吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (3): 936-945.doi: 10.13229/j.cnki.jdxbgxb20200157

表面处理对玄武岩纤维活性粉末混凝土力学性能的影响及断裂特性

- 吉林大学 交通学院,长春 130022

Influence of surface treatment on basalt fiber reactive powder concrete mechanical properties and fracture characteristics

Han-bing LIU( ),Xin GAO,Ya-feng GONG(

),Xin GAO,Ya-feng GONG( ),Shi-qi LIU,Wen-jun LI

),Shi-qi LIU,Wen-jun LI

- College of Transportation,Jilin University,Changchun 130022,China

摘要:

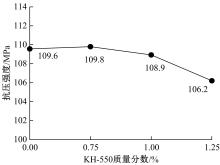

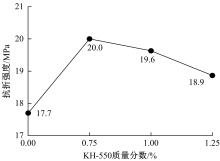

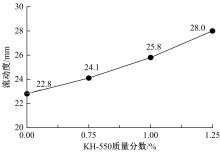

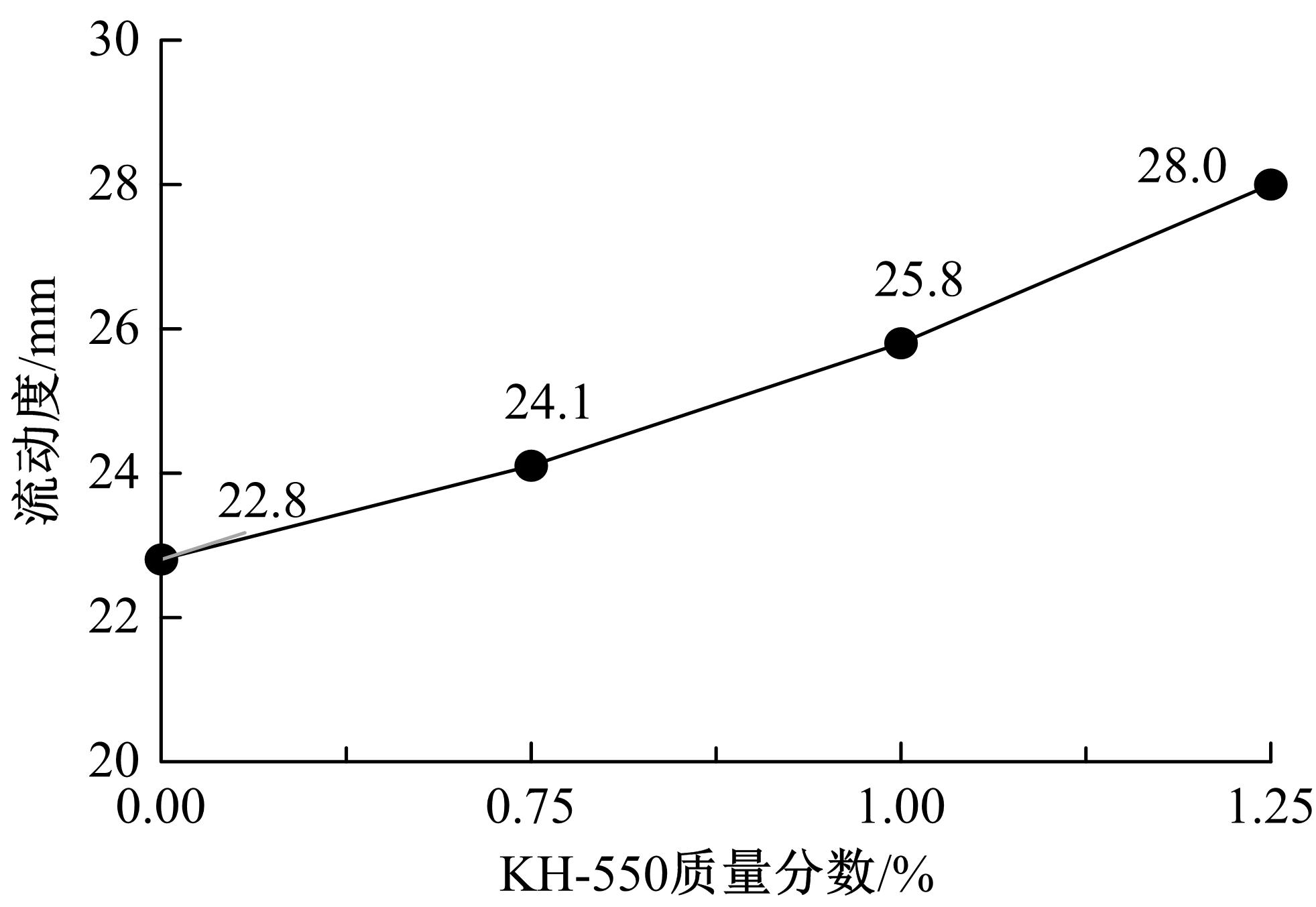

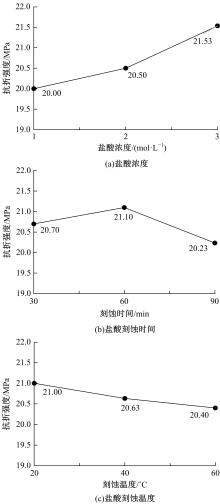

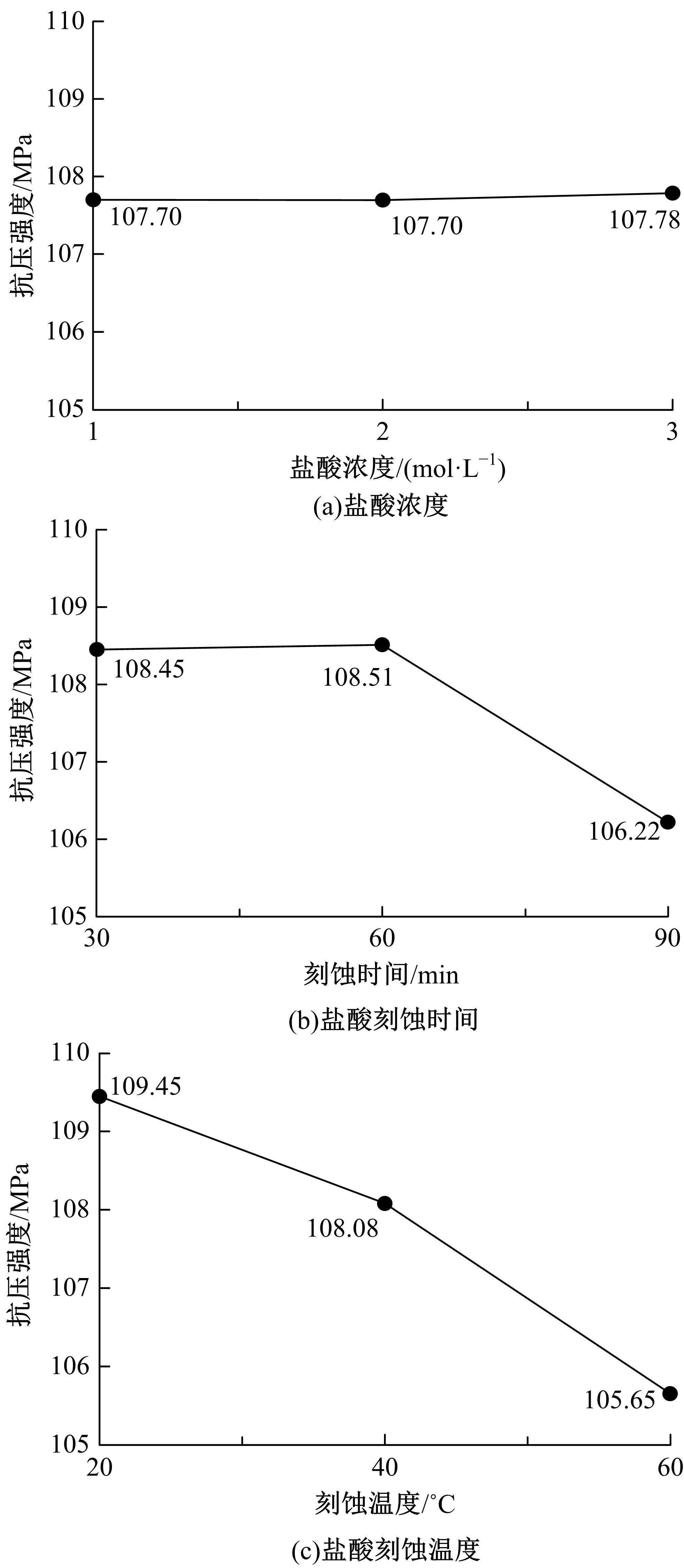

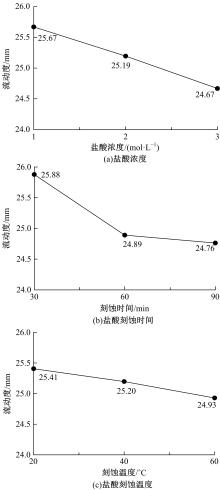

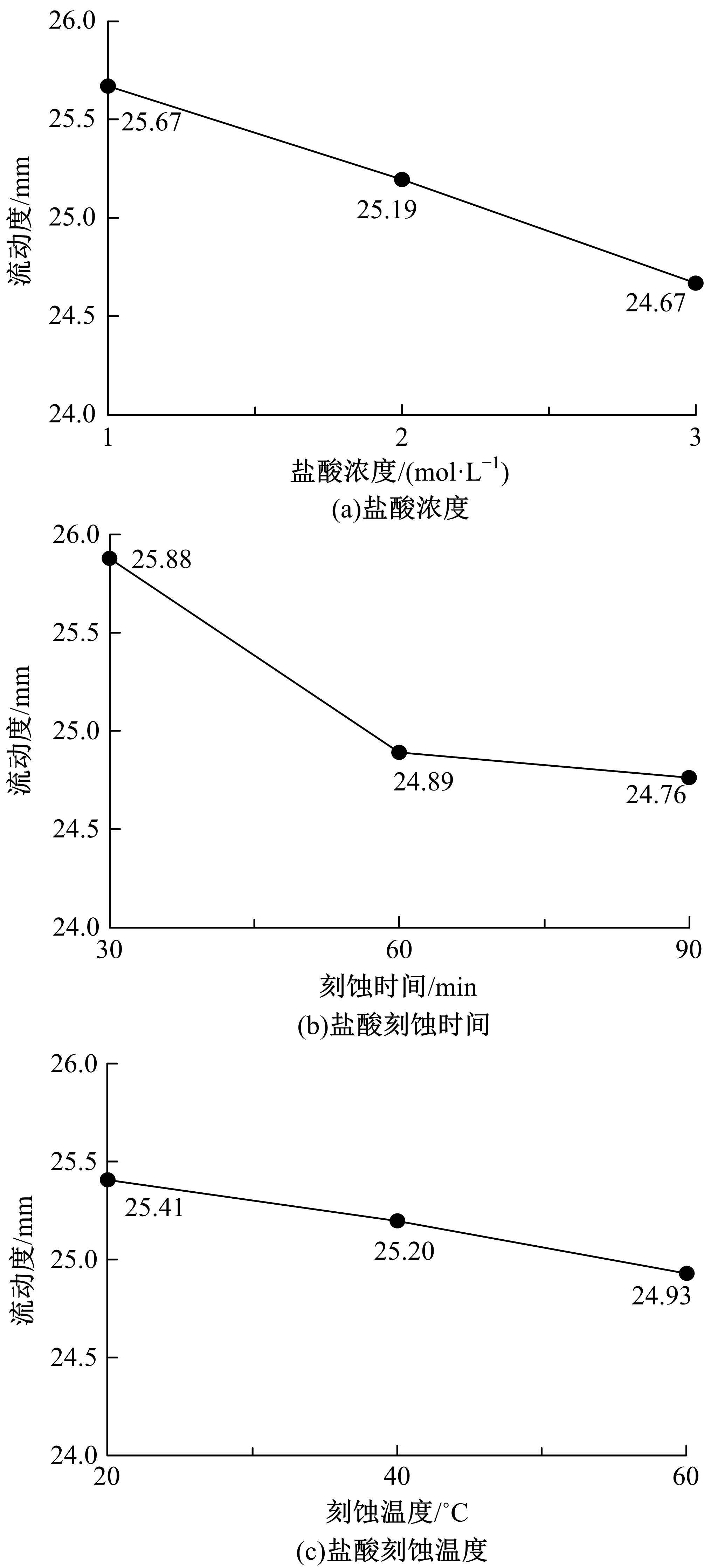

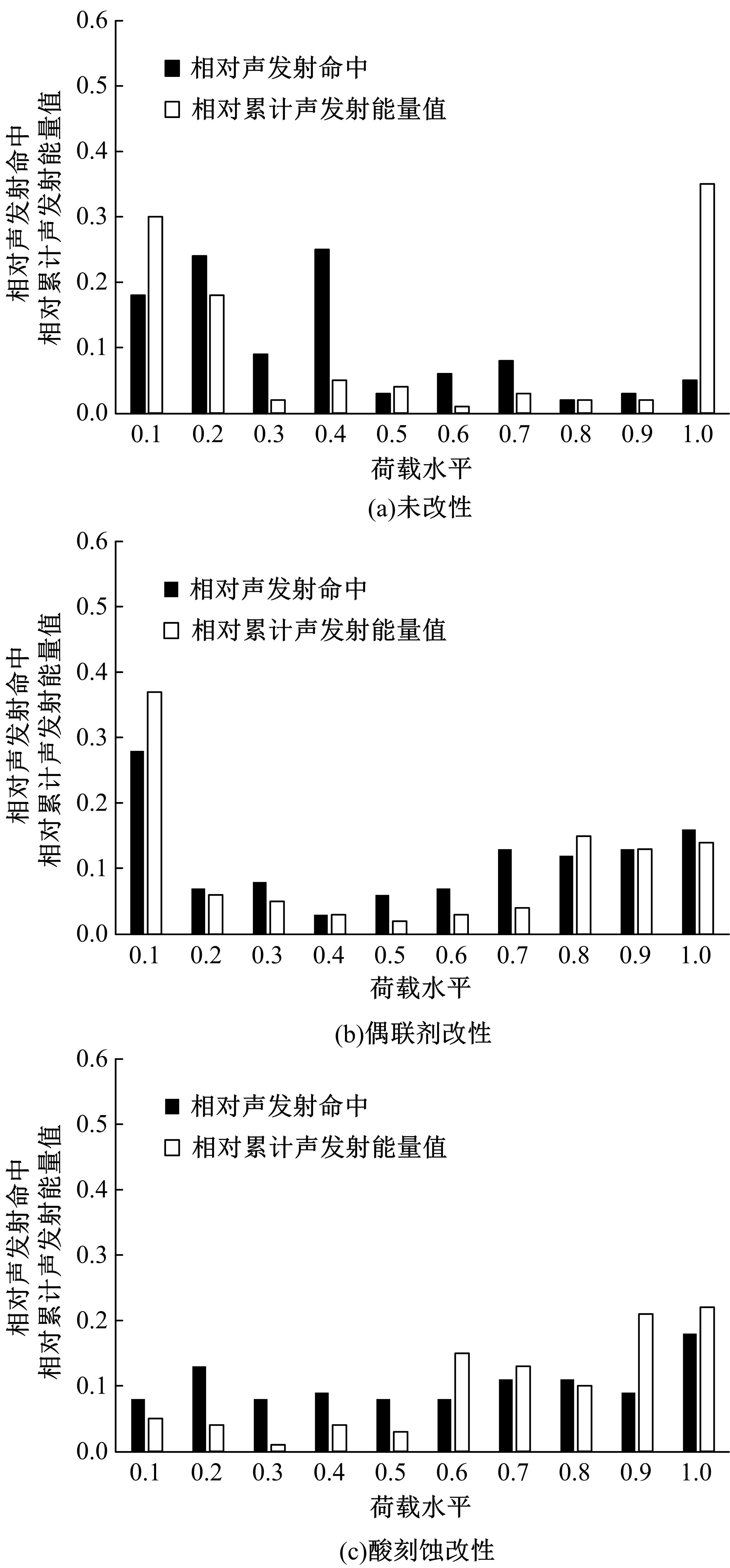

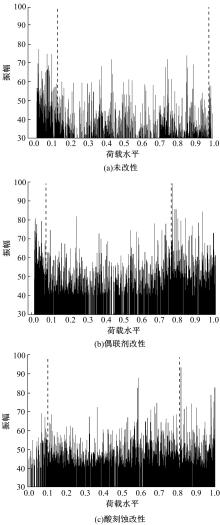

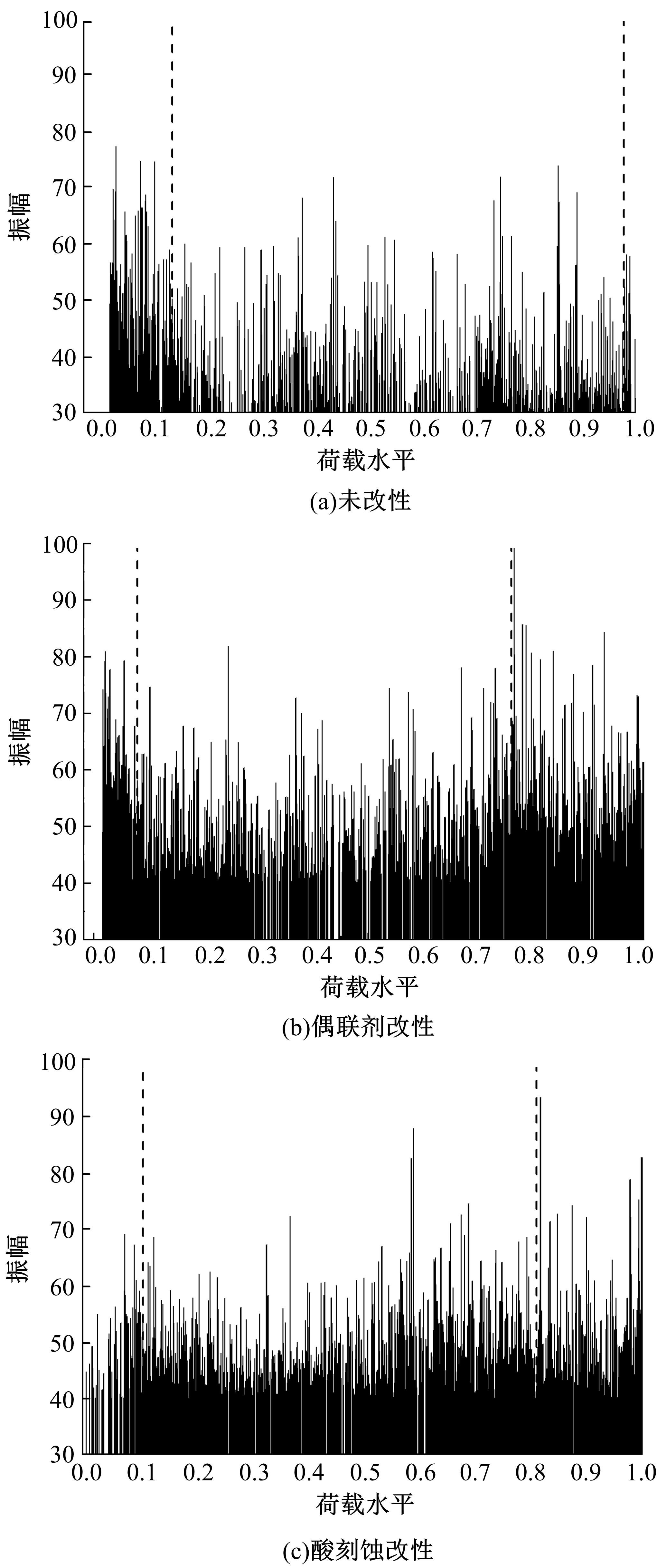

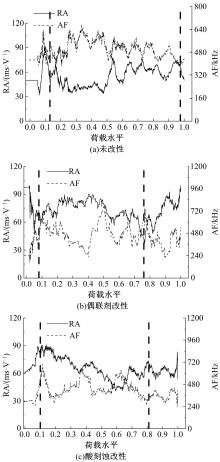

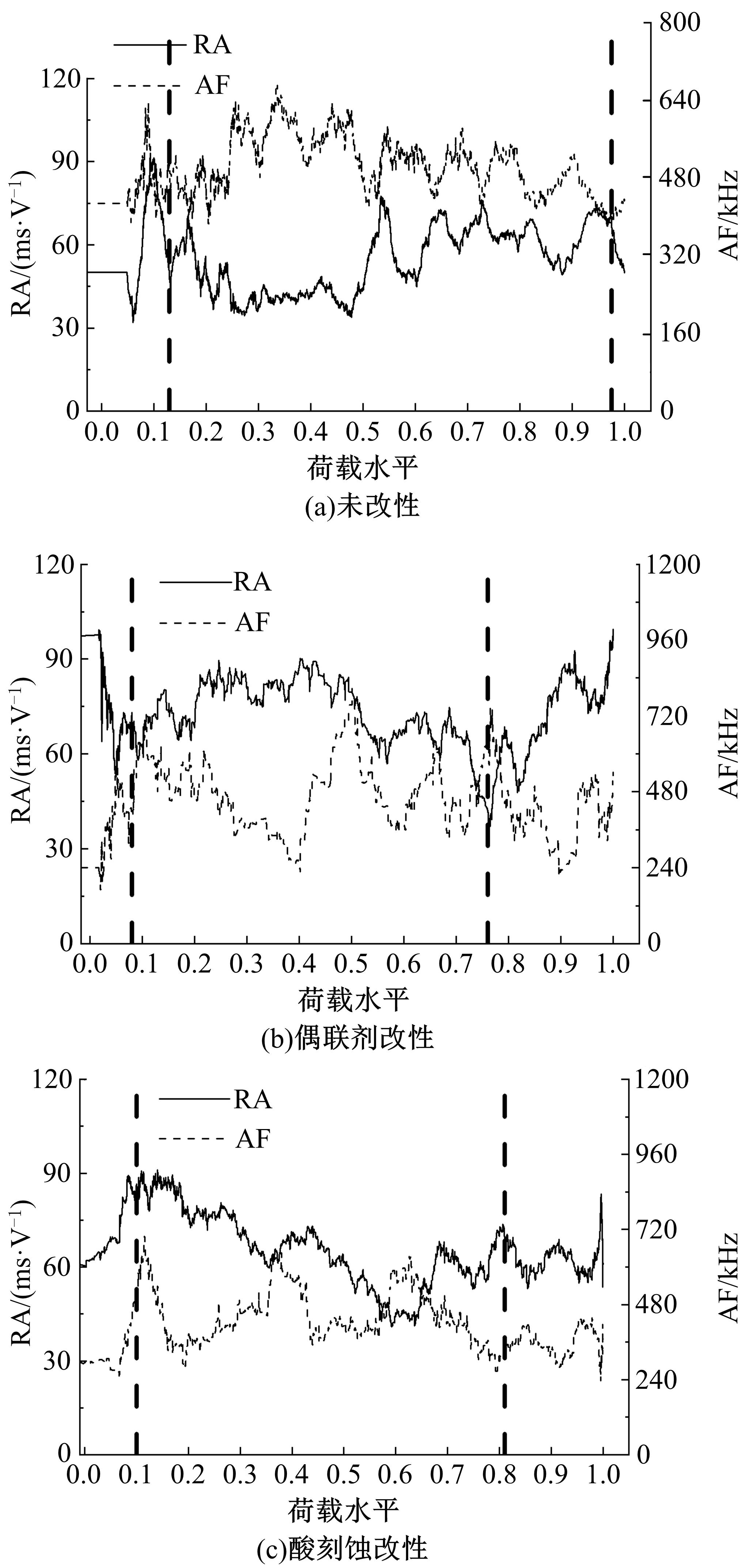

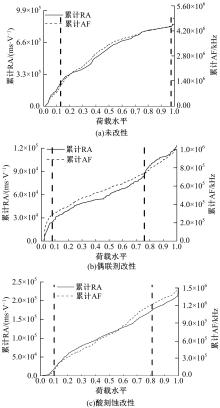

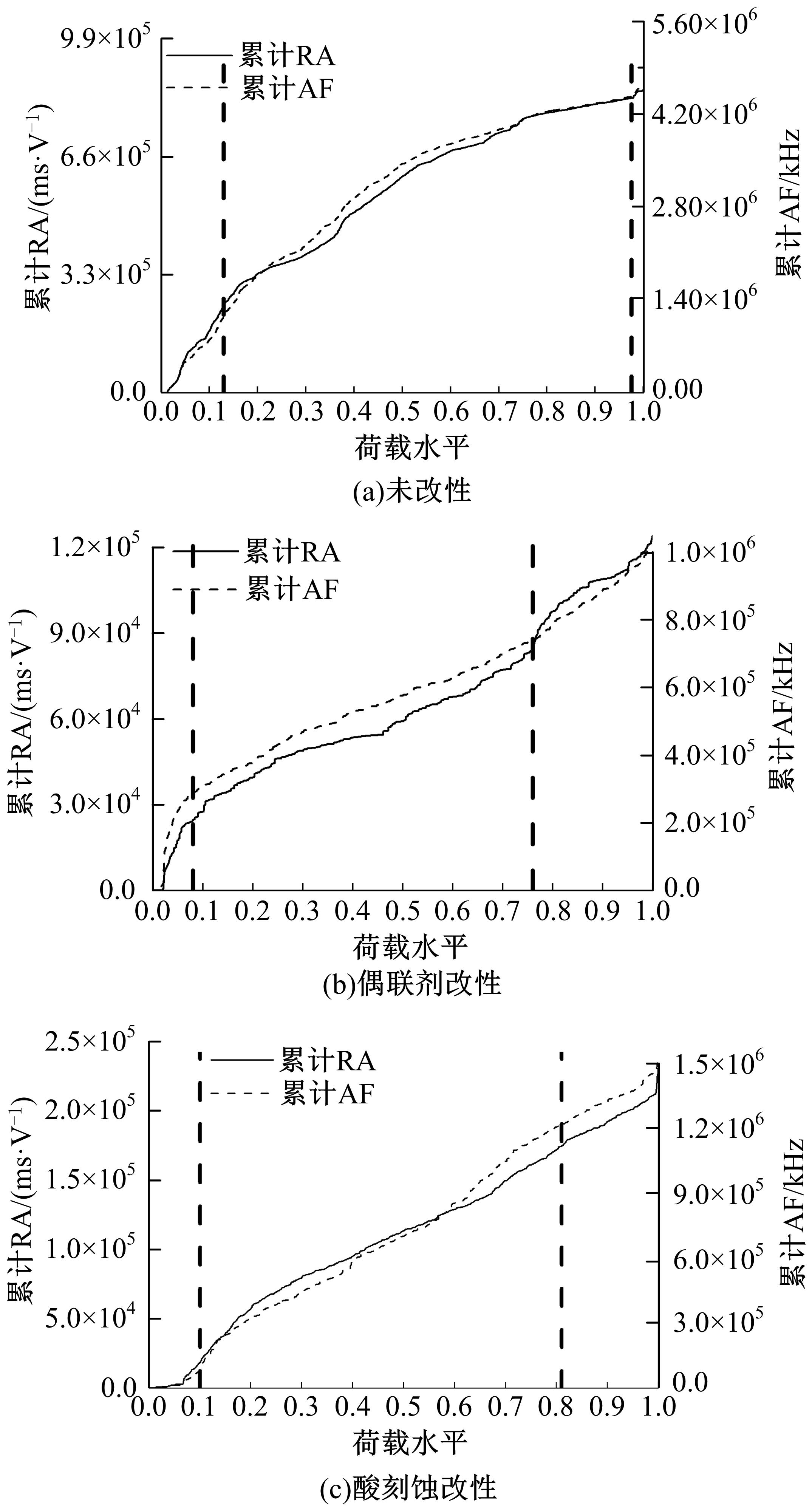

使用偶联剂KH-550和盐酸对玄武岩纤维进行表面处理,研究改性条件对玄武岩纤维活性粉末混凝土力学性能和工作性能指标的影响,并分别优选出最佳改性条件:偶联剂质量分数为0.75%,盐酸浓度为3 mol/L,刻蚀时间为60 min,刻蚀温度为20 ℃。采用声发射技术对比改性前、后玄武岩纤维活性粉末混凝土的损伤特征,确定试样在抗折试验中的断裂阶段和断裂模式。结果表明:声发射参数中,累计声发射(AE)命中、累计能量和振幅与玄武岩纤维活性粉末混凝土的损伤阶段有关,纤维改性对混凝土损伤的最后阶段有所影响。另外,在加载过程中,上升角(RA)和平均频率(AF)有相反的趋势,均随着断裂模式的变化而变化。

中图分类号:

- TU528.5

| 1 | Richard Pierre, Cheyrezy Marcel. Compositi-on of reactive powder concretes[J]. Cement and Concrete Research, 1995, 25(7):1501-1511. |

| 2 | 吴中伟, 廉慧珍. 高性能混凝土[M]. 北京:中国铁道出版社, 1999. |

| 3 | 吴炎海, 何雁斌. 活性粉末混凝土(RPC200)的配制实验研究[J]. 中国公路学报, 2003,16(4):44-49. |

| Wu Yan-hai, He Yan-bin. Experimental study on preparation of reactive powder concrete (RPC200)[J]. Journal of China Highway, 2003, 16(4): 44-49. | |

| 4 | Kunal S. A short review on basalt fiber[J]. International Journal of Textile Science, 2012, 1(4): 19-28. |

| 5 | 程永春, 毕海鹏, 马桂荣, 等. 纳米TiO2/CaCO3-玄武岩纤维复合改性沥青的路用性能[J]. 吉林大学学报:工学版,2018,48(2):460-465. |

| Cheng Yong-chun, Bi Hai-peng, Ma Gui-rong, et al. Pavement performance of nano-meter TiO2/CaCO3-basalt fiber composite modified asphalt[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(2):460-465. | |

| 6 | 朱春凤, 程永春, 梁春雨, 等. 硅藻土-玄武岩纤维复合改性沥青混合料路用性能试验[J]. 吉林大学学报:工学版, 2020, 50(1):165-173. |

| Zhu Chun-feng, Cheng Yong-chun, Liang Chun-yu, et al. Pavement performance test of diatomite-basalt fiber composite modified asphalt mixture[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(1):165-173. | |

| 7 | 汪晖. 玄武岩纤维活性粉末混凝土性能研究[D]. 哈尔滨: 哈尔滨工业大学建筑与土木工程学院, 2013. |

| Wang Hui. Research of the properties of basalt fiber reactive powder concrete[D]. Harbin:College of Architecture and Civil Engineering, Harbin Institute of Technology, 2013. | |

| 8 | Liu Han-bing, Liu Shi-qi, Zhou Pei-lei, et al. Mechanical properties and crack classification of basalt fiber RPC based on acoustic emission parameters[J]. Applied Sciences, 2019, 19(18):3931-3942. |

| 9 | 张运华, 姚丽萍, 徐仕进, 等. 表面处理玄武岩纤维增强水泥基复合材料力学性能[J]. 复合材料学报, 2017, 34(5):1159-1166. |

| Zhang Yun-hua, Yao Li-ping, Xu Shi-jin, et al. Mechanical properties of cement matrix composites reinforced with surface treated basalt fibers[J]. Acta Materiae Compositse Sinica, 2017, 34(5):1159-1166. | |

| 10 | 王晓东, 云斯宁, 张太宏. 硅烷偶联剂表面改性玄武岩纤维增强复合材料研究进展[J]. 材料导报, 2017, 31(5):77-83. |

| Wang Xiao-dong, Yun Si-ning, Zhang Tai-hong. Advances in basalt fiber-reinforced composites modified by silane coupling agents[J]. Materials Reports, 2017, 31(5): 77-83. | |

| 11 | 柳力, 刘朝晖, 向宇. 硅烷偶联剂改性玄武岩纤维的机理及其路用性能[J]. 建筑材料学报, 2017, 20(4):623-629. |

| Liu Li, Liu Zhao-hui, Xiang Yu. Mechanism and road performance of basalt fiber modified by silane coupling agent[J]. Journal of Building Materials, 2017, 20(4):623-629. | |

| 12 | Nair A, Cai C S. Acoustic emission monitoring of bridges: review and case studies[J]. Engineering Structures,2010, 32(6):1704-1714. |

| 13 | Aggelis D G, Soulioti D V, Sapouridis N, et al. Acoustic emission characterization of the fracture process in fibre reinforced concrete[J]. Construction and Building Materials, 2011, 25(11): 4126-4131. |

| 14 | 张璇子, 陈红迁, 王志勇. 混凝土材料三点弯曲破坏的声发射特性[J]. 实验力学, 2010, 25(4): 457-462. |

| Zhang Xuan-zi, Chen Hong-qian, Wang Zhi-yong. Acoustic emission characteristics of three points bending failure of concrete materials[J]. Experimental Mechanics, 2010, 25(4): 457-462. | |

| 15 | 丁幼亮, 邓扬, 李爱群. 声发射技术在桥梁结构健康监测中的应用研究进展[J]. 防灾减灾工程学报, 2010, 30(3): 341-351. |

| Ding You-liang, Deng Yang, Li Ai-qun. Advances in researches on application of acoustic emission technique to health monitoring for bridge structures[J]. Journal of Disaster Prevention Engineering, 2010,30(3):341-351. | |

| 16 | . 公路工程水泥及水泥混凝土试验规程[S]. |

| 17 | . 水泥胶砂强度检验方法(ISO法)[S]. |

| 18 | Fan X Q, Hu S W, Lu J, et al. Acoustic emission properties of concrete on dynamic tensile test[J]. Construction and Building Materials, 2016, 114(1):66-75. |

| 19 | Miller B, Muri P, Rebenfeld L. A microbond method for determination of the shear strength of a fiber /resin interface[J]. Composites Science & Technology, 1987, 28(1):17-32. |

| 20 | 张楚楚. 玄武岩纤维增强水泥基材料及其复合梁高性能化研究[D]. 南京:东南大学建筑与土木工程学院, 2018. |

| Zhang Chu-chu, The study on high performance of the basalt fibers reinforced cement-based materials and its composite beams[D]. Nanjing: College of Architecture and Civil Engineering, Southeast University, 2018. | |

| 21 | 杨军. 玄武岩纤维对高性能混凝土性能影响的研究[D]. 成都: 西南交通大学土木工程学院, 2015. |

| Yang Jun. The research on the effects of basalt fiber on high-performance concrete[D]. Chengdu: College of Civil Engineering, Southwest Jiaotong University,2015. | |

| 22 | Behnia A, Chai H K, Yorikawa M, et al. Integrated non-destructive assessment of concrete structures under flexure by acoustic emission and travel time tomography[J]. Construction & Building Materials, 2014, 67(6): 202-215. |

| 23 | Siracusano G, Lamonaca F, Tomasello R, et al. A framework for the damage evaluation of acoustic emission signals through Hilbert-Huang transform[J]. Mechanical Systems & Signal Processing, 2016, 75(2):109-122. |

| 24 | Li D, Du F. Monitoring and evaluating the failure behavior of ice structure using the acoustic emission technique[J]. Cold Regions Science and Technology, 2016, 129(1):51-59. |

| 25 | Soulioti D, Barkoula N M, Paipetis A, et al. Acoustic emission behavior of steel fibre reinforced concrete under bending[J]. Construction & Building Materials, 2009, 23(12):3532-3536. |

| [1] | 程永春,李赫,李立顶,王海涛,白云硕,柴潮. 基于灰色关联度的矿料对沥青混合料力学性能的影响分析[J]. 吉林大学学报(工学版), 2021, 51(3): 925-935. |

| [2] | 于江,赵志浩,秦拥军. 基于声发射和分形的钢筋混凝土受剪梁损伤[J]. 吉林大学学报(工学版), 2021, 51(2): 620-630. |

| [3] | 李义,黄东迪,于开锋,梁继才,何小玲,任希彤. 硅炭黑改性玄武岩纤维增强聚酰胺6复合材料性能[J]. 吉林大学学报(工学版), 2021, 51(1): 181-187. |

| [4] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [5] | 向红亮,陈盛涛,邓丽萍,张伟,詹土生. 微合金化2205双相不锈钢组织及性能[J]. 吉林大学学报(工学版), 2020, 50(5): 1645-1652. |

| [6] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

| [7] | 何娟,程从密,杨毅男,张亚芳,钟明峰. 湿热养护时掺合料对玻纤增强水泥性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 648-653. |

| [8] | 袁杰,陈歆,何虹霖,杨博,朱小骏. 微生物矿化作用下混凝土裂缝修复与性能补偿[J]. 吉林大学学报(工学版), 2020, 50(2): 641-647. |

| [9] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [10] | 朱春凤,程永春,梁春雨,肖波. 硅藻土⁃玄武岩纤维复合改性沥青混合料路用性能试验[J]. 吉林大学学报(工学版), 2020, 50(1): 165-173. |

| [11] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

| [12] | 佟鑫,张雅娇,黄玉山,胡正正,王庆,张志辉. 选区激光熔化304L不锈钢的组织结构及力学性能分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1615-1621. |

| [13] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [14] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [15] | 程永春, 毕海鹏, 马桂荣, 宫亚峰, 田振宏, 吕泽华, 徐志枢. 纳米TiO2/CaCO3-玄武岩纤维复合改性沥青的路用性能[J]. 吉林大学学报(工学版), 2018, 48(2): 460-465. |

|

||