吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (2): 400-409.doi: 10.13229/j.cnki.jdxbgxb.20220337

• 材料科学与工程 • 上一篇

碳纤维复合材料层合板三点弯曲疲劳性能

- 1.沈阳航空航天大学 机电工程学院,沈阳 110136

2.沈阳飞机工业(集团)有限公司53厂,沈阳 110034

Three⁃point bending fatigue properties of carbon fiber composite laminates

Liang XU1( ),Jing-hou XIAO1,Wan-wan SONG2,Song ZHOU1(

),Jing-hou XIAO1,Wan-wan SONG2,Song ZHOU1( )

)

- 1.School of Mechatronics Engineering,Shenyang Aerospace University,Shenyang 110136,China

2.Factory 53,Shenyang Aircraft Corporation,Shenyang 110034,China

摘要:

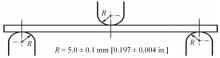

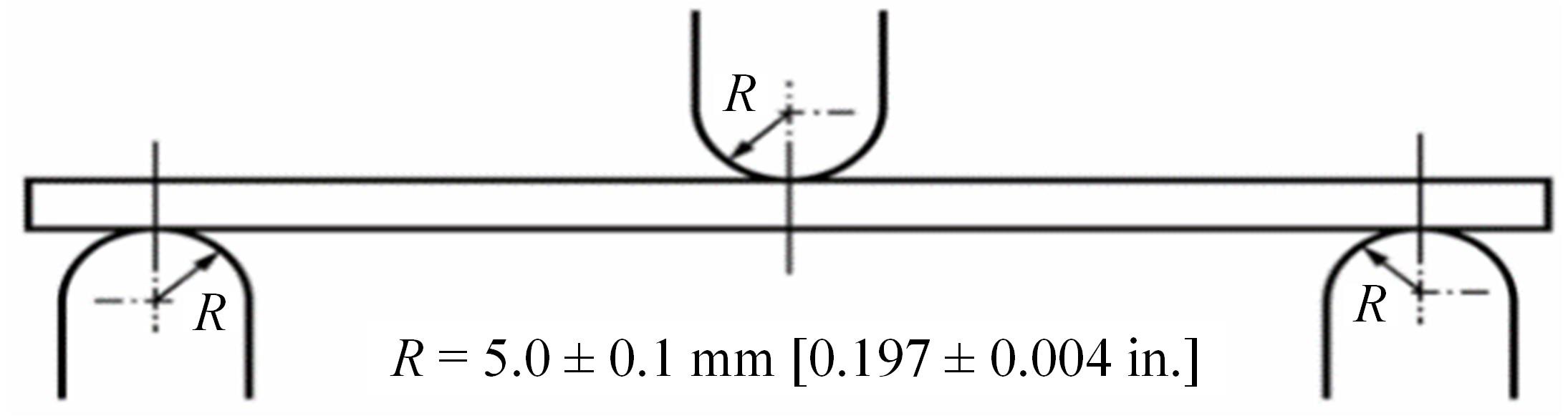

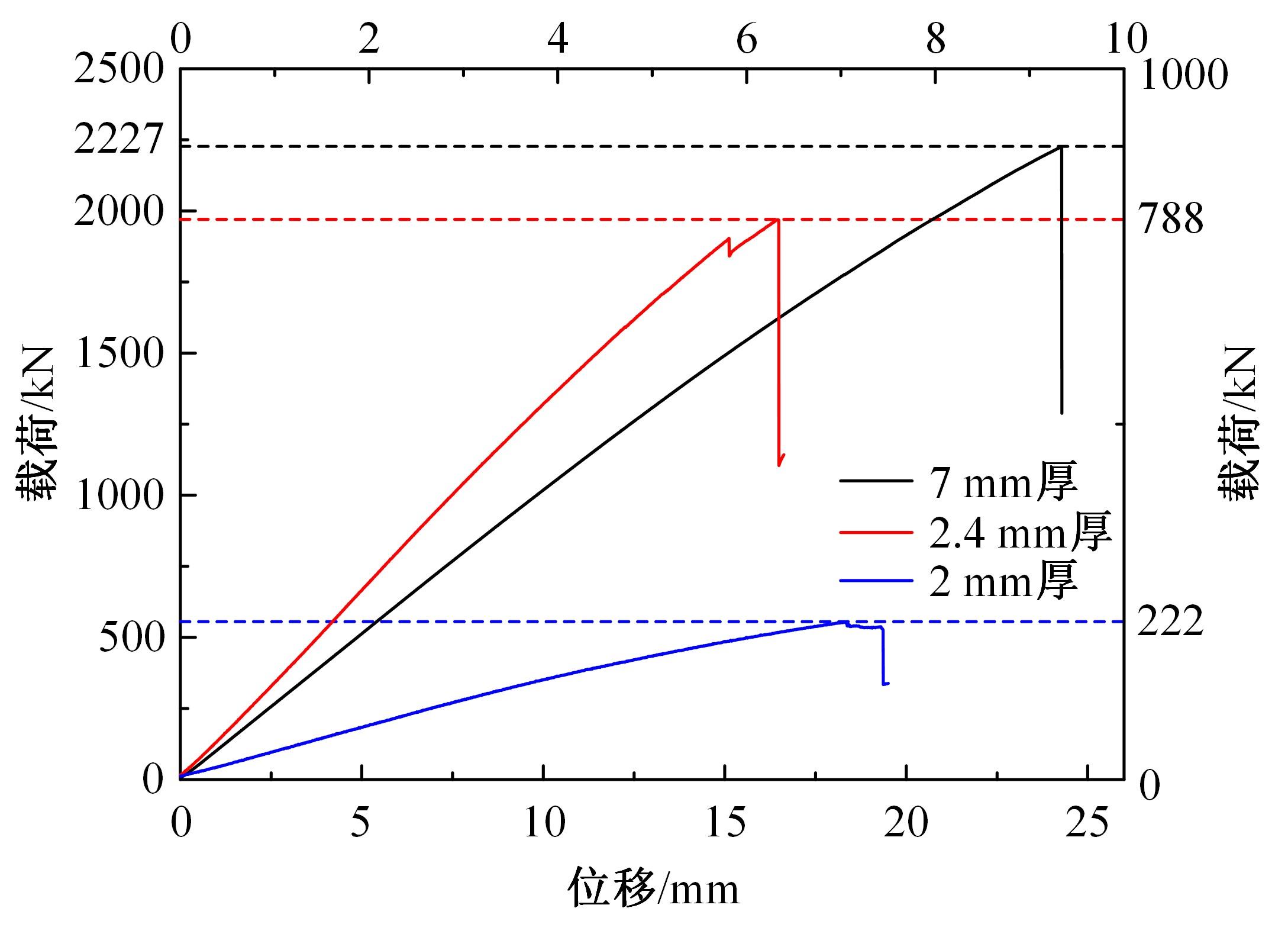

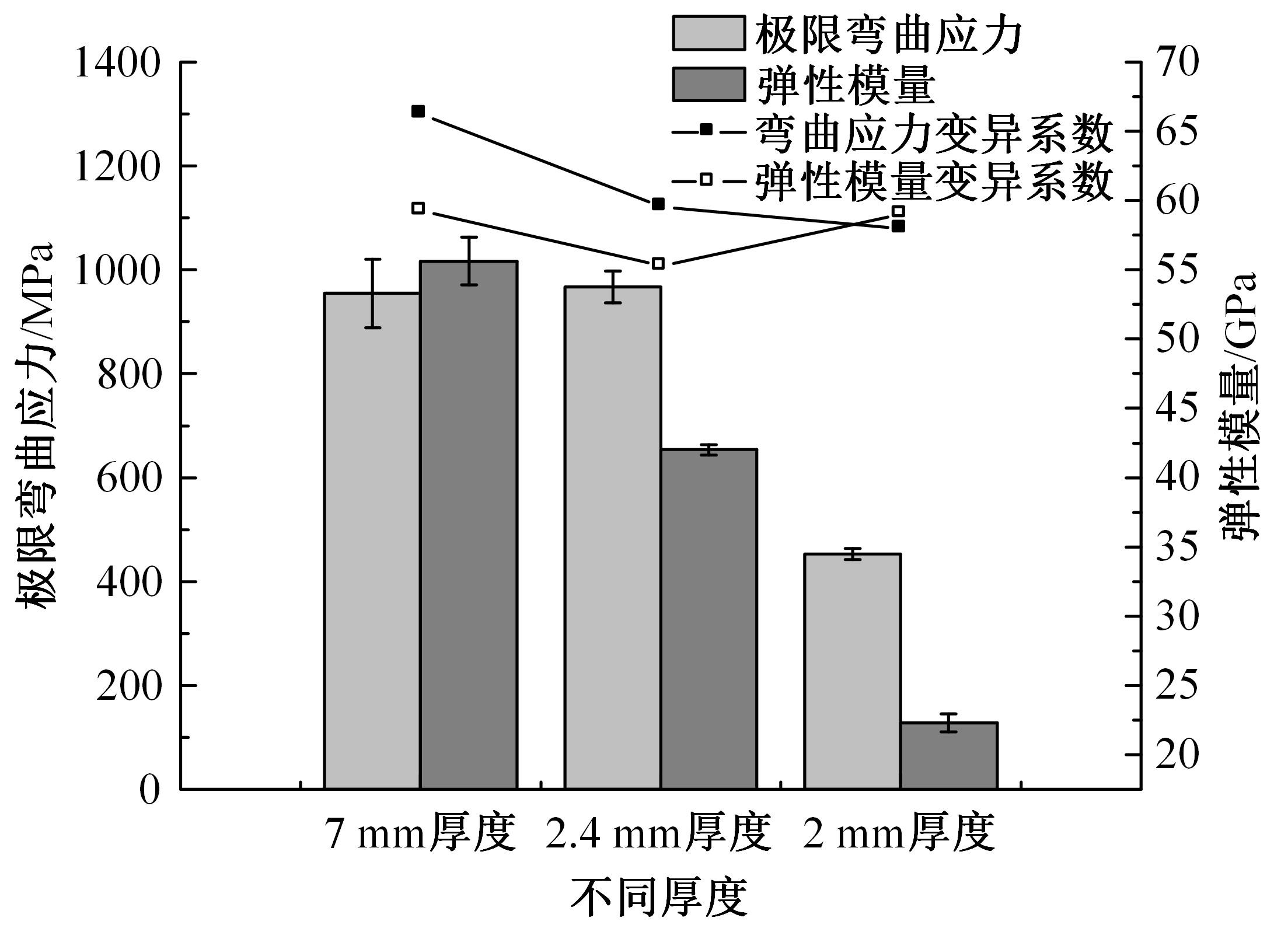

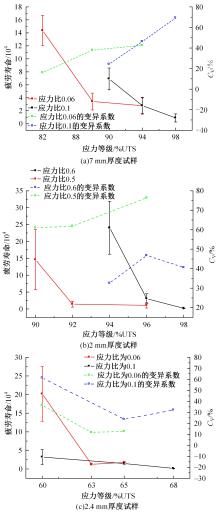

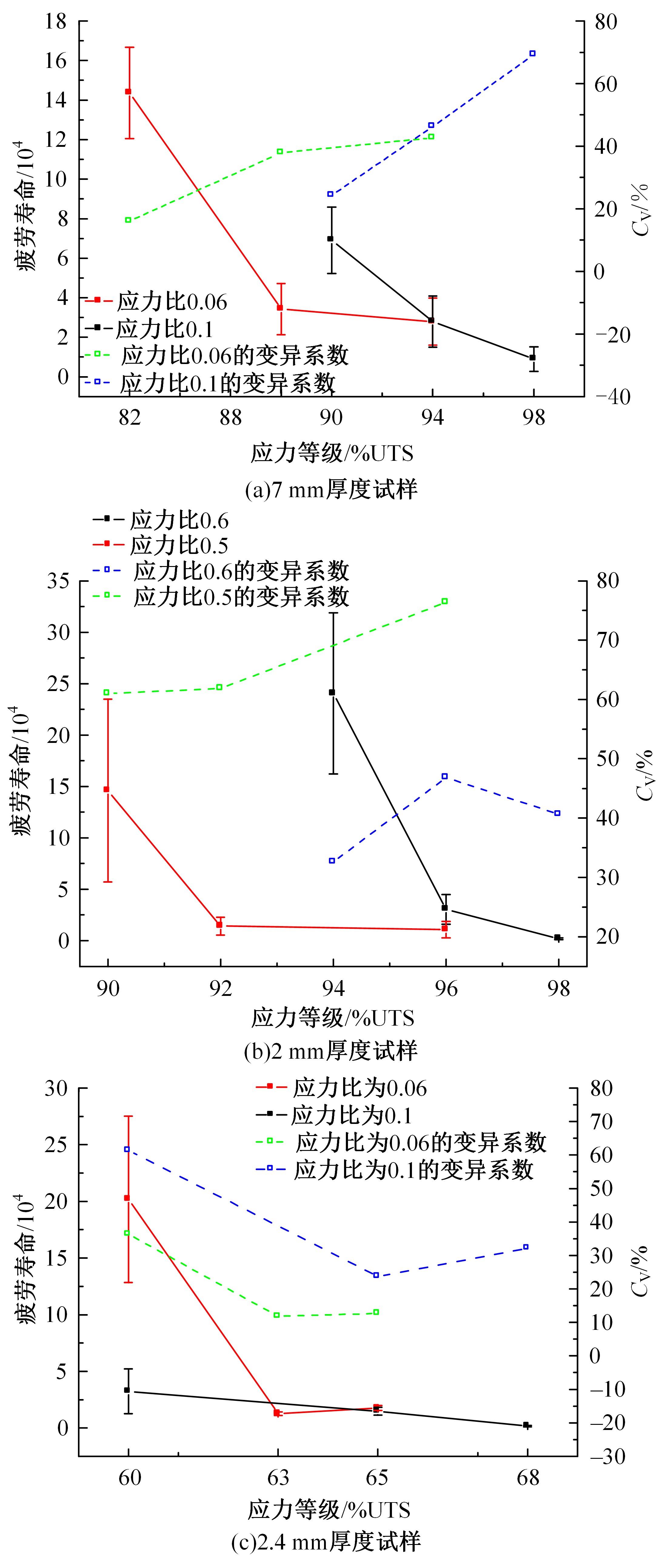

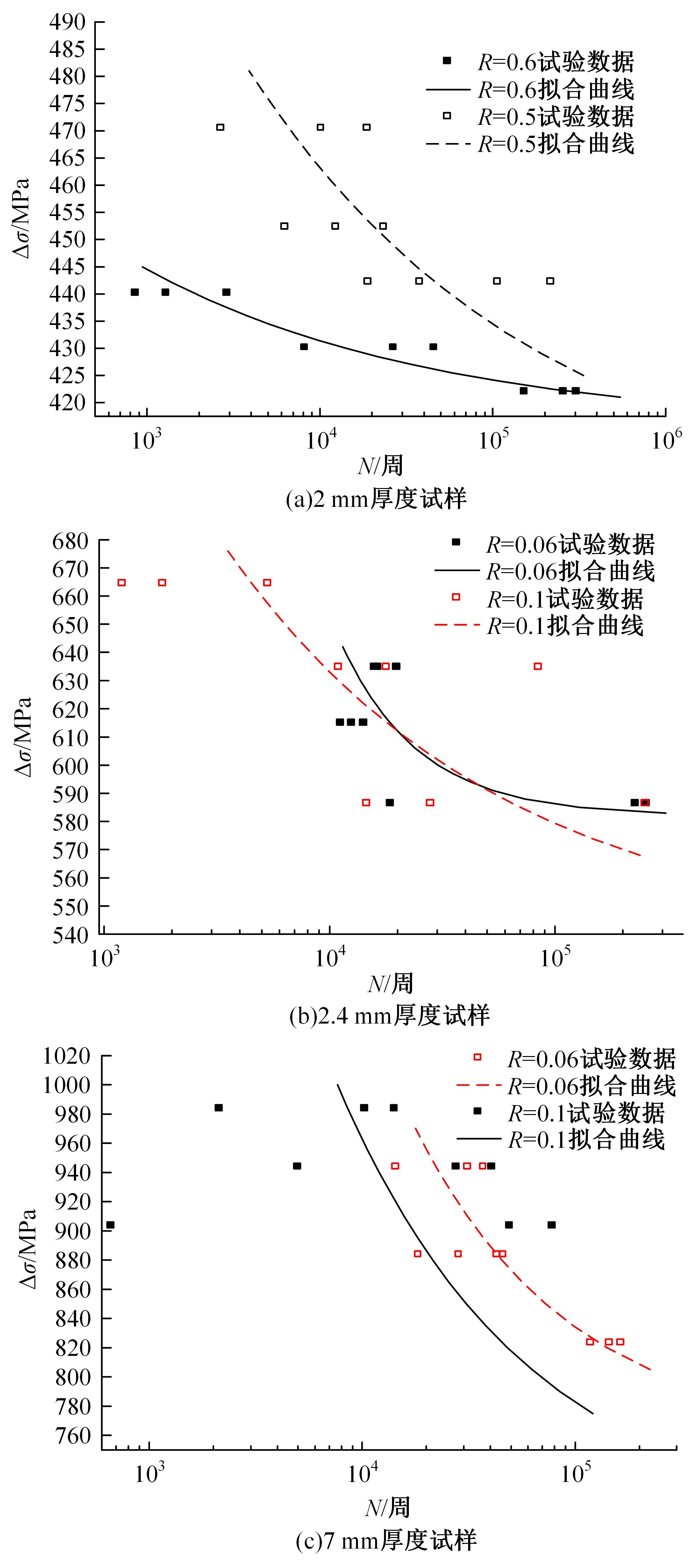

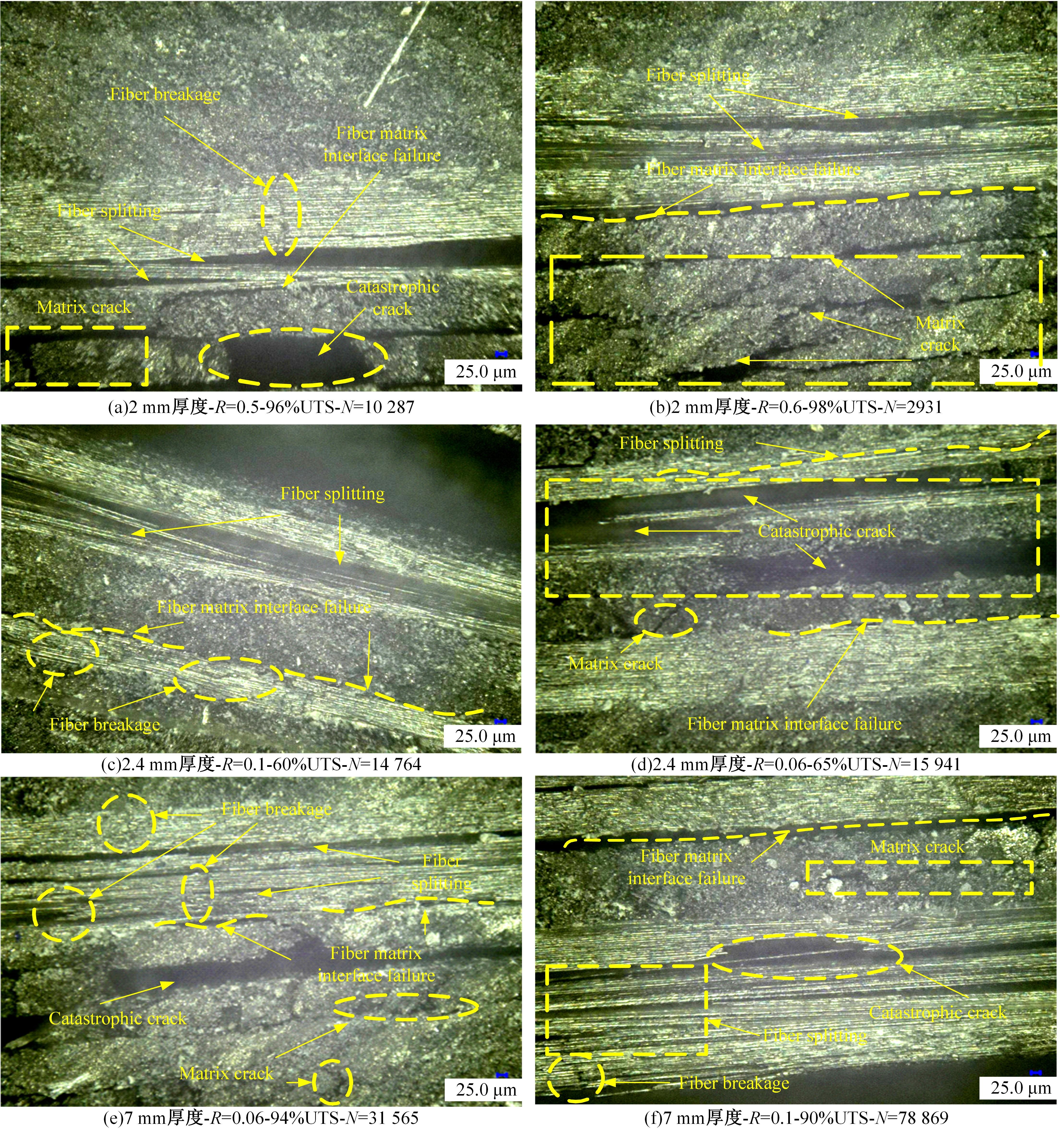

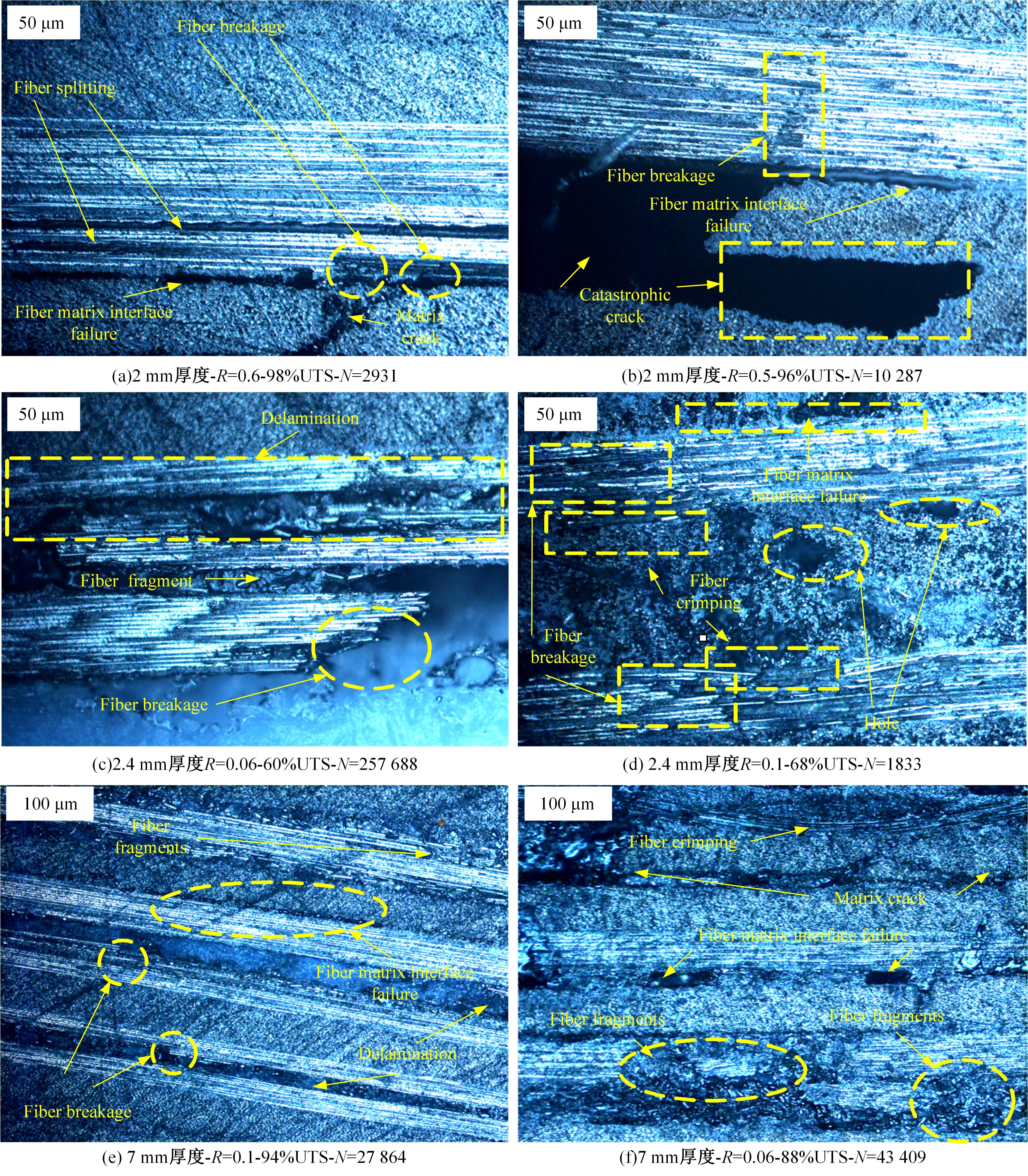

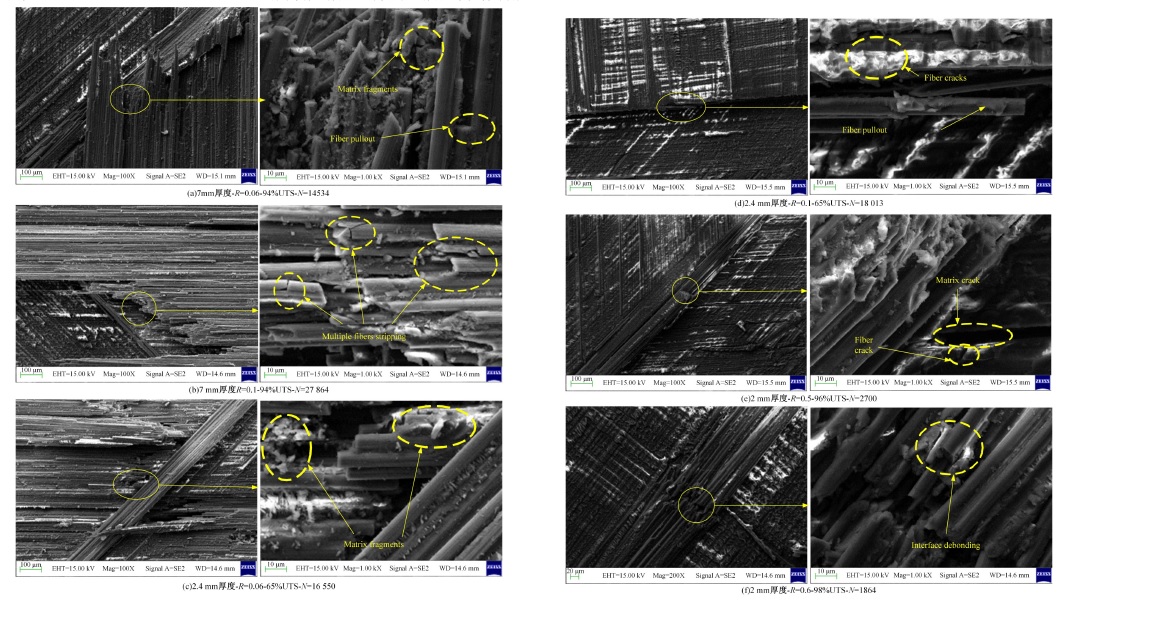

对3种不同厚度的T700碳纤维复合材料多向层合板在2种应力比及3种应力等级下进行三点弯曲试验,对其三点弯曲静态与疲劳性能进行分析。采用不同方式对破坏后形貌进行观察。结果显示:材料厚度的增加使试样弯曲强度与模量增加,复合材料多向层合板的三点弯曲疲劳寿命与材料厚度成正比关系,与试验应力比、应力等级成反比关系。试样最终的疲劳破坏程度与疲劳寿命有关,疲劳循环数越多,层合板在横向和纵向的破坏越剧烈。同时,试样厚度越大,分层现象越明显,同时存在纤维拔出现象。

中图分类号:

- TB332

| 1 | 王育虔,刘展,杜金强.高应力水平下T700/MTM46复合材料层合板拉-拉疲劳性能研究[J].玻璃钢/复合材料,2019(4):31-36. |

| Wang Yu-qian, Liu Zhan, Du Jin-qiang. Study on the tension-tension fatigue properties of T700/Mtm46 composite laminates under high stress level[J]. Fiber Reinforced Plastics/Composites, 2019(4): 31-36. | |

| 2 | Mouritz A P, Gellert E, Burchill P, et al. Review of advanced composite structures for naval ships and submarines[J]. Composite Structures, 2001, 53(1): 21-42. |

| 3 | Dvorak G J. Composite materials: inelastic behavior, damage, fatigue and fracture[J]. International Journal of Solids and Structures, 2000, 37(1/2): 155-170. |

| 4 | Belísio A S, Freire Júnior R C S. Comparative study between the PNL method and a MN in modelling fatigue of composite materials[J]. Fatigue & Fracture of Engineering Materials & Structures, 2013, 36(5): 392-400. |

| 5 | Song W, Fan W, Liu T, et al. Flexural fatigue properties and failure propagation of 3D stitched composites under 3-point bending loading[J]. International Journal of Fatigue, 2021, 153: 106507. |

| 6 | Qi H Y, Wen W D, Sun L W. Fatigue damage accumulation model based on stiffness degradation[J]. Journal of Beijing University of Aeronautics and Astronautics, 2004, 30(12): 1200-1203. |

| 7 | D'Amore A, Giorgio M, Grassia L. Modeling the residual strength of carbon fiber reinforced composites subjected to cyclic loading[J]. International Journal of Fatigue, 2015, 78: 31-37. |

| 8 | Li D, Dang M, Jiang L. Fatigue behavior and failure mechanisms of 3D angle-interlock woven composite at room and cryogenic temperatures under bending[J]. Composites Communications, 2021, 23: 100559. |

| 9 | Meng M Z, Le H R, Grove S, et al. Moisture effects on the bending fatigue of laminated composites[J]. Composite Structures, 2016, 154: 49-60. |

| 10 | 叶辉,李清原,闫康康. 变刚度复合材料层合板的力学性能[J]. 吉林大学学报: 工学版, 2020, 50(3): 920-928. |

| Ye Hui, Li Qing-yuan, Yan Kang-kang. Mechanical properties of variable⁃stiffness carbon fiber composite laminates[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(3): 920-928. | |

| 11 | Klesnil M, Lukác P. Fatigue of Metallic Materials[M]. Amsterdam: Elsevier, 1992. |

| 12 | 陈传尧. 疲劳与断裂[M]. 武汉: 华中科技大学出版社, 2002. |

| 13 | Yee A F. Modifying Matrix Materials for Tougher Composites[M]. West Conshohocken: ASTM International, 1987. |

| 14 | Talreja R. Fatigue of composite materials: damage mechanisms and fatigue-life diagrams[J]. Mathematical and Physical Sciences, 1981, 378: 461-475. |

| 15 | Barron V, Buggy M, McKenna N H. Frequency effects on the fatigue behaviour on carbon fiber reinforced polymer laminates[J]. Journal of Materials Science, 2001, 36(7): 1755-1761. |

| 16 | Kawai M, Takeuchi H, Taketa I, et al. Effects of temperature and stress ratio on fatigue life of injection molded short carbon fiber-reinforced polyamide composite[J]. Composites Part A: Applied Science and Manufacturing, 2017, 98: 9-24. |

| 17 | Zhang W, Zhou Z, Zheng P, et al. The fatigue damage mesomodel for fiber-reinforced polymer composite lamina[J]. Journal of Reinforced Plastics and Composites, 2014, 33(19): 1783-1793. |

| 18 | Kawai M, Yang K, Oh S. Effect of alternating R-ratios loading on fatigue life of woven fabric carbon/epoxy laminates[J]. Journal of Composite Materials, 2015, 49(27): 3387-3405. |

| 19 | Mouritz A P. Structural properties of z-pinned carbon-epoxy T-joints in hot-wet environment[J]. Journal of Composite Materials, 2014, 48(23): 2905-2914. |

| 20 | 王蔓, 李泽成, 白瑞祥. 复合材料格栅加筋板的分层扩展特性[J]. 吉林大学学报: 工学版, 2007, 37(1): 229-233. |

| Wang Man, Li Ze-cheng, Bai Rui-xiang. Delamination growth characteristics for composite grid stiffened plates[J]. Journal of Jilin University (Engineering and Technology Edition), 2007, 37(1): 229-233. | |

| 21 | Alam P, Mamalis D, Robert C, et al. The fatigue of carbon fibre reinforced plastics—a review[J]. Composites Part B: Engineering, 2019, 166: 555-579. |

| [1] | 郑植,袁佩,金轩慧,魏思斯,耿波. 桥墩复合材料柔性防撞护舷试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2581-2590. |

| [2] | 车佳玲,王俊,刘海峰,张居平. 沙漠砂制备高韧性水泥基复合材料在不同环境下的自愈合性能[J]. 吉林大学学报(工学版), 2023, 53(8): 2277-2286. |

| [3] | 许良,边钰博,周松,肖景厚. 高温水浸对T800/环氧树脂基复合材料性能的影响[J]. 吉林大学学报(工学版), 2023, 53(7): 1943-1950. |

| [4] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [5] | 魏海斌,马子鹏,毕海鹏,刘汉涛,韩栓业. 基于力学响应分析方法的导电橡胶复合路面铺装技术[J]. 吉林大学学报(工学版), 2023, 53(2): 531-537. |

| [6] | 郑植,耿波,王福敏,董俊宏,魏思斯. 既有低等级混凝土护栏防护能力提升[J]. 吉林大学学报(工学版), 2022, 52(6): 1362-1374. |

| [7] | 李伟,宋海生,陆浩宇,史文库,王强,王晓俊. 复合材料板簧迟滞特性线性辨识方法[J]. 吉林大学学报(工学版), 2022, 52(4): 829-836. |

| [8] | 庄蔚敏,陈沈,吴迪. 碳纤维增强复合材料包裹强化形式对钢管横向冲击性能的影响[J]. 吉林大学学报(工学版), 2022, 52(4): 819-828. |

| [9] | 王磊,黄秉汉,丛家慧,回丽,周松,徐永臻. 超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2542-2548. |

| [10] | 于开锋,何小玲,李俊涛,梁策. 玄武岩纤维对不饱和聚酯树脂复合材料的增韧[J]. 吉林大学学报(工学版), 2022, 52(10): 2300-2306. |

| [11] | 卫宇璇,张明,刘佳,刘硕,路明雨,王洪雨. 基于模态缺陷的变刚度复合材料圆柱壳屈曲特性[J]. 吉林大学学报(工学版), 2022, 52(1): 91-100. |

| [12] | 秦拥军,陈楠,蔺鹏杰,于江. 掺锂渣再生混凝土三点弯曲梁双K断裂特性[J]. 吉林大学学报(工学版), 2021, 51(6): 2121-2127. |

| [13] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

| [14] | 严庆光,冯梓轩,李湘吉,王瑛玮. 一机六件等应力三点弯曲疲劳试验机的研制[J]. 吉林大学学报(工学版), 2021, 51(6): 2013-2020. |

| [15] | 佟金,高子博,霍超,王子阳,马云海,常志勇. 低温下铜纳米颗粒对UHMWPE复合材料摩擦磨损性能影响[J]. 吉林大学学报(工学版), 2021, 51(2): 493-500. |

|

||