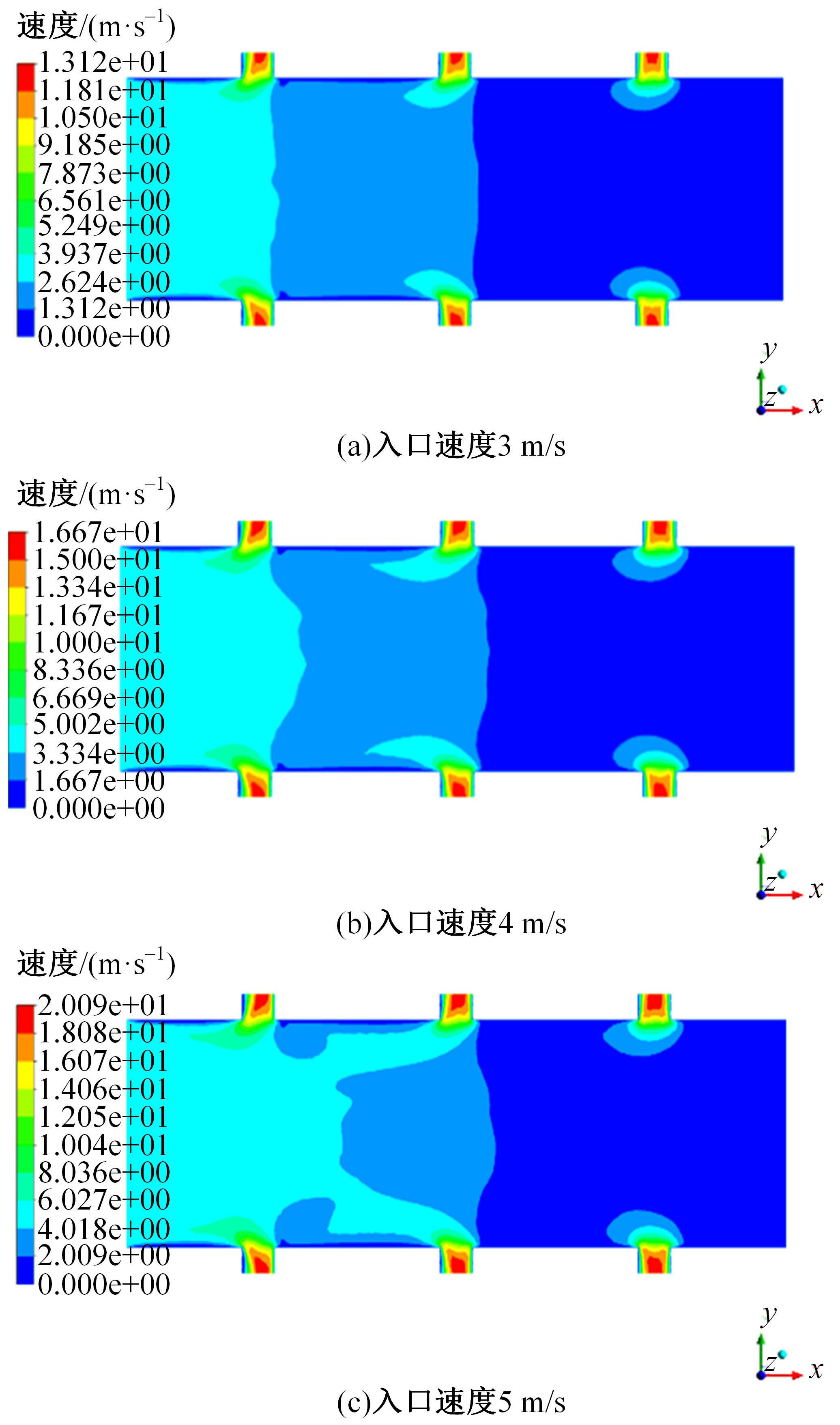

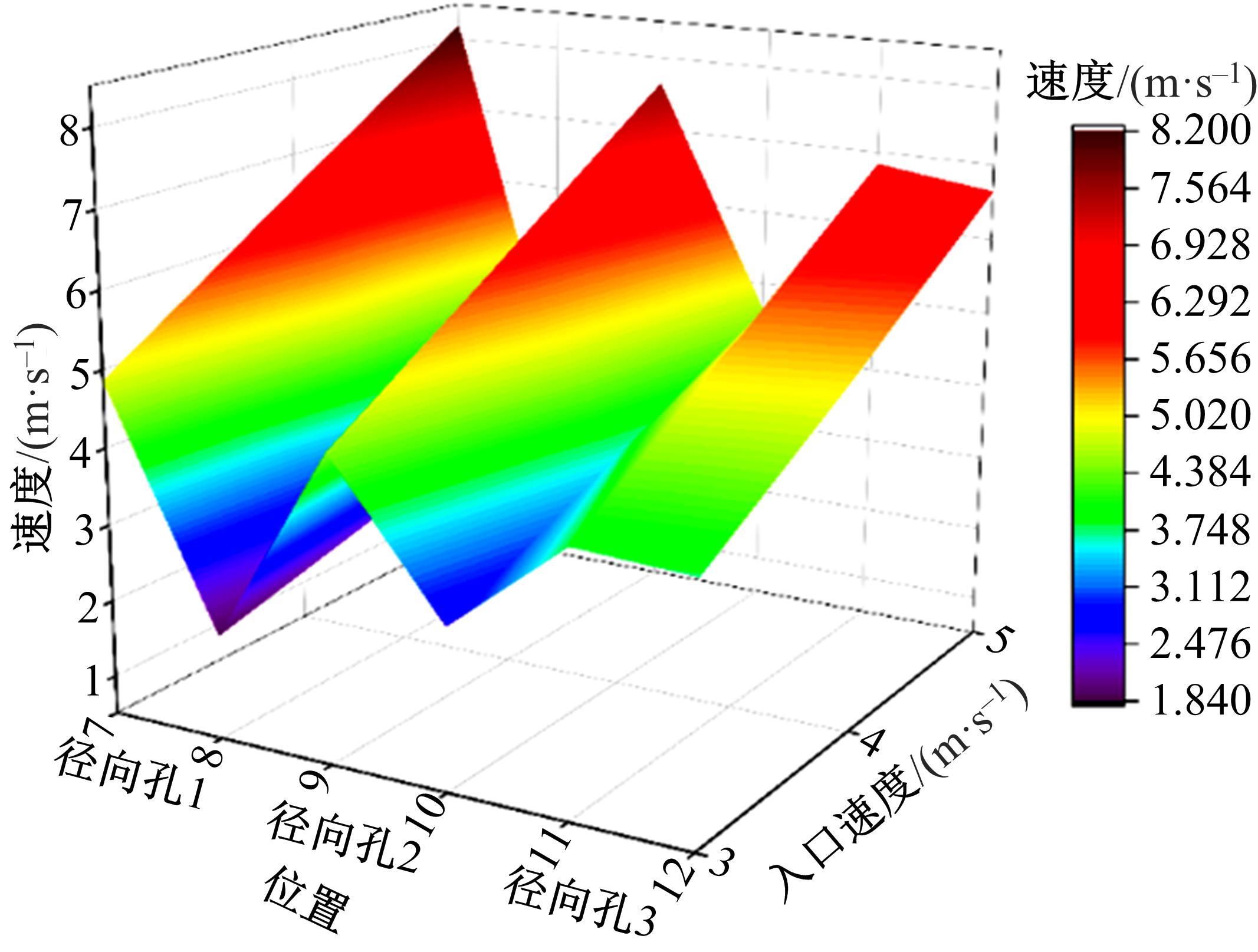

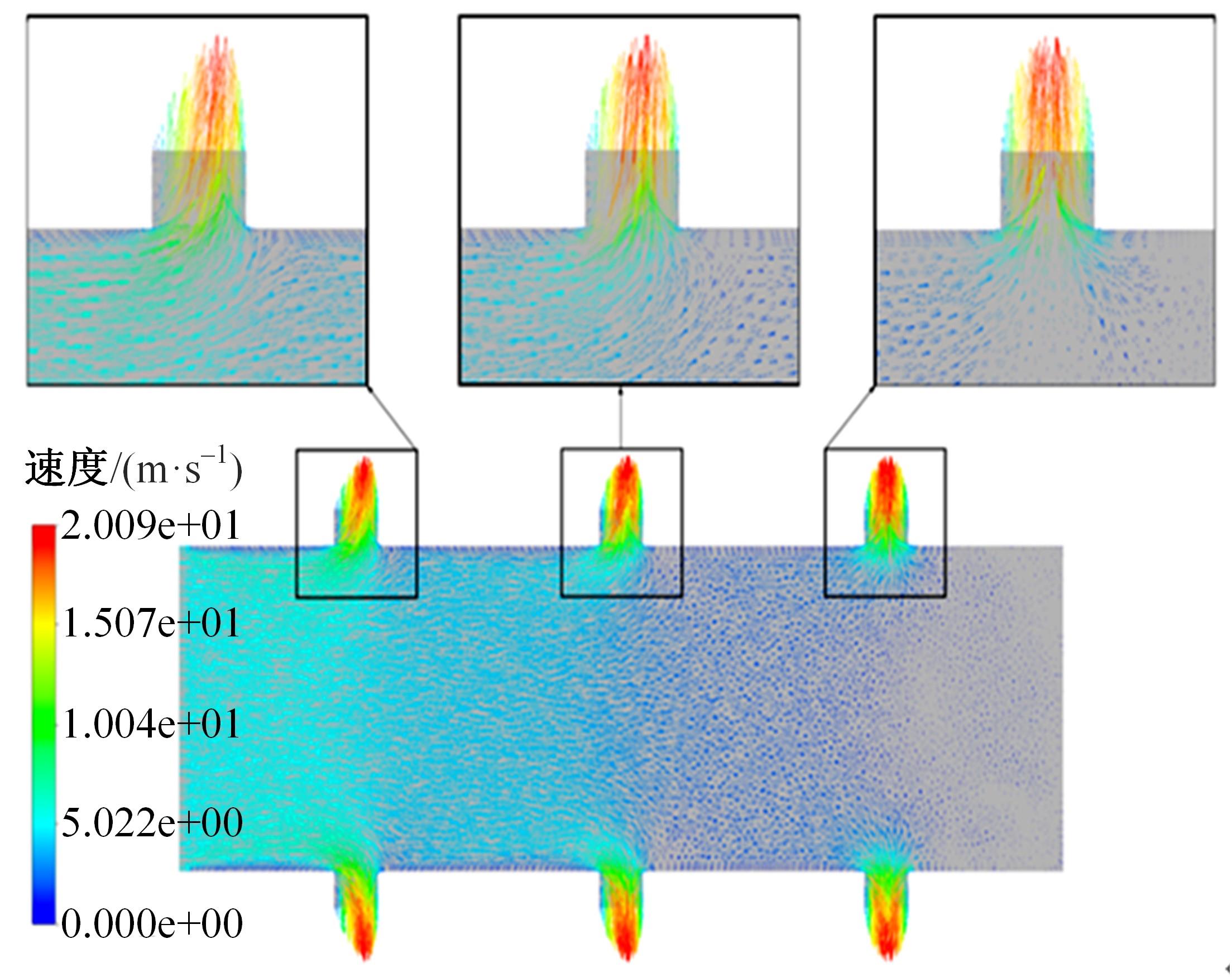

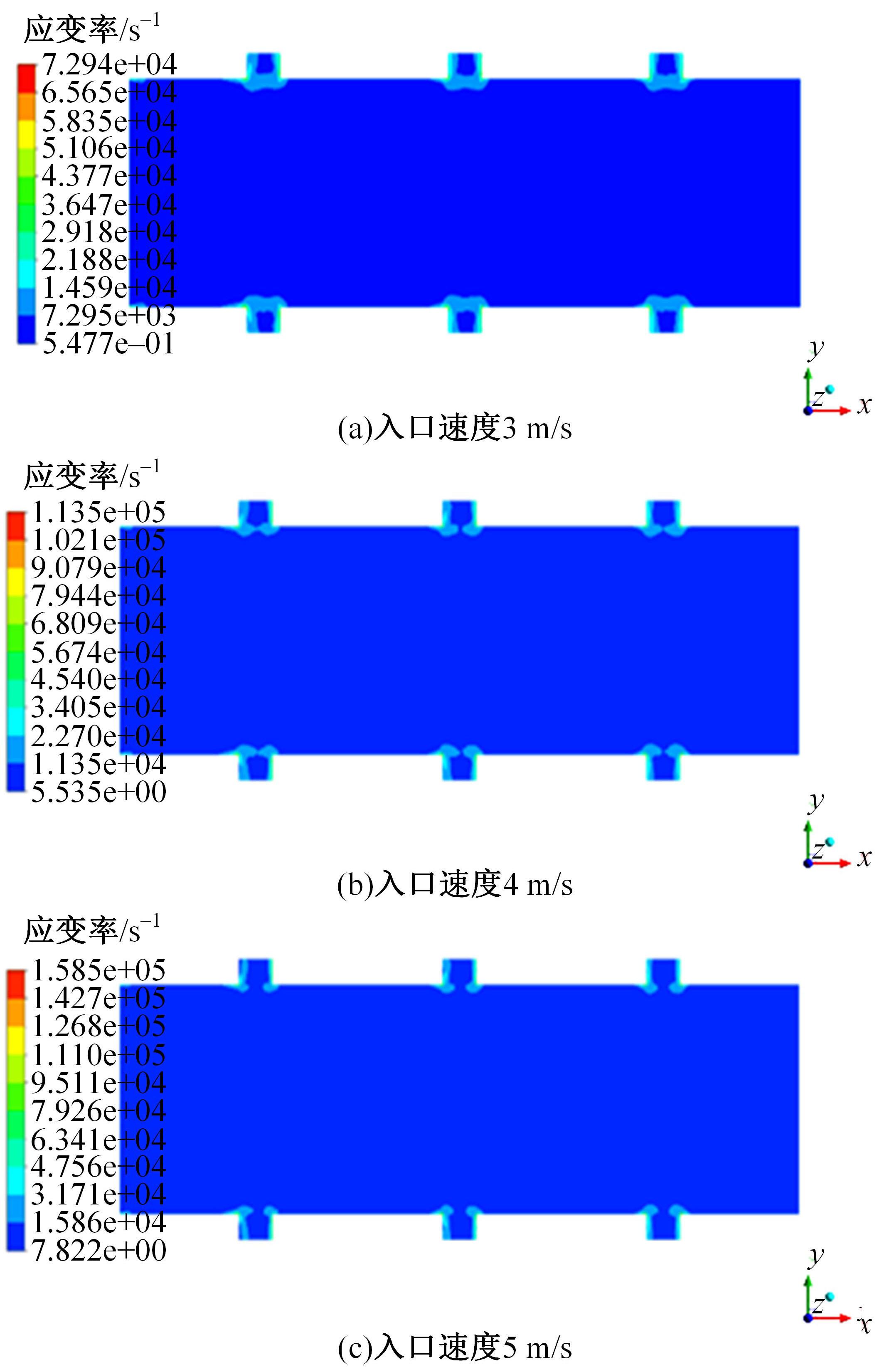

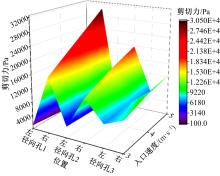

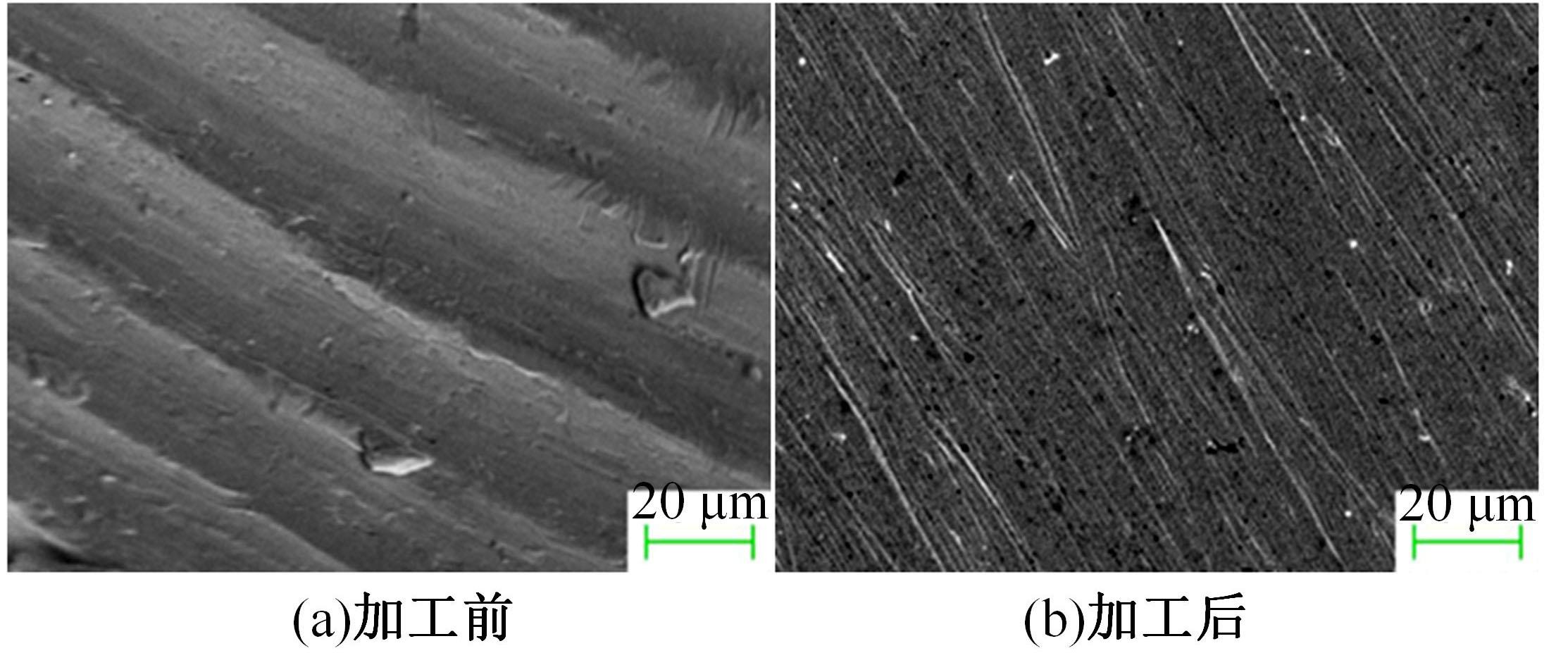

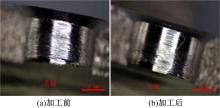

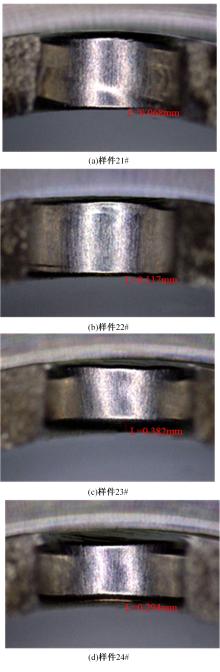

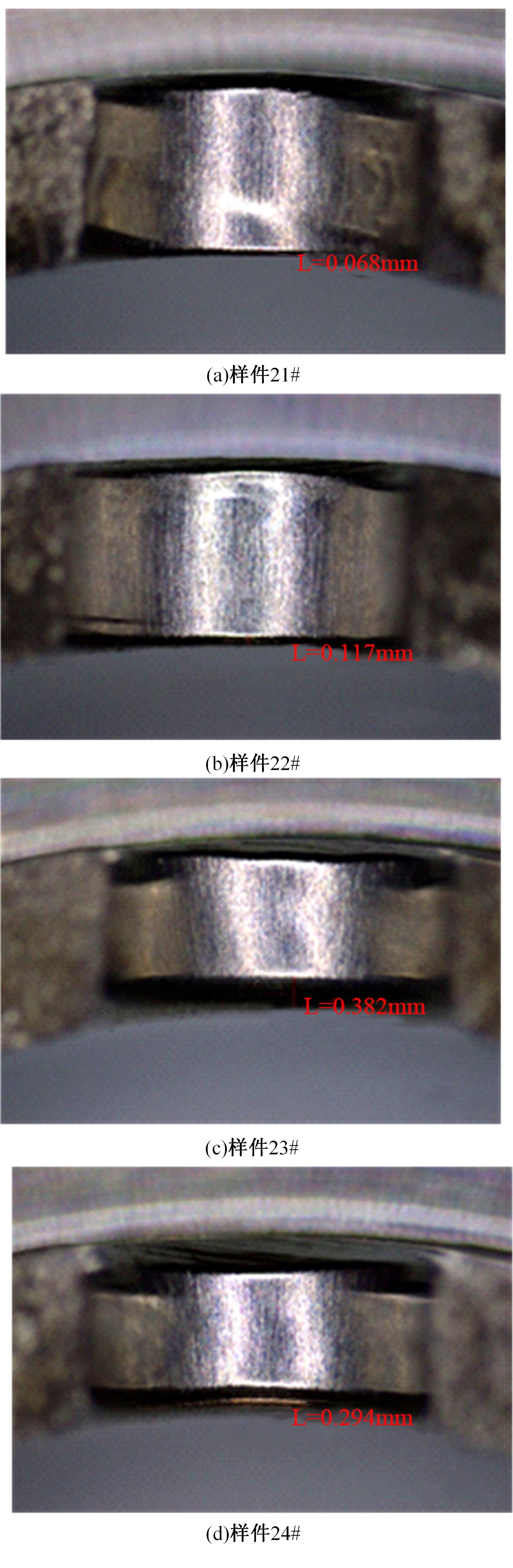

采用磨粒流精密加工方法对阀套交叉孔进行去毛刺处理,通过大涡模拟的方法和合理的亚格子模型对阀套工件在侧孔出流条件下进行数值模拟分析。在不同流速和黏度情况下,分析了流体应变率、速度矢量、壁面剪切力对交叉孔边缘圆角半径大小、毛刺去除以及径向孔壁面加工质量的影响。试验结果表明:流体黏度越低、速度越大,交叉孔边缘圆角半径越大;黏度越高、速度越大,径向孔壁面加工质量越高;为保证交叉孔边缘有较小的圆角,应选用低速、高黏流体进行阀套交叉孔的精密加工。

中图分类号:

- TH161.1

| 1 | 孙振贵, 邢天羿, 邵铭, 等. 超精密阀套内孔的珩磨工艺研究[J]. 航空精密制造技术,2019,55(2):53-56. |

| Sun Zhen-gui, Xing Tian-yi, Shao Ming, et al. Honing process research about ultra-precision valve sleeve bore[J]. Aviation Precision Manufacturing Technology, 2019, 55(2): 53-56. | |

| 2 | 朱西薇, 车飞, 方兵, 等. 电液伺服阀自动化配研磨技术研究[J]. 液压气动与密封, 2020, 40(3): 80-84. |

| Zhu Xi-wei, Che Fei, Fang Bing, et al. Research on auto-matching grinding technology of electro-hydraulic servo valve[J]. Hydraulics Pneumatics & Seals, 2020, 40(3): 80-84. | |

| 3 | 张静, 朱春江, 赵龙. 航空精密偶件去毛刺方法的研究[J]. 航空精密制造技术, 2014, 50(2): 54-55. |

| Zhang Jing, Zhu Chun-jiang, Zhao Long. Research on deburring approach of aviation precision matching parts[J]. Aviation Precision Manufacturing Technology, 2014, 50(2): 54-55. | |

| 4 | Gillespie L K. Deburring precision miniature parts[J]. Precision Engineering, 1979, 1(4): 189-198. |

| 5 | Kotte G. Precision machining: technology and machine development and improvement[J]. Precision Engineering, 2012, 15(4): 455-460. |

| 6 | Fu Y, Gao H, Yan Q, et al. Rheological characterisation of abrasive media and finishing behaviours in abrasive flow machining[J]. The International Journal of Advanced Manufacturing Technology, 2020, 107(7): 3569-3580. |

| 7 | Kumar S S, Hiremath S S. A review on abrasive flow machining (AFM)[J]. Procedia Technology, 2016, 25: 1297-1304. |

| 8 | Cheema M S, Venkatesh G, Dvivedi A, et al. Developments in abrasive flow machining: a review on experimental investigations using abrasive flow machining variants and media[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226(12): 1951-1962. |

| 9 | Fu Y, Gao H, Yan Q, et al. An efficient approach to improving the finishing properties of abrasive flow machining with the analyses of initial surface texture of workpiece[J]. The International Journal of Advanced Manufacturing Technology, 2020, 107(5): 2417-2432. |

| 10 | Suzuki H, Ohashi K. Special issue on precision abrasive technology of difficult-to-machine materials[J]. International Journal of Automation Technology, 2018, 12(6): 861. |

| 11 | Dixit N, Sharma V, Kumar P. Research trends in abrasive flow machining: a systematic review[J]. Journal of Manufacturing Processes, 2021, 64: 1434-1461. |

| 12 | Kim K J, Kim Y G, Kim K H. Characterization of deburring by abrasive flow machining for AL6061[J]. Applied Sciences, 2022, 12(4): No. 2048. |

| 13 | Li Jun-ye, Zhu Zhi-bao, Hu Jing-lei, et al. Particle collision-based abrasive flow mechanisms in precision machining[J]. International Journal of Advanced Manufacturing Technology, 2020, 110(7): 1819-1831. |

| 14 | 李俊烨, 胡敬磊, 杨兆军, 等. 离散相磨粒粒径对磨粒流研抛共轨管质量的影响[J]. 吉林大学学报:工学版, 2018, 48(2): 492-499. |

| Li Jun-ye, Hu Jing-lei, Yang Zhao-jun, et al. Effect on the quality of abrasive flow polishing the common rail pipe in size of discrete phase abrasive particle[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(2): 492-499. | |

| 15 | Li Jun-ye, Meng Wen-qing, Dong Kun, et al. Numerical analysis of solid-liquid two-phase abrasive flow in microcutting polycrystalline materials based on molecular dynamics[J]. International Journal of Precision Engineering and Manufacturing, 2018, 19(11): 1597-1610. |

| 16 | Wei H, Peng C, Gao H, et al. On establishment and validation of a new predictive model for material removal in abrasive flow machining[J]. International Journal of Machine Tools and Manufacture, 2019, 138: 66-79. |

| 17 | Guo J, Song C, Fu Y, et al. Internal surface quality enhancement of selective laser melted inconel 718 by abrasive flow machining[J]. Journal of Manufacturing Science and Engineering, 2020, 142(10): No. 101003. |

| 18 | Yuan Q, Qi H, Wen D. Numerical and experimental study on the spiral-rotating abrasive flow in polishing of the internal surface of 6061 aluminium alloy cylinder[J]. Powder Technology, 2016, 302: 153-159. |

| 19 | Furumoto T, Ueda T, Amino T, et al. A study of internal face finishing of the cooling channel in injection mold with free abrasive grains[J]. Journal of Materials Processing Technology, 2011, 211(11): 1742-1748. |

| 20 | 李俊烨, 朱旭, 杨兆军, 等. 固液两相磨料流的微小孔精密研抛行为[J].吉林大学学报: 工学版, 2020, 50(3): 903-913. |

| Li Jun-ye, Zhu Xu, Yang Zhao-jun, et al. Micro-hole precision grinding and polishing behavior of solid-liquid two-phase abrasive flow[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(3): 903-913. | |

| 21 | 李忠新. 精密复杂微小型构件车铣复合加工技术研究[D]. 北京: 北京理工大学机械与车辆学院, 2014. |

| Li Zhong-xin. Research on turning and milling compound machining technology of precise and complex micro-miniature components[D]. Beijing: School of Machinery and Vehicles, Beijing Institute of Technology, 2014. |

| [1] | 马芳武,陈实现,韩露,梁鸿宇,蒲永锋. 金属表面特征与金属⁃塑料直接连接强度的相关性[J]. 吉林大学学报(工学版), 2019, 49(3): 816-821. |

| [2] | 寇淑清, 石舟. 裂解连杆接合面三维重构及其强度与刚度[J]. 吉林大学学报(工学版), 2018, 48(5): 1515-1523. |

| [3] | 李俊烨, 胡敬磊, 杨兆军, 张心明, 周曾炜. 离散相磨粒粒径对磨粒流研抛共轨管质量的影响[J]. 吉林大学学报(工学版), 2018, 48(2): 492-499. |

| [4] | 陈超, 赵升吨, 崔敏超, 韩晓兰, 范淑琴, 石田徹. AL5052铝合金板平压重塑形连接试验[J]. 吉林大学学报(工学版), 2017, 47(5): 1512-1518. |

| [5] | 郎利辉, 阚鹏, 王耀, 孙志莹, 张泉达. 铝合金板材三向应力状态下的成形性能[J]. 吉林大学学报(工学版), 2017, 47(5): 1527-1533. |

| [6] | 张鹏, 寇淑清, 赵勇, 林宝君. 装配式凸轮轴三点式轴向滚花过程[J]. 吉林大学学报(工学版), 2016, 46(6): 1953-1960. |

| [7] | 王犇, 王晓力. 硅微球轴承关键工艺[J]. 吉林大学学报(工学版), 2016, 46(3): 824-830. |

| [8] | 郭哲锋, 汤文成. 杯形件二次拉深的应力分析[J]. 吉林大学学报(工学版), 2016, 46(2): 494-499. |

| [9] | 滕菲, 刘博, 张万喜, 高嵩. 柔性三维拉弯成形工艺稳健设计[J]. 吉林大学学报(工学版), 2015, 45(5): 1481-1487. |

| [10] | 寇淑清, 张鹏, 韩广秘, 杨慎华. 装配式凸轮轴多道次扩径联接工艺[J]. 吉林大学学报(工学版), 2014, 44(2): 398-403. |

| [11] | 寇淑清, 杨宏宇, 高岩, 杨慎华. 裂解连杆断裂结合面缺损面积定量描述与分析[J]. 吉林大学学报(工学版), 2013, 43(06): 1541-1545. |

| [12] | 洪肇斌, 杨兆军, 张学成, 王佰超. 基于齿面发生线的弧齿锥齿轮铣削加工仿真分析[J]. 吉林大学学报(工学版), 2013, 43(02): 334-339. |

| [13] | 宋占杰, 张美, 何改云, 刘佩佩. 基于质心Voronoi结构的自由曲面布点策略[J]. 吉林大学学报(工学版), 2013, 43(01): 34-38. |

| [14] | 李松生, 赵燕伟, 顾熙仁. 改进的FUP算法在五金产品质量分析系统中的应用[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 251-254. |

| [15] | 张雷, 耿伟强, 鲍勇吉, 赵继. 用于羟基磷灰石冷喷涂的超声波送粉系统[J]. , 2012, (06): 1402-1408. |

|

||