吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (4): 819-828.doi: 10.13229/j.cnki.jdxbgxb20200939

• 车辆工程·机械工程 • 上一篇

碳纤维增强复合材料包裹强化形式对钢管横向冲击性能的影响

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Influence of strengthening form of CFRP on transverse impact performance of steel tube

Wei-min ZHUANG( ),Shen CHEN,Di WU

),Shen CHEN,Di WU

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

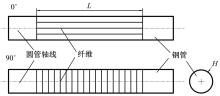

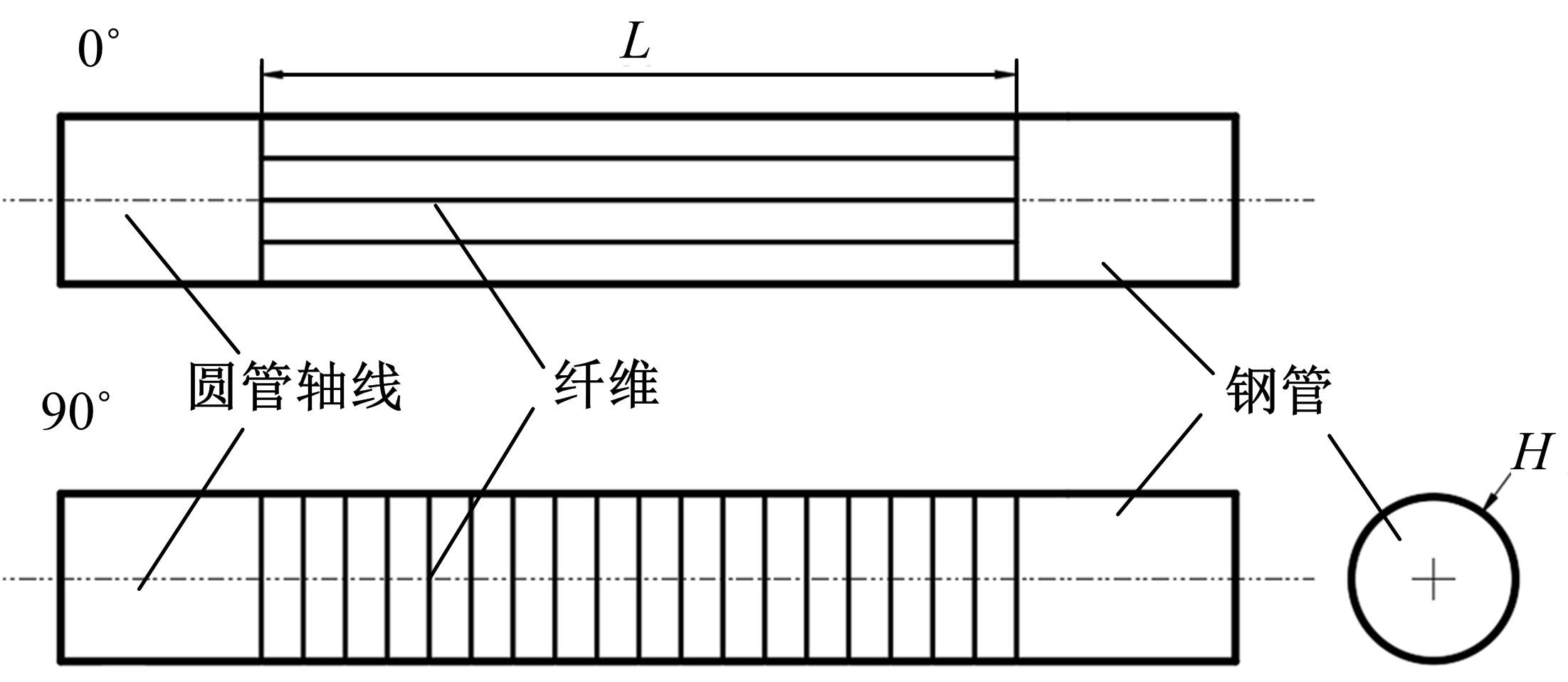

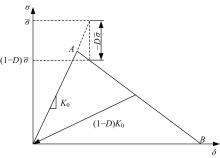

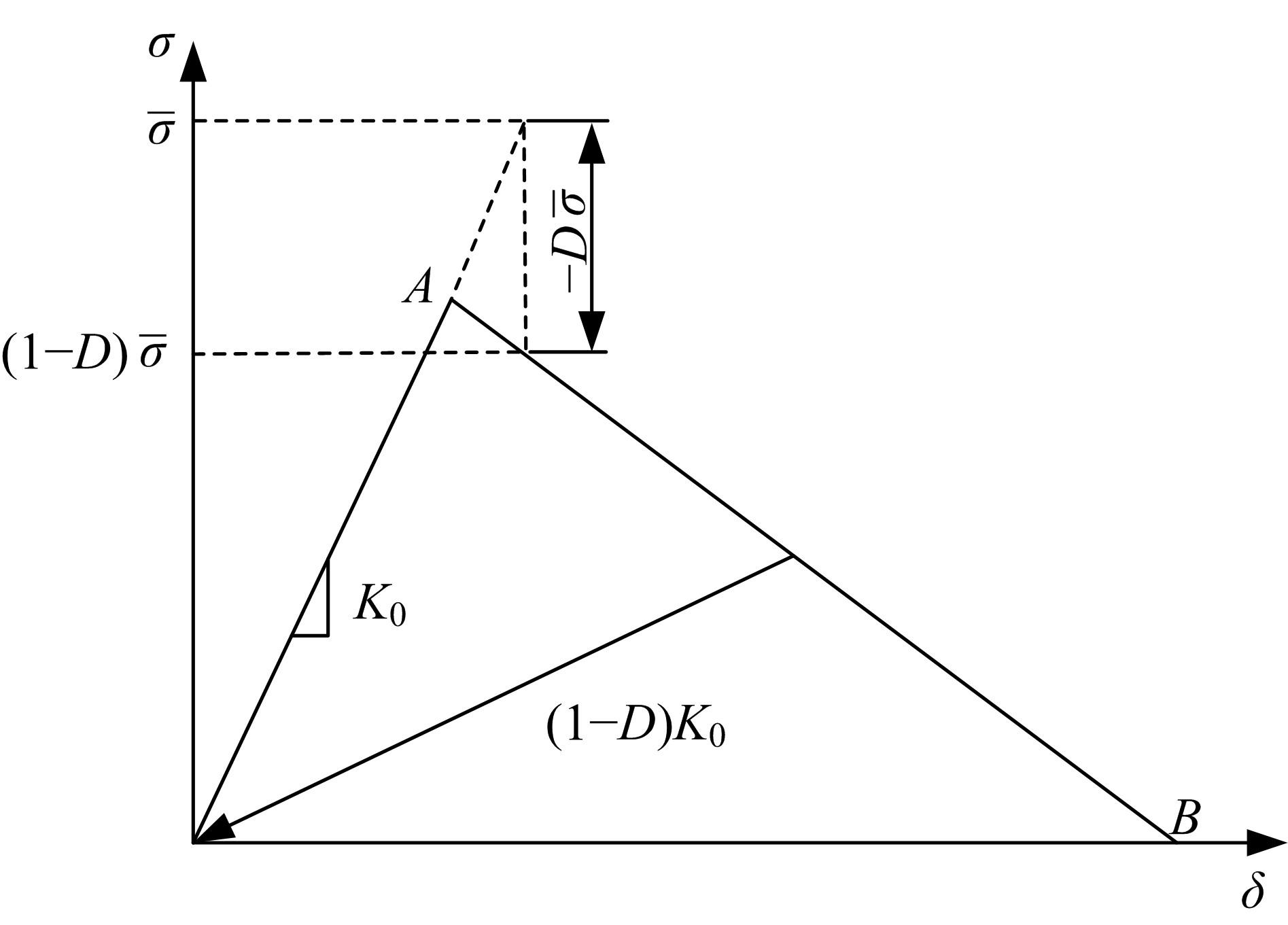

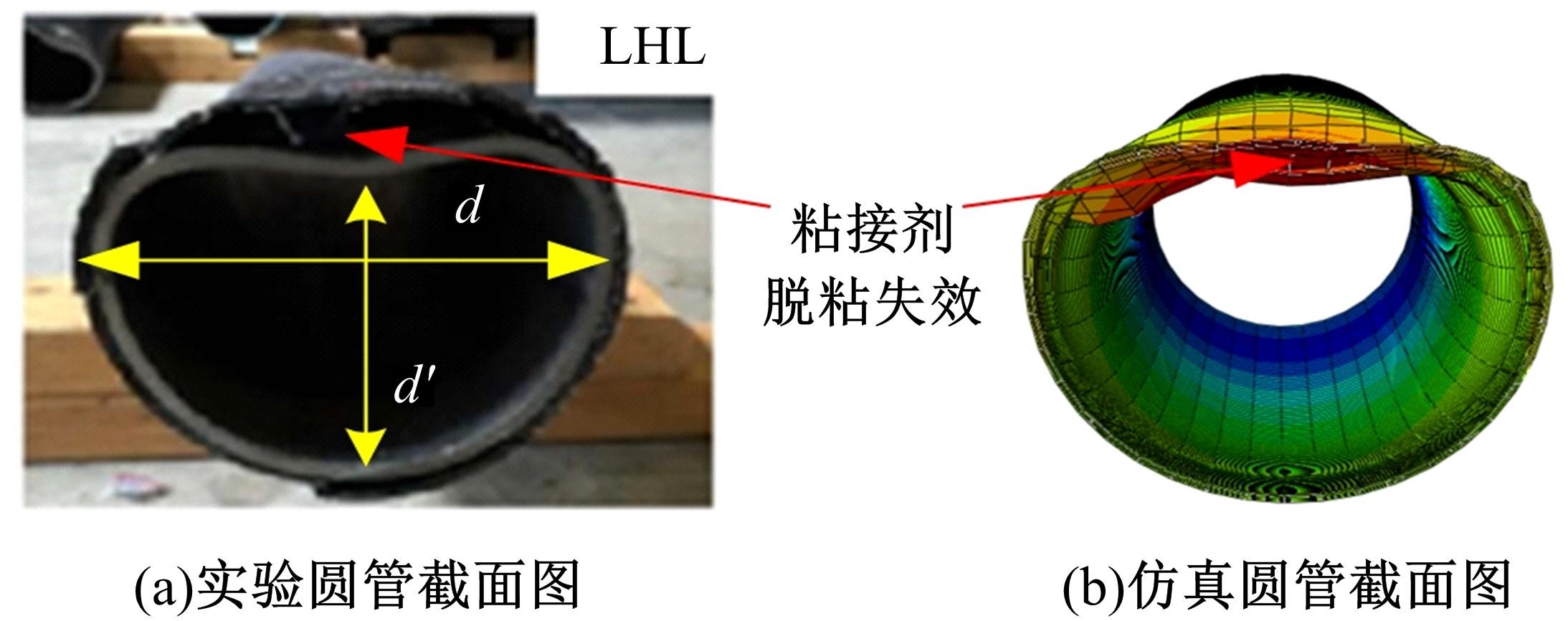

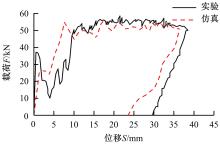

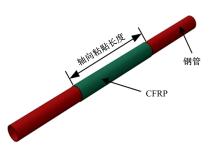

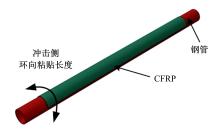

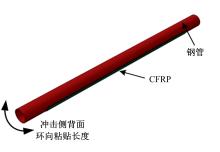

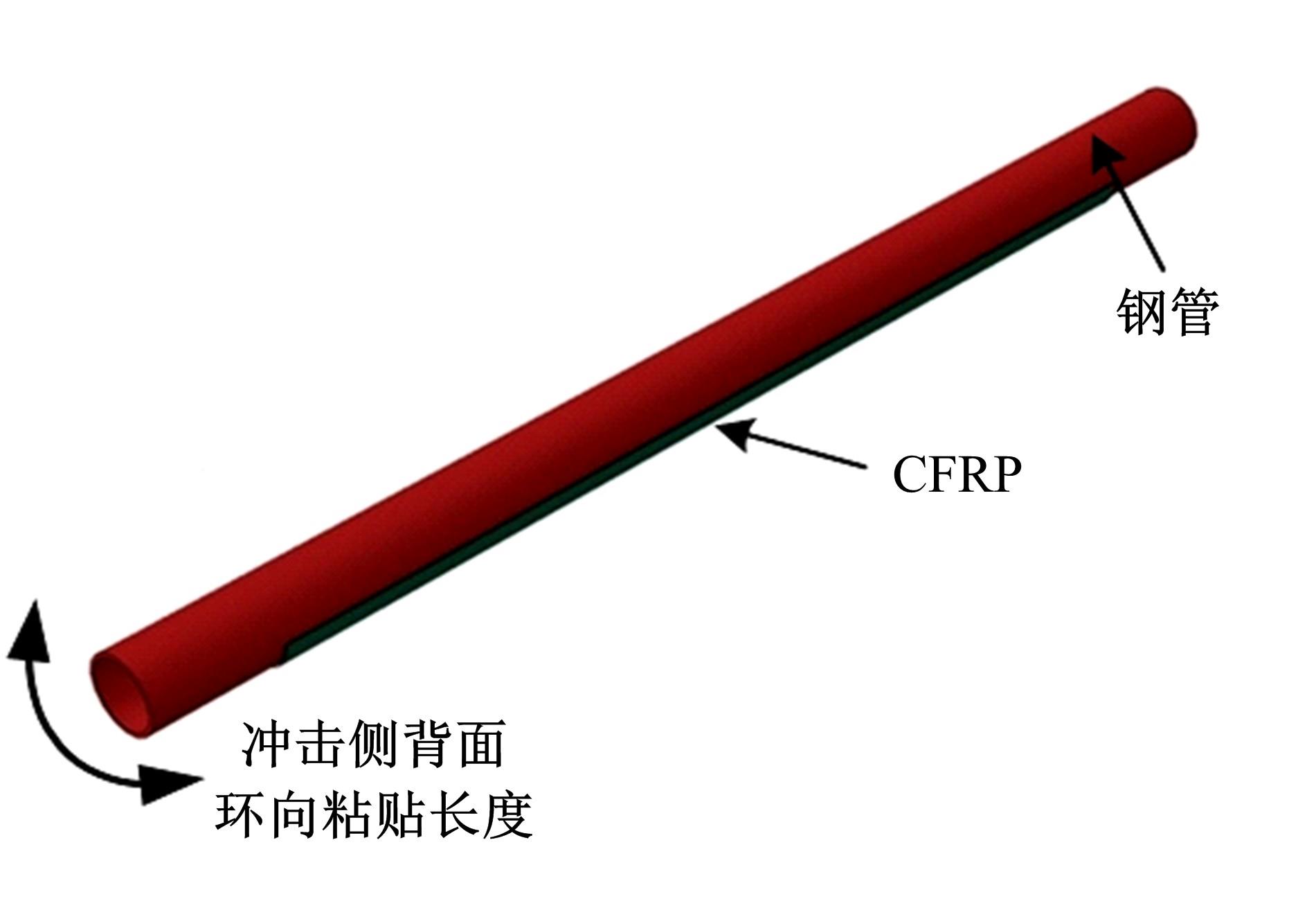

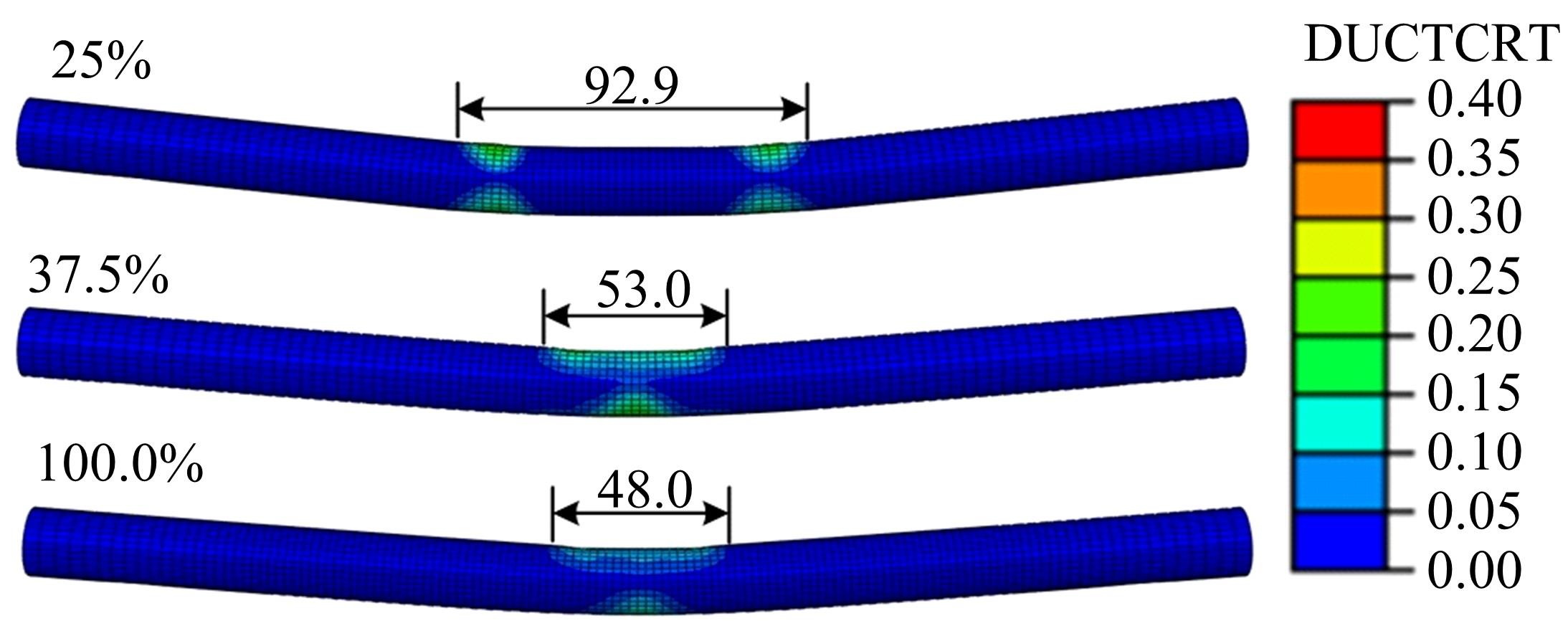

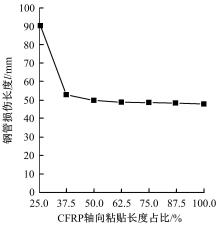

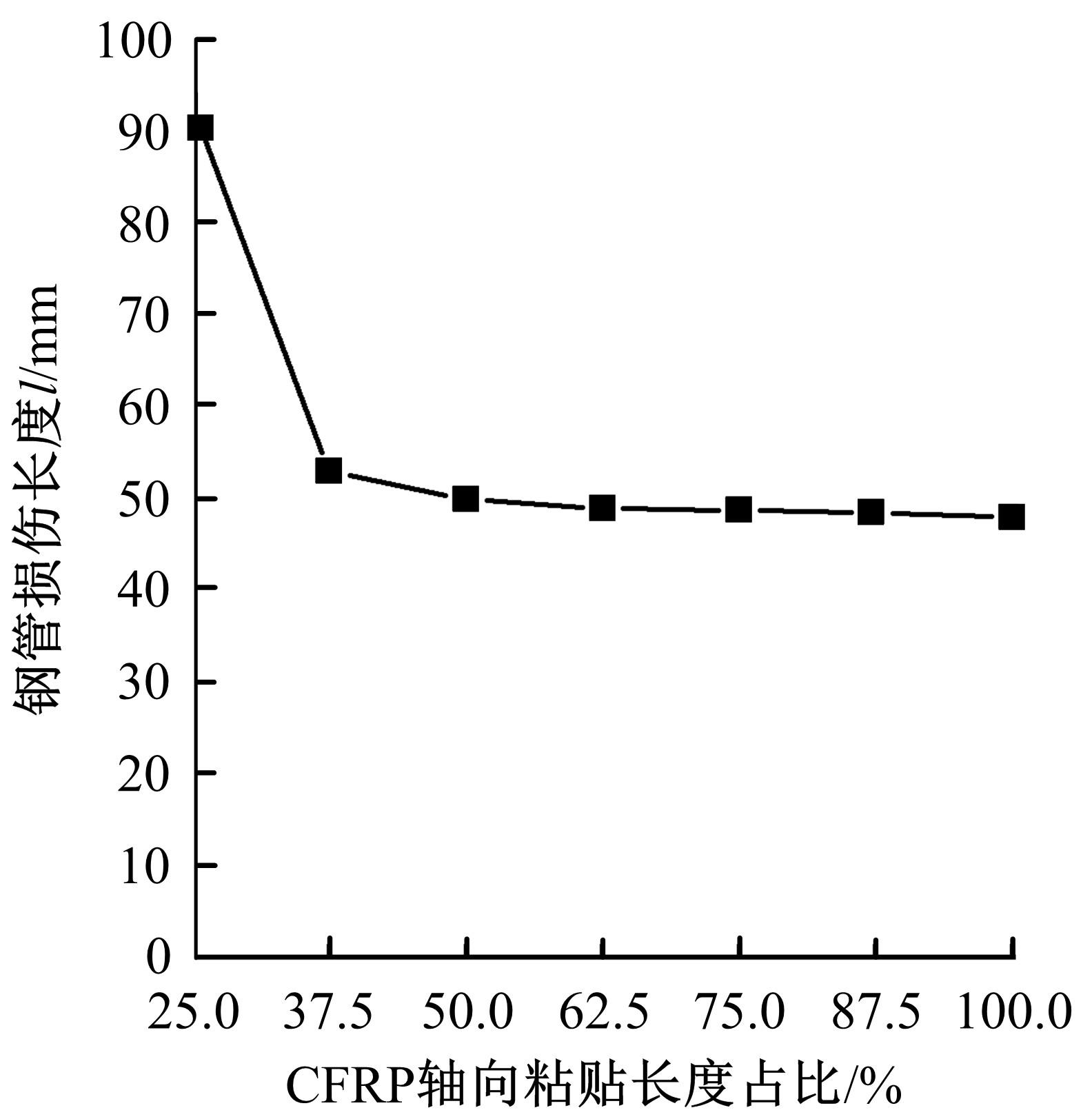

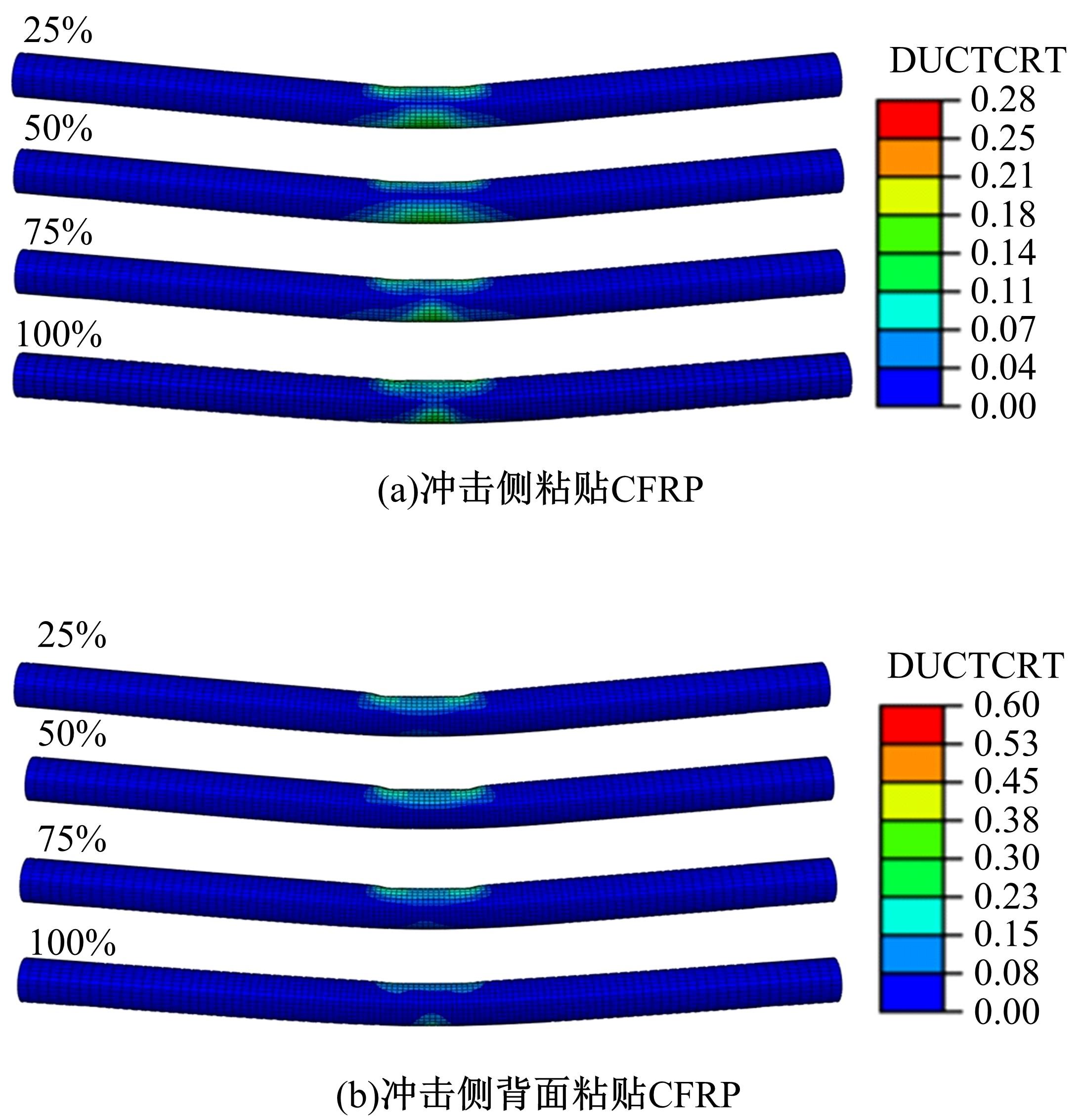

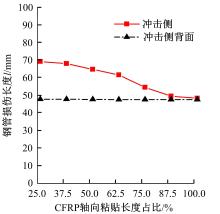

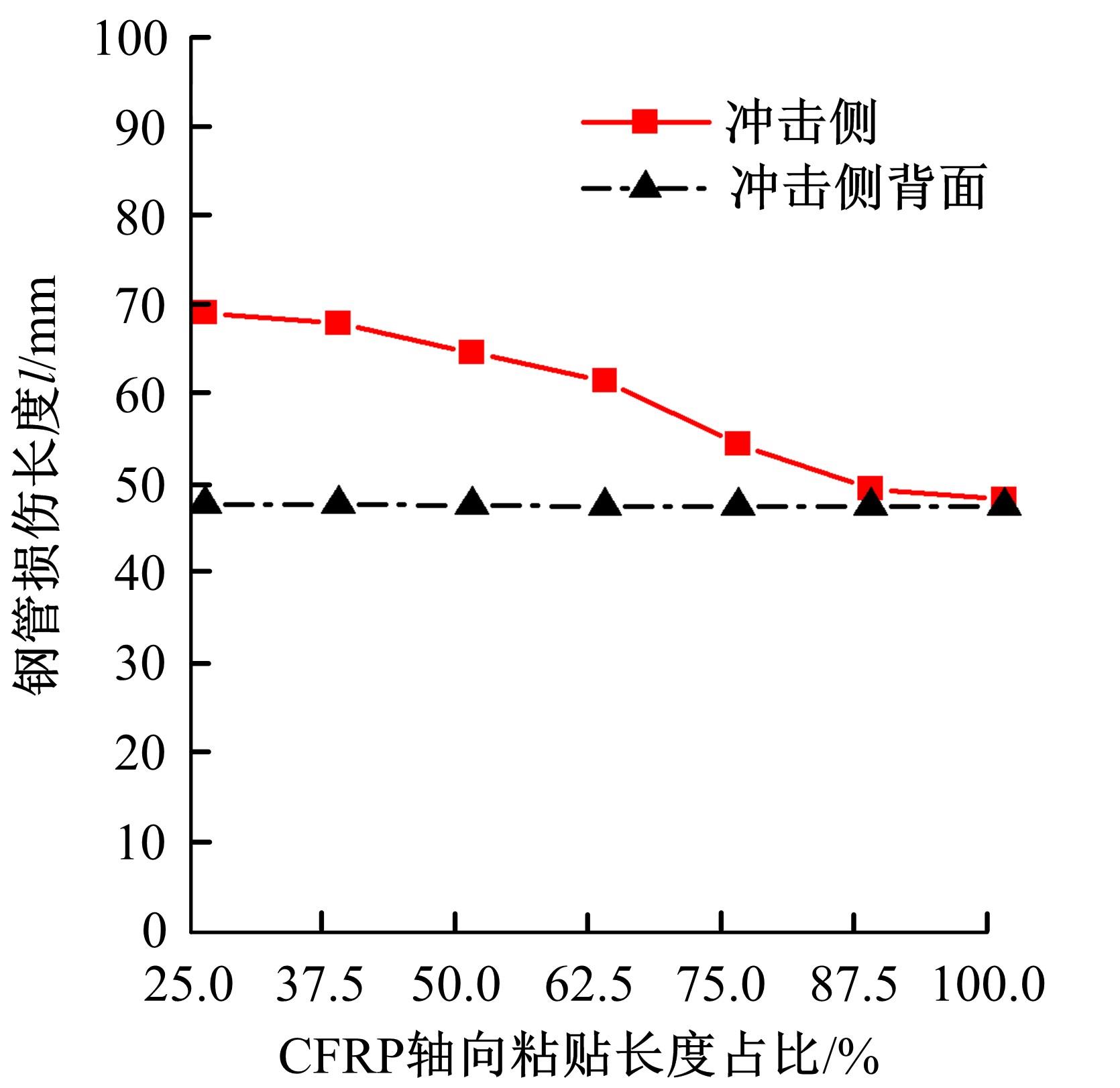

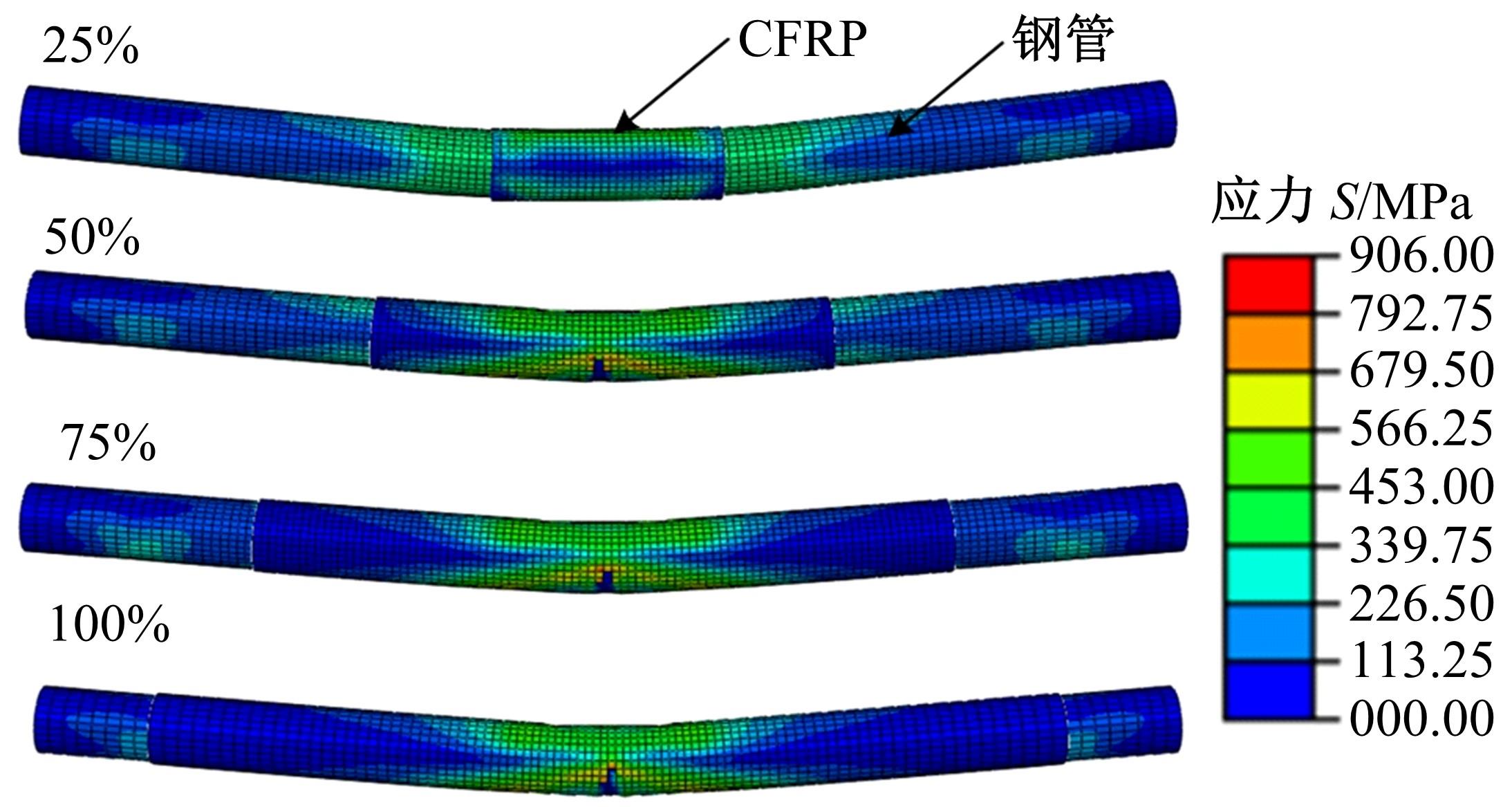

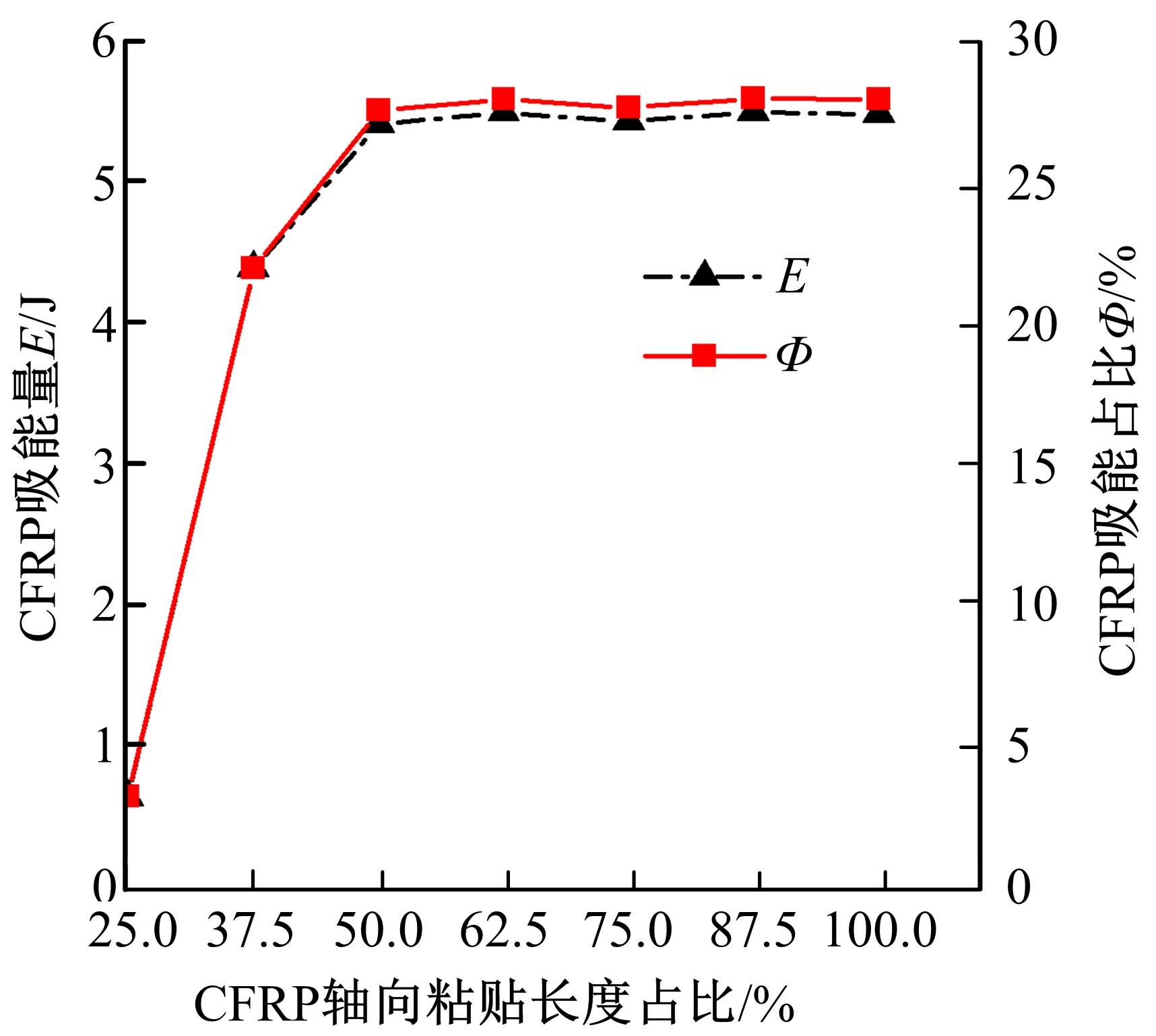

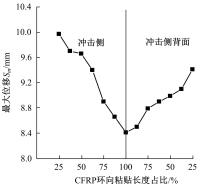

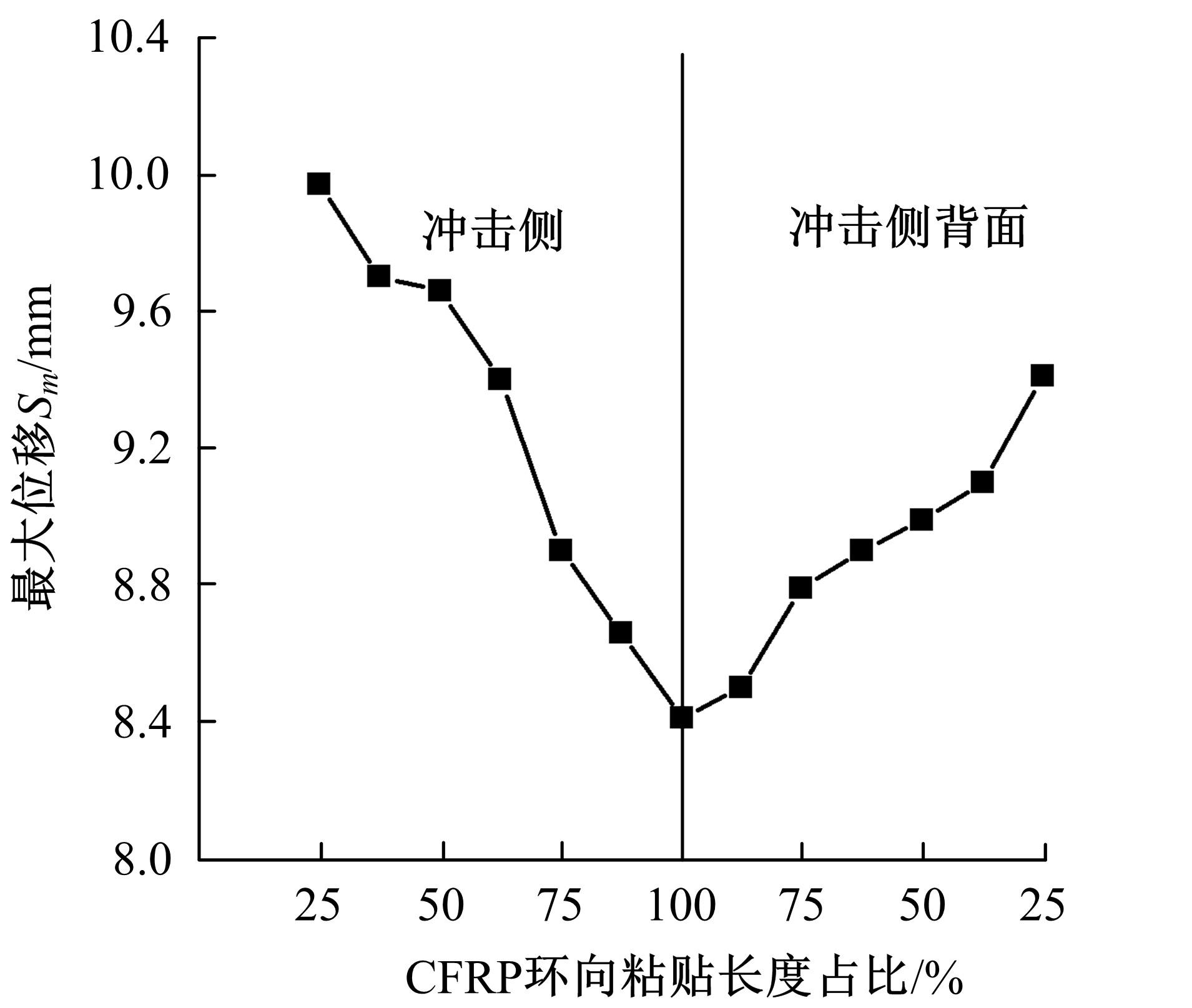

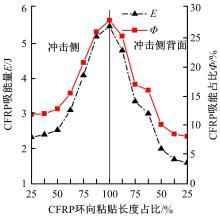

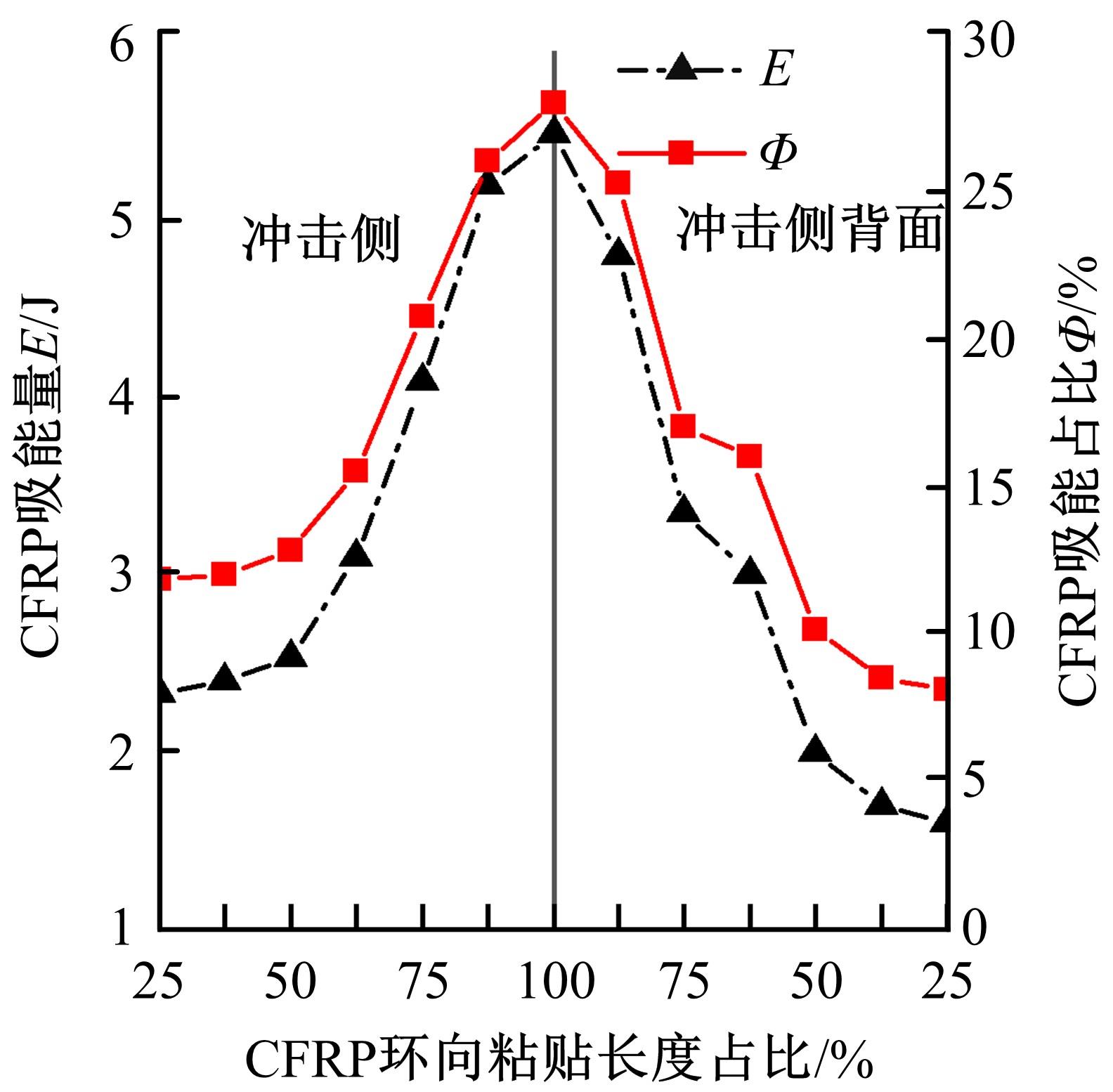

针对碳纤维增强复合材料(CFRP)非全包裹可以在提高钢管性能的前提下实现进一步的轻量化,对CFRP强化钢管进行了横向冲击仿真研究,获得了CFRP包裹钢管的强化形式和尺寸对钢管横向冲击性能的影响规律。基于Hashin复合材料失效准则和Ductile金属失效准则,建立了CFRP全包裹钢管的落锤横向冲击仿真模型并验证模型的有效性。研究CFRP在钢管表面轴向粘贴、冲击侧环向粘贴和冲击侧背面环向粘贴时,CFRP粘贴尺寸与CFRP强化钢管抗冲击性能的关系。进行落锤横向冲击仿真,研究冲击作用下钢管损伤的分布规律,对比不同粘贴长度下强化钢管的最大位移和CFRP的吸能量。结果表明,增大CFRP轴向粘贴尺寸对钢管的强化作用更为明显;当环向全部粘贴、轴向粘贴长度为50%钢管跨距和轴向全部粘贴、环向粘贴长度为87.5%圆管外部周长时,CFRP强化钢管抗冲击性能与CFRP全包裹钢管基本一致。

中图分类号:

- TB33

| 1 | Vermeeren C. An historic overview of the development of fibre mental laminates[J]. Applied Composite Materials, 2003, 10(4): 189-205. |

| 2 | 朱国华, 成艾国, 王振, 等. 电动车轻量化复合材料车身骨架多尺度分析[J]. 机械工程学报, 2016, 52(6): 145-152. |

| Zhu Guo-hua, Cheng Ai-guo, Wang Zhen, et al. Analysis of lightweight composite body structure for electrical vehicle using the multiscale approach[J]. Journal of Mechanical Engineering, 2016, 52(6): 145-152. | |

| 3 | 李永兵, 李亚庭, 楼铭, 等. 轿车车身轻量化及其对连接技术的挑战[J]. 机械工程学报, 2012, 48(18): 44-54. |

| Li Yong-bing, Li Ya-ting, Lou Ming, et al. Lightweighting of car body and its challenges to joining technologies[J]. Journal of Mechanical Engineering, 2012, 48(18): 44-54. | |

| 4 | Karbhari V M, Shulley S B. Use of composites for rehabilitation of steel structures-determination of bond durability[J]. Journal of Materials in Civil Engineering, 1995, 7(4): 239-245. |

| 5 | Phan V N, Yukihiro M. Experimental analytical and theoretical investigations of CFRP strengthened thin-walled steel plates under shear loads[J]. Thin-Walled Structures, 2020, 155: No. 106908. |

| 6 | Chahkand N A, Jumaat M Z, Ramli S N H, et al. Experimental and theoretical investigation on torsional behaviour of CFRP strengthened square hollow steel section[J]. Thin-Walled Structures, 2013, 68: 135-140. |

| 7 | 钮鹏, 杨刚, 金春福, 等. 几何缺陷影响下的CFRP-方钢管极限承载力解析解[J]. 工程力学, 2015, 32(): 322-326. |

| Niu Peng, Yang Gang, Jin Chun-fu, et al. Analytical solutions on ultimate bearing capacity of a square CFRP-steel tube member with initial imperfection[J]. Engineering Mechanics, 2015, 32(S1): 322-326. | |

| 8 | Kim H C, Dong K S, Lee J J. Characteristics of aluminum/CFRP short square hollow section beam under transverse quasi-static loading[J]. Composites Part B: Engineering, 2013, 51: 345-358. |

| 9 | Ma Q H, Zha Y B, Dong B Y, et al. Structure design and multi-objective optimization of CFRP /aluminum hybrid crash box[J]. Polymer Composites, 2020, 41(10): 4202-4220. |

| 10 | Sha Y Y, Hao H. Laboratory tests and numerical simulations of CFRP strengthened RC pier subjected to barge impact load[J]. International Journal of Structural Stability and Dynamics, 2015, 15(2): No. 1450037. |

| 11 | Haider A Z, Riadh A M, Zhao X L. Experimental investigation of bond characteristics between CFRP fabrics and steel plate joints under impact tensile loads[J]. Composite Structures, 2011, 94(2): 510-518. |

| 12 | Alam M I, Fawzia S, Zhao X L, et al. Experimental study on FRP-strengthened steel tubular members under lateral impact[J]. Journal of Composites for Construction, 2017, 21(5): No:04017022. |

| 13 | Alam M I, Fawzia S. Numerical studies on CFRP strengthened steel columns under transverse impact[J]. Composite Structures, 2015, 120: 428-441. |

| 14 | 刘斌, 赵亮, 徐红炉. 基于Hashin失效准则的复合材料螺栓连接损伤破坏研究[J]. 科学技术与工程, 2012, 12(8): 1740-1744. |

| Liu Bin, Zhao Liang, Xu Hong-lu. The research about damage of composite laminate in bolted joints based on the Hashin failure criteria[J]. Science Technology and Engineering, 2012, 12(8): 1740-1744. | |

| 15 | 吴振, 陈健. 基于Hashin准则的复合材料层合结构低速冲击研究[J]. 沈阳航空航天大学学报, 2017, 34(5): 12-20. |

| Wu Zhen, Chen Jian. Low-velocity impact damage of composite structure based on Hashin criteria[J]. Journal of Shenyang Institute of Aeronautical Engineering, 2017, 34(5): 12-20. | |

| 16 | Hashin Z. Failure criteria for unidirectional fiber composites[J]. Journal of Applied Mechanics, 1980, 47(2): 329-334. |

| 17 | Fanteria D, Lazzeri L, Panettieri E, et al. Experimental characterization of the inter laminar fracture toughness of a woven and a unidirectional carbon/epoxy composite[J]. Composites Science and Technology, 2017, 142: 20-29. |

| 18 | Guo Y Q, Saanouin K, Cherouat A, et al. Two methodologies for the simulation of ductile damage in sheet metal forming processes[J]. Journal of Plasticity Engineering, 2002, 43(373): 3227-3237. |

| 19 | 孟利平, 程远征, 张伦平, 等. 应变率和应力三轴度对Q345B钢动态力学性能的影响研究[J]. 船舶力学, 2019, 23(10): 1210-1220. |

| Meng Li-ping, Cheng Yuan-zheng, Zhang Lun-ping, et al. Influence of strain rate and stress triaxiality on the dynamic mechanical behavior of Q345B steel[J]. Journal of Ship Mechanics, 2019, 23(10): 1210-1220. | |

| 20 | 杨卓云, 赵长财, 董国疆, 等. 基于Lou-2013韧性断裂准则5182铝板成形极限研究[J]. 机械工程学报, 2019, 55(16): 47-57. |

| Yang Zhuo-yun, Zhao Chang-cai, Dong Guo-jiang, et al. Forming limit research of 5182 aluminum alloy sheet based on Lou-2013 ductile fracture criterion[J]. Journal of Mechanical Engineering, 2019, 55(16): 47-57. | |

| 21 | 朱浩, 朱亮, 陈剑虹. 应力三轴度和应变率对6063铝合金力学性能的影响及材料表征[J]. 材料科学与工程学报, 2007, 25(3): 358-362. |

| Zhu Hao, Zhu Liang, Chen Jian-hong. Influence of stress triaxiality and strain rate on the mechanics behavior of 6063 aluminum alloy and material characterization[J]. Journal of Materials Science and Engineering, 2007, 25(3): 358-362. | |

| 22 | Ranz D, Cuartero J, Castejon L, et al. A cohesive zone model approach to interlaminar behavior of carbon/epoxy laminated curved beams[J]. Composite Structures, 2020, 238: No. 111983. |

| 23 | Deng J, Li J, Wang Y, et al. Numerical study on notched steel beams strengthened by CFRP plates[J]. Construction and Building Materials, 2018, 163: 622-633. |

| 24 | 寇剑锋, 徐绯, 郭家平. 黏聚力模型破坏准则及其参数选取[J]. 机械强度, 2011, 33(5): 714-718. |

| Kou Jian-feng, Xu Fei, Guo Jia-ping. Damage laws of Cohesive zone model and selection of the parameters[J]. Journal of Mechanical Strength, 2011, 033(5): 14-718. | |

| 25 | Adams C, Bös J, Slomski E M., et al. Scaling laws obtained from a sensitivity analysis and applied to thin vibrating structures[J]. Mechanical Systems and Signal Processing, 2018, 110: 590-610. |

| [1] | 李杰,陈涛,郭文翠,赵旗. 汽车非平稳随机振动空间域虚拟激励法及应用[J]. 吉林大学学报(工学版), 2022, 52(4): 738-744. |

| [2] | 史文库,张曙光,张友坤,陈志勇,江逸飞,林彬斌. 基于改进海鸥算法的磁流变减振器模型辨识[J]. 吉林大学学报(工学版), 2022, 52(4): 764-772. |

| [3] | 张英朝,李昀航,郭子瑜,王国华,张喆,苏畅. 长头重型卡车气动减阻优化[J]. 吉林大学学报(工学版), 2022, 52(4): 745-753. |

| [4] | 庄蔚敏,陈沈,王楠. 温度对车身钢铝胶铆连接结构热应力变化的影响[J]. 吉林大学学报(工学版), 2022, 52(1): 70-78. |

| [5] | 段亮,宋春元,刘超,魏苇,吕成吉. 基于机器学习的高速列车轴承温度状态识别[J]. 吉林大学学报(工学版), 2022, 52(1): 53-62. |

| [6] | 胡兴军,张靖龙,罗雨霏,辛俐,李胜,胡金蕊,兰巍. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1933-1942. |

| [7] | 陈剑斌,周宋泽,费峰永,陈永龙,凌国平. 过盈量及滚花方式对装配式凸轮轴压装失效的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1959-1966. |

| [8] | 罗勇,韦永恒,黄欢,肖人杰,任淋,崔环宇. 驾驶员意图识别的P2.5插混构型双离合器起步控制[J]. 吉林大学学报(工学版), 2021, 51(5): 1575-1582. |

| [9] | 曾小华,宋美洁,宋大凤,王越. 基于车联网信息的公交客车行驶工况数据处理方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1692-1699. |

| [10] | 马超,高云凯,刘哲,段月星,田林雳. 骨架式车身多材料及梁截面形状和尺寸优化[J]. 吉林大学学报(工学版), 2021, 51(5): 1583-1592. |

| [11] | 兰凤崇,李继文,陈吉清. 面向动态场景复合深度学习与并行计算的DG-SLAM算法[J]. 吉林大学学报(工学版), 2021, 51(4): 1437-1446. |

| [12] | 杨建,夏琦,周海超,王国林. 修正胎体弦轮廓载重子午线轮胎的降噪机理[J]. 吉林大学学报(工学版), 2021, 51(4): 1198-1203. |

| [13] | 龙江启,向锦涛,俞平,王骏骋. 适用于非线性主动悬架滑模控制的线性干扰观测器[J]. 吉林大学学报(工学版), 2021, 51(4): 1230-1240. |

| [14] | 陈鑫,于贵申,张彪,潘凯旋,杨立飞. 搅拌摩擦点焊接头拉伸-剪切行为的等效建模[J]. 吉林大学学报(工学版), 2021, 51(4): 1190-1197. |

| [15] | 宋大凤,杨丽丽,曾小华,王星琦,梁伟智,杨南南. 基于行驶工况合成的混合动力汽车电池寿命优化[J]. 吉林大学学报(工学版), 2021, 51(3): 781-791. |

|

||