吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (1): 91-100.doi: 10.13229/j.cnki.jdxbgxb20200715

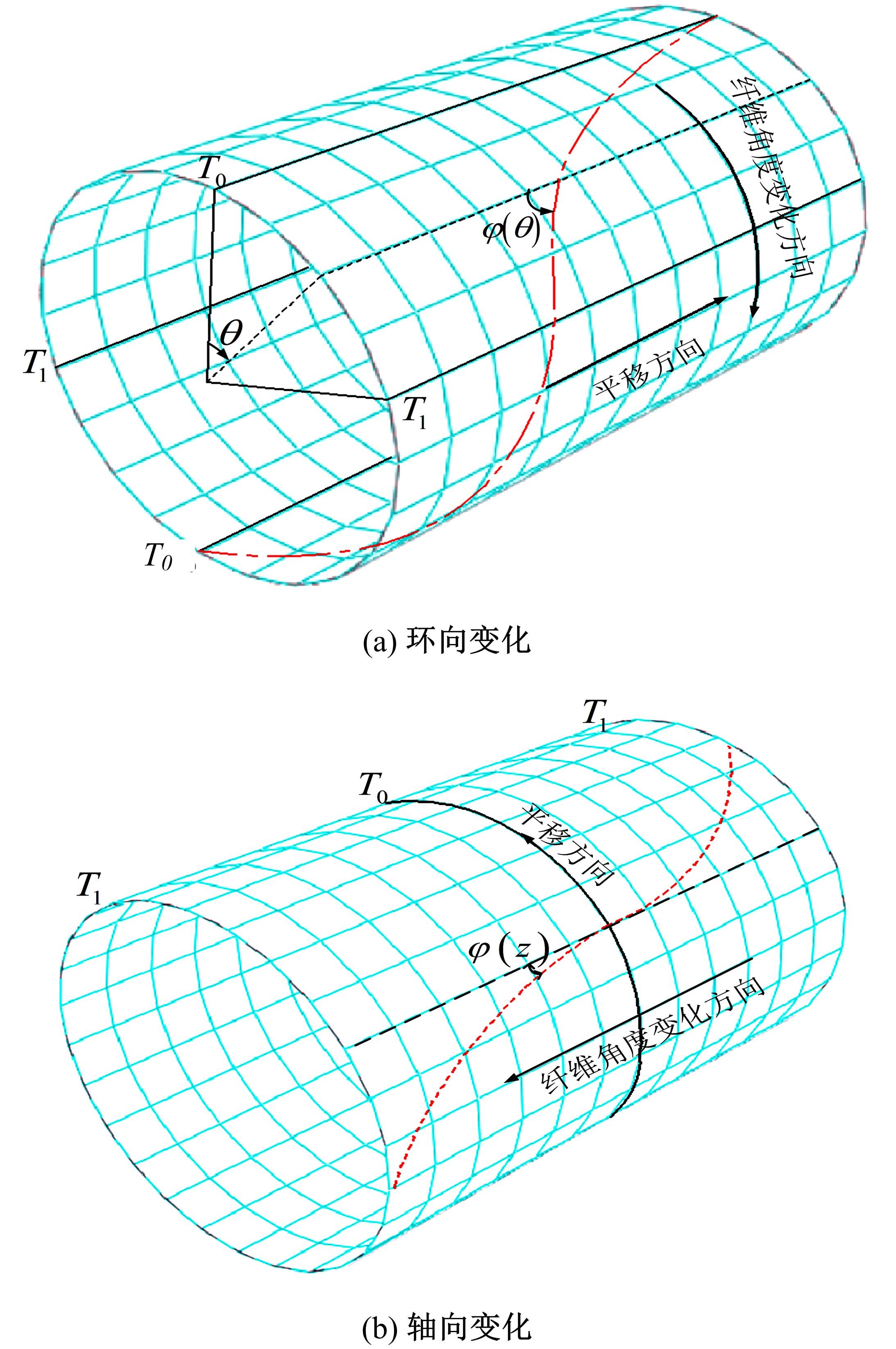

基于模态缺陷的变刚度复合材料圆柱壳屈曲特性

卫宇璇1( ),张明2(

),张明2( ),刘佳1,刘硕1,路明雨1,王洪雨1

),刘佳1,刘硕1,路明雨1,王洪雨1

- 1.北京卫星制造厂有限公司,北京 100094

2.中国空间技术研究院,北京 100094

Buckling performance of variable stiffness composite cylindrical shells based on mode imperfections

Yu-xuan WEI1( ),Ming ZHANG2(

),Ming ZHANG2( ),Jia LIU1,Shuo LIU1,Ming-yu LU1,Hong-yu WANG1

),Jia LIU1,Shuo LIU1,Ming-yu LU1,Hong-yu WANG1

- 1.Beijing Satellite Manufacturing Factory Co. ,Ltd,Beijing 100094,China

2.China Academy of Space Technology,Beijing 100094,China

摘要:

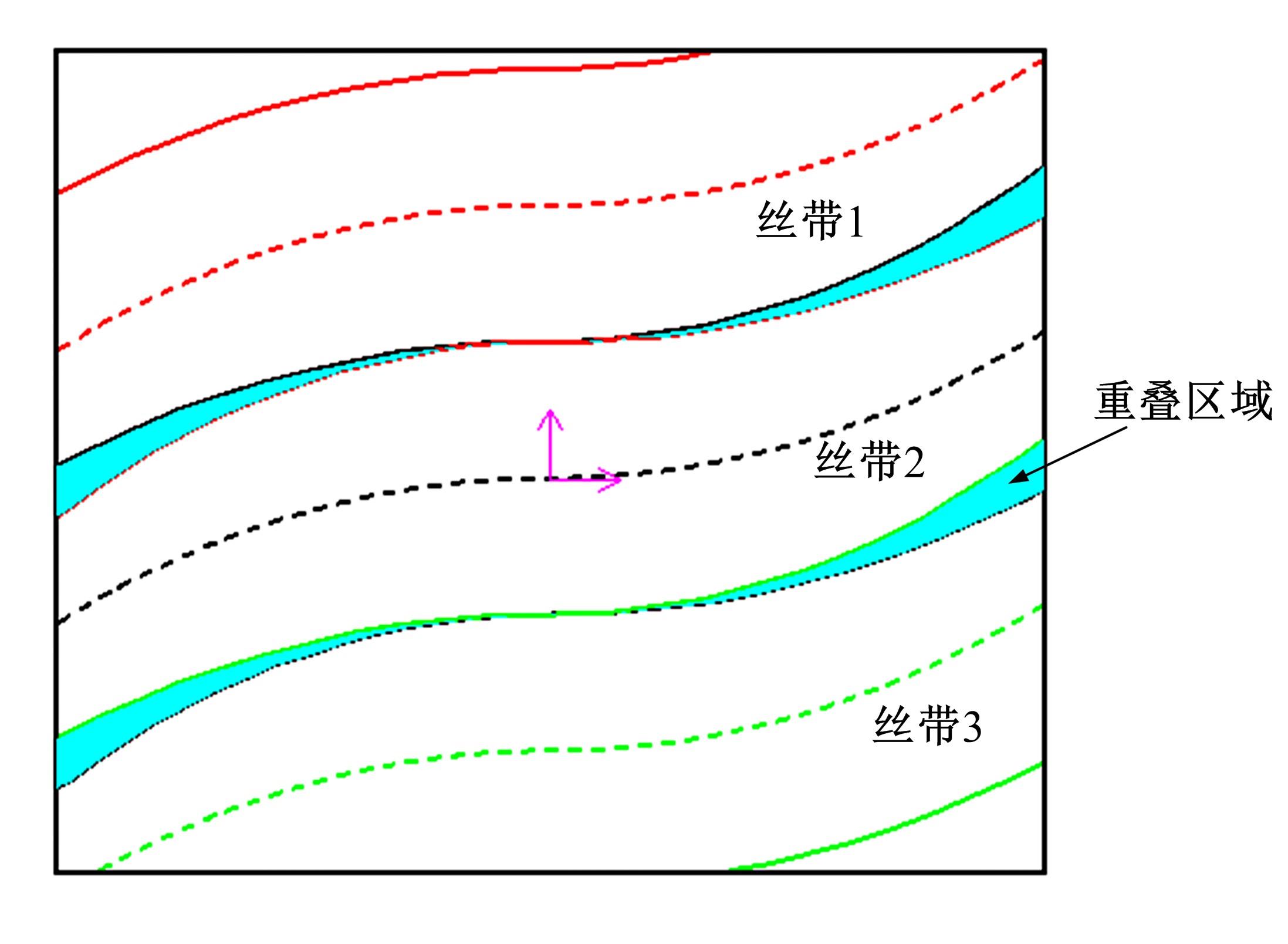

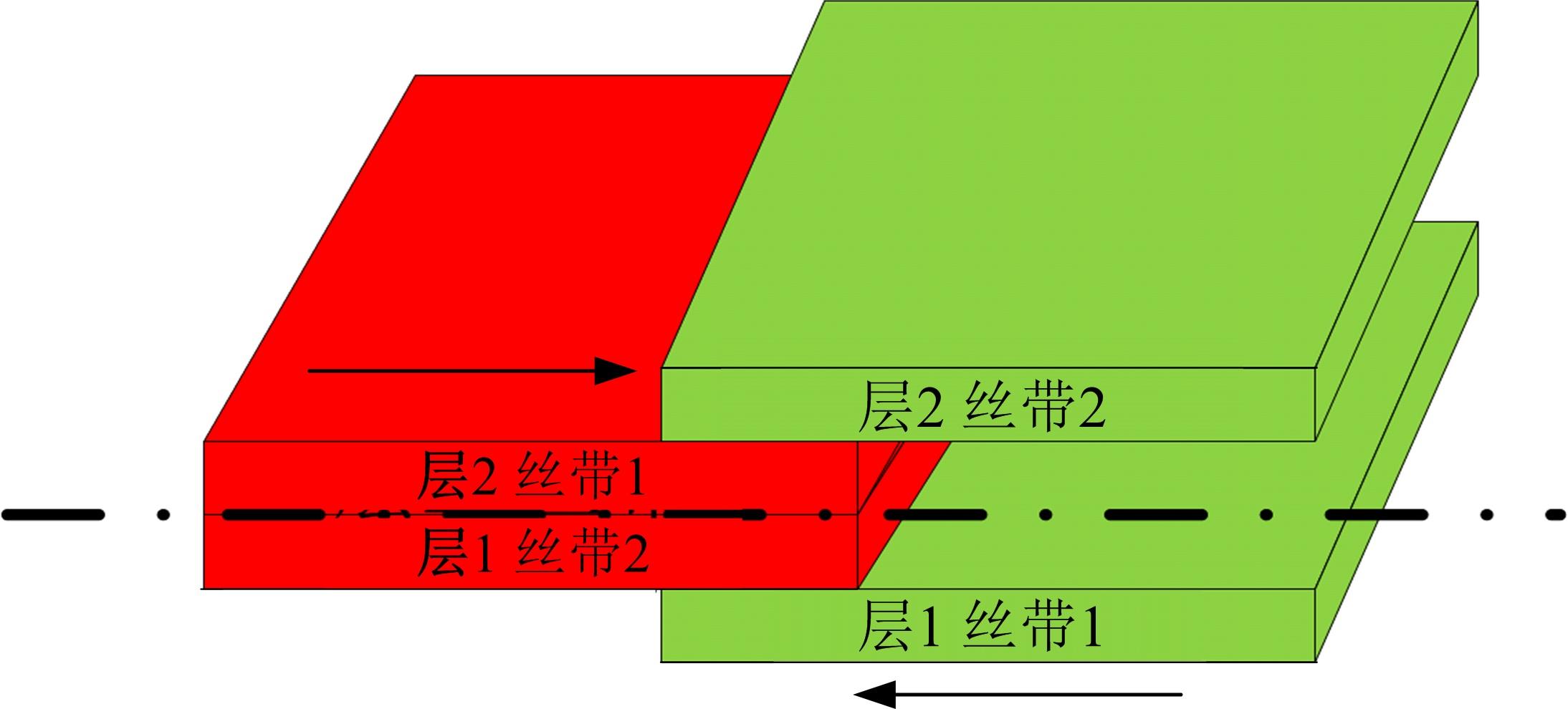

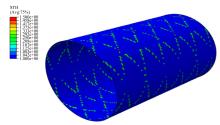

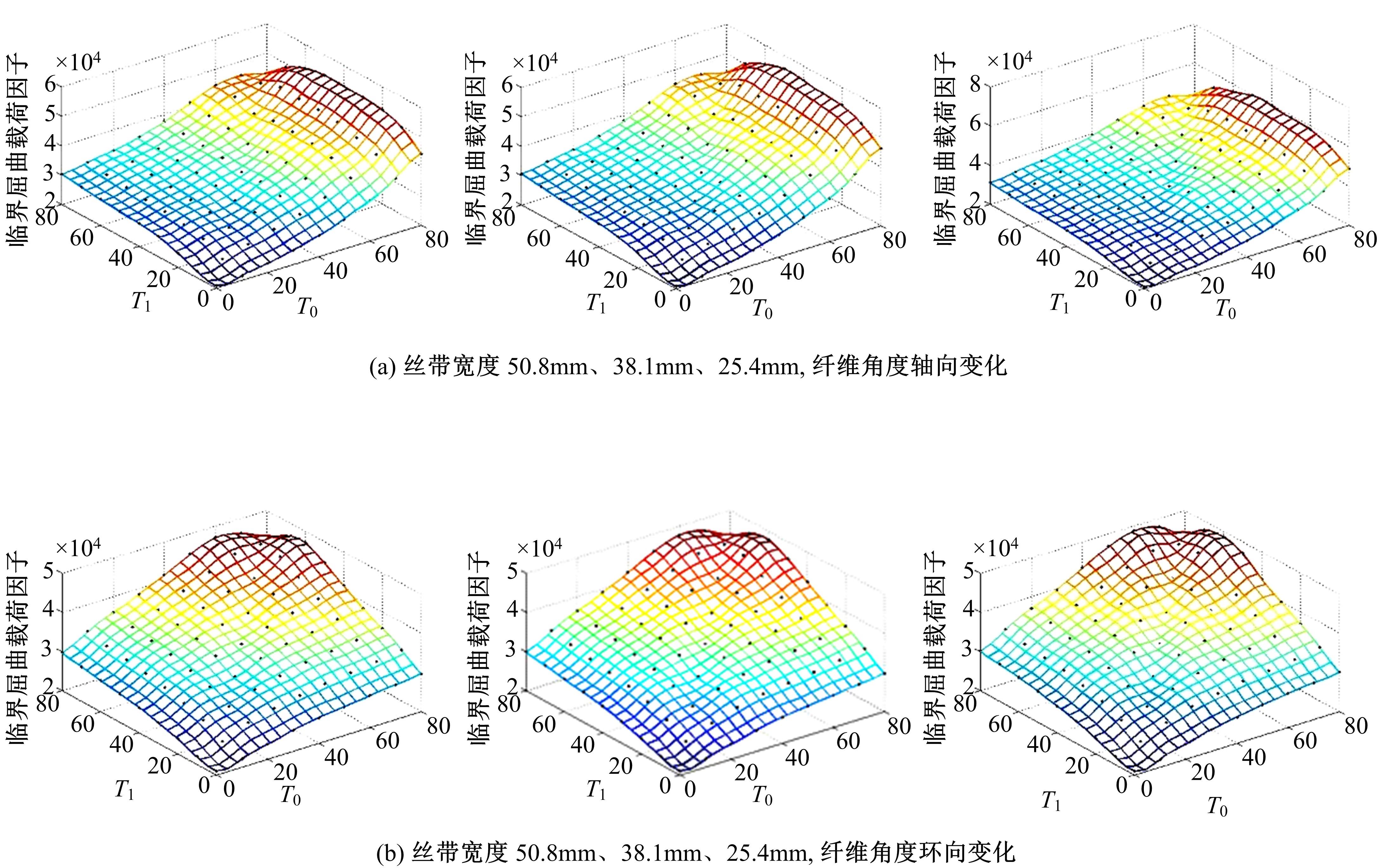

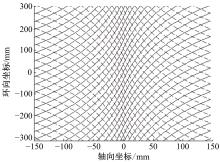

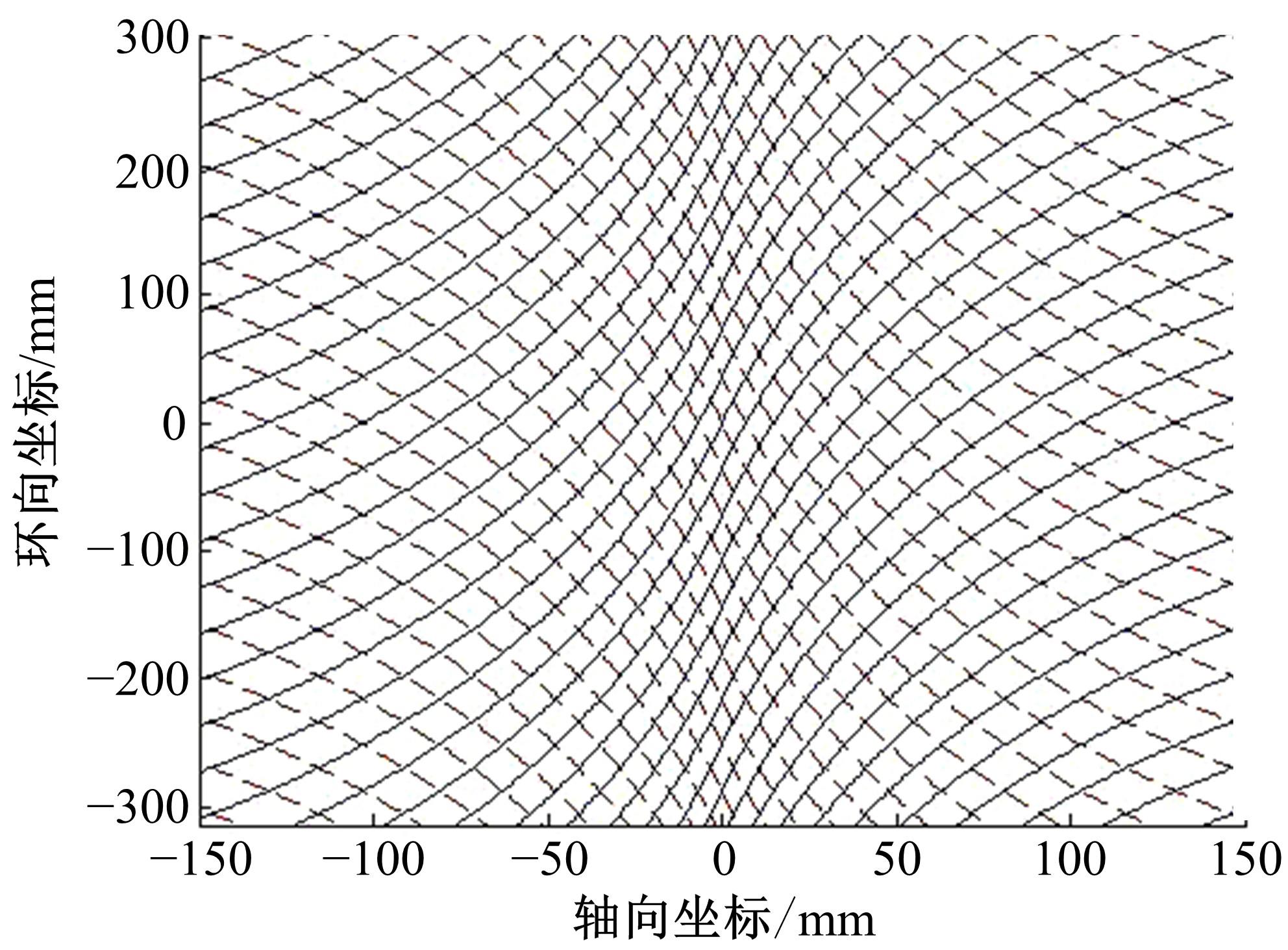

研究了基于自动铺丝技术的变刚度复合材料圆柱壳的屈曲性能和缺陷敏感性。基于丝束剪切/重送技术,提出了可以精确模拟圆柱壳面内重叠/间隙区域的简便算法,使有限元模型更加贴近实际制造过程。开展了复合载荷作用下曲线纤维铺层方式对圆柱壳屈曲性能影响的研究,结合Kriging模型和遗传算法,对纤维角度沿环向和轴向线性变化的铺层设计方式进行了优化。最后,利用改进弧长法对不同模态缺陷条件下变刚度复合材料圆柱壳的缺陷敏感性进行了分析。结果表明:在轴压和均匀外压复合作用下,纤维角度沿轴向变化的铺层方式可以有效提高结构的屈曲性能。当带宽为25.4 mm、

中图分类号:

- TB332

| 1 | 刘书田, 陈秀华, 曹先凡,等. 夹芯圆柱壳稳定性优化[J]. 工程力学, 2005, 22(1): 135-140. |

| Liu Shu-tian, Chen Xiu-hua, Cao Xian-fan, et al. Optimization of buckling-prone cylindrical shells with porous material core[J]. Engineering Mechanics, 2005, 22(1): 135-140. | |

| 2 | 文立伟, 肖军, 王显峰, 等. 中国复合材料自动铺放技术研究进展[J]. 南京航空航天大学学报, 2015, 47(5): 637-649. |

| Wen Li-wei, Xiao Jun, Wang Xian-feng, et al. Process of automated placement technology for composites in china[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2015, 47(5): 637-649. | |

| 3 | 周晓芹, 曹正华. 复合材料自动铺放技术的发展及应用[J]. 航空制造技术, 2009, 42(s1): 1-3, 7. |

| Zhou Xiao-qin, Cao Zheng-hua. Development and application of automated placement technology for composites[J]. Aeronautical Manufacturing Technology, 2009, 42(s1): 1-3, 7. | |

| 4 | Shirinzadeh B, Cassidy G, Oetomo D, et al. Trajectory generation for open-contoured structures in robotic fibre placement[J]. Robotics and Computer-Integrated Manufacturing, 2007, 23(4): 380-394. |

| 5 | Abdalla M M, Setoodeh S, Gürdal Z. Design of variable stiffness composite panels for maximum fundamental frequency using lamination parameters[J]. Composite Structures, 2007, 81(2): 283-291. |

| 6 | Hyer M W, Charette R F. Use of curvilinear fiber format in composite structure design[J]. AIAA Journal, 1991, 29(6): 1011-1015. |

| 7 | Rouhi M, Ghayoor H, Fortin-Simpson J, et al. Design, manufacturing, and testing of a variable stiffness composite cylinder[J]. Composite Structures, 2018, 184: 146-152. |

| 8 | 叶辉, 李清原, 闫康康. 变刚度复合材料层合板的力学性能[J]. 吉林大学学报:工学版, 2020, 50(3):920-928. |

| Ye Hui, Li Qing-yuan, Yan Kang-kang. Mechanical properties of variable⁃stiffness carbon fiber composite laminates[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(3):920-928. | |

| 9 | Gürdal Z, Tatting B F, Wu C K. Variable stiffness composite panels: effects of stiffness variation on the in-plane and buckling response[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(5): 911-922. |

| 10 | Setoodeh S, Abdalla M M, Ijsselmuiden S T, et al. Design of variable-stiffness composite panels for maximum buckling load[J]. Composite Structures, 2009, 87(1): 109-117. |

| 11 | Blom A W, Stickler P B, Gürdal Z. Optimization of a composite cylinder under bending by tailoring stiffness properties in circumferential direction[J]. Composites Part B: Engineering, 2010, 41(2): 157-165. |

| 12 | Rouhi M, Ghayoor H, Hoa S V, et al. Multi-objective design optimization of variable stiffness composite cylinders[J]. Composites Part B: Engineering, 2015, 69: 249-255. |

| 13 | Nopour H, Kabiri A A, Shokrieh M M. Fiber path optimization in a variable-stifness cylinder to maximize its buckling load under external hydrostatic pressure[J]. Mechanics of Composite Materials, 2019, 54(6): 765-774. |

| 14 | Khani A, Abdalla M M, Gürdal Z. Optimum tailoring of fibre-steered longitudinally stiffened cylinders[J]. Composite Structures, 2015, 122: 343-351. |

| 15 | 孙士平, 张冰, 邓同强, 等. 复合载荷作用变刚度复合材料回转壳屈曲优化[J]. 复合材料学报, 2019, 36(4): 1052-1061. |

| Sun Shi-ping, Zhang Bing, Deng Tong-qiang, et al. Buckling optimization of variable stiffness composite rotary shell under combined loads[J]. Acta Materiae Compositae Sinica, 2019, 36(4): 1052-1061. | |

| 16 | 钟继凡. 基于代理模型的变刚度复合材料结构优化设计[D]. 武汉:华中科技大学航空航天学院, 2018. |

| Zhong Ji-fan. Optimization design of variable stiffness composite structurres based on meta-models[D]. Wuhan: Huazhong University of science and Technology School of Aerospace Engineering, 2018. | |

| 17 | 闫光, 韩小进, 闫楚良,等. 含口盖复合材料圆柱壳轴压屈曲性能分析[J]. 吉林大学学报:工学版, 2015, 45(1): 187-192. |

| Yan Guang, Han Xiao-jin, Yan Chu-liang, et al. Buckling analysis of composite cylindrical shell with cover under axial compressive load[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(1): 187-192. | |

| 18 | Arbelo M A, Degenhardt R, Castro S G P, et al. Numerical characterization of imperfection sensitive composite structures[J]. Composite Structures, 2014, 108: 295-303. |

| 19 | Zimmermann R. Buckling research for imperfection tolerant fiber composite structures[C]∥Conference on Spacecraft Structures Materials & Mechanical Testing Noordwijk,Niederlande, 1996:27-29. |

| 20 | Kim B C, Hazra K, Weaver P M, et al. Limitations of fibre placement techniques for variable angle tow composites and their process-induced defects[C]∥The 18th International Conference on Composite Materials, Jeju, Korea, 2011: 109-117. |

| 21 | Acar E, Guler M A, Gereker B, et al. Multi-objective crashworthiness optimization of tapered thin-walled tubes with axisymmetric indentations[J]. Thin-Walled Structures, 2011, 49(1): 94-105. |

| 22 | 卫宇璇, 张明, 刘佳, 等. 基于自动铺放技术的高精度变刚度复合材料层合板屈曲性能[J]. 复合材料学报, 2020, 37(11):2807-2815. |

| Wei Yu-xuan, Zhang Ming, Liu Jia, et al. Buckling performance of high-precision variable stiffness composites laminate based on automatic placement technology[J]. Acta Materiae Compositae Sinica, 2020, 37(11):2807-2815. | |

| 23 | EN1993-1-1. Eurocode 3-Design of Steel Structures[S]. |

| [1] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

| [2] | 佟金,高子博,霍超,王子阳,马云海,常志勇. 低温下铜纳米颗粒对UHMWPE复合材料摩擦磨损性能影响[J]. 吉林大学学报(工学版), 2021, 51(2): 493-500. |

| [3] | 杨帆,张旭东,赵蒙,折波,邓俊楷. 基于有限元计算的形状记忆合金⁃金属玻璃复合材料变形行为[J]. 吉林大学学报(工学版), 2021, 51(1): 172-180. |

| [4] | 慕文龙,那景新,谭伟,王广彬,申浩,栾建泽. 基于FTIR分析的CFRP-铝合金粘接接头剩余强度预测[J]. 吉林大学学报(工学版), 2021, 51(1): 139-146. |

| [5] | 李义,黄东迪,于开锋,梁继才,何小玲,任希彤. 硅炭黑改性玄武岩纤维增强聚酰胺6复合材料性能[J]. 吉林大学学报(工学版), 2021, 51(1): 181-187. |

| [6] | 叶辉,刘畅,闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2): 417-425. |

| [7] | 叶辉,朱艳荣,蒲永锋. 纤维增强复合材料应变率效应的数值仿真[J]. 吉林大学学报(工学版), 2019, 49(5): 1622-1629. |

| [8] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [9] | 李碧雄,廖桥,章一萍,周练,隗萍,刘侃. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版), 2019, 49(4): 1153-1161. |

| [10] | 胡志清, 郑会会, 徐亚男, 张春玲, 党停停. 表面微沟槽对Al/CFRP胶结性能的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [11] | 刘耀辉, 陈乔旭, 宋雨来, 沈艳东. 火山灰-SBS、胶粉-SBS和SBS改性沥青压缩变形行为及机理[J]. 吉林大学学报(工学版), 2017, 47(6): 1861-1867. |

| [12] | 李静, 王哲. 真三轴加载条件下混凝土的力学特性[J]. 吉林大学学报(工学版), 2017, 47(3): 771-777. |

| [13] | 王军年, 叶涛, 孙文, 王庆年. 可变刚度和阻尼的半主动馈能悬架隔振性能[J]. 吉林大学学报(工学版), 2017, 47(3): 701-708. |

| [14] | 杨悦, 李雪, 徐晓丹. Ti-B-C-N粉末烧结的微观组织及其性能[J]. 吉林大学学报(工学版), 2017, 47(2): 552-556. |

| [15] | 陈江义, 刘保元. 纤维断裂损伤对复合材料板中导波频散特性的影响[J]. 吉林大学学报(工学版), 2017, 47(1): 180-184. |

|

||