吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (2): 445-452.doi: 10.13229/j.cnki.jdxbgxb.20220341

• 交通运输工程·土木工程 • 上一篇

碳化湿度对碳化砌块力学与耐久性能的影响

陈凯祥1,2( ),张鹤年3,4(

),张鹤年3,4( ),席培胜3,王长丹1,2,余涛5,张炳锌6

),席培胜3,王长丹1,2,余涛5,张炳锌6

- 1.同济大学 道路与交通工程教育部重点实验室,上海 201804

2.同济大学 上海市轨道交通结构耐久与系统安全重点实验室,上海 201804

3.安徽建筑大学 安徽省城市建设和地下空间工程研究中心,合肥 230022

4.中国科学院大学 南京学院,南京 210007

5.东北电力大学 电气工程学院,吉林省 吉林市 132011

6.华能沁北发电有限责任公司,河南 济源 454650

Influence of carbonization humidity on mechanics and durability of carbonization block

Kai-xiang CHEN1,2( ),He-nian ZHANG3,4(

),He-nian ZHANG3,4( ),Pei-sheng XI3,Chang-dan WANG1,2,Tao YU5,Bing-xin ZHANG6

),Pei-sheng XI3,Chang-dan WANG1,2,Tao YU5,Bing-xin ZHANG6

- 1.Key Laboratory of Road and Traffic Engineering of the Ministry of Education,Tongji University,Shanghai 201804,China

2.Shanghai Key Laboratory of Rail Infrastructure Durability and System Safety,Tongji University,Shanghai 201804,China

3.Anhui Urban Construction and Underground Space Engineering Research Center,Anhui Jianzhu University,Hefei 230022,China

4.University of Chinese Academy of Sciences Nanjing,Nanjing 210007,China

5.School of Electrical Engineering,Northeast Electric Power University,Jilin 132011,China

6.Huaneng Qinbei Power Generation Co. ,Ltd. ,Jiyuan 454650,China

摘要:

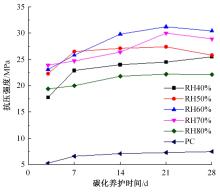

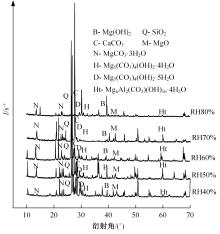

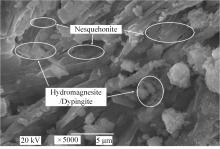

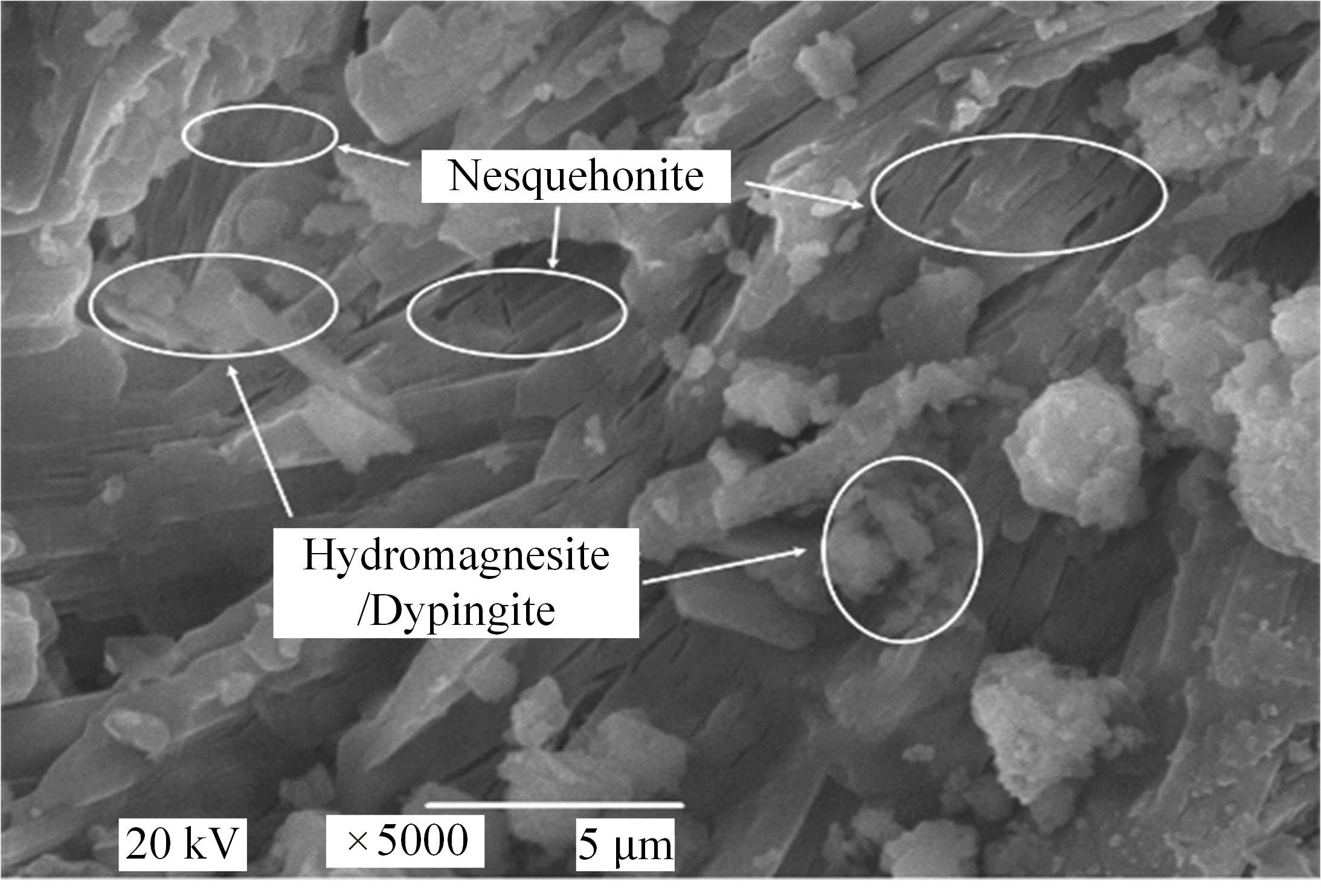

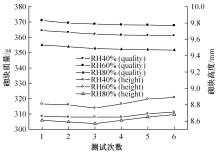

碳化砌块是基于活性氧化镁水泥碳化技术研发的新型砌块,即先采用活性氧化镁水泥与骨料进行搅拌,然后利用CO2进行碳化,以达到提高强度目的。通过室内试验,开展了无侧限抗压强度、X射线衍射、电镜扫描和热重分析试验,研究了碳化湿度对碳化砌块强度和碳化产物的影响,并进行耐久性测试。结果表明:碳化砌块强度明显高于普通水泥砌块,在碳化养护三天,碳化砌块能达到70%~80%强度,碳化湿度为60%的砌块强度最佳;碳化砌块具有很强的耐久性能,碳化湿度为60%碳化砌块耐久性能明显高于40%和80%的碳化砌块;活性氧化镁的碳化产物是碳酸镁石、水菱镁石和球碳镁石,碳化湿度为60%的碳化砌块内部碳化产物最密集。

中图分类号:

- TU522.3

| 1 | 梁丰. 砌体在建筑更新中的命运与前景[D].天津:天津大学建筑学院,2010. |

| Liang Feng. Fate and future of masonry in architecture renewal[D]. Tianjing: School of Architecture, Tianjin University, 2010. | |

| 2 | 周文杰. 新型再生混凝土空心砌块砌体力学性能研究[D].西安:长安大学建筑工程学院,2021. |

| Zhou Wen-jie. Study on masonry properties of new recycled concrete hollow block[D]. Xian: School of Architectural Engineering, Chang'an University, 2021. | |

| 3 | 田伟,郭学东,尹新生. 混凝土空心砌块墙梁墙身斜截面抗裂度的理论与试验[J]. 吉林大学学报:工学版, 2011, 41 (): 189-193. |

| Tian Wei, Guo Xue-dong, Yin Xin-sheng. Theoretical and experimental research on oblique cross-section cracking resistance of wall-beam by concrete hollow block[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41 (Sup.2): 189-193. | |

| 4 | 孙绪杰,潘景龙,郑文忠. 玻璃纤维增强聚合物混凝土小型空心砌块复合墙片的抗震性能[J]. 吉林大学学报:工学版, 2008, 38(5): 1054-1059. |

| Sun Xu-jie, Pan Jing-long, Zheng Wen-zhong. Ant-iseismic behavior of composite GFRP-concrete small hollow block wall[J]. Journal of Jilin University (Engineering and Technology Edition), 2008, 38(5): 1054-1059. | |

| 5 | Yi Yao-lin, Martin L, Unluer C, et al. Carbonating magnesia for soil stabilization[J]. Canadian Geotechnical Journal, 2013, 50(8):899-905. |

| 6 | Higgins D D. GGBS and sustainability[J]. Construction Materials, 2007, 160: 99-101. |

| 7 | Harrison J. New cements based on the addition of reactive magnesia to Portland cement with or without added pozzolan[C]∥Proceedings of the CIA Conference: Concrete in the Third Millennium, CIA, Brisbane, Australia, 2003. |

| 8 | Harrison J. Reactive magnesium oxide cements[P]. United States Patent, 2003. |

| 9 | 刘松玉,李晨.氧化镁活性对碳化固化效果影响研究[J].岩土工程学报,2015,37(1):148-155. |

| Liu Song-yu, Li Chen. Influence of MgO activity on stabilization efficiency of carbonated mixing method[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(1): 148-155. | |

| 10 | Martin L, Vandeperre L J, Al-Tabbaa A. Influence of carbonation on the properties of reactive magnesia cement-based pressed masonry units[J]. Advances in Cement Research, 2007, 19(1): 1-12. |

| 11 | Jin F, Gu K, Abdollahzadeh A, et al. Effects of different reactive MgOs on the hydration of MgO-activated GGBS paste[J]. Journal of Materials in Civil Engineering, 2015,27(7):1-9. |

| 12 | Jin F, Wang F, Al-Tabbaa A. Three-year performance of in-situ solidified/stabilised soil using novel MgO-bearing binders[J]. Chemosphere,2016, 144(10): 681-688. |

| 13 | 易耀林. 基于可持续发展的搅拌桩新技术与理论[D]. 南京:东南大学交通运输工程学院, 2013. |

| Yi Yao-lin. Sustainable novel deep mixing methods and theory[D]. Nanjing: School of Transportation, Southeast University, 2013. | |

| 14 | Yi Y L, Martin L, Jin F, et al. Mechanism of reactive magnesia-ground granulated blastfurnace slag (GGBS) soil stabilization[J]. Canadian Geotechnical Journal, 2016, 53(5):773-782. |

| 15 | Yi Y L, Zheng X, Liu SY, et al. Comparison of reactive magnesia- and carbide slag-activated ground granulated blastfurnace slag and Portland cement for stabilisation of a natural soil[J]. Applied Clay Science,2016,111(7): 21-26. |

| 16 | 张鹤年,陈凯祥,席培胜. 基于活性氧化镁掺量的碳化砌块性能及机理研究[J]. 建筑材料学报,2017, 20(6):981-985. |

| Zhang He-nian, Chen Kai-xiang, Xi Pei-sheng. Property and mechanism of carbonization blocks at different reactive MgO amounts[J]. Journal of Building Materials, 2017, 20(6): 981-985. | |

| 17 | Zhang H N, Shen C, Xi P S, et al. Study on effect of the activated magnesia carbonized building blocks based on the content of fly ash[J]. Construction and Building Materials, 2018, 185(10):609-616. |

| 18 | 左锋,叶奋,宋卿卿. RAP掺量对再生沥青混合料路用性能影响[J]. 吉林大学学报:工学版, 2020, 50 (4): 1403-1410. |

| Zuo Feng, Ye Fen, Song Qing-qing. Influence of RAP content on road performance of recycled asphalt mixture[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(4): 1403-1410. | |

| 19 | Martin L, Al-Tabbaa A. Performance of magnesia cements in pressed masonry units with natural aggregates: production parameters optimization[J]. Construction and Building Materials, 2008, 22(8): 1789-1797. |

| 20 | 刘竞, 邓德华, 刘赞群. 养护措施和湿养护时间对掺与未掺矿渣混凝土性能的影响[J]. 硅酸盐学报, 2008, 36(7):11-17. |

| Liu Jing, Deng De-hua, Liu Zan-qun. Effect of curing methods and wet curing duration on properties of plain and slag-cement concrete[J]. Journal of the Chinese Ceramic Society,2008, 36(7):11-17. | |

| 21 | Alizadeh R, Ghods P, Chini M, et al. Effect of curing conditions on the service life design of RC structures in the persian gulf region[J]. Journal of Materials in Civil Engineering, 2008, 20(1):1-9. |

| 22 | Steven H K, Beatrix K, William C P, 等. 混凝土设计与控制[M]. 重庆:重庆大学出版社, 2005. |

| 23 | 李艺,姬胜鹏. 冬期施工混杂纤维混凝土宏观性能及微观结构[J]. 吉林大学学报:工学版, 2019, 49 (3): 781-787. |

| Li Yi, Ji Sheng-peng. Macro⁃properties and microstructure of hybrid fiber reinforced concrete in winter construction[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49 (3): 781-787. | |

| 24 | ,混凝土砌块和砖试验方法 [S]. |

| 25 | . 蒸压加气混凝土性能试验方法 [S]. |

| 26 | 梁春雨,郭有蒙,张利东,等. 季冻区多指标水泥稳定碎石性能评价及级配优选[J]. 吉林大学学报:工学版, 2020, 50(3): 998-1005. |

| Liang Chun-yu, Guo You-meng, Zhang Li-dong,et al. Performance evaluation and gradation optimal selection of multi⁃index cement stabilized macadam in seasonal frozen area[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(3): 998-1005. |

| [1] | 姜屏,周琳,毛天豪,袁俊平,王伟,李娜. 水泥改性废弃泥浆损伤模型及时间效应[J]. 吉林大学学报(工学版), 2022, 52(12): 2874-2882. |

| [2] | 王毅红,田桥罗,兰官奇,姚圣法,张建雄,刘喜. 630 MPa高强钢筋混凝土大偏压柱受力性能试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2626-2635. |

| [3] | 汤东,韩宇彬,华伦,潘金冲,刘胜. 润滑油灰分对直喷汽油机颗粒捕集器性能影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2501-2507. |

| [4] | 刘寒冰,高鑫,宫亚峰,刘诗琪,李文俊. 表面处理对玄武岩纤维活性粉末混凝土力学性能的影响及断裂特性[J]. 吉林大学学报(工学版), 2021, 51(3): 936-945. |

| [5] | 袁杰,陈歆,何虹霖,杨博,朱小骏. 微生物矿化作用下混凝土裂缝修复与性能补偿[J]. 吉林大学学报(工学版), 2020, 50(2): 641-647. |

| [6] | 戴文亭,司泽华,王振,王琦. 剑麻纤维水泥加固土的路用性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 589-593. |

| [7] | 何娟,程从密,杨毅男,张亚芳,钟明峰. 湿热养护时掺合料对玻纤增强水泥性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 648-653. |

| [8] | 宫亚峰, 申杨凡, 谭国金, 韩春鹏, 何钰龙. 不同孔隙率下纤维土无侧限抗压强度[J]. 吉林大学学报(工学版), 2018, 48(3): 712-719. |

| [9] | 高小建, 孙博超, 叶焕, 王子龙. 矿物掺合料对自密实混凝土流变性能的影响[J]. 吉林大学学报(工学版), 2016, 46(2): 439-444. |

| [10] | 苏迎社, 杨媛媛. 高温对建筑混凝土材料抗震抗压的作用及原理[J]. 吉林大学学报(工学版), 2015, 45(5): 1436-1442. |

| [11] | 肖锐, 邓宗才, 兰明章, 申臣良. 不掺硅粉的活性粉末混凝土配合比试验[J]. 吉林大学学报(工学版), 2013, 43(03): 671-676. |

| [12] | 孟松鹤, 高慧婷, 孙莉安, 史洪军. 硅灰-矿渣对聚丙烯纤维混凝土性能的影响[J]. 吉林大学学报(工学版), 2010, 40(增刊): 214-0217. |

|

||