吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (6): 1362-1374.doi: 10.13229/j.cnki.jdxbgxb20210023

• 交通运输工程·土木工程 • 上一篇

既有低等级混凝土护栏防护能力提升

- 1.重庆大学 土木工程学院,重庆 400045

2.招商局重庆交通科研设计院有限公司 桥梁工程结构动力学国家重点实验室,重庆 400067

Improvement of protective ability for existing low⁃grade concrete guardrail

Zhi ZHENG1,2( ),Bo GENG2(

),Bo GENG2( ),Fu-min WANG2,Jun-hong DONG1,Si-si WEI2

),Fu-min WANG2,Jun-hong DONG1,Si-si WEI2

- 1.School of Civil Engineering,Chongqing University,Chongqing 400045,China

2.National Key Laboratory of Structural Dynamics of Bridge Engineering,China Merchants Chongqing Communications Technology Research and Design Institute Co. ,Ltd. ,Chongqing 400067,China

摘要:

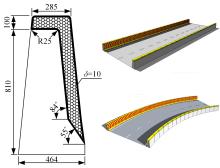

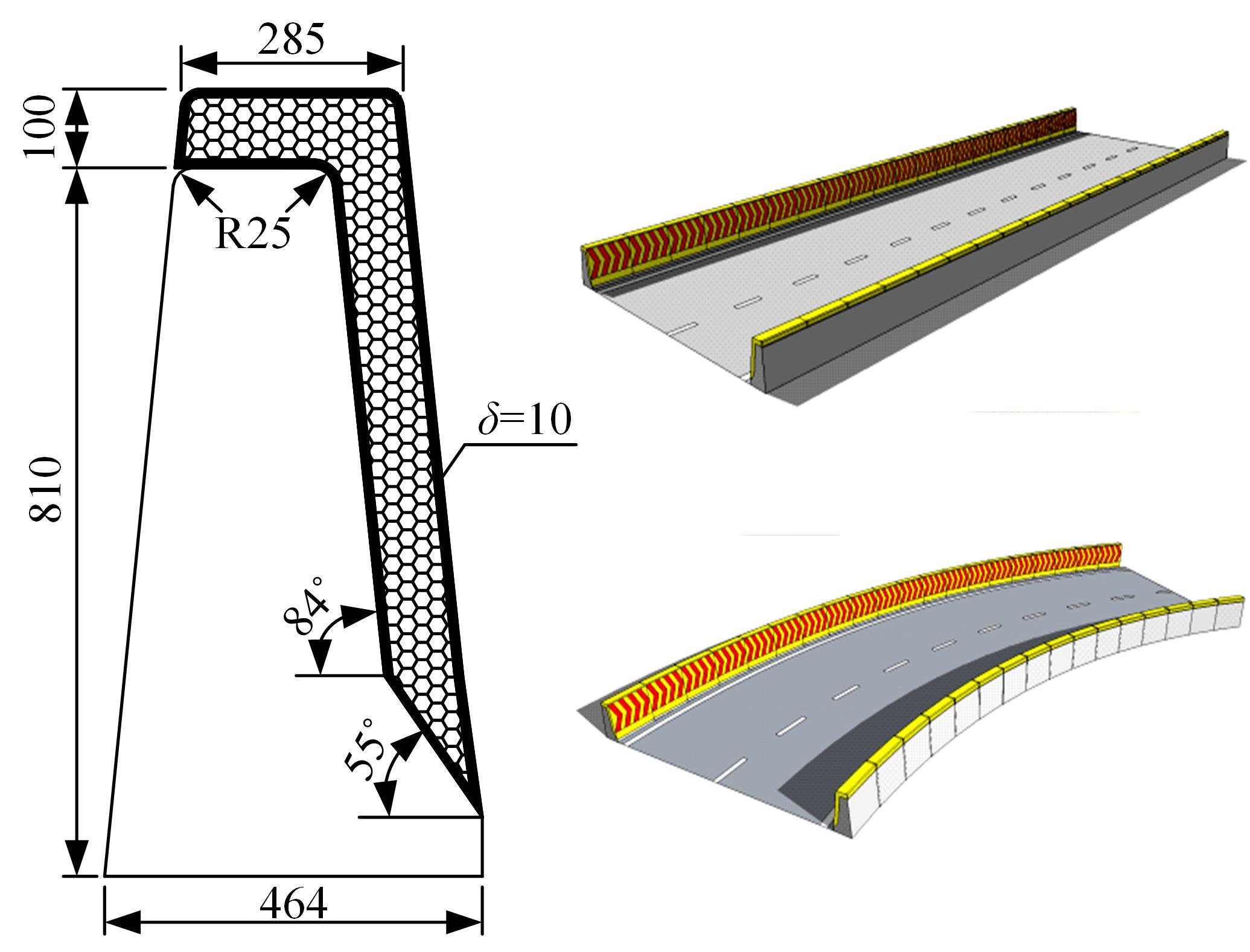

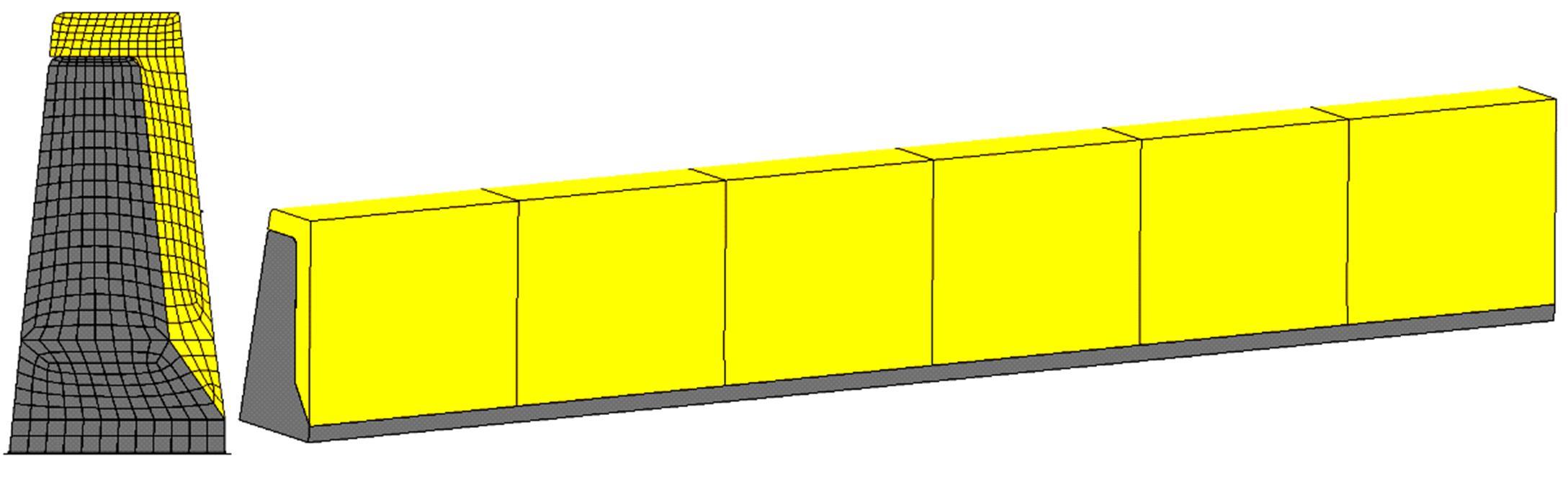

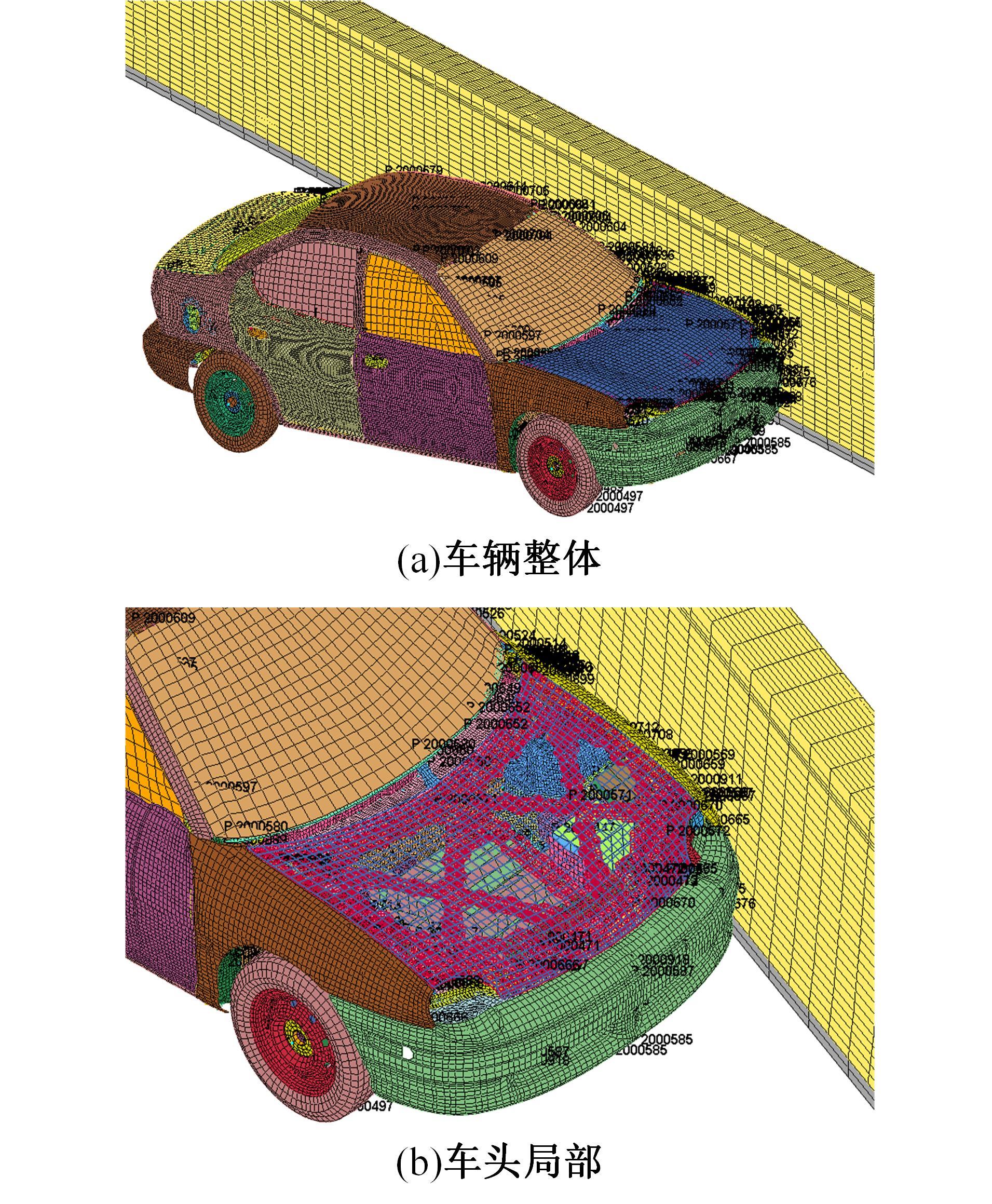

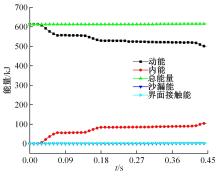

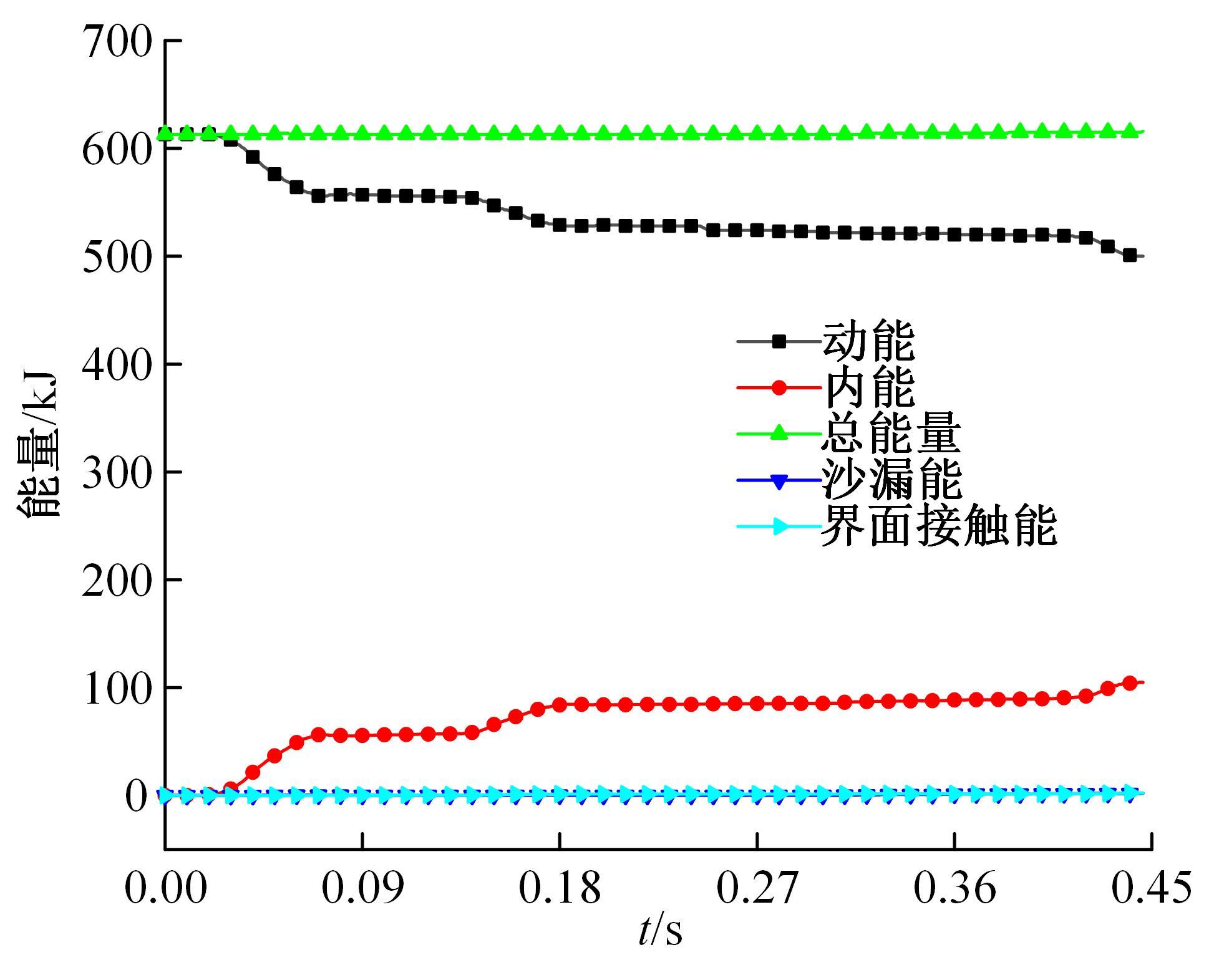

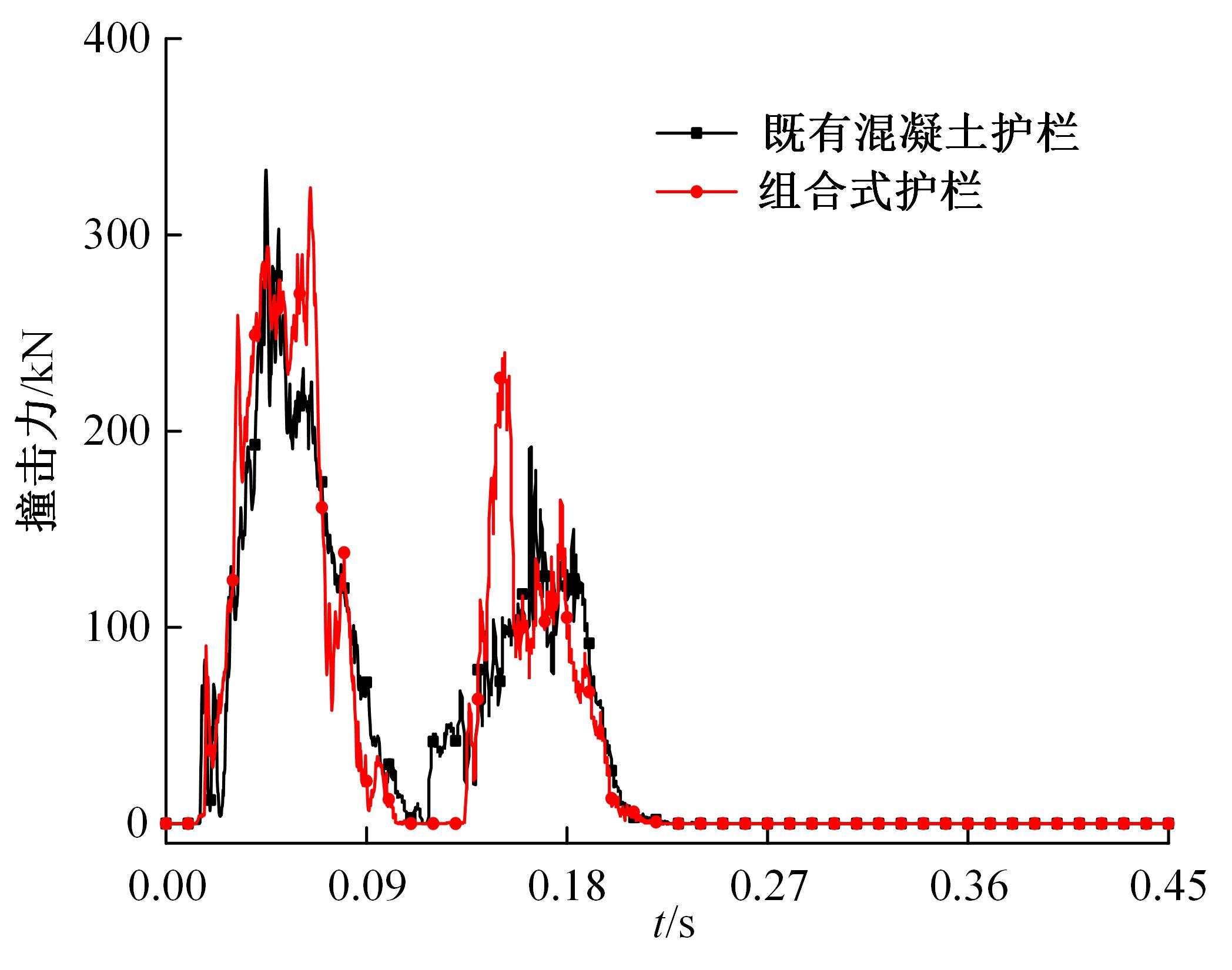

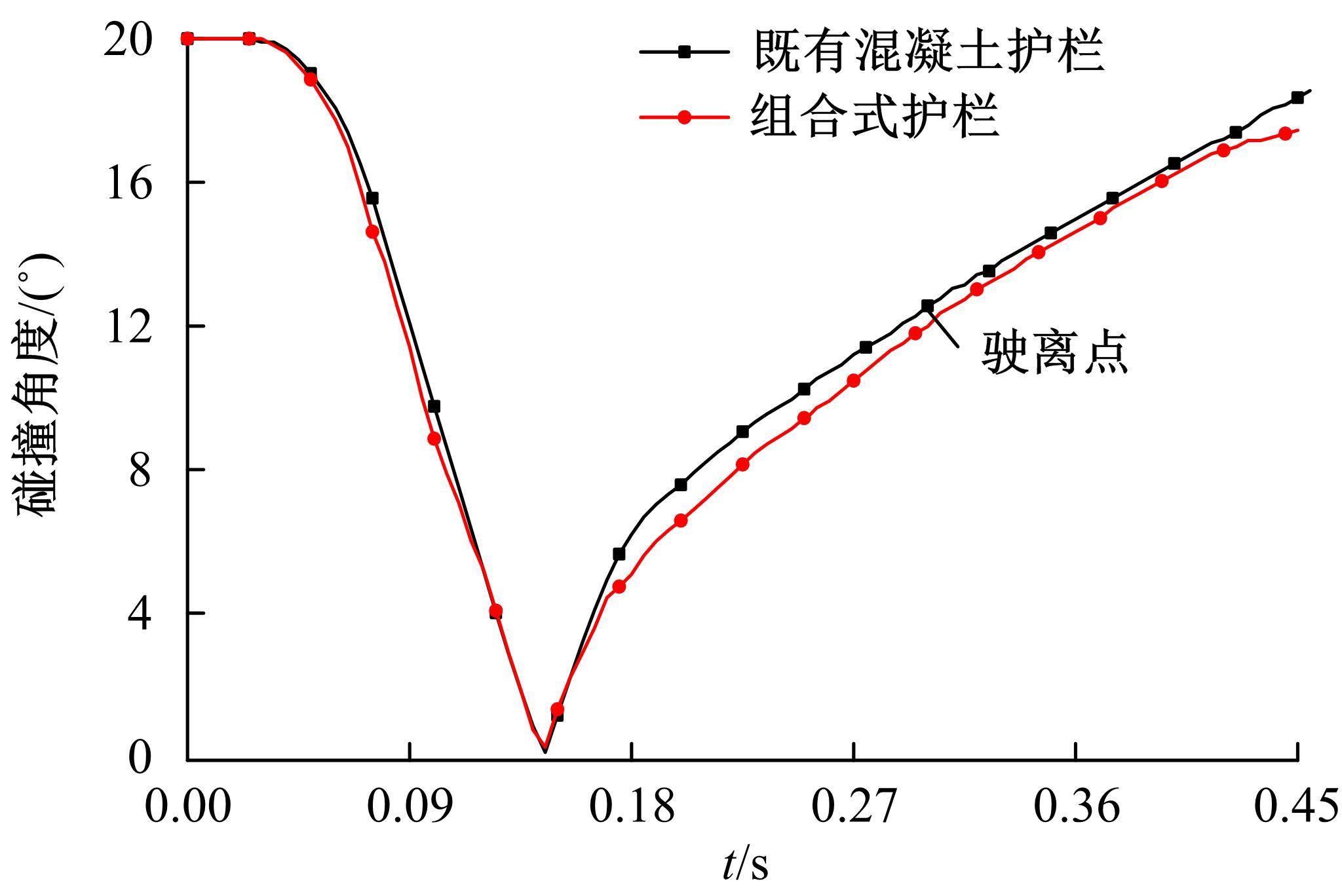

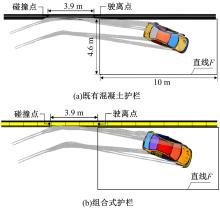

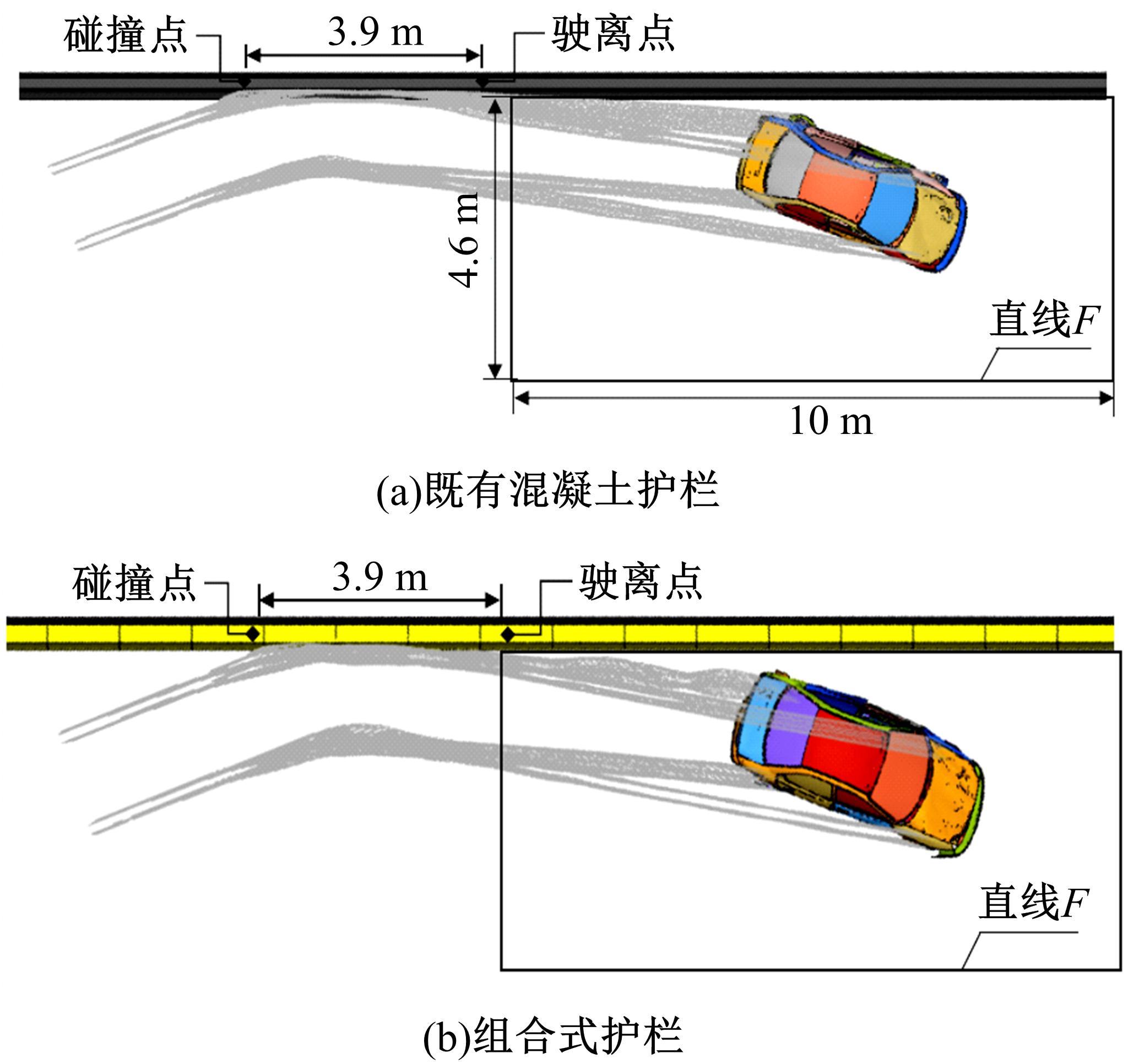

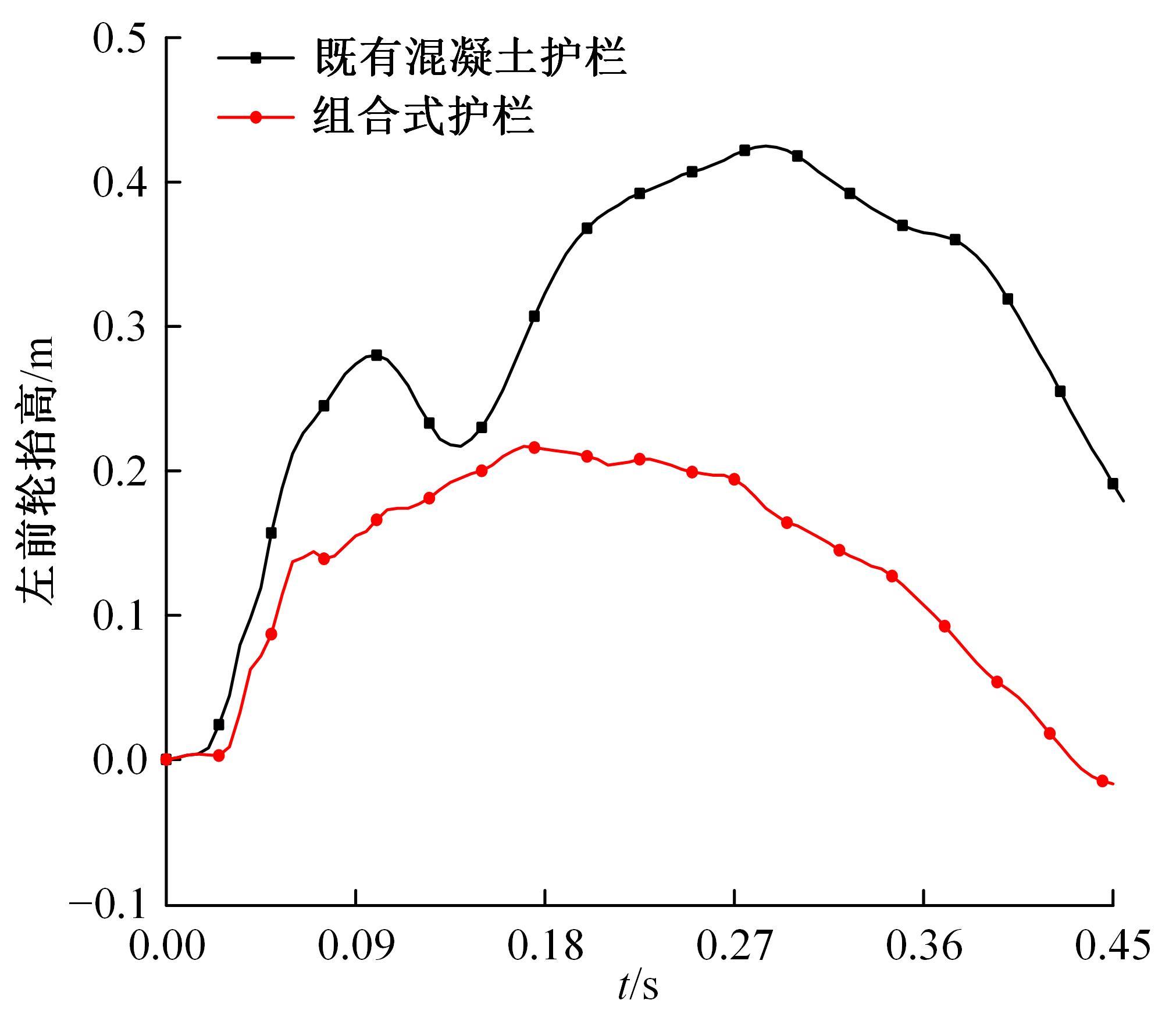

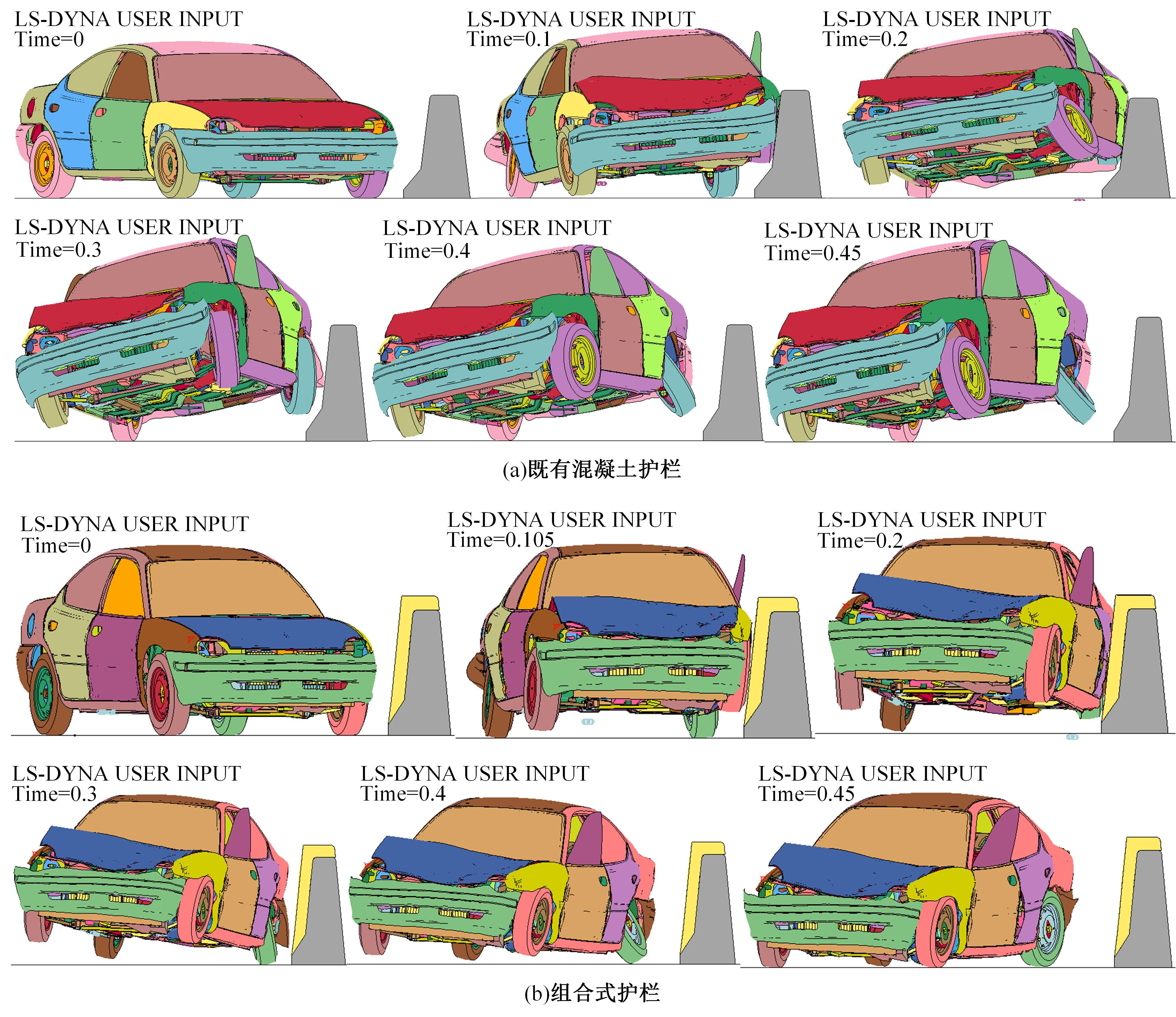

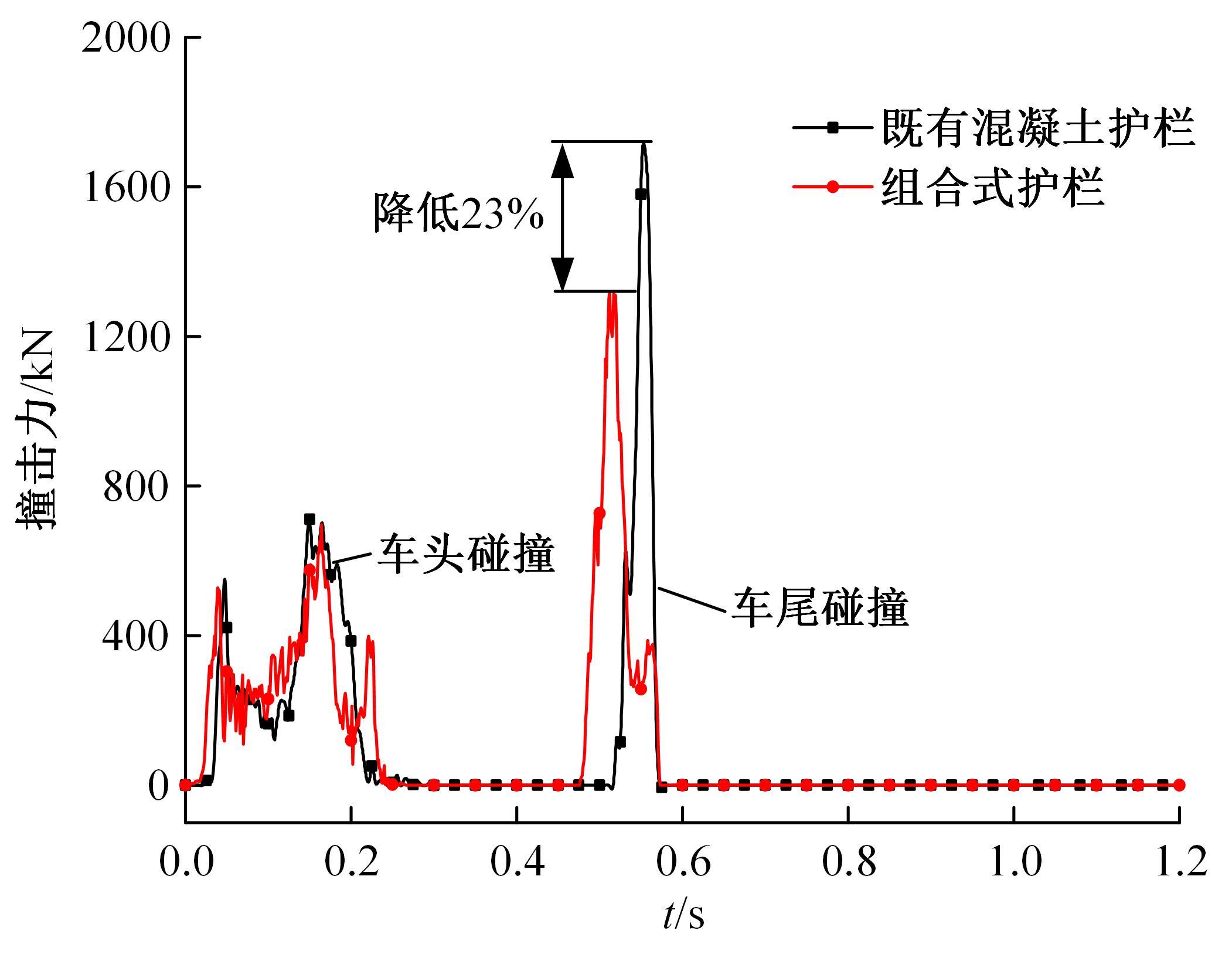

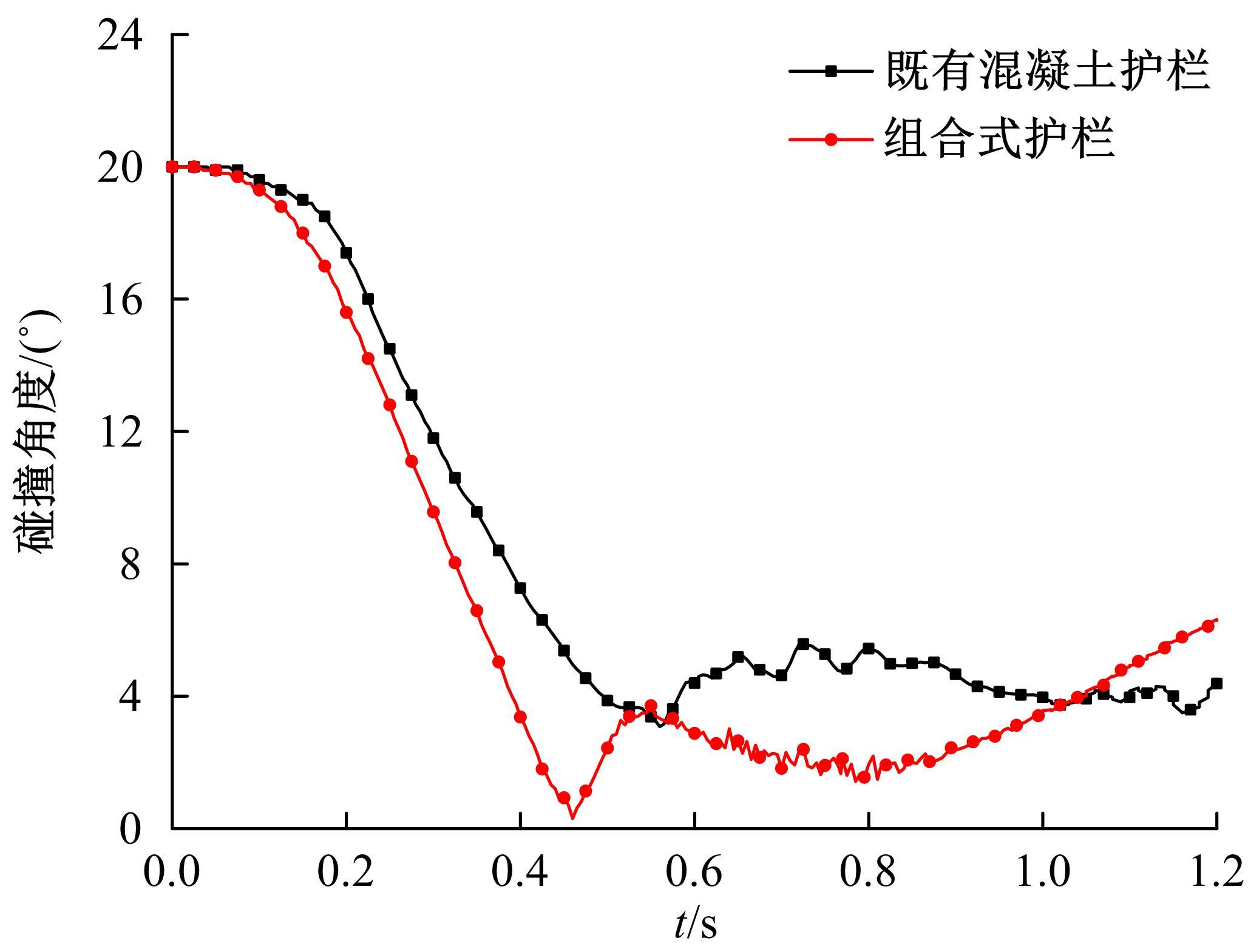

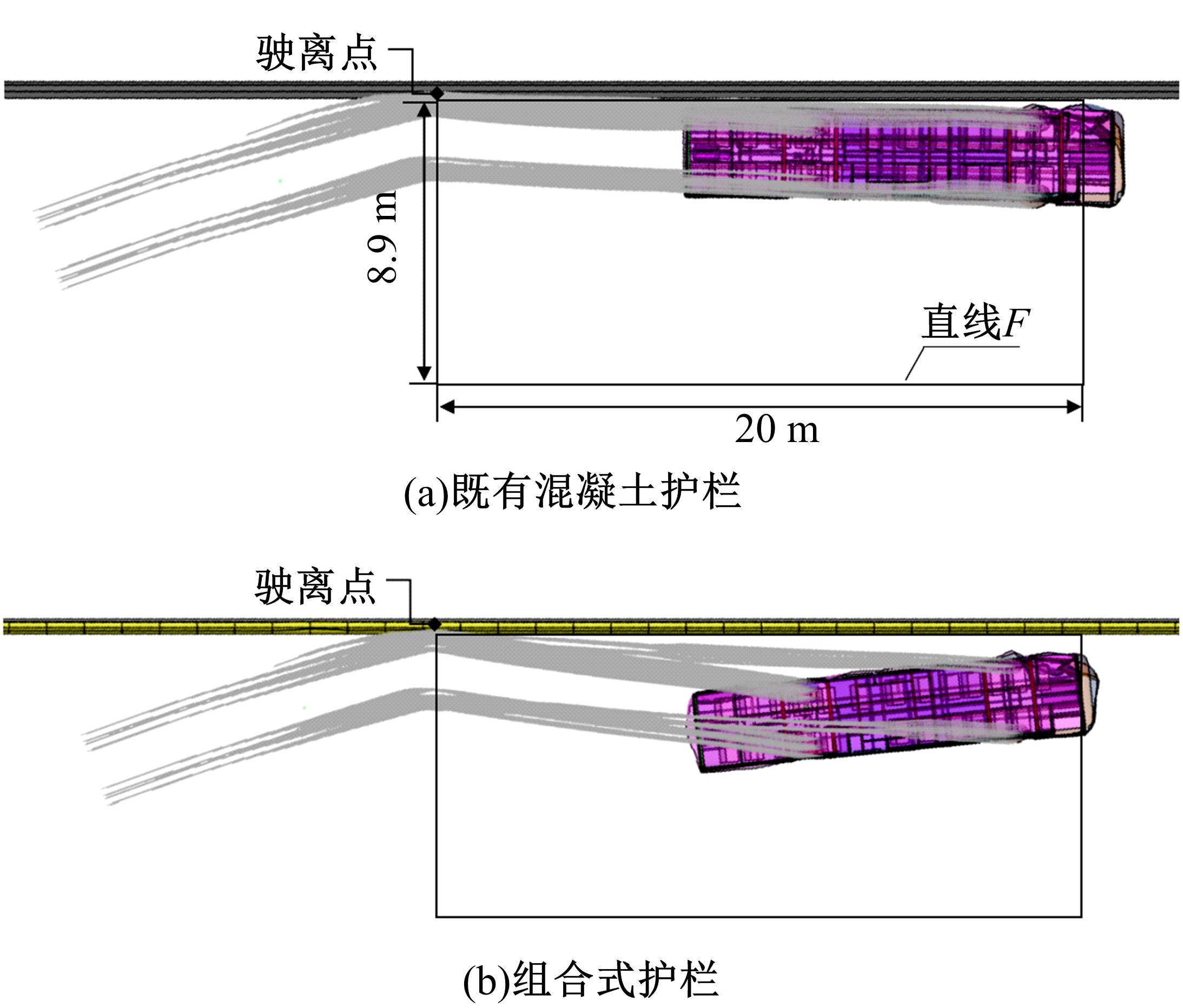

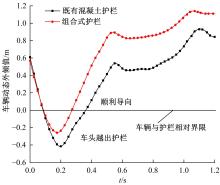

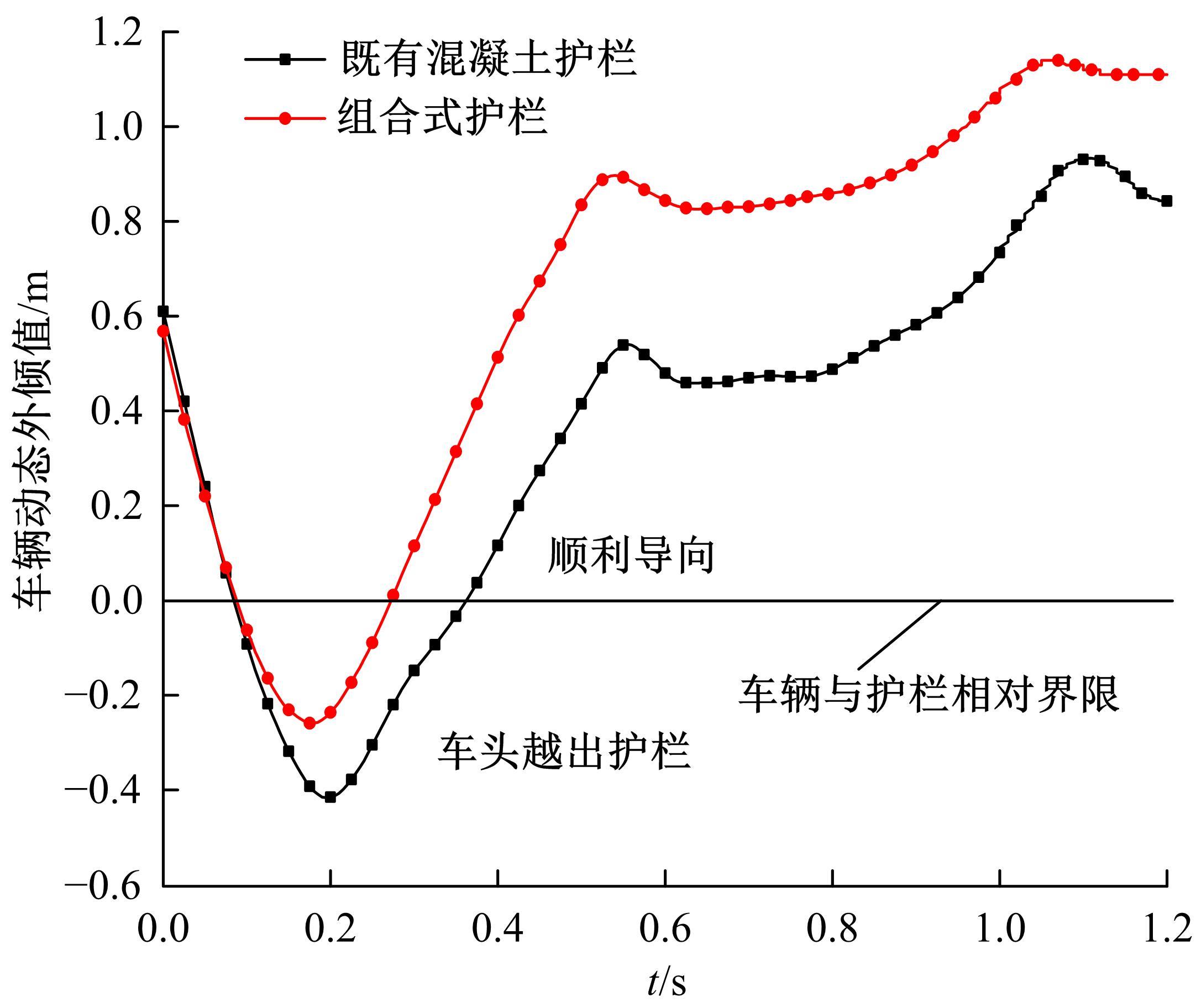

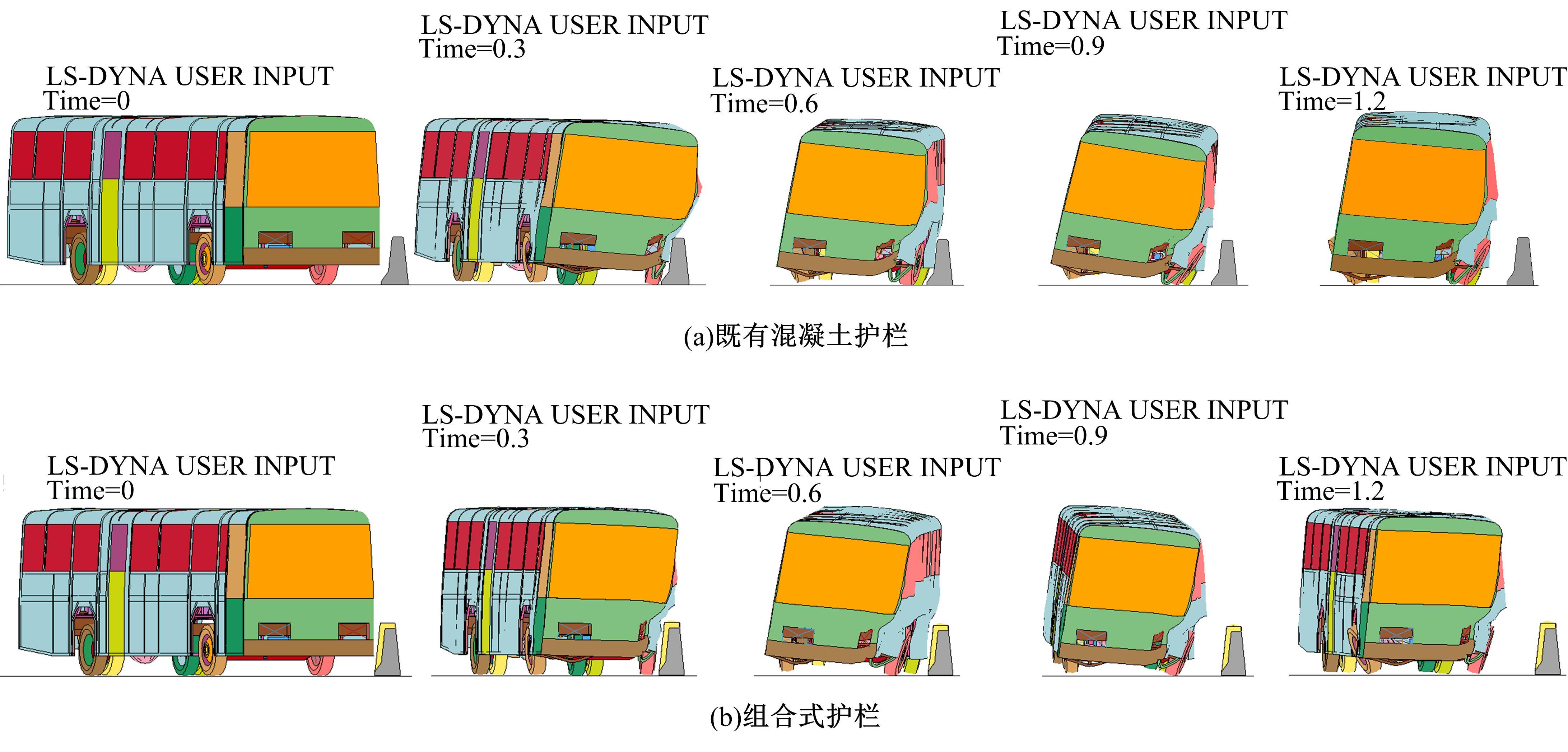

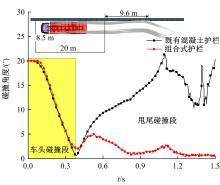

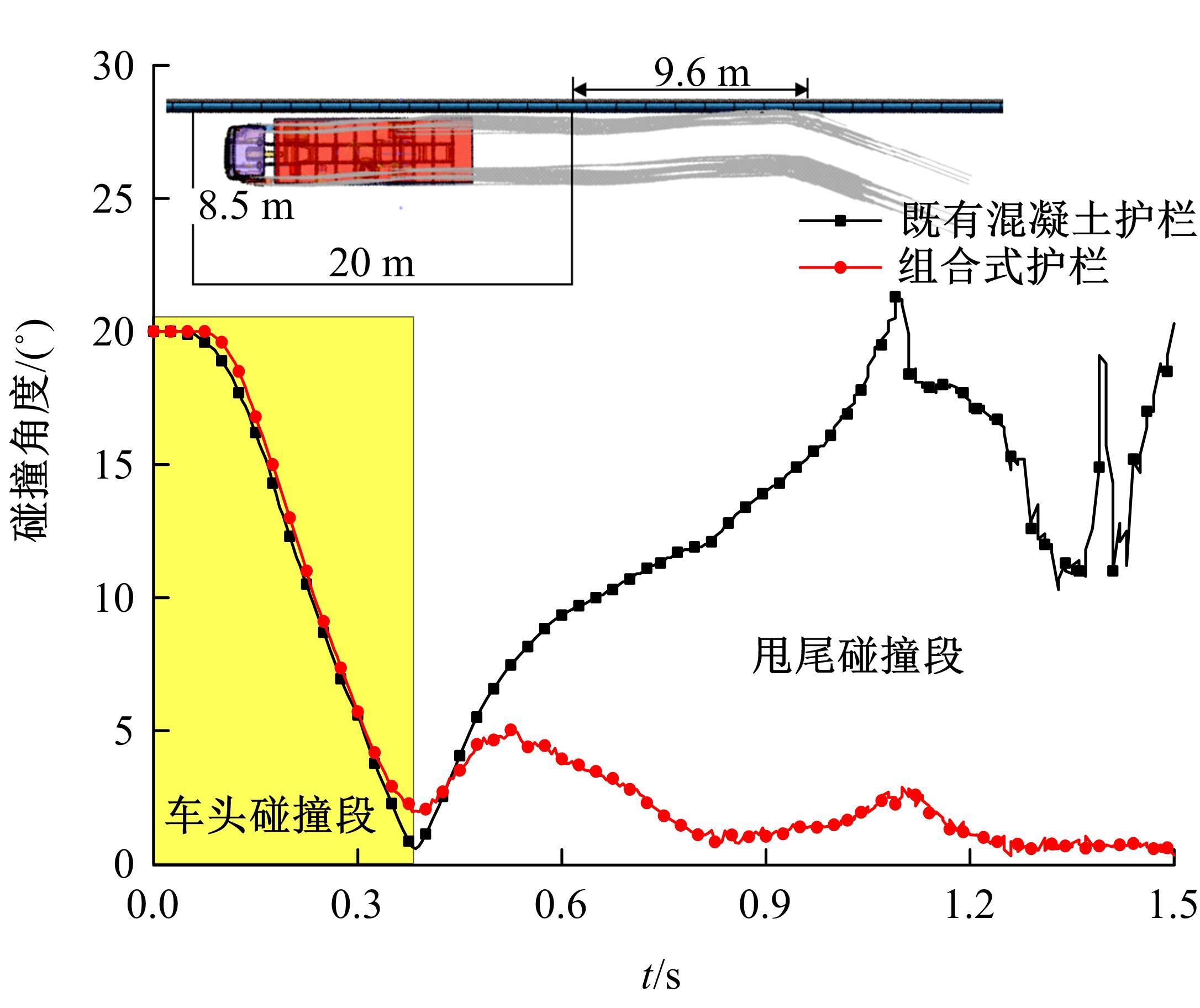

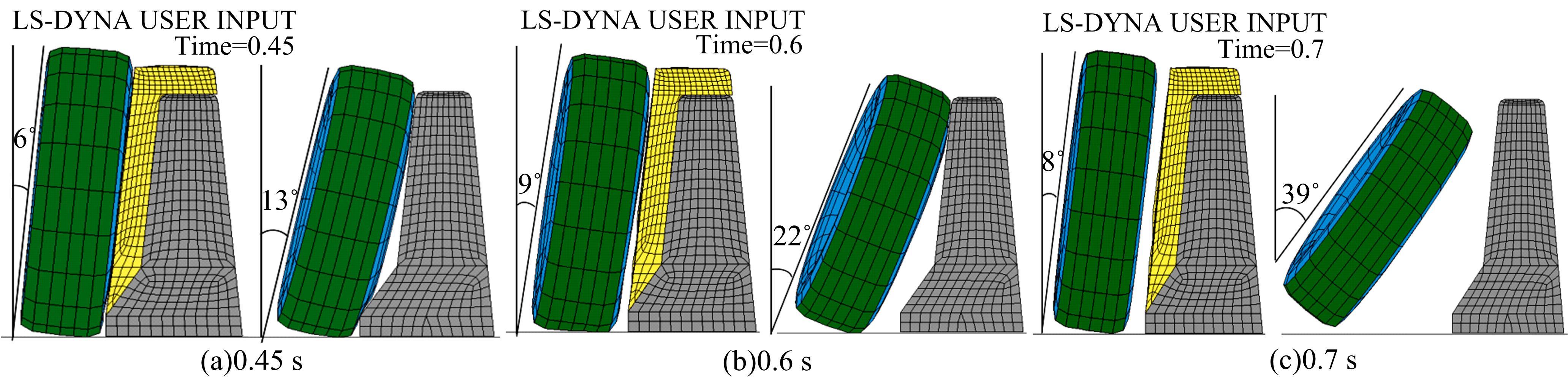

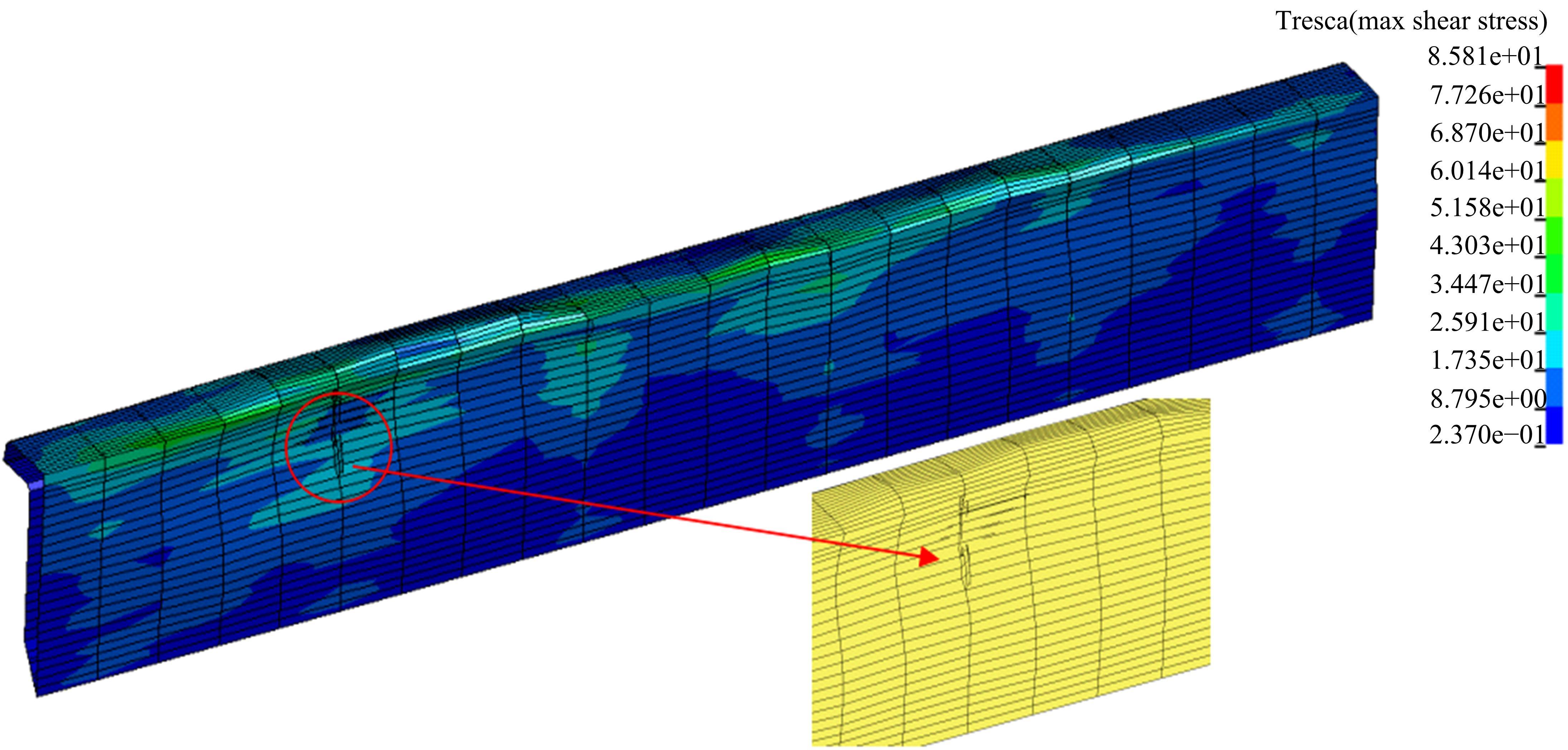

针对早期修建的低等级混凝土护栏防护能力与现阶段交通流不匹配的问题,提出了一种可直接设置在混凝土护栏表面的复合材料新型护板,改造形成组合式护栏。建立车-护栏有限元模型,分析了组合式护栏的防车撞性能,并与既有混凝土护栏进行对比。结果表明:在小型客车、中型客车碰撞下,组合式护栏的缓冲、导向性能并未受到影响,各项指标优于既有混凝土护栏;在大型货车碰撞下,既有混凝土护栏无法有效抑制侧倾,车辆发生翻车;组合式护栏能克服侧翻顺利导向,驶出角仅为0.32°;改造后的组合式护栏防护能量达到290 kJ,防护能力是改造前的1.8倍。

中图分类号:

- U417.1

| 1 | 《中国公路学报》编辑部. 中国汽车工程学术研究综述·2017[J]. 中国公路学报,2017,30(6):1-197. |

| Editorial Board of«China Journal of Highway and Transport». Review on China's automotive engineering research progress:2017[J]. China Journal of Highway and Transport,2017,30(6):1-197. | |

| 2 | . 高速公路交通安全设施设计及施工技术规范 [S]. |

| 3 | . 公路交通安全设施设计技术规范 [S]. |

| 4 | . 公路交通安全设施设计规范 [S]. |

| 5 | 李慧珍. 高速公路旧有波形梁护栏改造方式探析[J]. 中外公路,2014,34(5):324-327. |

| Li Hui-zhen. Analysis on modification of old rail-shaped guardrail of freeway[J].Journal of China&Foreign Highway,2014,34(5):324-327. | |

| 6 | 陈岳峰,陈礼彪,曾俊铖. 高速公路在用波形梁护栏适应性评价和提升改造技术研究[J]. 公路交通科技,2019,36(9):124-128, 149. |

| Chen Yue-feng, Chen Li-biao, Zeng Jun-cheng. Study on adaptation evaluation and upgrading technology for W-beam barrier used in expressway[J].Journal of Highway and Transportation Research and Development,2019,36(9):124-128, 149. | |

| 7 | 陈涛,吴灵生,田东翔,等. 高速公路波形梁护栏安全性评价[J]. 长安大学学报: 自然科学版,2017,37(6):92-98. |

| Chen Tao, Wu Ling-sheng, Tian Dong-xiang,et al.Safety evaluation of W-beam guardrail on freeway[J]. Journa of Chang'an University(Natural Science Edition),2017,37(6):92-98. | |

| 8 | 赵庆云,卜令涛,吴军鹏,等. 三横梁组合式桥梁护栏仿真与试验研究[J]. 公路工程,2020,45(5):135-141. |

| Zhao Qing-yun, Bu Ling-tao, Wu Jun-peng,et al.Simulation and experimental study of a 3-beam combined bridge barrier[J].Highway Engineering,2020,45(5):135-141. | |

| 9 | 刘伟庆,方海,祝露,等. 船-桥碰撞力理论分析及复合材料防撞系统[J]. 东南大学学报:自然科学版,2013,43(5): 1080-1086. |

| Liu Wei-qing, Fang Hai, Zhu Lu,et al.Ship-bridge collision force mechanism and composite anti-collision system[J]. Journal of Southeast University (Natural Science Edition),2013,43(5):1080-1086. | |

| 10 | 方海,王健,祝露,等. 武汉鹦鹉洲长江大桥中塔墩防船撞装置研究[J]. 桥梁建设,2020,50(1):20-25. |

| Fang Hai, Wang Jian, Zhu Lu,et al.Study of collision protection devices for central pylon pier of Yingwuzhou Chang jiang river bridge in Wuhan[J]. Bridge Construction,2020,50(1):20-25. | |

| 11 | Fang H, Mao Y, Liu W,et al. Manufacturing and evaluation of large-scale composite bumper system for bridge pier protection against ship collision[J]. Composite Structures,2016,158:187-198. |

| 12 | 张锡祥,王智祥,巫祖烈,等. 一种新型FRP桥墩防撞浮箱结构[J]. 重庆交通大学学报:自然科学版,2011,30(3):388-393, 510. |

| Zhang Xi-xiang, Wang Zhi-xiang, Wu Zu-lie,et al.A late-model FRP floating pontoon protection structure for bridge piers in the ship collison[J].Journa of Chongqing Jiaotong University(Natural Science),2011,30(3):388-393, 510. | |

| 13 | 潘晋,方涵,吴亚锋,等. 桥墩复合材料防车撞结构碰撞性能试验研究[J]. 华中科技大学学报: 自然科学版,2018,46(10):14-20. |

| Pan Jin, Fang Han, Wu Ya-feng,et al. Experimental study on performance of composite protection structure for bridge pier against vehicle collision[J].Journal of Huazhong University of Science and Technology,(Natural Science Edition),2018,46(10):14-20. | |

| 14 | Pan Jin, Fang Han, Xu Ming-cai,et al. Study on the performance of energy absorption structure of bridge piers against vehicle collision[J]. Thin Walled Structures,2018,130:85-100. |

| 15 | Bank L C, Gentry T R. Development of a pultruded composite material highway guardrail[J]. Composites Part A: Applied Science and Manufacturing,2001,32(9):1329-1338. |

| 16 | Dutta P K. An investigation into the design and manufacture of FRP composite W-beam guardrail[J]. International Journal of Materials and Product Technology,2003,19(1/2):130-152. |

| 17 | 金思宇,黄有平,范欣愉,等. 玻纤增强热塑性复合材料公路护栏应用技术开发[J]. 高科技纤维与应用,2016,41(4):56-64, 69. |

| Jin Si-yu, Huang You-ping, Fan Xin-yu,et al.Technical development of highway guardrail with glass fiber reinforced thermoplastic composites[J]. Hi-Tech Fiber&Application,2016,41(4):56-64, 69. | |

| 18 | 孙胜江,朱长华,梅葵花. 玄武岩纤维复合材料梁-柱式护栏防撞性能[J]. 振动与冲击,2019,38(21):265-270. |

| Sun Sheng-jiang, Zhu Chang-hua, Mei Kui-hua. Anti-collision performance of basalt fiber composite beam-column guardrails[J].Journal of Vibration and Shock,2019,38(21):265-270. | |

| 19 | . 公路交通安全设施设计细则 [S]. |

| 20 | 闫书明. 有限元仿真方法评价护栏安全性能的可行性[J].振动与冲击,2011,30(1):152-156. |

| Yan Shu-ming. Feasibility analysis of barrier safety evaluation with finite element simulation method[J]. Journal of Vibration and Shock,2011,30(1):152-156. | |

| 21 | Yin H, Fang H, Wang Q,et al. Design optimization of a MASH TL-3 concrete barrier using RBF-based meta models and nonlinear finite element simulations[J]. Engineering Structures, 2016, 114:122-134. |

| 22 | Marzougui D, Kan C D, Opiela K S. Crash test & simulation comparisons of a pickup truck & a small car oblique impacts into a concrete barrier[C]∥The 13th International LS-DYNA Users Conference, Dearborn,2013: 1-18. |

| 23 | Polivka K A, Faller R K, Sicking D L,et al. Performance evaluation of the permanent new Jersey safety shape barrier-update to NCHRP 350 Test No.4-12(2214NJ-2),TRP-03-178-06[EB/OL].[2020-12-18]. |

| 24 | Chen J Y, Fang H, Liu W Q,et al. Energy absorption of foam-filled multi-cell composite panels under quasi-static compression[J]. Composites Part B:Engineering,2018,153:295-305. |

| 25 | Wang J J, Song Y C, Wang W,et al. Evaluation of composite crash worthy device for pier protection against barge impact[J]. Ocean Engineering,2018,169:144-158. |

| 26 | 雷正保,彭作,刘兰,等. 弯道混凝土护栏碰撞特性的优化设计[J]. 振动与冲击,2009,28(5):6-9, 26, 200. |

| Lei Zheng-bao, Peng Zuo, Liu Lan,et al. Optimization design of the collision characteristics of curved concrete guardrail[J].Journal of Vibration and Shock,2009,28(5):6-9, 26, 200. | |

| 27 | 杨济匡,孔成,肖志. 高速公路双波护栏对客车碰撞的防护性能仿真研究与改进[J]. 公路交通科技,2014,31(10):134-140. |

| Yang Ji-kuang, Kong Cheng, Xiao Zhi. Simulation and improvement of protective performance of expressway W-beam guardrailagainst bus collisions[J]. Journal of Highway and Transportation Research and Development,2014,31(10):134-140. | |

| 28 | . 公路护栏安全性能评价标准 [S]. |

| [1] | 华琛,牛润新,余彪. 地面车辆机动性评估方法与应用[J]. 吉林大学学报(工学版), 2022, 52(6): 1229-1244. |

| [2] | 盖松雪,曾小清,岳晓园,袁子豪. 基于用户-系统双层优化算法的车位引导模型[J]. 吉林大学学报(工学版), 2022, 52(6): 1344-1352. |

| [3] | 吴文静,战勇斌,杨丽丽,陈润超. 考虑安全间距的合流区可变限速协调控制方法[J]. 吉林大学学报(工学版), 2022, 52(6): 1315-1323. |

| [4] | 徐洪峰,陈虹瑾,张栋,陆千惠,安娜,耿现彩. 面向网联汽车环境的单点全感应式信号配时技术[J]. 吉林大学学报(工学版), 2022, 52(6): 1324-1336. |

| [5] | 李伟,宋海生,陆浩宇,史文库,王强,王晓俊. 复合材料板簧迟滞特性线性辨识方法[J]. 吉林大学学报(工学版), 2022, 52(4): 829-836. |

| [6] | 庄蔚敏,陈沈,吴迪. 碳纤维增强复合材料包裹强化形式对钢管横向冲击性能的影响[J]. 吉林大学学报(工学版), 2022, 52(4): 819-828. |

| [7] | 李先通,全威,王华,孙鹏程,安鹏进,满永兴. 基于时空特征深度学习模型的路径行程时间预测[J]. 吉林大学学报(工学版), 2022, 52(3): 557-563. |

| [8] | 冯天军,孙学路,黄家盛,田秀娟,宋现敏. 基于三种过街方式的两相位信号交叉口延误[J]. 吉林大学学报(工学版), 2022, 52(3): 550-556. |

| [9] | 李兴华,冯飞宇,成诚,王洧,唐鹏程. 网约拼车服务选择偏好分析及建模[J]. 吉林大学学报(工学版), 2022, 52(3): 578-584. |

| [10] | 尹超英,邵春福,黄兆国,王晓全,王晟由. 基于梯度提升决策树的多尺度建成环境对小汽车拥有的影响[J]. 吉林大学学报(工学版), 2022, 52(3): 572-577. |

| [11] | 贾洪飞,邵子函,杨丽丽. 终点不确定条件下网约车合乘匹配模型及算法[J]. 吉林大学学报(工学版), 2022, 52(3): 564-571. |

| [12] | 卫宇璇,张明,刘佳,刘硕,路明雨,王洪雨. 基于模态缺陷的变刚度复合材料圆柱壳屈曲特性[J]. 吉林大学学报(工学版), 2022, 52(1): 91-100. |

| [13] | 薛锋,何传磊,黄倩,罗建. 多式轨道交通网络的耦合协调度[J]. 吉林大学学报(工学版), 2021, 51(6): 2040-2050. |

| [14] | 商拥辉,徐林荣,刘维正,蔡雨. 重载铁路改良土和A组填料过渡段的动力特性[J]. 吉林大学学报(工学版), 2021, 51(6): 2128-2136. |

| [15] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

|

||